Method for eliminating surface unevenness of aluminum alloy roll

An alloy aluminum and flattening technology is applied in the field of eliminating surface unevenness of alloy aluminum coils, which can solve problems such as surface unevenness of aluminum coils, and achieve the effects of eliminating unevenness, promoting strength and facilitating annealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

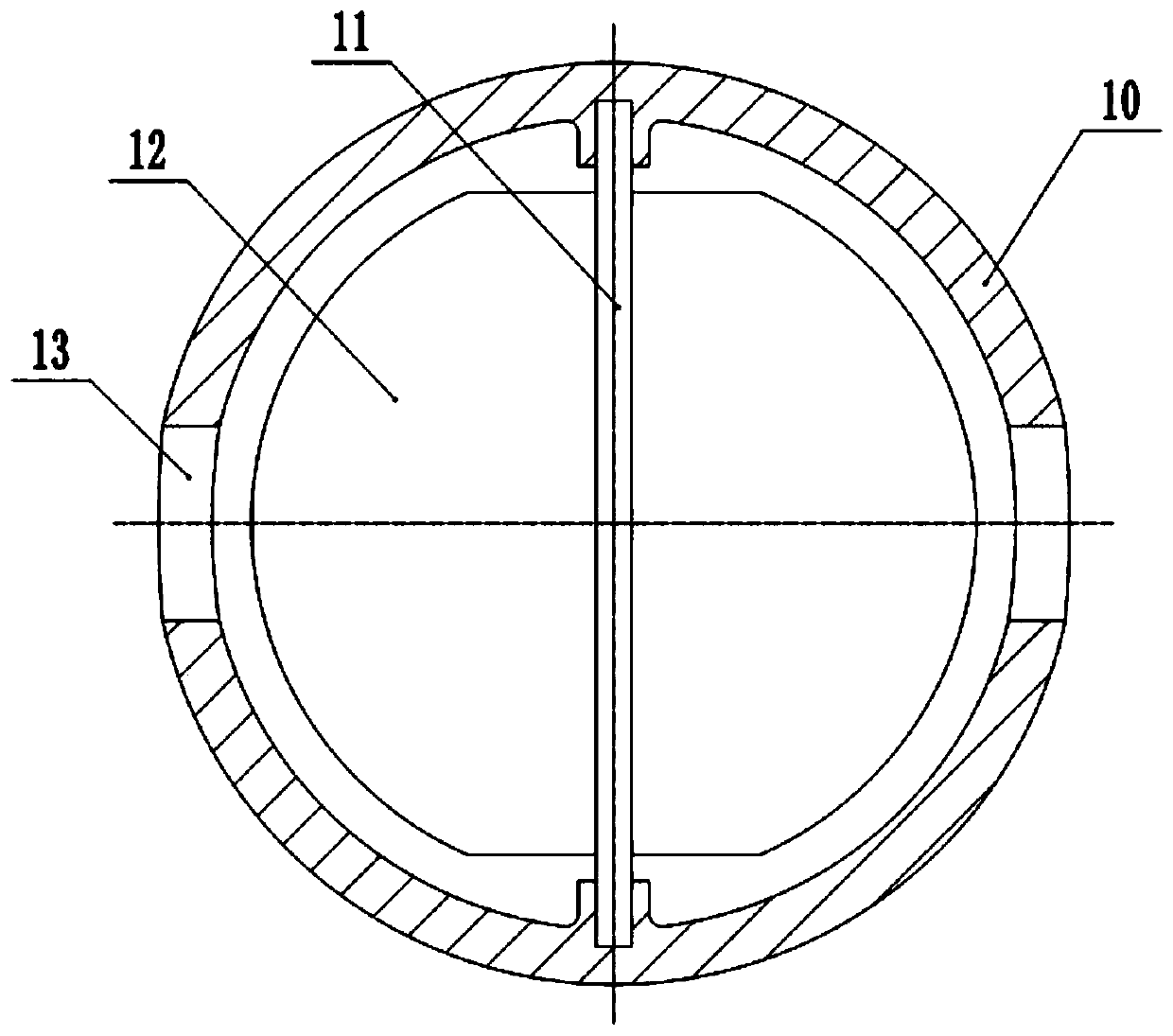

[0030] The reference signs in the accompanying drawings of the specification include: an air outlet pipe 10 , a vertical shaft 11 , a buffer plate 12 , and an air outlet hole 13 .

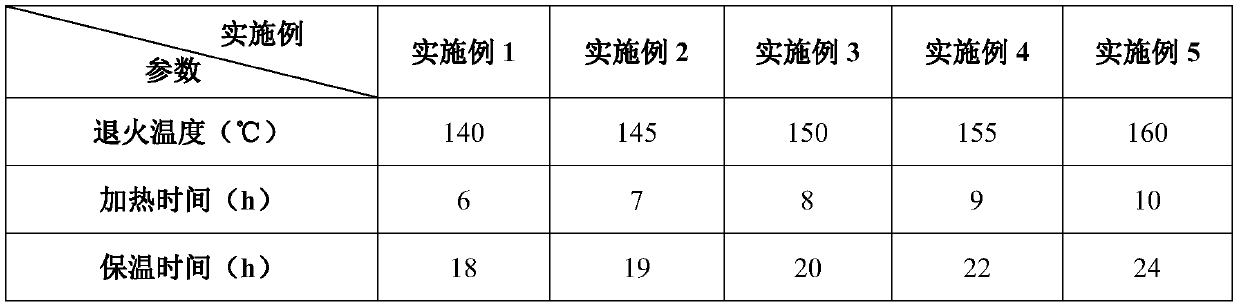

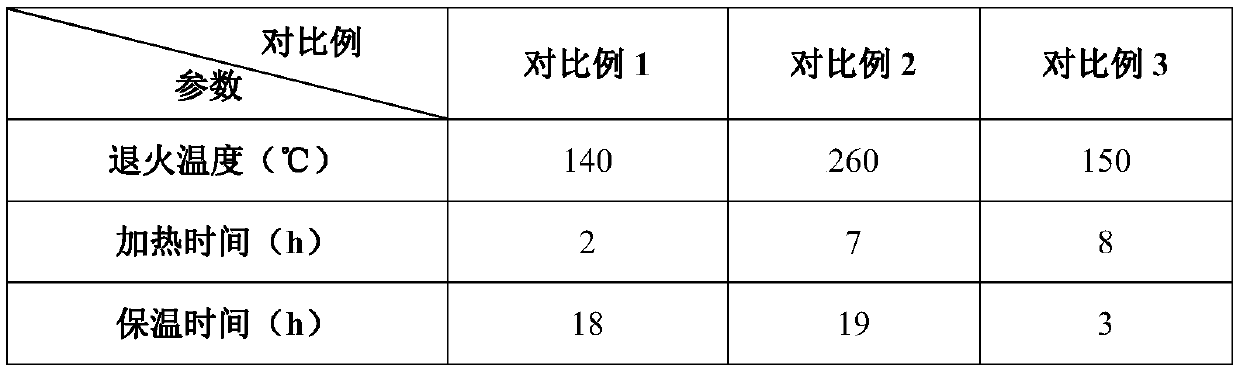

[0031] The parameter of embodiment 1-5 is as shown in table 1 below:

[0032] Table 1 is a kind of parameter that eliminates the method embodiment 1-5 of alloy aluminum coil surface unevenness

[0033]

[0034] A method for eliminating the surface unevenness of the alloy aluminum coil is described in detail below with Example 1 as an example:

[0035] Put the coiled aluminum coil into the annealing furnace for annealing treatment. The annealing temperature is 140°C, the heating time is 6h (that is, it takes 6h to heat from room temperature to 140°C), and the holding time is 18h. After the annealing is completed, , open the annealing furnace to take out the aluminum coil, and allow the aluminum coil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com