Film temperature sensor for turbine blades of aero-engine

A thin-film temperature sensor technology, which is applied in the field of temperature measurement technology and sensors, can solve problems such as long response time, damage to the structure of turbine blades, and the influence of target temperature field distribution, and achieve the effect of solving high-temperature insulation of the film layer and improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

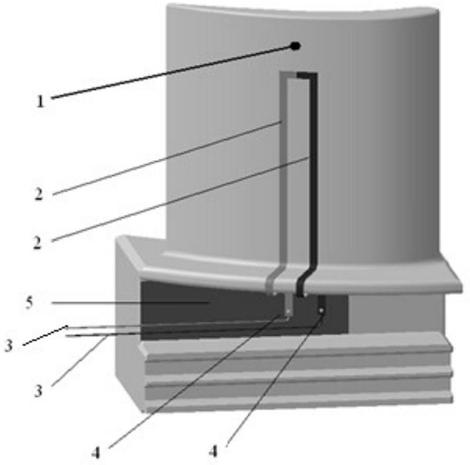

[0040] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0041] The thin film temperature sensor uses ion sputtering and patterning technology to directly fabricate a functional and structurally integrated thin film thermocouple on the surface of the turbine blade, which is an advanced temperature measurement technology. Thin film sensors have the advantages of thin structure, small heat capacity, fast response time, and little impact on the test environment, and do not require special processing and sensor fixing methods, will not damage the test structure, have little impact on the physical properties of the test object, and have pressure resistance. , heat resistance, thermal shock resistance and anti-stripping performance.

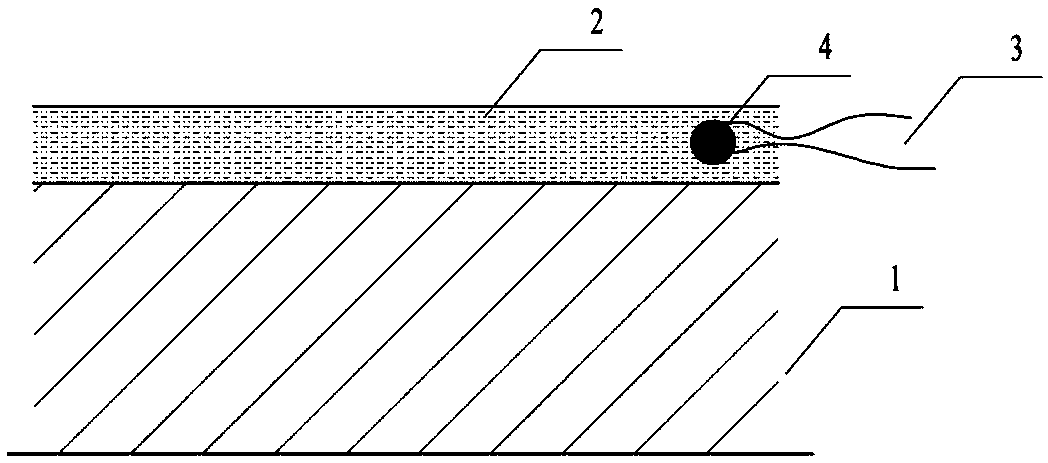

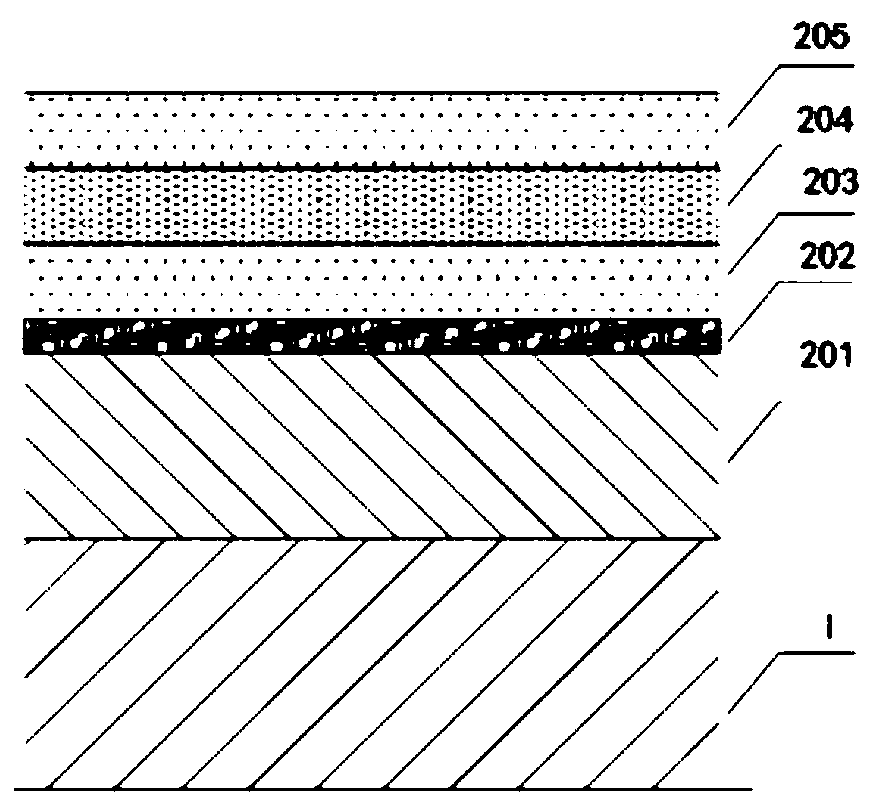

[0042] combine Figure 1-2 , the sensor of the present invention includes a multi-layer film layer 2 , a connection point 4 of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com