Patents

Literature

37results about How to "Avoid Nitrogen Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling nitrogen content of low nitrogen steel

InactiveCN102787202AAvoid Nitrogen ProblemsEliminate downgradesManufacturing convertersProcess efficiency improvementVacuum pumpingLow nitrogen

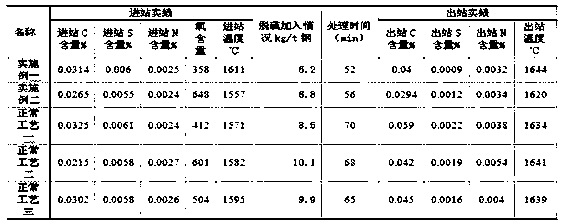

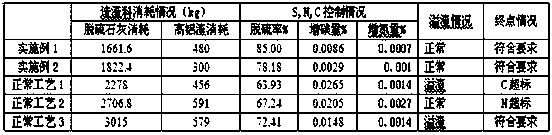

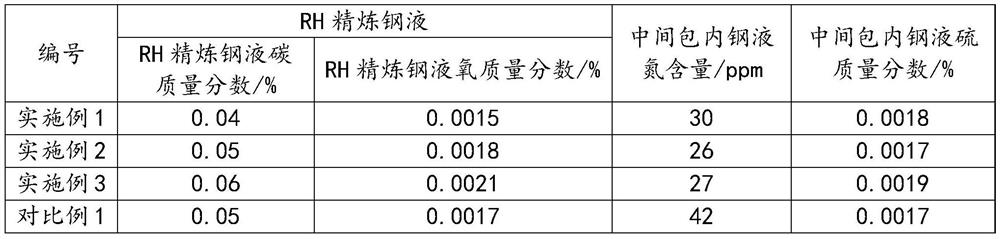

The invention provides a method for controlling the nitrogen content of a low nitrogen steel, a converter smelting process comprises the following steps: a ratio of high molten iron and low scrap steel is used, wherein the tapping temperature is no less than 1700 DEG C, ferrosilicon is used for preparing silicon to 0.4%, a gas cover is declined during a whole course of oxygen blowing period; the high carbon with carbon weight at 0.05-0.07% is used when tapping, carbon tapping can be carried out at a time, argon is not blown during the tapping process and at an argon station; a RH refining process comprises the following steps: the argon flow can be controlled at 150N1 / h from vacuum-pumping, the deep vacuum treatment time is controlled in 8-12 minutes, static duration after adding an alloy is 7-9 minutes; argon is continuously blown during continuous casting, and argon is used for casting protection. The method of the invention can effectively solve the nitrogen addition problem in steel, the nitrogen sample content in the argon station is controlled at 0.0011-0.0013%, the nitrogen sample content after finishing the RH treatment is controlled at 0.0013-0.0015%, and the nitrogen sample content of the finished products is controlled at 0.0016-0.0020%, and the degrading and steel judgment accidents due to improper component of the finished product nitrogen can be thoroughly eliminated.

Owner:ANGANG STEEL CO LTD

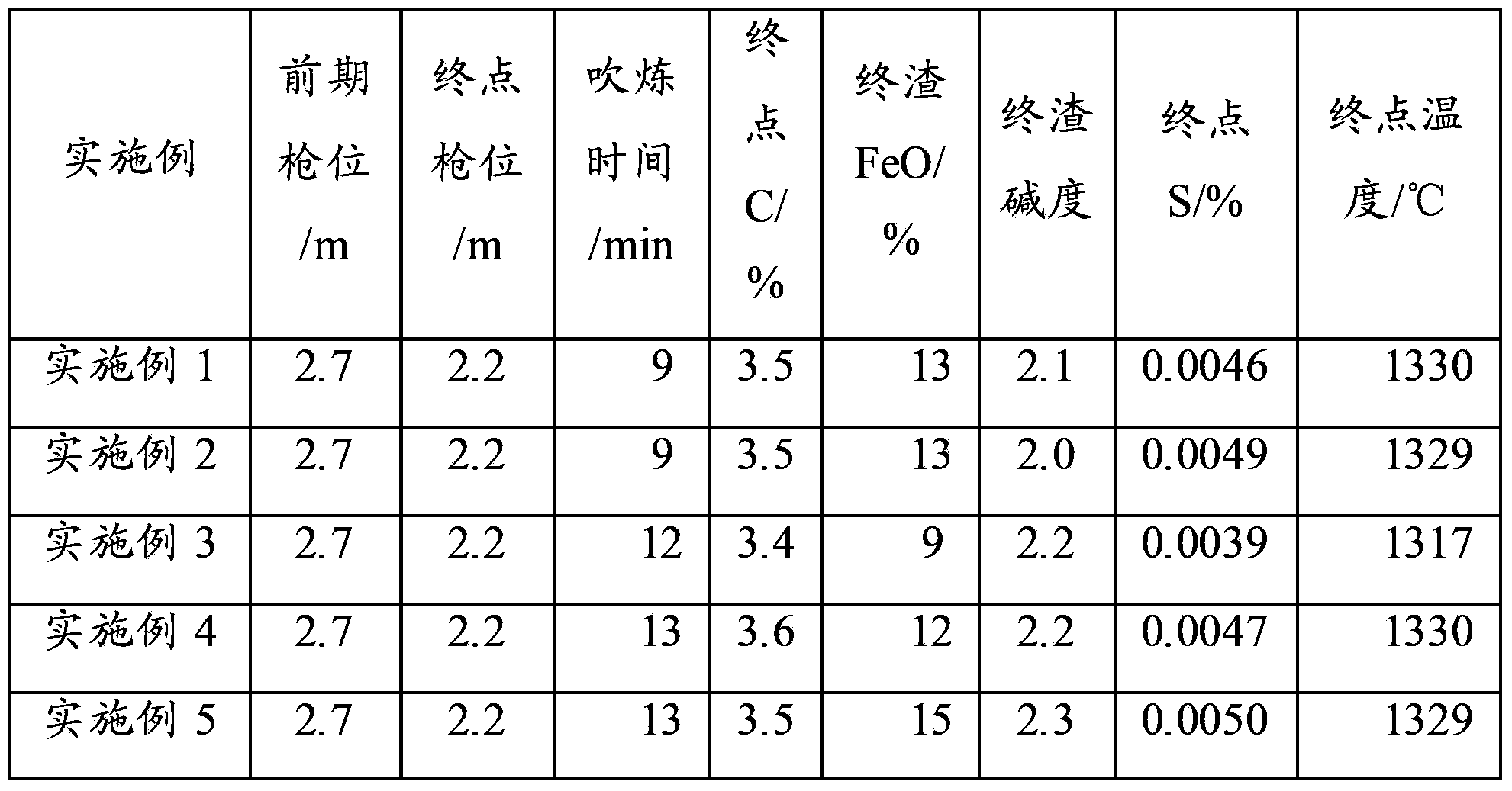

Method for controlling nitrogen content in Al deoxidization steel by converter process

ActiveCN101457275AAvoid Nitrogen ProblemsReduce the nitrogen content of the slabManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention belongs to the technical field of ferrous metallurgy, in particular relates to a method for controlling nitrogen content of aluminum killed steel produced in a converter process, and is used for preventing the problem that the nitrogen content increases in the aluminum killed steel produced in the converter process. The technical problem is solved by controlling the nitrogen content of the aluminum killed steel produced in the converter process according to the technical proposal as follows: the alkalinity of converter slag CaO / SiO2 is adjusted to 5-7 when a converter starts to produce the slag, the denitrification rate can be increased in the converter smelting process by controlling the alkalinity of the converter slag, the denitrification rate is increased from 50%-70% to 65%-85%, and the terminal nitrogen content of the molten steel in the converter can be controlled within 15PPm. The alkalinity is controlled, special slag is added, and a seal washer with brim is employed to seal between a steel ladle lower opening and a protection tube before starting continuous casting, thus realizing the stable control that the casting blank nitrogen content is not more than 35PPm by an LD-LF-SCC process and the casting blank nitrogen content is not more than 30PPm by an LD-LF-RH-BCC process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Production method of pipeline steel

The invention provides a production method of pipeline steel. The production method comprises following steps: molten iron in a foundry ladle is subjected to slagging treatment, to desulphurization after addition of a desulfurizer, and then to slagging treatment for a second time; the molten iron is added into a dephosphorization furnace, steel scraps and slag materials are added into the molten iron, the mixture is subjected to converting decarburization treatment so as to obtain molten steel, and then the molten steel is added into the dephosphorization furnace; slag materials are added into the molten steel in the dephosphorization furnace, the mixture is subjected to converting decarburization treatment so as to obtain decarburized molten steel; the decarburized molten steel is subjected to steel tapping treatment, and the molten steel is added into a steel ladle; the molten steel in the steel ladle is subjected to RH refining; and then the refined molten steel is subjected to teeming treatment by using a continuous caster. According to the production method of pipeline steel, ' three removal' pre-treatment technologies on full molten iron are employed, secondary refining desulphurization is not needed, low-sulfur molten steel with S less than 0.006% can be producted by raw material controlling and converter operation, production cost is low, and cleanliness of products is high.

Owner:SHOUGANG CORPORATION

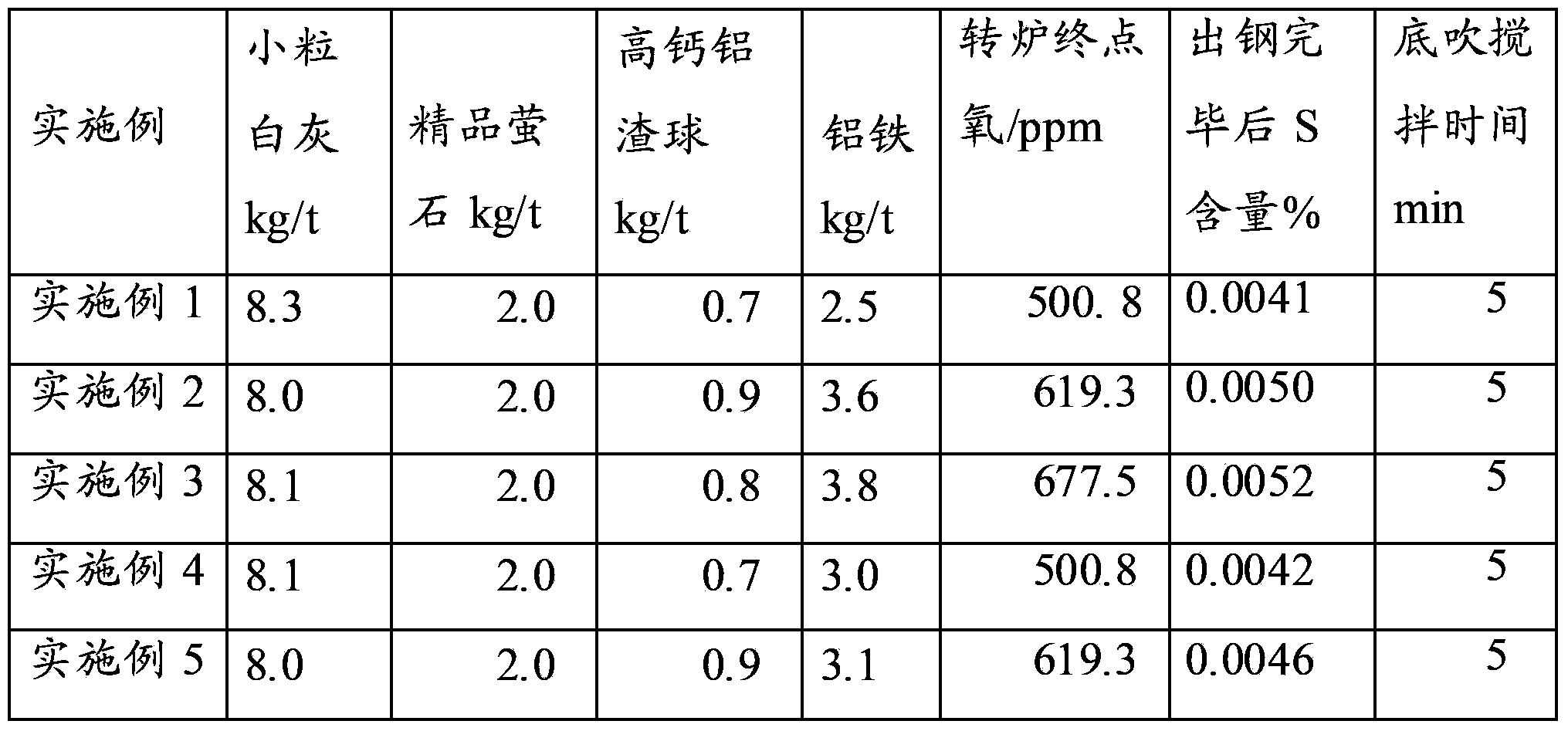

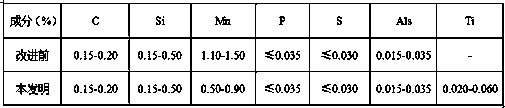

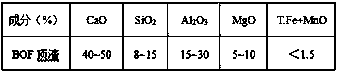

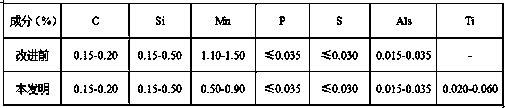

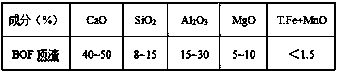

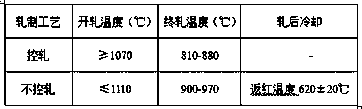

Low-cost manufacturing method of flaw-detection-ensured Q345B stage steel plate

The invention discloses a low-cost manufacturing method of a flaw-detection-ensured Q345B stage steel plate. The steel plate comprises, by mass percent, 0.15 to 0.20% of C, 0.15 to 0.50% of Si, 0.50 to 0.90% of Mn, not larger than 0.035% of P, not larger than 0.025% of S, 0.020 to 0.060% of Ti, 0.015 to 0.035% of Als, and the balance Fe and inevitable impurities. During preparing, molten iron is subject to KR desulfurization treatment firstly, the molten iron obtained after desulfurization treatment is subject to slag removal, the molten iron is converted into a converter to be smelted, outputmolten steel is subject to continuous casting and rolling, finally, the rolled steel plate is subject to stacking for slow-cooling for 24 to 72 hours, and then sampling inspection is carried out; thechemical components and the production process of the prepared Q345B stage steel plate are simple, the production cost is low, the flaw detection property is good, and the method has the good application and popularization prospects.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

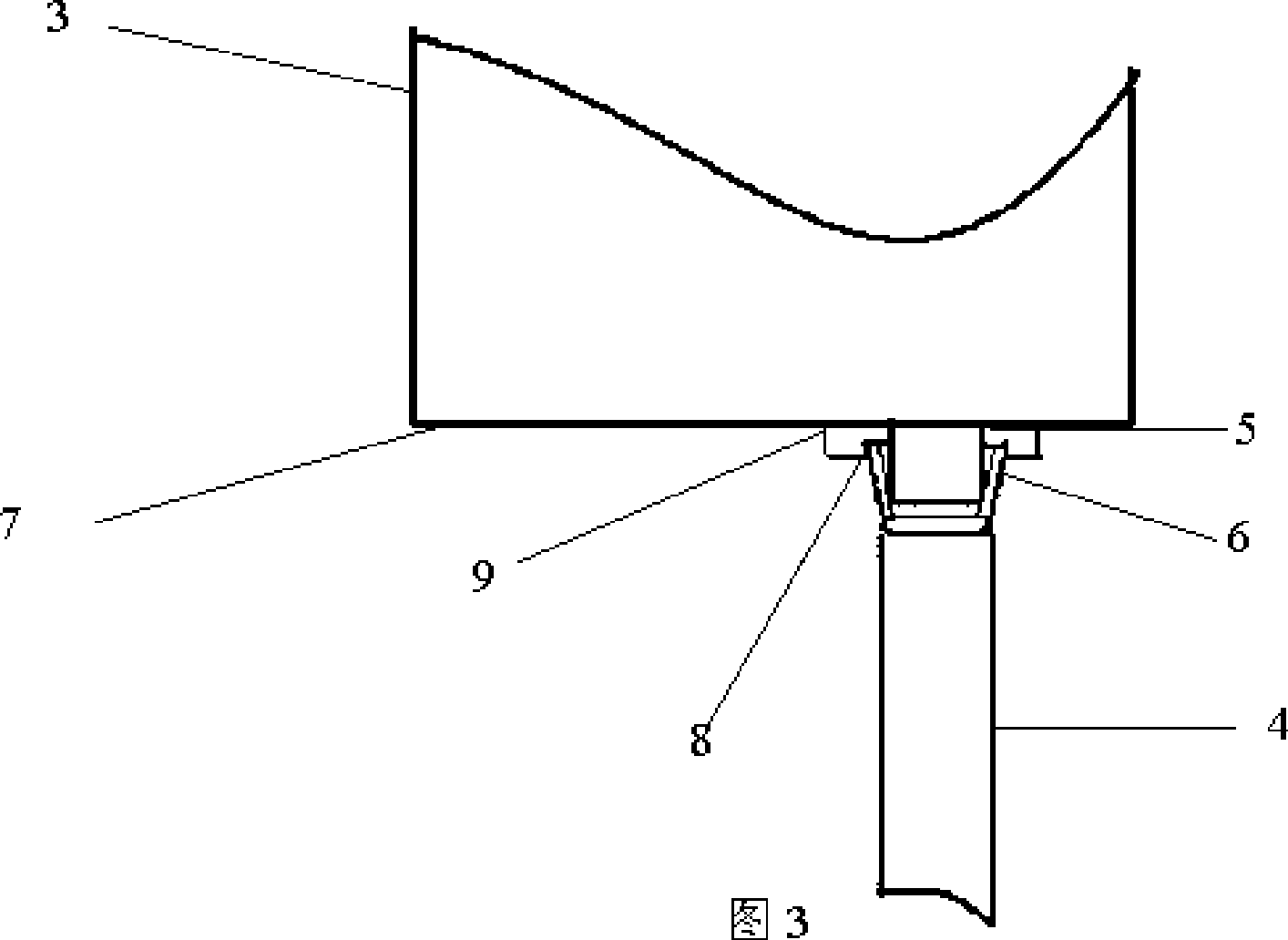

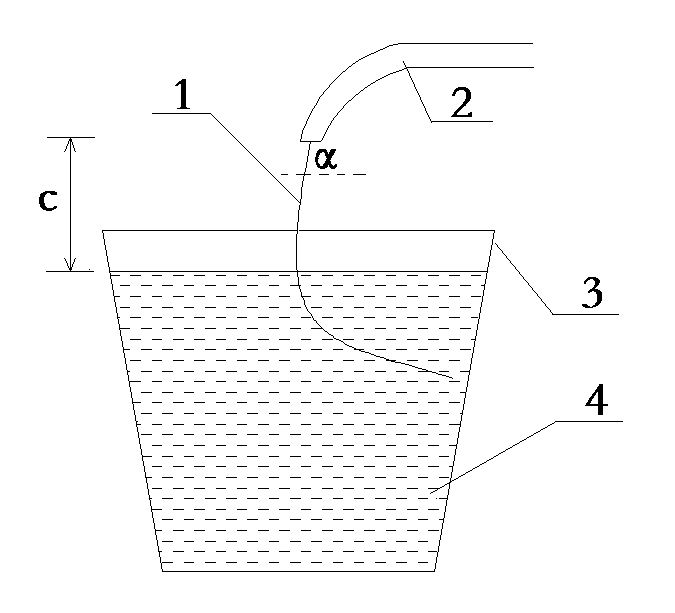

Vacuum temperature measurement sampling system and operation method thereof

ActiveCN103134706APrevent oxidationAvoid Nitrogen ProblemsWithdrawing sample devicesThermometer applicationsProcess engineeringMolten steel

A vacuum temperature measurement sampling system is characterized by comprising an automatic opening-and-closing vacuum chamber system and an automatic temperature measurement sampling gun system, wherein the automatic opening-and-closing vacuum chamber system is welded on an outer shell of a vacuum metallurgy container. The automatic temperature measurement sampling gun system comprises an automatic temperature measurement system sampling gun which is installed in the automatic opening-and-closing vacuum chamber system. The automatic temperature measurement system sampling gun comprises a paper tube probe which is capable of achieving self-sampling of molten metal in a melted steel bag in the vacuum metallurgy container due to the up-and-down movement of the paper tube probe. According to the vacuum temperature measurement sampling system and an operation method thereof, due to the fact that the automatic temperature measurement system sampling gun system is arranged in the automatic opening-and-closing vacuum chamber system, the automatic temperature measurement sampling gun can enters the vacuum metallurgy container for obtaining sample of melt steel at any time on the premise that vacuum environment of the metallurgy container is not damaged, process time is saved, operation environment of workers is improved, the operation method is simple and easy to implement, consistency of test conditions is guaranteed, and accuracy of a test result is improved.

Owner:CISDI ENG CO LTD

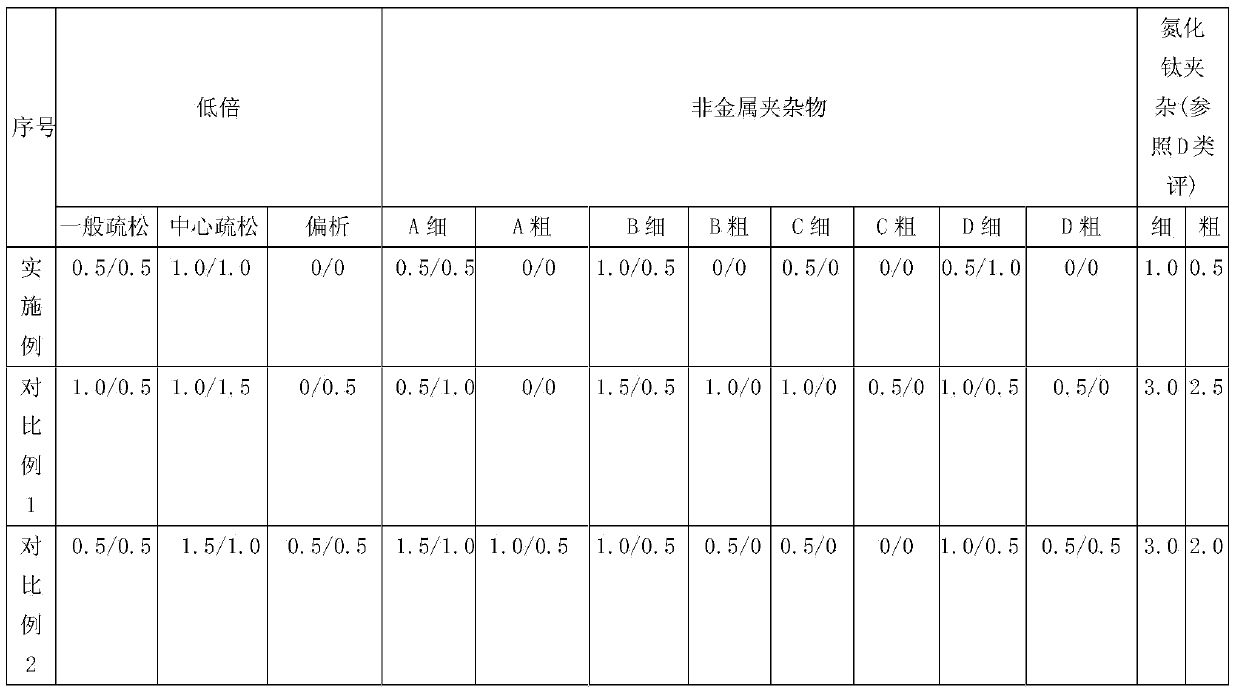

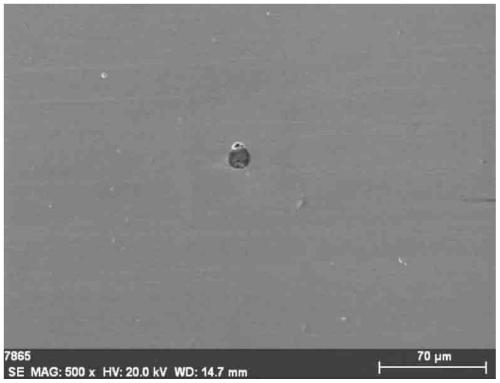

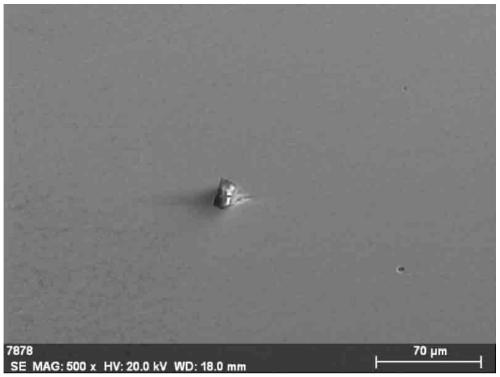

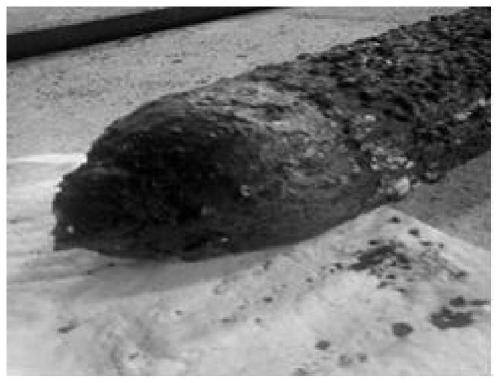

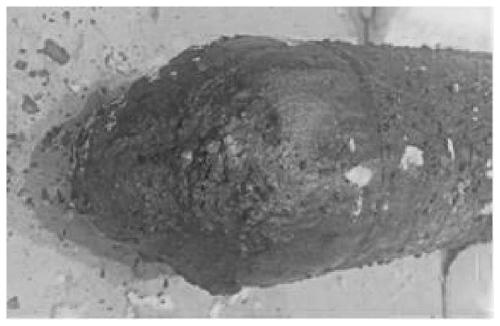

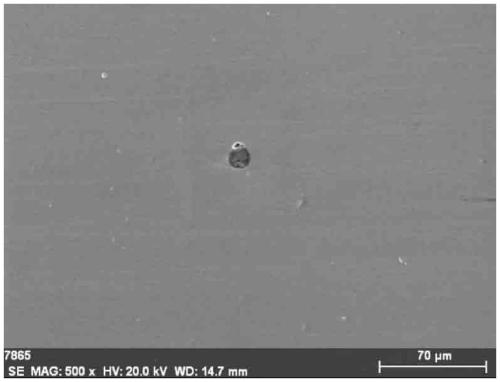

Control method for titanium nitride inclusion of gear steel bar material

InactiveCN104212934AReduce precipitationIncrease cooling intensityManufacturing convertersTitanium nitrideMolten steel

The invention discloses a control method for a titanium nitride inclusion of a gear steel bar material. The control method adopts a production process of converter smelting-LF refining-RH refining-rectangular blank continuous casting, and comprises the following specific operation steps: (1) converter smelting: molten iron and waste steel are added in a converter; and the weight ratio of the molten iron to the waste steel is greater than 15: 1; (2) LF refining: the LF refining is performed for the molten steel to prevent the molten steel from being contacted with air; (3) RH vacuum refining: the vacuum degassing treatment is performed for the molten steel; the treatment time is kept not lower than 15 minutes under high vacuum degree not higher than 66.7 Pa; and an titanium-iron alloy is added in the period; and (4) continuous casting: after the RH refining is finished, the molten steel ladle is continuously cast; and in the continuous casting process, a crystallizer electromagnetic mixing technology with low superheat degree not higher than 35 DEG C, constant temperature and constant casting speed is adopted, and the argon sealing is performed. Thereby, the separated concentration product of titanium nitride is controlled.

Owner:SGIS SONGSHAN CO LTD

Smelting method of low-carbon low-nitrogen high-chrome steel

ActiveCN105908056AStable productionGuaranteed reliabilityManufacturing convertersLow nitrogenMolten steel

The invention relates to a smelting method of low-carbon low-nitrogen high-chrome steel. The low-carbon low-nitrogen high-chrome steel comprises the following components in mass percent: less than 0.03% of C, equal to or less than 0.10% of Si, equal to or less than 0.20% of Mn, 3.0-3.55% of Cr, less than 0.05% of N, equal to or less than 0.020% of P, equal to or less than 0.020% of S, and the balance of Fe and unavoidable impurities. The smelting method of low-carbon low-nitrogen high-chrome steel comprises the following steps: molten iron is pretreated; the pretreated molten iron is boiled in a converter and steel tapping is carried out, during the steel tapping, C is controlled to be between 0.03-0.05%, the temperature is higher than 1710 DEG C, and the oxygen activity in steel in a tank is ensured to be between 500-700 ppm; if the oxygen activity in steel is greater than 700 ppm, the oxygen activity of molten steel in the tank is controlled to be between 500-700 ppm; steel ladles are carried back to the converter after being carried out of an RH furnace, after the large tank is moved to a steel tapping position, argon blowing is carried out, low-carbon chromium iron is fed in the tank through a stock bin at the same time, and argon blowing is carried out for 5 minutes and then stopped; temperature is measured after the steel ladles are fed in an LF furnace, if the temperature is higher than 1575 DEG C, the steel ladles are fed in a machine for pouring, and if the temperature is lower than 1575 DEG C, the steel ladles are moved out after the temperature is raised to 1575 DEG C. The smelting method of low-carbon low-nitrogen high-chrome steel has the advantages of realizing the purpose that low-carbon low-nitrogen high-chrome steel is produced in a plain carbon steel factory and ensuring the reliability of RH production.

Owner:TANGSHAN GANGLU IRON & STEEL

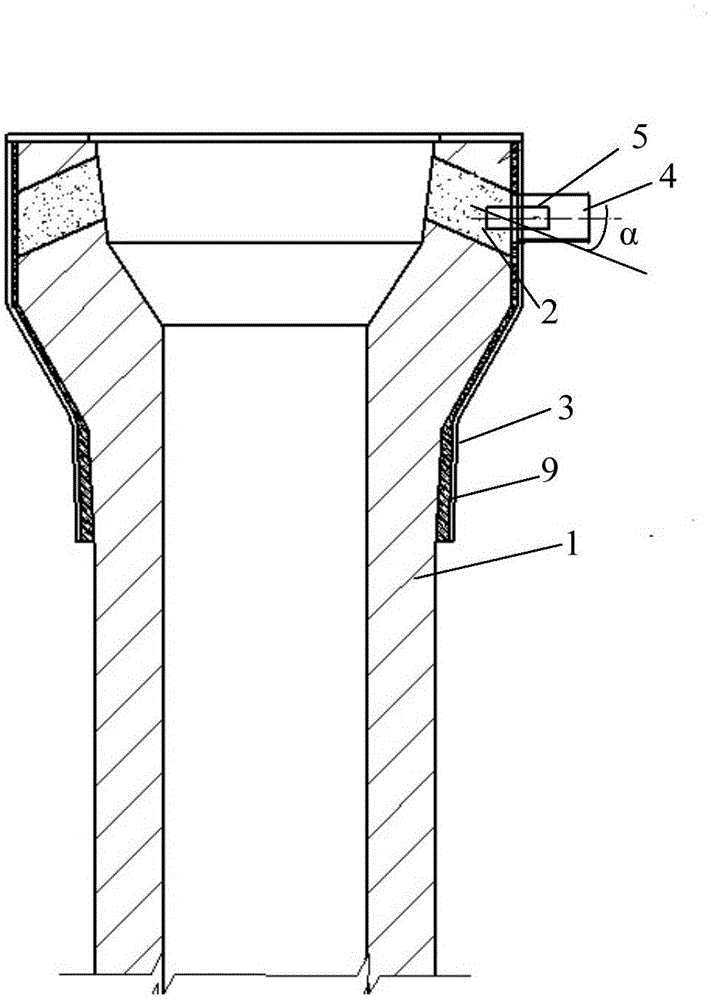

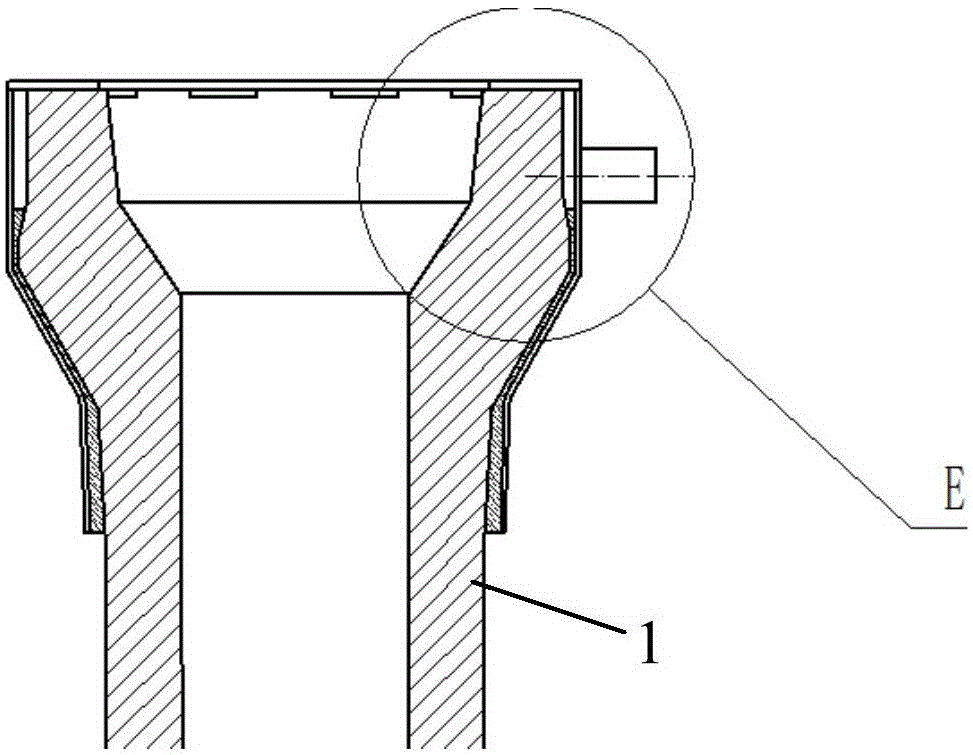

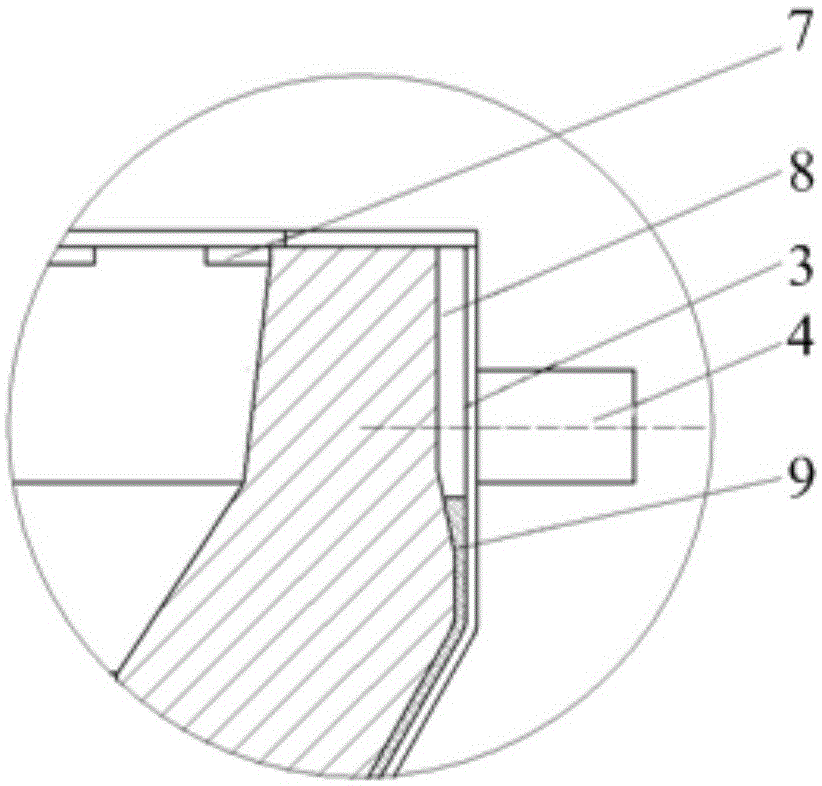

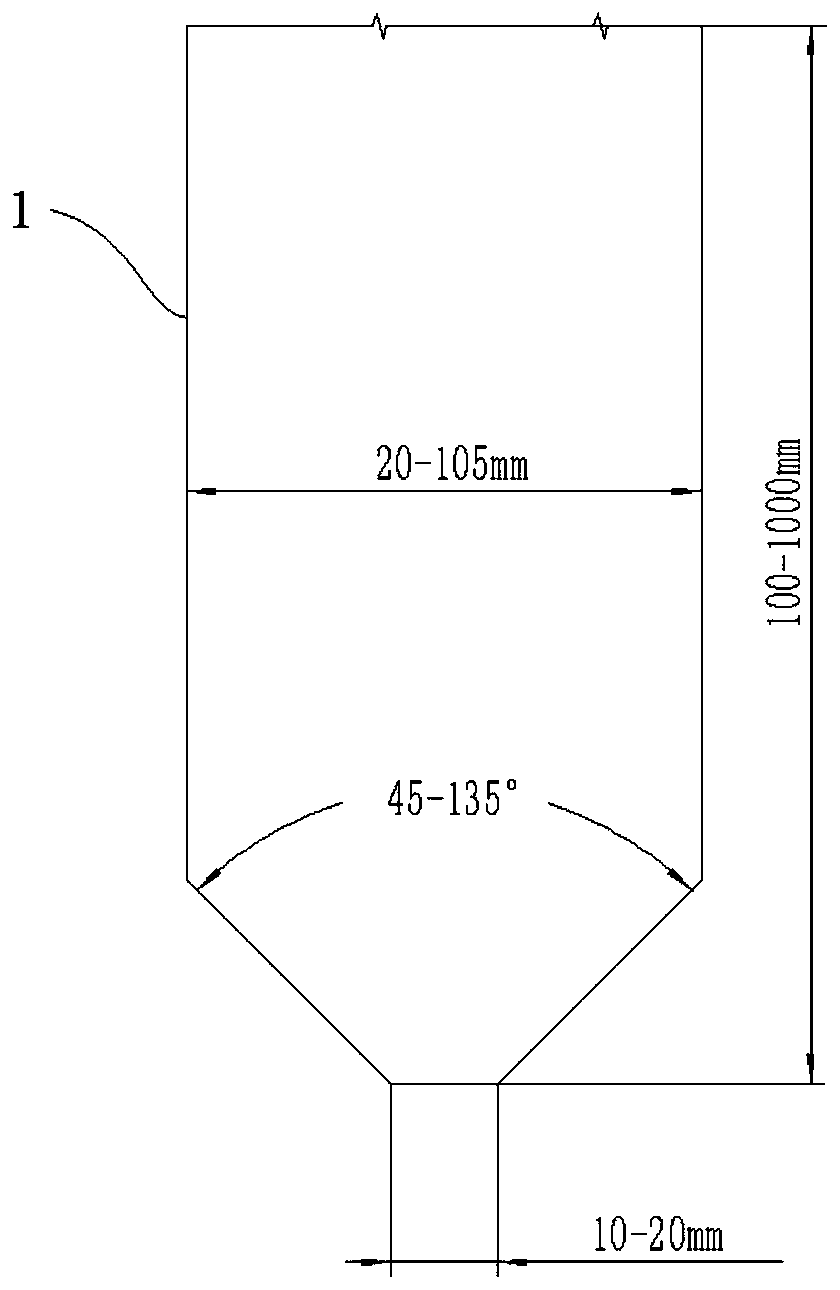

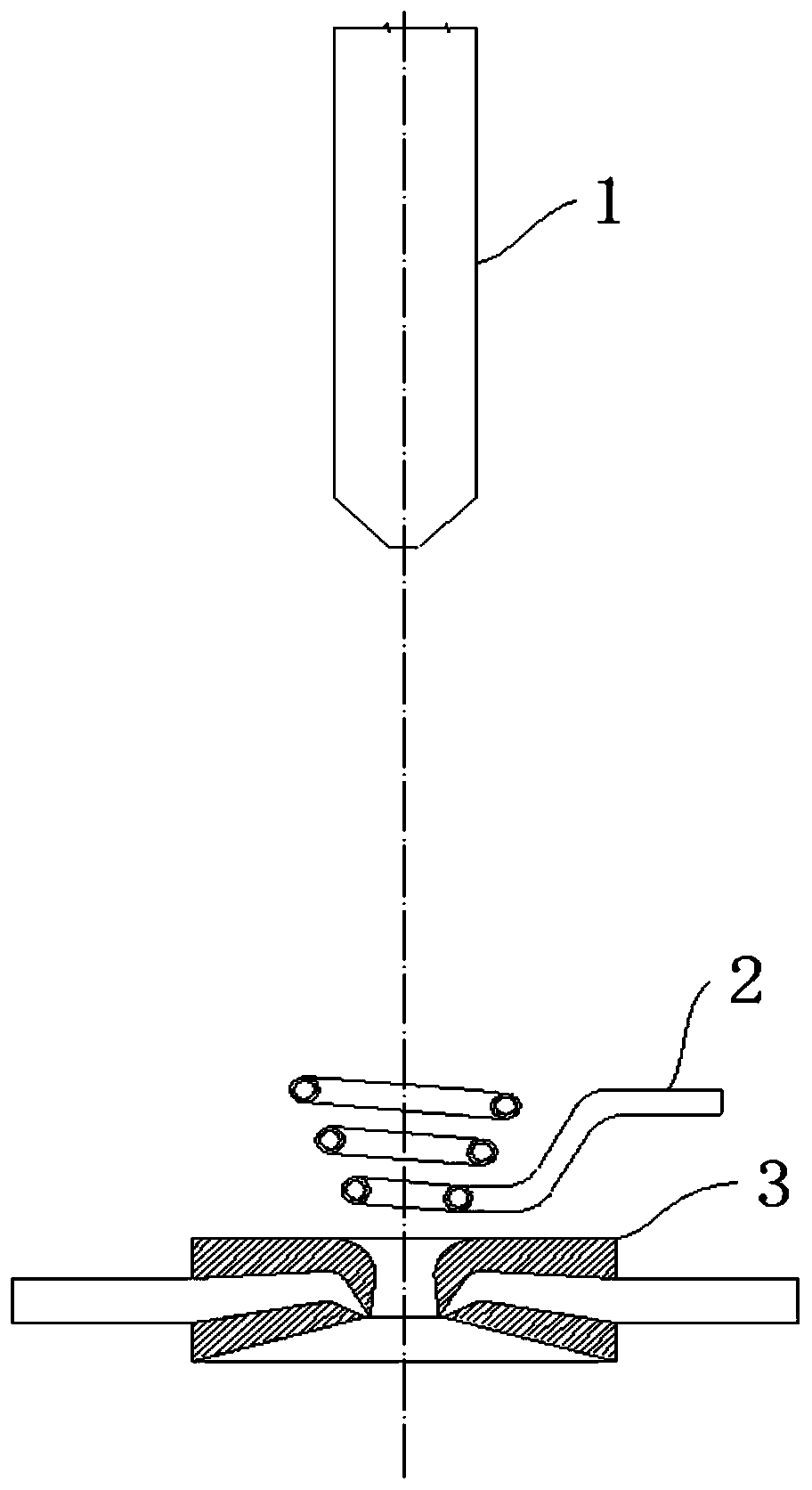

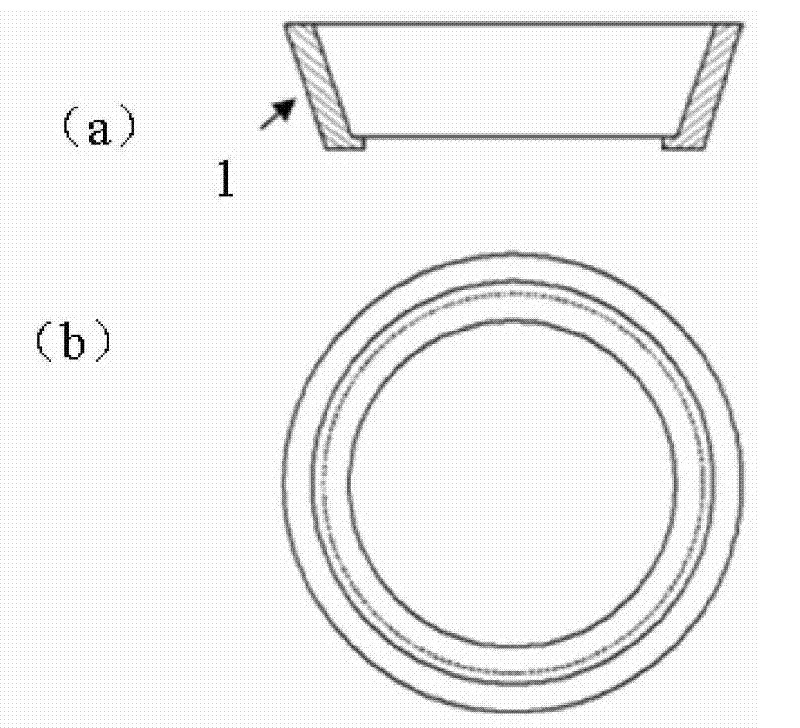

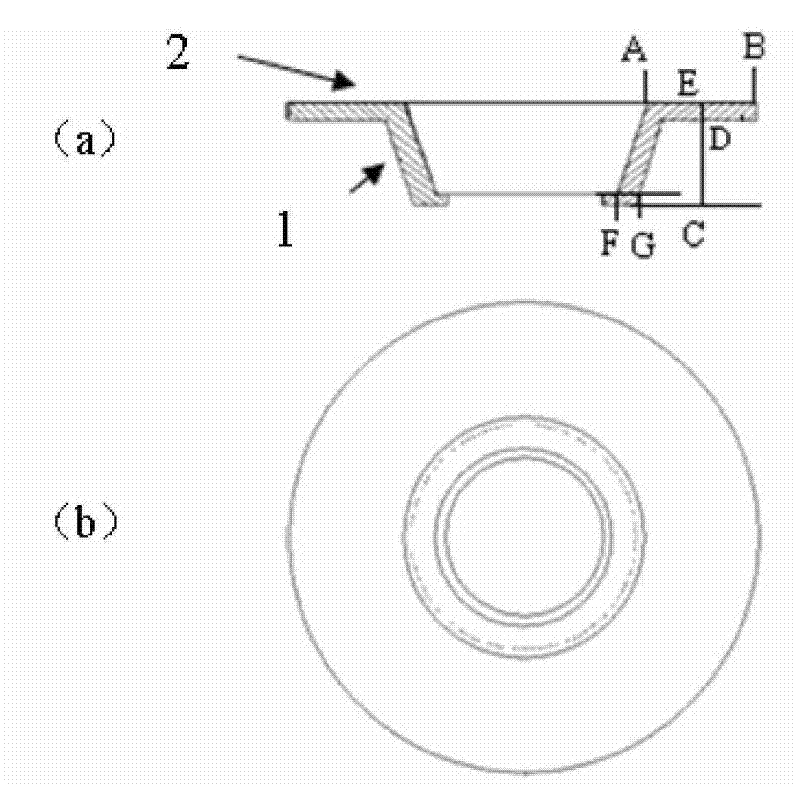

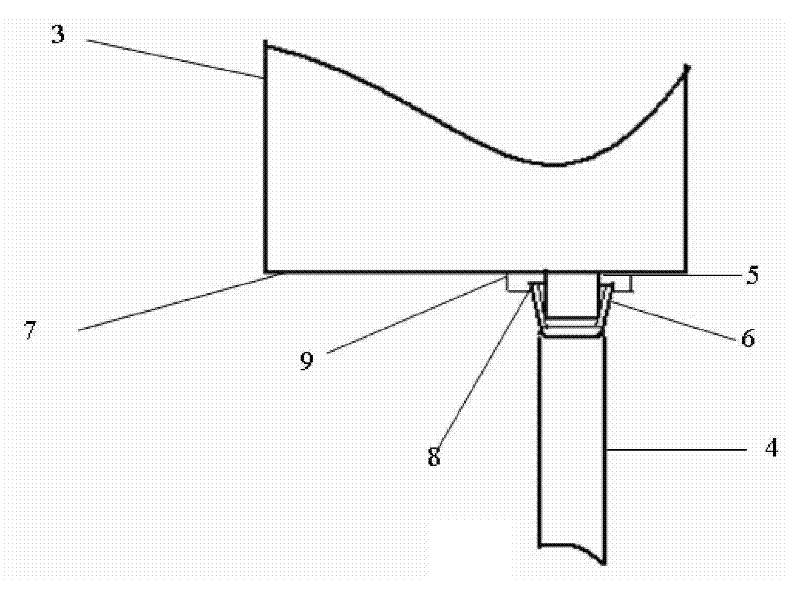

Nitrogen-increase-preventing long nozzle for continuous casting ladle

The invention relates to the technical field of ferrous metallurgy, in particular to a nitrogen-increase-preventing long nozzle for a continuous casting ladle. The nitrogen-increase-preventing long nozzle for the continuous casting ladle comprises a long nozzle body, a ventilation strip, an outer steel shell, an argon connect-in end and a hollow ceramic pipe. The outer steel shell is arranged outside the long nozzle body in a sleeving manner. The ventilation strip is arranged on a long nozzle device. The argon connect-in end is arranged on the steel outer shell. One end of the hollow ceramic pipe penetrates through the steel outer shell and is communicated with the argon connect-in end, and the other end of the hollow ceramic pipe is arranged in the ventilation strip. According to the nitrogen-increase-preventing long nozzle, by arranging the ventilation strip and the hollow ceramic pipe, the sealing performance of the long nozzle body is improved, the argon connect-in end is directly connected with the hollow ceramic pipe, blown-in argon can directly enter the ventilation strip, annular and uniform gas curtains which are equal in width are formed on the inner wall of a bowl part of the long nozzle body, it is guaranteed that air is effectively isolated in the steel casting process, molten steel nitrogen increase is prevented, the purity degree of molten steel is improved, and high quality of the continuously cast billets is guaranteed.

Owner:北京利尔高温材料股份有限公司

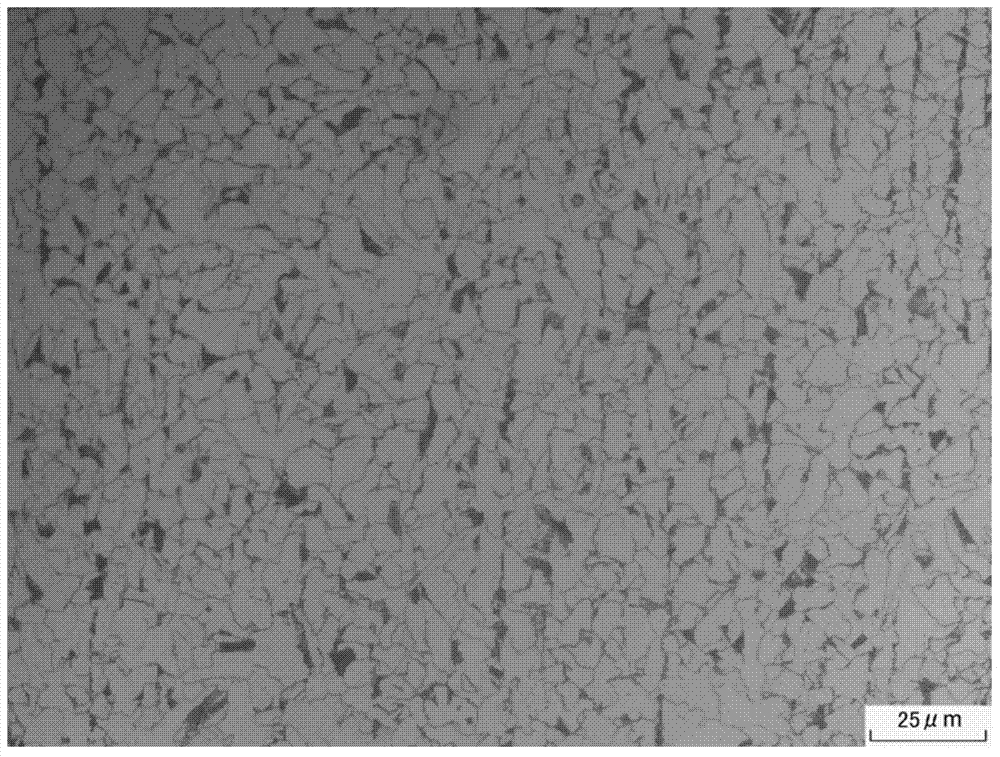

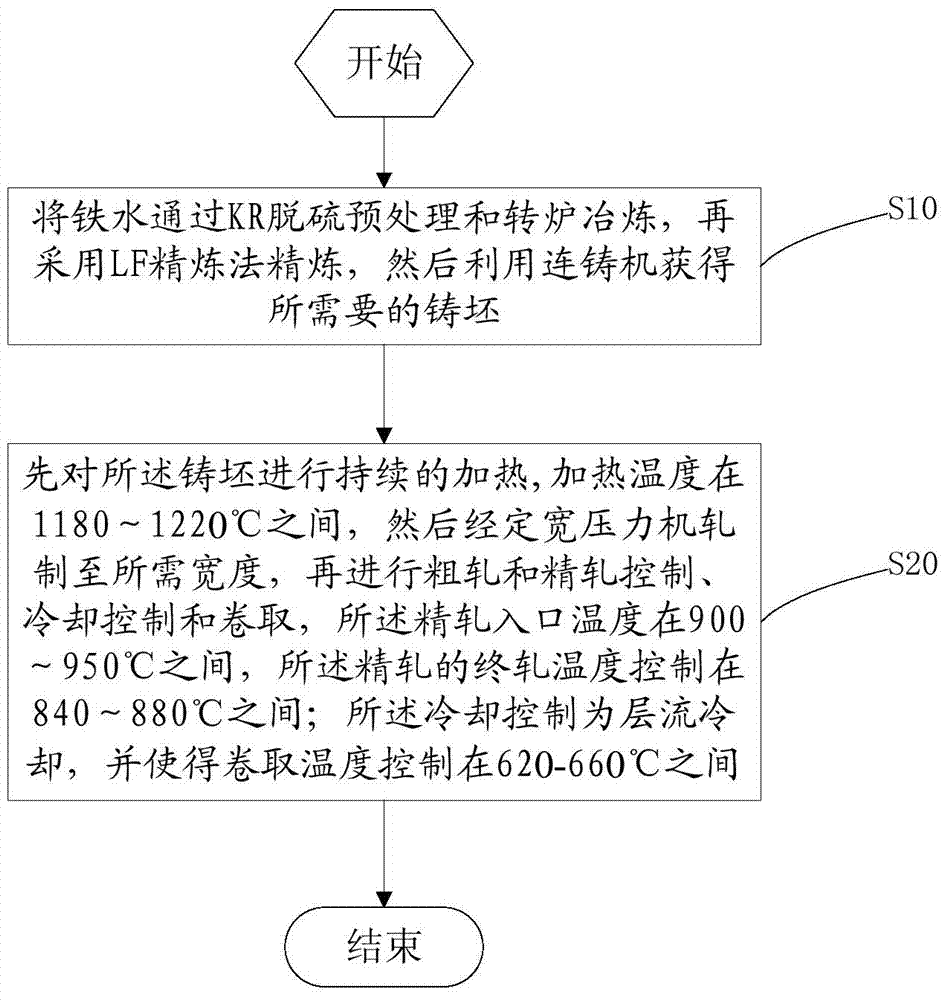

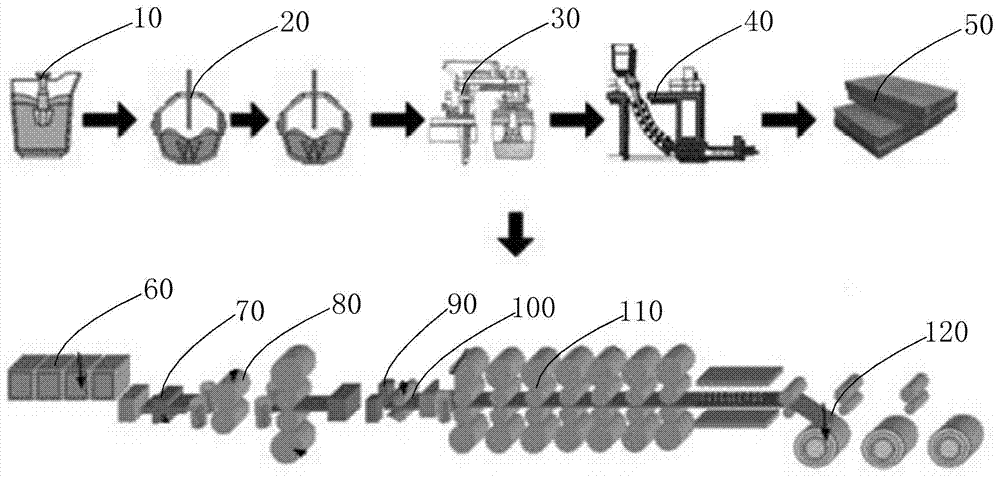

Steel for heavy-truck super-thick steel-made spokes and manufacturing method of steel

The invention relates to the technical field of steel rolling, and relates to steel for heavy-truck super-thick steel-made spokes and a manufacturing method of steel. The steel comprises the following trace elements in percent by mass: carbon, 0.07~0.12%; silicon, 0.05-0.15%; manganese, 0.7-1.1%; niobium, 0.01-0.03%; titanium, 0.01-0.03%; phosphor, <=0.015%; sulfur, <=0.005%; aluminium, 0.02-0.05%; and nitrogen, <=0.006%. The manufacturing method comprises: performing KR desulphurization and LF-method processing to obtain casting blanks, performing rough rolling and finish rolling, and performing laminar flow cooling and reeling to obtain the needed steel. By utilizing smelting to obtain the casting blanks with the above trace-element mass percentages and employing the technologies of low-temperature heating, low-temperature rolling and high-temperature reeling, the demands of heavy-truck spokes on easy spinning property, surface quality and performance stability are satisfied, and the collapsing crushing rate of heavy-truck wheels is substantially reduced.

Owner:SHOUGANG CORPORATION

Calcium treatment-free production process of low-carbon silicon-containing killed clean steel

The invention discloses a calcium treatment-free production process of low-carbon silicon-containing killed clean steel, and belongs to the technical field of iron and steel metallurgy. The process ischaracterized in that the production of the molded low-carbon low-aluminum killed clean steel is carried out under the condition that calcium treatment is not used, and the specific flow comprises the steps of processing molten iron, performing combined oxygen blowing to a converter from the top and the bottom, LF refining (adjusting the aluminum component of the molten steel, feeding aluminum for three times, and feeding aluminum-iron-rare earth core-spun yarn), performing argon soft blowing to the bottom of a ladle, continuous casting and continuous rolling. Compared with the prior art, a calcium treatment process is not adopted, so that the calcium treatment cost is saved, the problem that high-melting-point aluminate is prone to generate floccule flow is avoided, the forming performance of a steel sheet is improved, and the occurrence probability of cold bending cracking is reduced.

Owner:RIZHAO STEEL HLDG GROUP

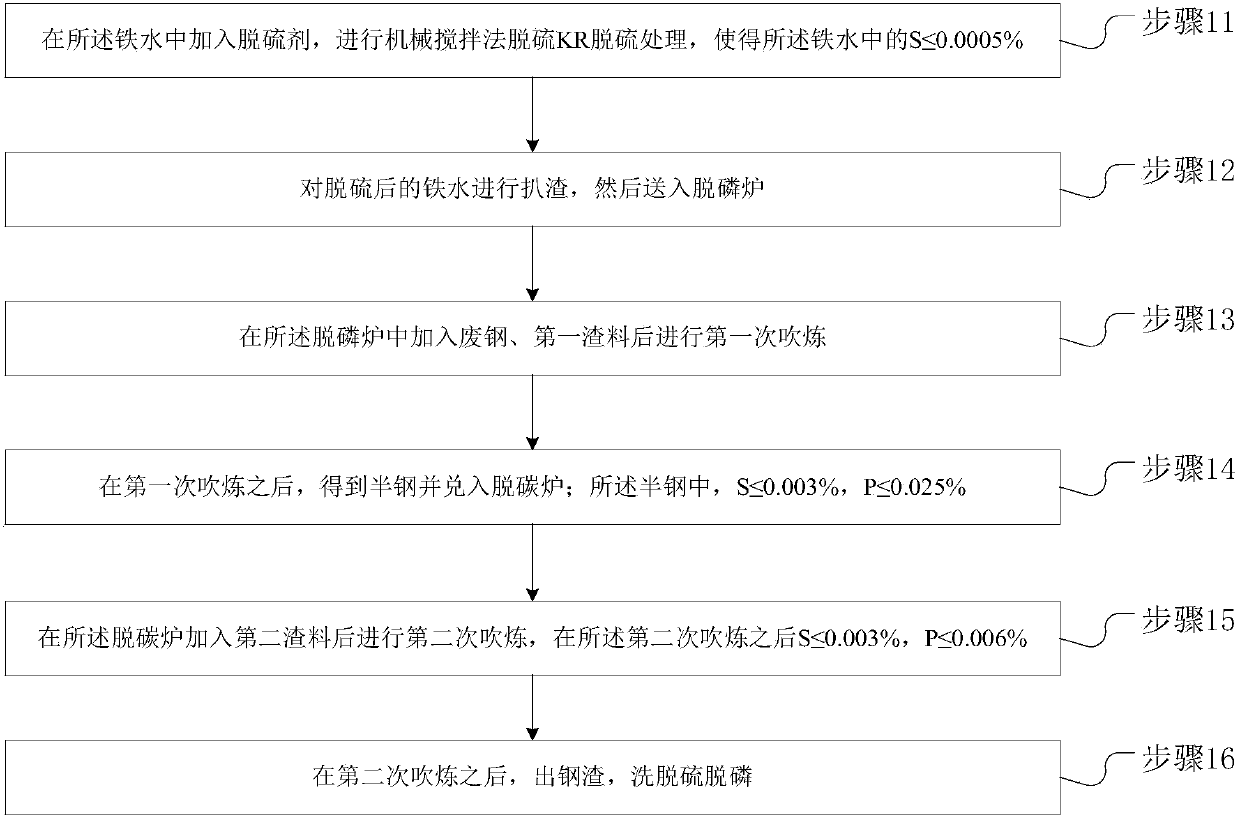

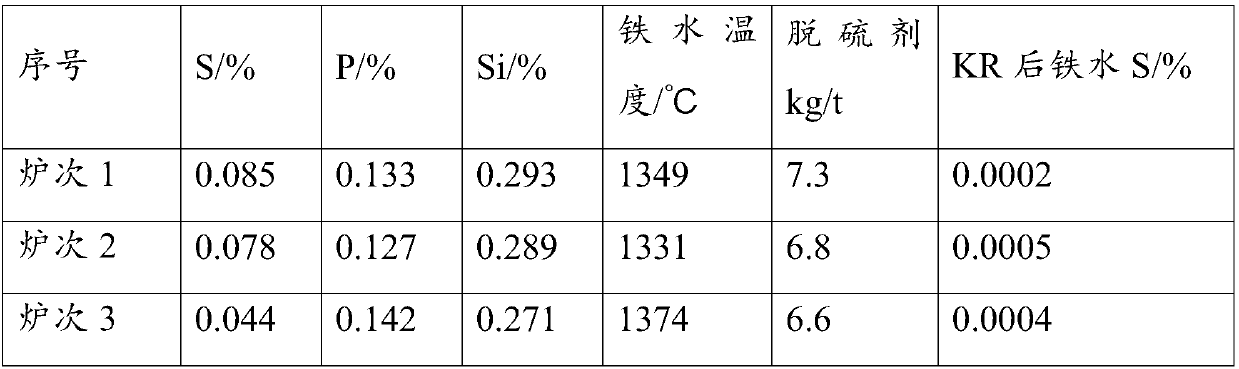

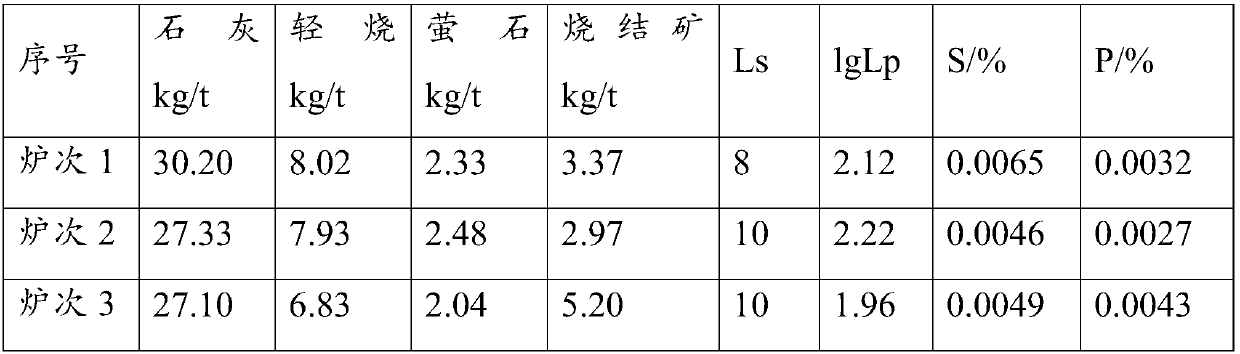

Production method of low-sulfur low-phosphorus steel

InactiveCN107868858AAvoid Nitrogen ProblemsReduce nitrogen contentProcess efficiency improvementSteelmakingSulfur

The invention discloses a production method of low-sulfur low-phosphorus steel. The production method adopts a double-converter process to perform dephosphorization and decarburization treatment on molten iron, and comprises the following steps that a desulfurizing agent is added into the molten iron, a mechanical stirring method desulfurization KR desulfurization treatment is carried out, and then slag removal and dephosphorization are carried out; then steel scraps and first slag material are added into a dephosphorization furnace to perform first blowing; after the first blowing, semisteelis added into a decarbonization furnace, then second slag material is added into the decarbonization furnace for second blowing, after the second blowing, S is less than or equal to 0.003%, and P is less than or equal to 0.006%; and then after the second blowing, steel slag is obtained and then washed for desulfurization and dephosphorization. According to the production method, double convertersare combined for smelting so that the nitrogen content of the molten iron can be reduced, cost of the steelmaking process is reduced, the low-sulfur low-phosphorus steel with s + p of less than or equal to 0.008% can be produced, cleanliness deterioration, the long smelting period and increased nitrogen of the molten iron caused by LF refining can be avoided, and meanwhile, matching of the continuous casting production rhythm is facilitated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

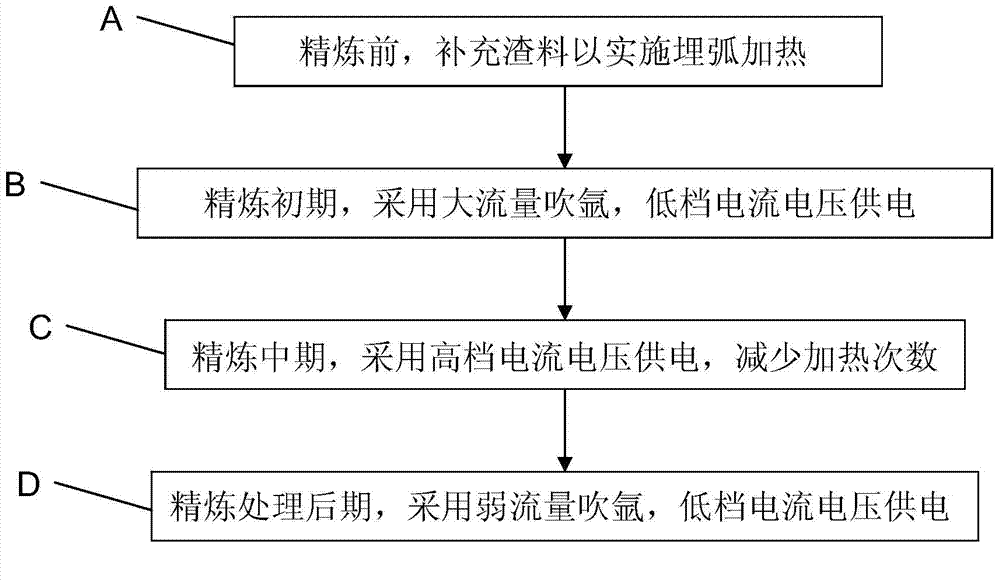

Control method for preventing nitrogen increasing in LF refining treatment

The invention discloses a control method for preventing nitrogen increasing in LF refining treatment. The control method comprises: before refining, performing submerged-arc heating via replenishing slag materials; in an initial stage of refining, producing white slag via ladle bottom high-flow-argon blowing, and adopting a low-current and low-voltage power supply; in an intermediate stage of refining, adopting a high-current and high-voltage power supply, and reducing frequency of heating and frequency of opening a furnace door for temperature measurement and sampling in order to improve the temperature raising efficiency; and in a later stage of refining, adopting ladle bottom small-flow-argon blowing, and the low-current and low-voltage power supply. The control method adopts the ways above for preventing nitrogen increasing, so that nitrogen increasing of an LF during a working process is effectively prevented; the average amount of nitrogen increasing is controlled in a range of 3-5ppm; and the quality of molten steel is further improved.

Owner:BAOSHAN IRON & STEEL CO LTD

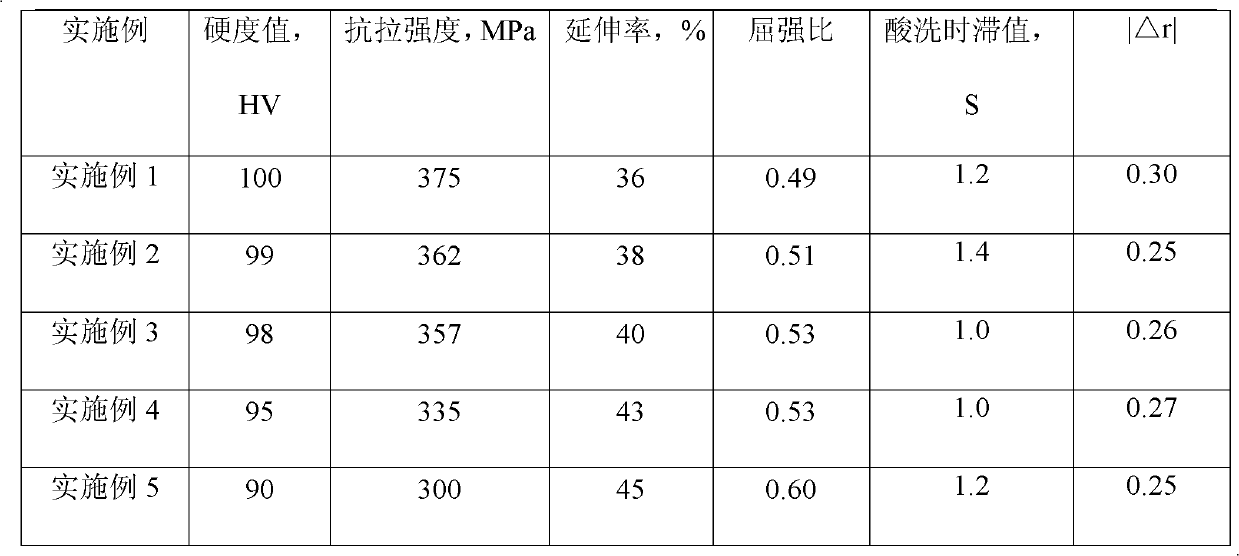

Corrosion-resistant steel with impact molding rate not smaller than 150 per minute for cell shell and preparation method thereof

The invention relates to steel capable of being subjected to rapid impact molding for a cell shell and a preparation method thereof. The steel comprises the components in percentage by weight: 0.0001-0.0050% of C, 0.10-0.20% of Mn, 0.010-0.050% of Al, 0.0001-0.0040% of N, 0.010-0.030% of Nb, not more than 0.020% of P, not more than 0.015% of S, not more than 0.05% of Cu, not more than 0.05% of Ni, not more than 0.08% of Cr, not more than 0.05% of Mo and not more than 0.020% of Si. The preparation method comprises the steps: smelting according to a pure steel process and carrying out continuous casting to obtain a blank; heating the continuous cast blank; carrying out rough rolling; carrying out finish rolling in a single-phase austenite region; coiling; pickling; carrying out cold rolling; degreasing; annealing in a full-hydrogen bell-type furnace; and leveling for later use. The finished product obtained in the invention has stable mechanical properties, hardness being 90-100, tensile strength being not lower than 300 MPa, elongation percentage being not lower than 36% and yield ratio being not more than 0.6; the impact-molded cell shell is not easy to crack and has good drum body shape fixity; and the finished product has high corrosion resistance.

Owner:武钢集团有限公司

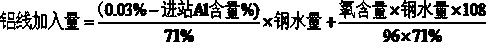

Calcium treatment method of ultra-low-carbon and high-aluminum steel

The invention discloses a calcium treatment method of ultra-low-carbon and high-aluminum steel. The calcium treatment method mainly solves the technical problem that when an existing slab caster casts ultra-low-carbon and high-aluminum steel comprising 0.001%-0.01% of carbon and 0.1%-0.3% of aluminum, a continuous casting water gap is knotted. The calcium treatment method of ultra-low-carbon and high-aluminum steel comprises the following steps that firstly, decarburization is carried out on molten steel in an RH furnace inlet station for 10-20 min under the vacuum degree of 270 Pa; secondly, silicon is adopted for decarburized molten steel for deoxidation, circulation is carried out for more than three minutes, an appropriate number of aluminum blocks are added to the component design range, circulation is carried out for more than five minutes under the situation that the circular flow is 1,600-3,000 L / min, and Alt and Als in the detected molten steel are sampled; thirdly, calcium iron alloy blocks are added through an RH furnace burden bin to carry out calcium treatment on molten steel, and the vacuum degree is reduced to 10-20 KPa; and after the calcium iron alloy blocks are added, circulation is carried out for more than three minutes in the state that the circular flow is 1,400-2,500 L / min. Compared with a common calcium treatment technology, the continuous casting water gap is effectively prevented from being knotted.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

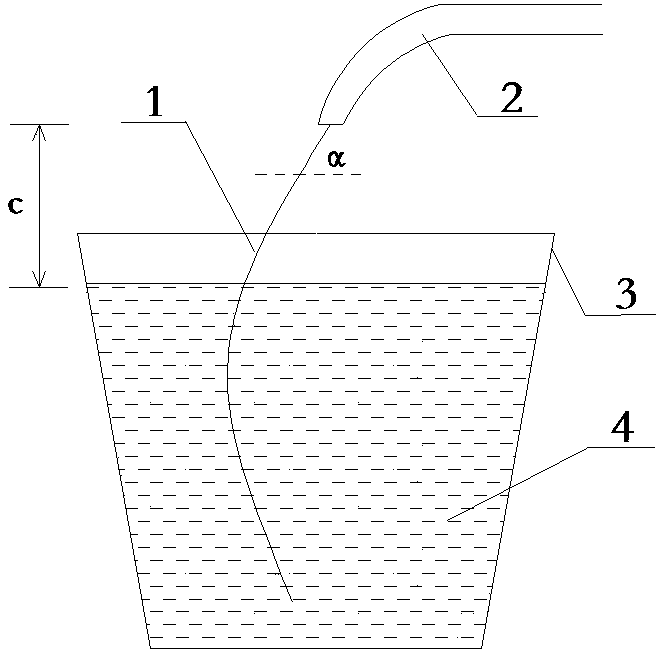

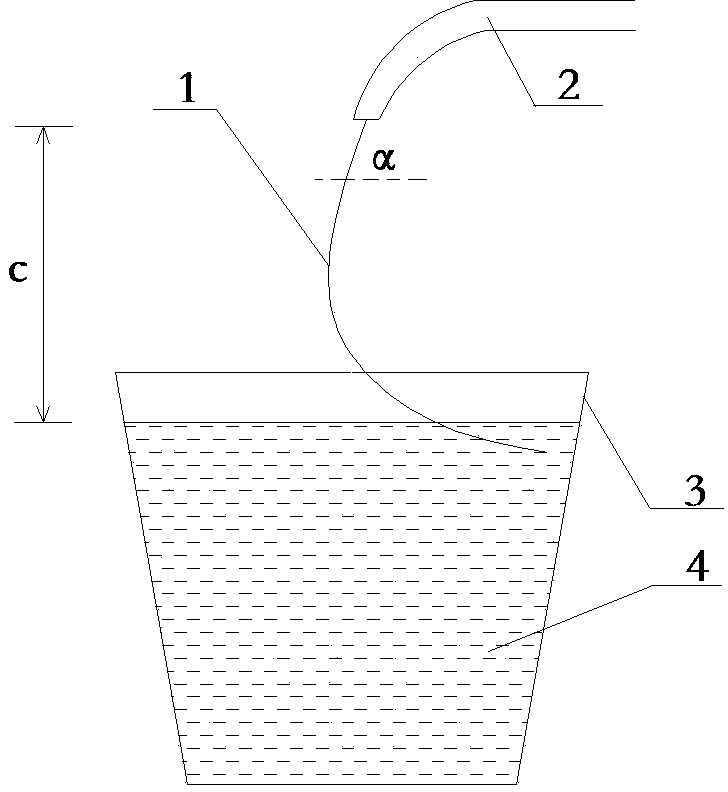

Method for reducing nitrogen increment of molten steel in refining process

The invention provides a method for reducing nitrogen increment of molten steel in a refining process. The scheme is mainly realized by the following technical measures: (1) after molten steel reaches the refining step, lifting the furnace cover of a finery and starting a buggy ladle to underface of the furnace cover of the finery; (2) reducing the furnace cover of the finery to a lower limit position; (3) meanwhile, inserting argon blowing conduits the original accidental argon gun hole, the original wire feeding hole and a new argon blowing hole, wherein the distance from the argon blowing conduits to the molten steel level is 200-1000mm; and (4) blowing argon to the refinery along the argon blowing conduits, wherein the pressure range of argon is 0.5-1.0Mpa. An argon protective layer is formed on the molten steel surface to increase the reducing atmosphere in the furnace cover, so that the probability of contact of molten steel and air is reduced, and nitrogen increment caused by high temperature ionized air during heating is avoided, therefore, secondary oxidation of the molten steel during stirring is greatly reduced, and the degree of purity of the molten steel is improved.

Owner:JIGANG GRP

Galvanizing bake hardening steel plate with timeliness being larger than 6 months and production method of galvanizing bake hardening steel plate

InactiveCN110499471AReduce precipitation tendencySolve the lack of anti-agingHot-dipping/immersion processesSteel platesDecarburization

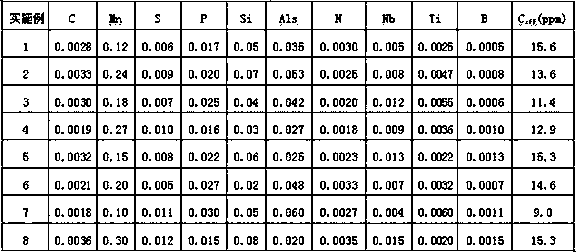

The invention discloses a galvanizing bake hardening steel plate with the timeliness being larger than 6 months and a production method of the galvanizing bake hardening steel plate. The steel plate includes, by mass, 0.0018%-0.0036% of C, 0.10%-0.30% of Mn, smaller than or equal to 0.012% of S, 0.015%-0.030% of P, smaller than or equal to 0.08% of Si, 0.020%-0.060% of Als, smaller than or equal to 0.0035% of N, 0.0040%-0.0150% of Nb, 0.0020%-0.0060% of Ti, smaller than or equal to 0.0015% of B and the balance Fe and inevitable impurities. The production method includes a molten iron pretreatment process, a decarburization converter process, a RH vacuum treatment process, a continuous casting process, a slab hot charging process, a hot rolling process, an acid continuous rolling process, acontinuous hot galvanizing process and an after-plating finishing process. The problem that traditional bake hardening steel is insufficient in timeliness resistance, and the timeliness resistance ofthe bake hardening steel is improved to 6 month or longer.

Owner:TANGSHAN IRON & STEEL GROUP +1

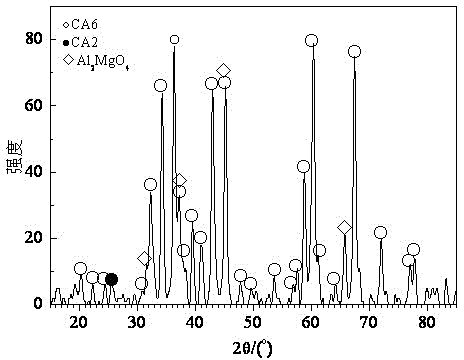

Preparation process of slag-stopping wire-feeding low-carbon aluminum killed clean steel

PendingCN111218619AAvoid the problem of prone to flocculationGood molding effectAluminateFlocculation

The invention discloses a preparation process of slag-stopping wire-feeding low-carbon aluminum killed clean steel, belonging to the technical field of ferrous metallurgy. The preparation process is characterized in that the production of the formed low-carbon aluminum killed clean steel is carried out without calcium treatment, and comprises the following steps of: adjusting 0.02-0.04% of refinedincoming molten steel [ Al ] in an LF (ladle furnace) refining step, wherein the temperature of the molten steel is not less than 1550 DEG C; adding lime according to 6-7 Kg / ton, controlling the slagcomposition, wherein the alkalinity CaO / SiO2 value is 8-9; refining to prepare white slag; adjusting the aluminum component of the molten steel, adding aluminum twice, and feeding a limestone cored wire; and controlling the mass percent of the refined outgoing molten steel component. Compared with the prior art, the preparation process has the advantages that a calcium treatment process is not adopted, the calcium treatment cost is saved, the problem that high-melting-point aluminate is easy to generate flocculation flow is avoided, the forming performance of a steel plate is improved, and the cold bending cracking occurrence probability is reduced.

Owner:RIZHAO STEEL HLDG GROUP

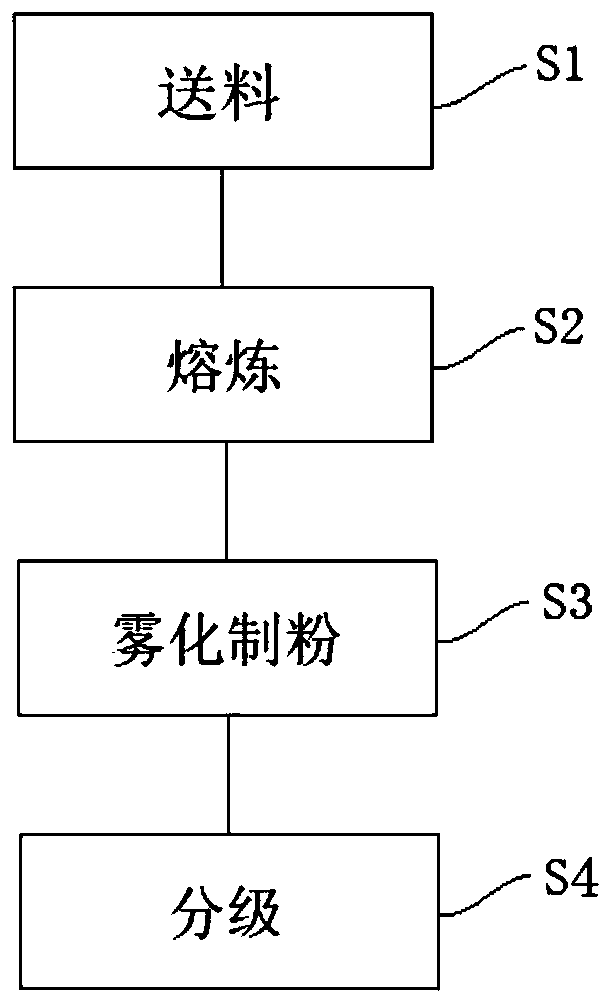

Spherical high-chromium high-copper alloy powder for 3D printing and preparation method of alloy powder

ActiveCN111069615AIncrease superheatIncrease yieldAdditive manufacturing apparatusTransportation and packagingVacuum induction meltingChromium

The invention provides a spherical high-chromium high-copper alloy powder for 3D printing and a preparation method of the alloy powder. The preparation method comprises the following steps of first, feeding, wherein in a shield gas environment, a bar stock is enabled to carry out autorotation and moves from one limiting position to another limiting position by being driven by a feeding mechanism at a preset feeding speed; second, smelting, wherein the gas pressure state inside a system is adjusted, vacuum induction smelting is carried out on the bar stock to melt a top conical surface of the bar stock, and the molten top conical surface gathers at a top conical tip of the bar stock to form droplets; third, atomization powder making, wherein atomization treatment is carried out on the droplets in an atomizer to obtain metal powder; and fourth, grading, wherein in the shield gas environment, size grading treatment is carried out on the metal powder which is sufficiently cooled to obtainthe high-chromium high-copper alloy powder which meets requirements. The powder obtained by adopting the preparation method is relatively low in oxygen content and nitrogen content without introducedimpurities, and no macrosegregation appears.

Owner:中航迈特粉冶科技(徐州)有限公司

Smelting method of medium-high-carbon sulfur-lead complex system free-cutting structural steel

The invention discloses a smelting method of medium-high-carbon sulfur-lead complex system free-cutting structural steel. The smelting method comprises the processes of primary smelting, LF refining and vacuum degassing refining, wherein the process of primary smelting involves an electric furnace or a converter, and during tapping, sulphur or ferrous sulfide blocks are used according to the requirements for the original S content in steel and the components of steel balls and the desulfurization rate of an initial slag system during special steel tapping to achieve resulfurization; lime and high-purity quartz sand are adopted for preparing components of the main slag system, a deoxidizing agent and alloy containing C, Si, Al and Mn are taken as deoxidation alloying materials, and harmfuloccluded foreign substances are well controlled. By means of the smelting method, consideration to the good gas removal effect and good control over lead content can be guaranteed, and the situation that the gas content rises again to a great extent due to leading operation after vacuumizing is avoided; and meanwhile, through the combination of different vacuum modes and leading modes, a process dedusting system can be effectively utilized to collect lead vapor, the environment is prevented from being affected, and a great effect is achieved.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

Calcium adding method for deoxidation calcium treatment of liquid steel

The invention belongs to steelmaking external refining technologies and particularly relates to a calcium adding method for deoxidation calcium treatment of liquid steel. The calcium adding method is characterized in that a calcium core wire with a composite structure is adopted and consists of a calcium core, a middle layer and a coating layer, wherein the coating layer wraps the outside surface of the middle layer, the middle layer wraps the outside surface of the calcium core, and the diameter of the calcium core is 6-8mm; the height of incidence of the calcium core wire is that the calcium core wire is just above the liquid surface of the liquid steel in a ladle by 38-42cm, and the angle of incidence of the calcium core wire is that the calcium core wire and the liquid surface of the liquid steel in the ladle form an included angle of 53-57 degrees. The calcium adding method has the advantages that the problem of splashing during the calcium treatment of the liquid steel can be effectively solved due to the adoption of the calcium core wire with the composite structure; meanwhile, the calcium core wire feeding success rate is increased through adopting the best feeding speed, height of incidence and angle of incidence, so that the yield of calcium metal is increased.

Owner:ZHANJIANG SHENGBAO TECH CO LTD

Process for low-carbon silicon-controlled aluminum killed clean steel

The invention discloses a process for low-carbon silicon-controlled aluminum killed clean steel and belongs to the field of steel preparation. The production process comprises the following steps: (1)reducing the sulfur content of molten iron to 0.02% or below by means of molten iron pretreatment and the like; (2) an oxygen top-bottom combined blown converter is adopted, specifically, slag stop and tapping are carried out, and the end-point molten steel [O] of the converter is less than 600 ppm; (3) LF refining is carried out, specifically, the slag is controlled to comprise 55-60% of CaO, 35-40% of Al2O3, 2-4% of SiO2 and 5-7% of MgO, specifically, the alkalinity value of CaO / SiO2 is 20-26, refining is carried out to make white slag, the aluminum component of the molten steel is adjusted, and aluminum is dosed twice; (4) soft blowing and calming argon at the bottom of a steel ladle; (5) continuous casting is carried out; and (6) rolling steel. Compared with the prior art, the methodhas the advantages that the calcium treatment cost is saved, the problems that high-melting point aluminate is prone to flocculation and nitrogen increase are avoided, the forming performance of a steel plate is improved, and the occurrence probability of cold bending cracking is reduced.

Owner:RIZHAO STEEL HLDG GROUP

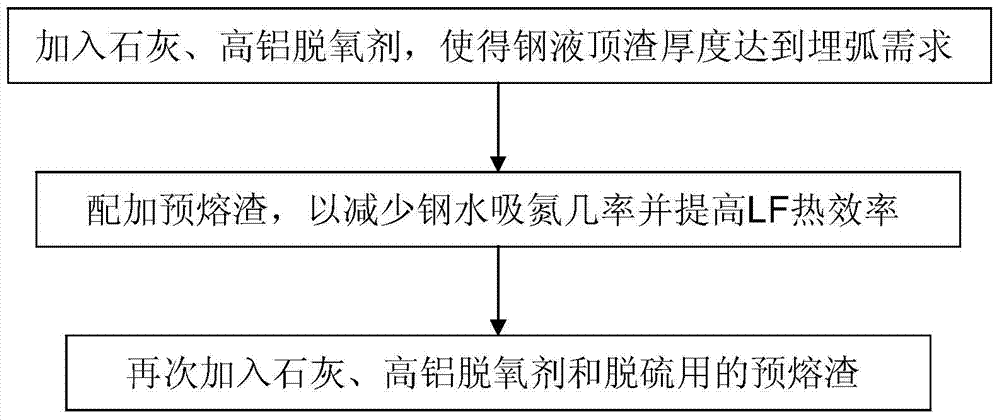

lf furnace desulfurization control carbon nitrogen control method

The invention relates to a LF furnace desulphurization carbon-control nitrogen-protection controlling method. The controlling method comprises the following steps: 1) pull-in molten steel is observed, a rapid temperature thermocouple is used for temperature measurement and sampling is carried out, 2) after slugging the molten steel in the step 1), under condition that the slag amount is insufficient, and the fluidity is good, the molten steel is easily exposed, an electrode is brushed, at the same time, desulfurized lime and a high-aluminum deoxidizer submerged arc material are continuously added, 3) when the molten steel temperature is increased to 1590-1600 DEG C, the surface of the molten steel is covered by a layer of protection slag, then submerged-arc heating is carried out, the deoxidation depth is controlled, white residues are generated and deep desulphurization is performed, submerged arc heating is carried out for carbon protection, the nitrogen is controlled; and 4) the dedusting opening degree is adjusted at 20-40% for stabilizing the micro-positive pressure in the furnace, the micro-positive pressure atmosphere in the furnace is guaranteed during a whole processing course of a LF furnace, according to the practical status of ladle permeability, and the argon flow at each phase is set in a reasonable mode.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

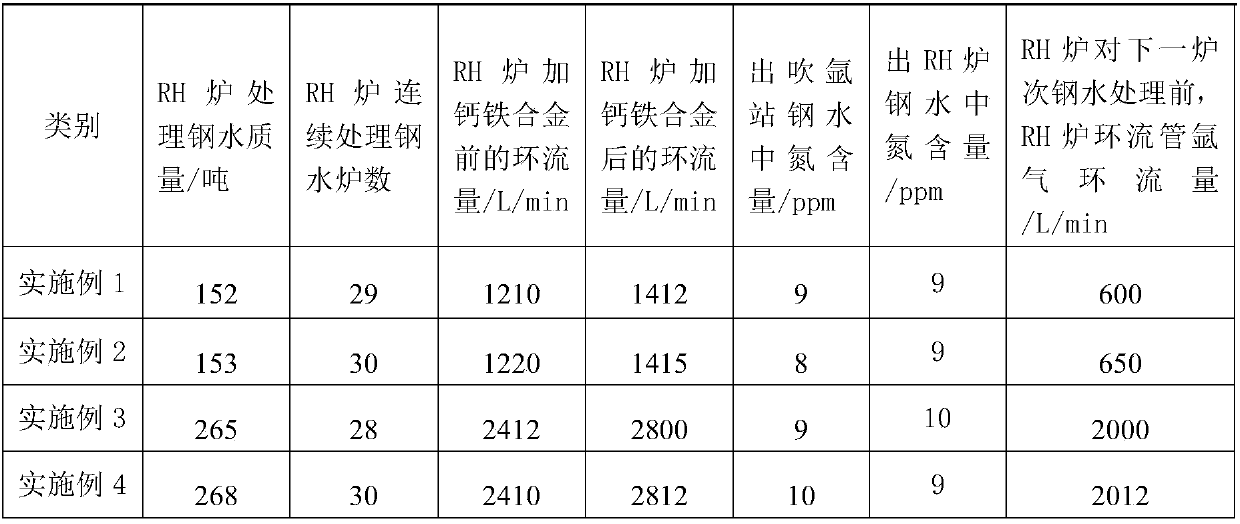

Low-cost calcium treatment method of ultralow-carbon high-aluminum steel

InactiveCN110317927ASolve the splatter problemSolve the fierce industry problemsLight treatmentNitrogen

The invention discloses a low-cost calcium treatment method of ultralow-carbon high-aluminum steel. The technical problems of high cost, molten steel splashing and molten steel nitrogen increasing ofthe calcium treatment conducting on the ultralow-carbon high-aluminum steel by an RH furnace in the prior art are solved. According to the technical scheme, the low-cost calcium treatment method for the ultralow-carbon high-aluminum steel comprises the following steps that decarbonizing is conducted on molten steel; deoxidizing is conducted the decarburized molten steel by adopting silicon; controlling a molten steel treatment mode of the RH furnace to be switched into a light treatment mode; conducting the calcium treatment on the molten steel; introducing argon into a RH furnace circulationpipe before the RH furnace finishes the next-furnace molten steel treatment, circulating the argon in the RH furnace circulation pipe, and the argon circulating flow rate is 500-2400 L / min. Accordingto the method, the cost for conducting the calcium treatment on the ultralow-carbon high-aluminum steel in the RH furnace is reduced, and the production cost of the ultralow-carbon high-aluminum steelis reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Production method for reducing surface corner transverse cracks of boron-containing steel billets produced in short process

InactiveCN114855066AReduce oxygen contentReduce contentProcess efficiency improvementElectric furnaceElectric arc furnaceContinuous casting

The invention provides a production method for reducing surface corner transverse cracks of a boron-containing steel billet produced in a short process. The production method comprises the following steps: step S1, burdening; step S2, smelting; s3, electric arc furnace end point control; step S4, deoxidizing and alloying; step S5, LF refining; s6, VD smelting and calcium treatment; and S7, continuous casting is conducted. By controlling the production process of the boron-containing steel, the occurrence rate of the surface corner transverse crack defect of the boron-containing steel billet can be remarkably reduced, the product quality is improved, and meanwhile, the operation rate of a casting machine is improved.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

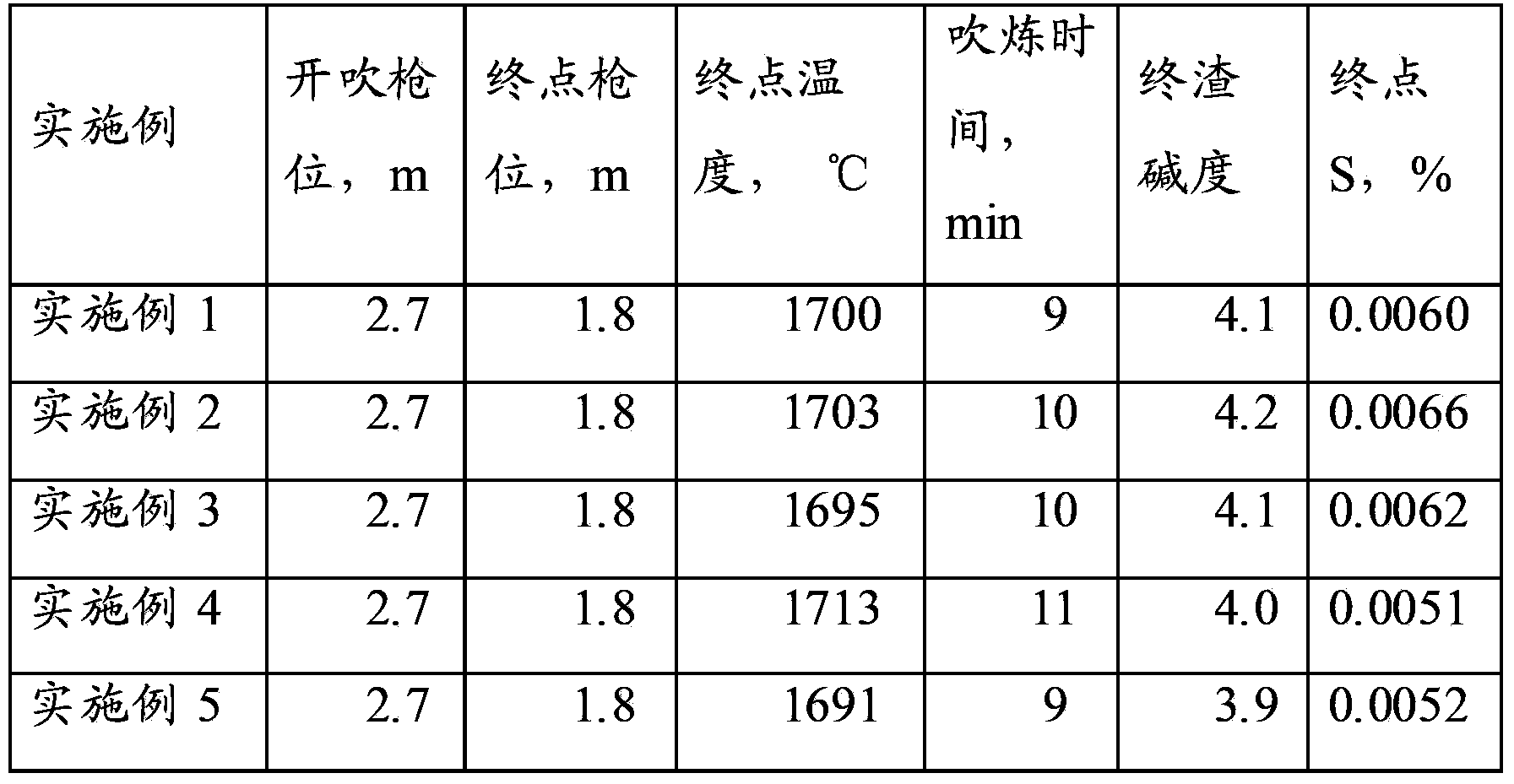

A low-cost manufacturing method for flaw detection q345b grade steel plate

ActiveCN108660381BReduce the amount addedReduce temperature lossManufacturing convertersChemical compositionSheet steel

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Method for producing white slag in bearing steel LF refining process

PendingCN113930586AReduce oxygen contentPrevent nitrogen increase and secondary oxidationSlagIron production

The invention discloses a method for producing white slag in a bearing steel LF (ladle furnace) refining process, and relates to the technical field of steel production. On the basis of the requirement of bearing steel on ultra-purity, the bearing steel LF deoxidation refining process is optimized in process details; and 70 minutes LF refining slagging of the bearing steel is optimized for the first 20 minutes, so that rapid deoxidation, white slag production and power supply atmosphere protection can be conveniently realized, the purpose of reducing the oxygen content of the bearing steel is achieved, nitrogen increase and secondary oxidation of molten steel are prevented, and the LF refining time of the bearing steel is shortened.

Owner:NANJING IRON & STEEL CO LTD

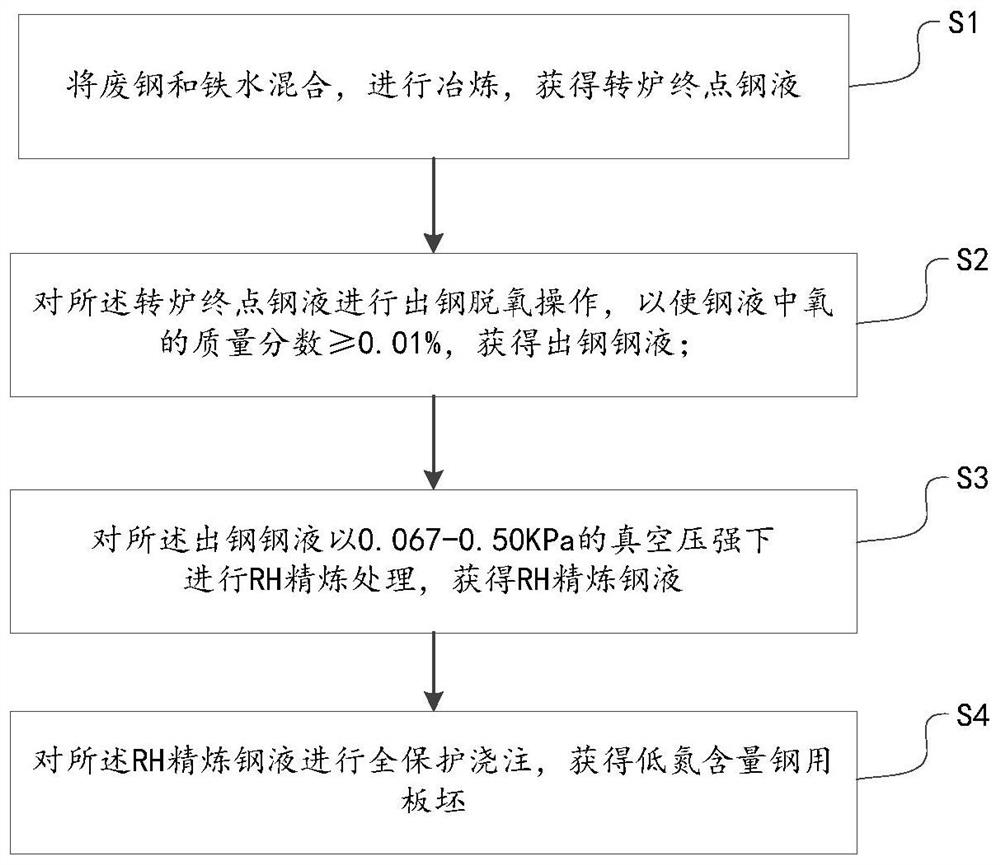

Method for reducing nitrogen content in steel

PendingCN114214481AReduce nitrogen contentInhibition of nitrogen uptakeProcess efficiency improvementSteelmakingVacuum pressure

The invention provides a method for reducing the content of nitrogen in steel, which comprises the following steps: mixing scrap steel and molten iron, and smelting to obtain final molten steel; tapping deoxidation operation is conducted on the smelted molten steel, so that the mass fraction of oxygen in the molten steel is larger than or equal to 0.01%, and tapping molten steel is obtained; the tapping molten steel is subjected to RH refining treatment under the vacuum pressure of 0.067-0.50 KPa, and RH refined molten steel is obtained; and the RH refined molten steel is subjected to full-protection pouring, and the plate blank for the low-nitrogen-content steel is obtained. By adopting the method provided by the invention, the nitrogen content in the plate blank can be as low as 26-32ppm, the nitrogen content is low, the sulfur content is 0.0017-0.0019%, the requirement of high-strength steel is met, and the pouring process is smooth.

Owner:SHOUGANG CORPORATION

A Calcium-Free Treatment Killed Clean Steel Production Process

ActiveCN108330389BAvoid the problem of prone to flocculationGood molding effectAluminateFlocculation

The invention discloses a production process of calcium-free treated calm and clean steel, which belongs to the technical field of iron and steel metallurgy, and is characterized in that the production of formable low-carbon aluminum killed and clean steel is performed without calcium treatment, and the specific process is: molten iron→oxygen Top-bottom compound blowing converter → LF refining → soft argon blowing at the bottom of the ladle → continuous casting → continuous rolling. Compared with the existing technology, the calcium treatment process is not used, which saves the cost of calcium treatment, avoids the problem of flocculation of high melting point aluminate, improves the formability of the steel plate, and reduces the probability of cold bending cracking.

Owner:RIZHAO STEEL HLDG GROUP

A method for smelting low-carbon, low-nitrogen, high-chromium steel

ActiveCN105908056BStable productionGuaranteed reliabilityManufacturing convertersLow nitrogenMolten steel

The invention relates to a smelting method of low-carbon low-nitrogen high-chrome steel. The low-carbon low-nitrogen high-chrome steel comprises the following components in mass percent: less than 0.03% of C, equal to or less than 0.10% of Si, equal to or less than 0.20% of Mn, 3.0-3.55% of Cr, less than 0.05% of N, equal to or less than 0.020% of P, equal to or less than 0.020% of S, and the balance of Fe and unavoidable impurities. The smelting method of low-carbon low-nitrogen high-chrome steel comprises the following steps: molten iron is pretreated; the pretreated molten iron is boiled in a converter and steel tapping is carried out, during the steel tapping, C is controlled to be between 0.03-0.05%, the temperature is higher than 1710 DEG C, and the oxygen activity in steel in a tank is ensured to be between 500-700 ppm; if the oxygen activity in steel is greater than 700 ppm, the oxygen activity of molten steel in the tank is controlled to be between 500-700 ppm; steel ladles are carried back to the converter after being carried out of an RH furnace, after the large tank is moved to a steel tapping position, argon blowing is carried out, low-carbon chromium iron is fed in the tank through a stock bin at the same time, and argon blowing is carried out for 5 minutes and then stopped; temperature is measured after the steel ladles are fed in an LF furnace, if the temperature is higher than 1575 DEG C, the steel ladles are fed in a machine for pouring, and if the temperature is lower than 1575 DEG C, the steel ladles are moved out after the temperature is raised to 1575 DEG C. The smelting method of low-carbon low-nitrogen high-chrome steel has the advantages of realizing the purpose that low-carbon low-nitrogen high-chrome steel is produced in a plain carbon steel factory and ensuring the reliability of RH production.

Owner:TANGSHAN GANGLU IRON & STEEL

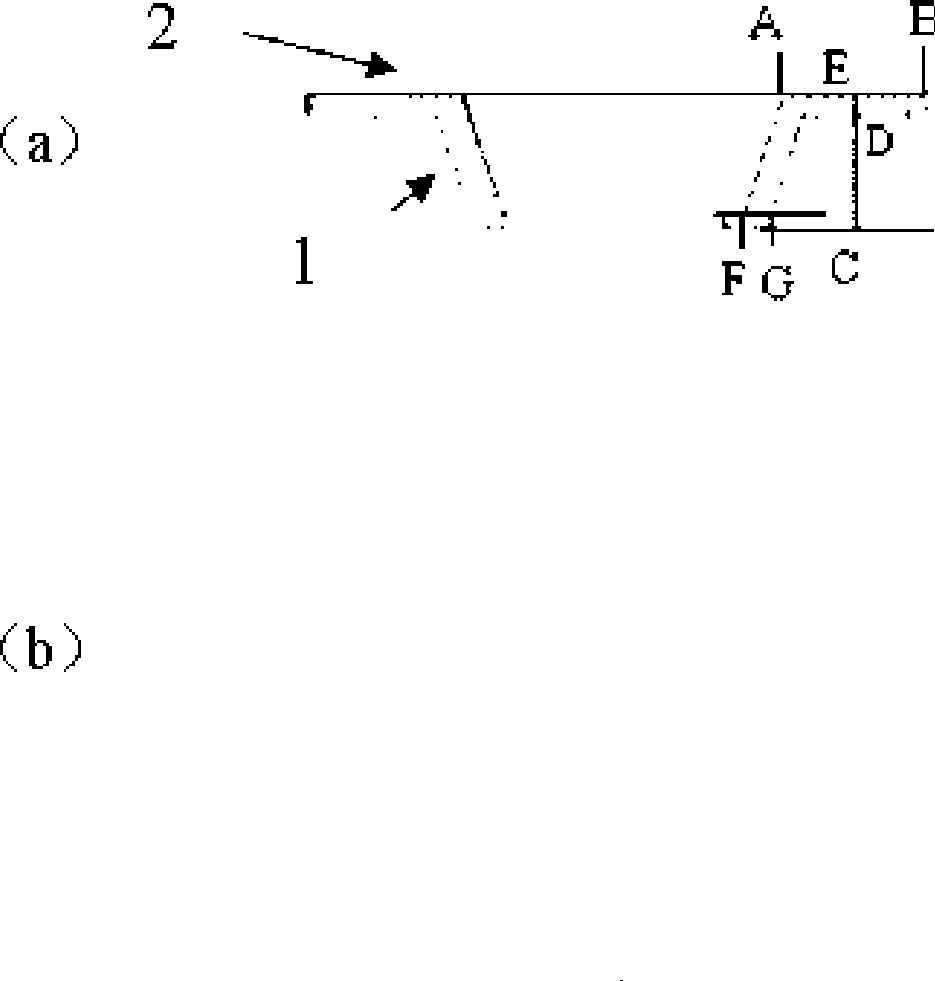

Method for controlling nitrogen content in Al deoxidization steel by converter process

ActiveCN101457275BAvoid Nitrogen ProblemsReduce the nitrogen content of the slabManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention belongs to the technical field of ferrous metallurgy, in particular relates to a method for controlling nitrogen content of aluminum killed steel produced in a converter process, and is used for preventing the problem that the nitrogen content increases in the aluminum killed steel produced in the converter process. The technical problem is solved by controlling the nitrogen content of the aluminum killed steel produced in the converter process according to the technical proposal as follows: the alkalinity of converter slag CaO / SiO2 is adjusted to 5-7 when a converter starts to produce the slag, the denitrification rate can be increased in the converter smelting process by controlling the alkalinity of the converter slag, the denitrification rate is increased from 50%-70% to 65%-85%, and the terminal nitrogen content of the molten steel in the converter can be controlled within 15PPm. The alkalinity is controlled, special slag is added, and a seal washer with brim is employed to seal between a steel ladle lower opening and a protection tube before starting continuous casting, thus realizing the stable control that the casting blank nitrogen content is not more than 35PPm by an LD-LF-SCC process and the casting blank nitrogen content is not more than 30PPm by an LD-LF-RH-BCC process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com