Corrosion-resistant steel with impact molding rate not smaller than 150 per minute for cell shell and preparation method thereof

A corrosion-resistant, per-minute technology, which is applied in the field of rapid stamping and forming of steel for battery shells and its preparation, can solve problems such as poor aging resistance, many inclusions, and reduced deep drawing performance, and achieve good shape fixity and mechanical strength of the barrel body. Stable performance and the effect of preventing nitrogen increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

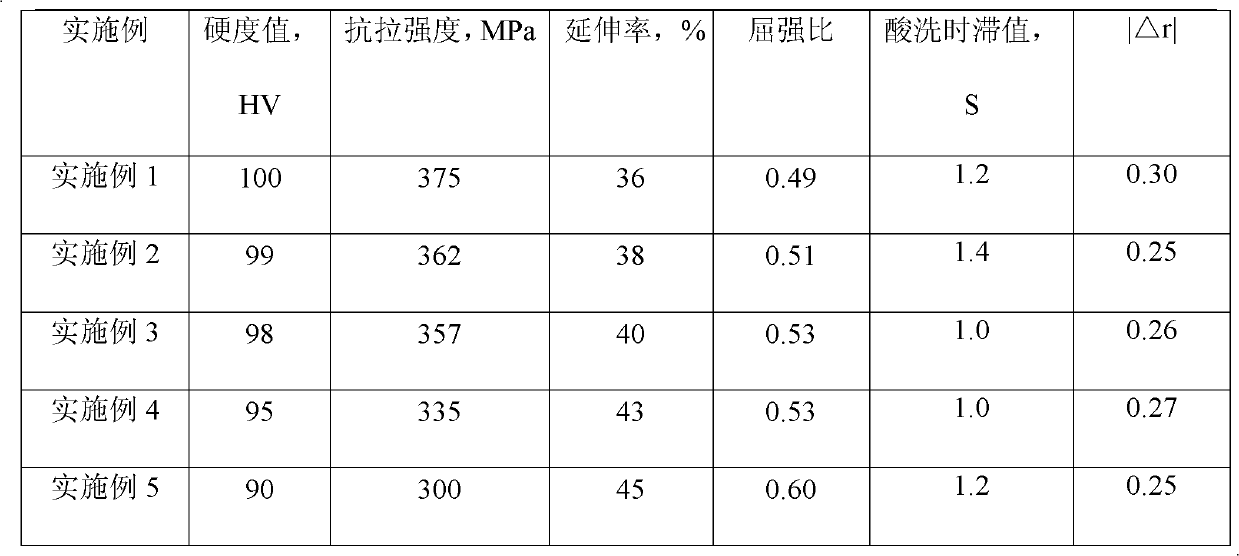

Examples

Embodiment 1

[0035] Corrosion-resistant steel for battery shells with a speed of ≥ 150 per minute, its composition and weight percentage are: C: 0.0001%, Mn: 0.10%, Al: 0.010%, N: 0.0040%, Nb: 0.030%, and control : P: 0.020%, S: 0.014%, Cu: 0.04%, Ni: 0.05%, Cr: 0.07%, Mo: 0.04%, Si: 0.018%, and the rest are Fe and unavoidable impurities.

[0036] A method for preparing steel for corrosion-resistant battery shells with a punching speed ≥ 150 per minute, the steps of which are as follows:

[0037] 1) According to the process of pure steel smelting and continuous casting into billets;

[0038] 2) Heating the continuous casting slab to 1170-1180°C;

[0039] 3) Carry out rough rolling, and control the exit temperature of rough rolling at 1060-1070°C;

[0040] 4) Fine rolling is carried out in the single-phase austenite zone, and the final rolling temperature is controlled at 900-910°C, and the cumulative reduction rate is 90%;

[0041] 5) Carry out coiling, and the coiling temperature is co...

Embodiment 2

[0048]Corrosion-resistant steel for battery shells with a speed of ≥ 150 per minute, its composition and weight percentage are: C: 0.0005%, Mn: 0.12%, Al: 0.022%, N: 0.0001%, Nb: 0.023%, and control : P: 0.019%, S: 0.015%, Cu: 0.03%, Ni: 0.04%, Cr: 0.08%, Mo: 0.05%, Si: 0.017%, and the rest are Fe and unavoidable impurities.

[0049] A method for preparing steel for corrosion-resistant battery shells with a punching speed ≥ 150 per minute, the steps of which are as follows:

[0050] 1) According to the process of pure steel smelting and continuous casting into billets;

[0051] 2) Heating the continuous casting slab to 1190-1200°C;

[0052] 3) Carry out rough rolling, and control the exit temperature of rough rolling at 1075-1085°C;

[0053] 4) Fine rolling is carried out in the single-phase austenite zone, and the final rolling temperature is controlled at 905-915°C, and the cumulative reduction rate is at 90%;

[0054] 5) Carry out coiling, and the coiling temperature is ...

Embodiment 3

[0061] Corrosion-resistant steel for battery shells with a speed of ≥ 150 per minute, its composition and weight percentage are: C: 0.0009%, Mn: 0.20%, Al: 0.050%, N: 0.0010%, Nb: 0.010%, and control : P: 0.018%, S: 0.014%, Cu: 0.05%, Ni: 0.03%, Cr: 0.06%, Mo: 0.03%, Si: 0.020%, and the rest are Fe and unavoidable impurities.

[0062] A method for preparing steel for corrosion-resistant battery shells with a punching speed ≥ 150 per minute, the steps of which are as follows:

[0063] 1) According to the process of pure steel smelting and continuous casting into billets;

[0064] 2) Heating the continuous casting slab to 1195-1205°C;

[0065] 3) Carry out rough rolling, and control the exit temperature of rough rolling at 1080-1090°C;

[0066] 4) Fine rolling is carried out in the single-phase austenite zone, and the final rolling temperature is controlled at 915-925°C, and the cumulative reduction rate is at 95%;

[0067] 5) Carry out coiling, and the coiling temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com