Patents

Literature

49results about How to "Solve the splatter problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

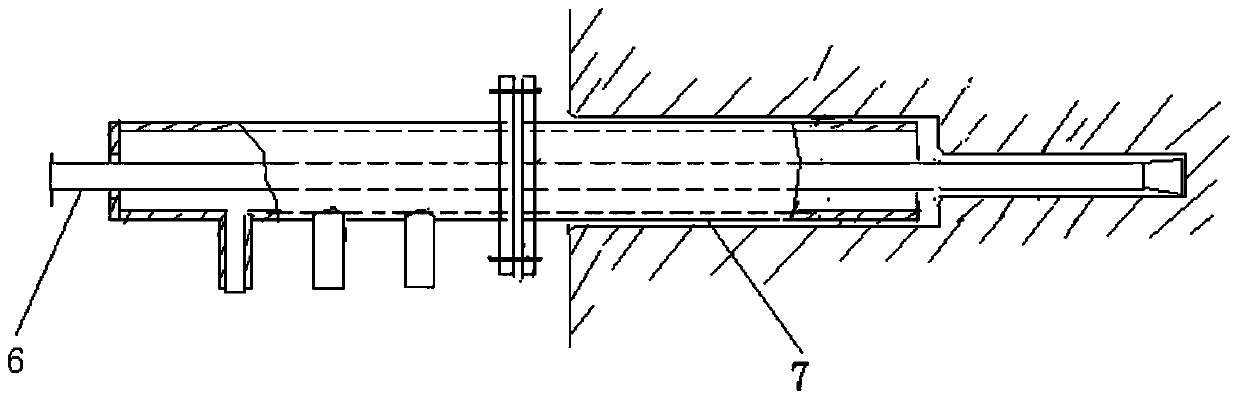

Environment-friendly alloying method of metal bismuth for free-cutting steel

The invention relates to an environment-friendly alloying method of metal bismuth for free-cutting steel, belongs to the technical field of metallurgy and aims to prevent violent reaction produced bydirection addition of metal bismuth, reduce smoke pollution, increase yield of bismuth and further normalize a bismuth alloying method. According to the method, metal bismuth is fed into molten steelin an alloy cored wire manner by a wire feeder, diameter of a bismuth cored wire is 8-14 mm, thickness of steel skin is 0.5-1.5 mm, and diameter of bismuth particles is 0-3 mm; bottom blowing stirringis performed on a steel ladle, feeding temperature is in a range of 1600-1780 DEG C, feeding rate is 80-110 m / min, and stirring is continued for 3-8 min after feeding. With adoption of the method, the problems of high volatilization, sedimentation and oxidation loss caused by low melting and boiling points and active nature of metal bismuth are solved, yield reaches 50% or higher, and splashing danger and a large amount of smoke pollution due to the violent reaction produced by direction addition of metal bismuth are effectively reduced.

Owner:TAIYUAN IRON & STEEL GROUP

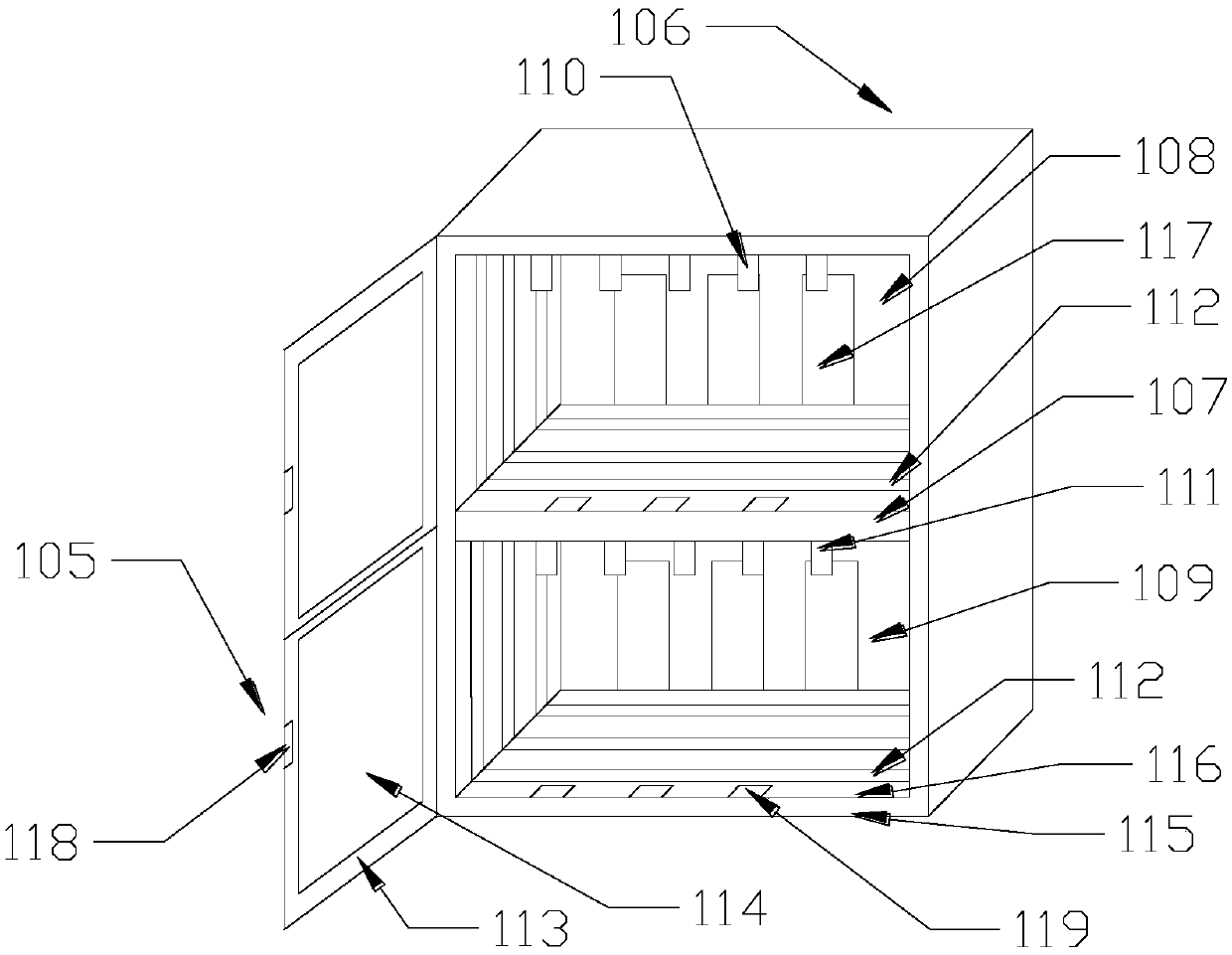

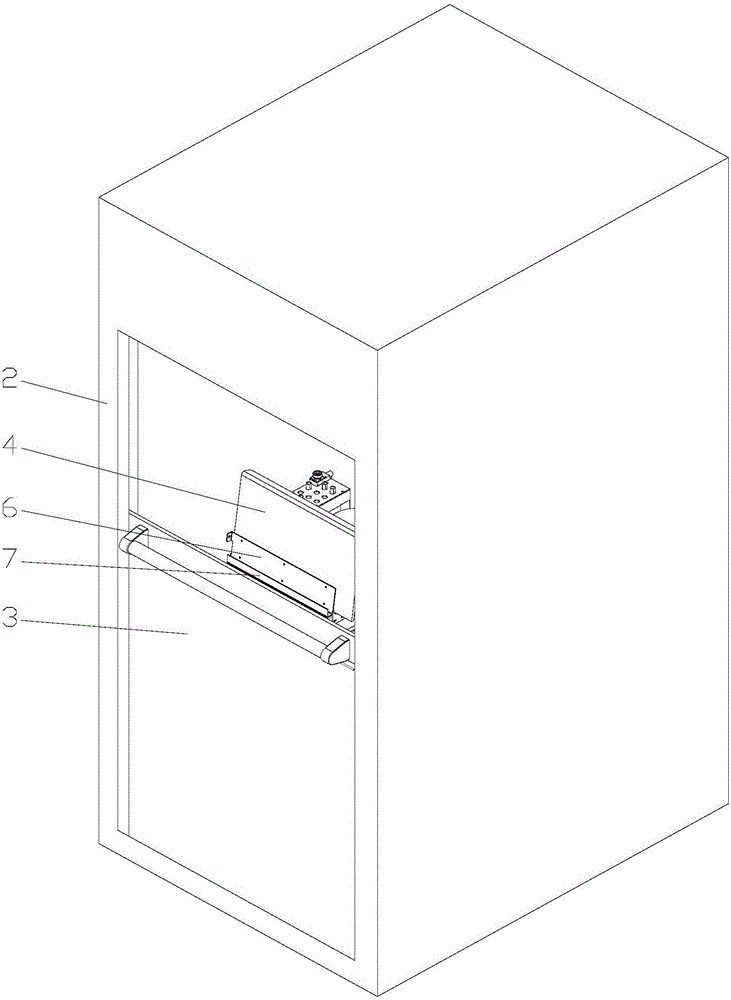

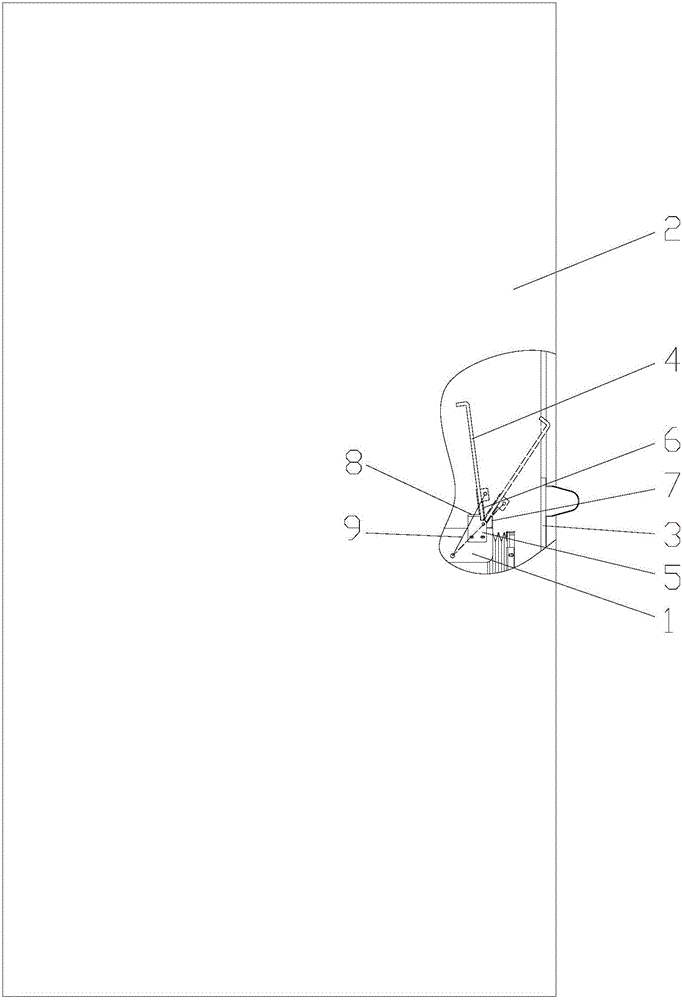

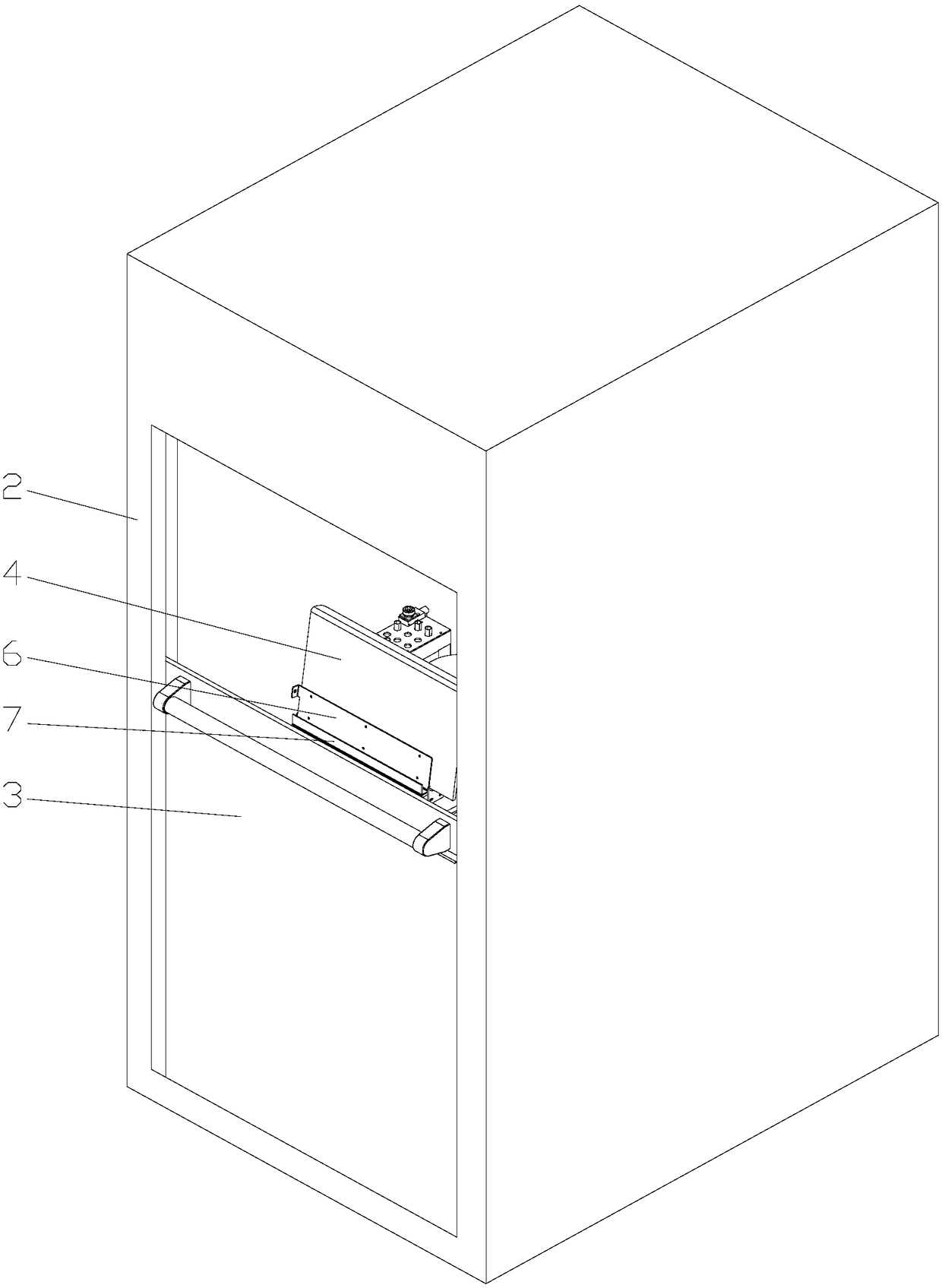

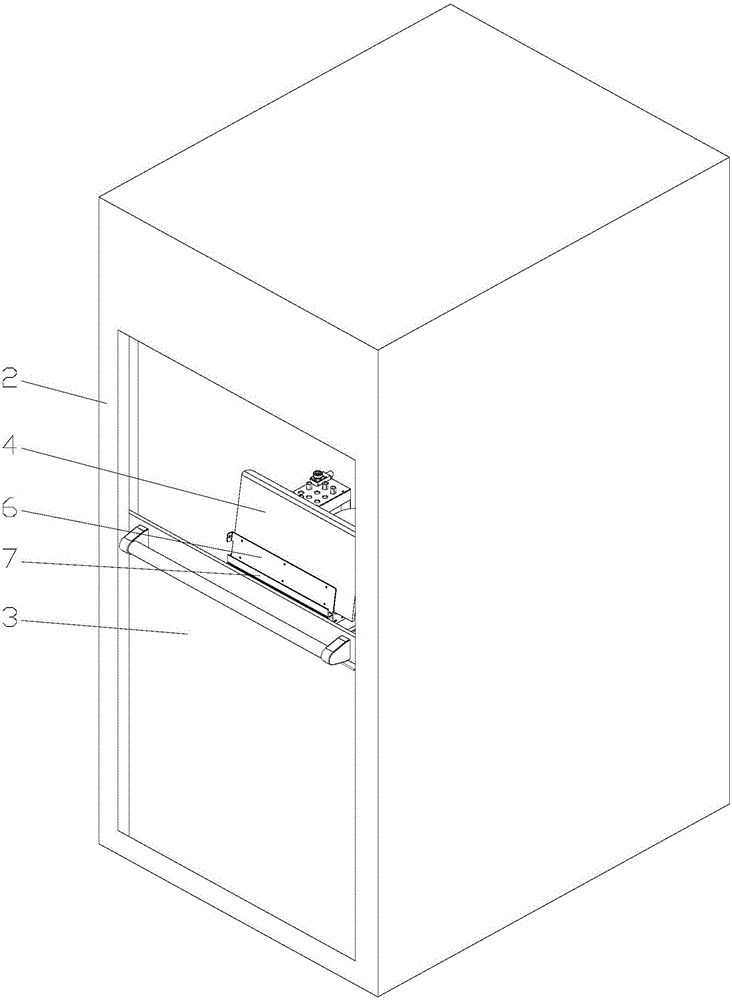

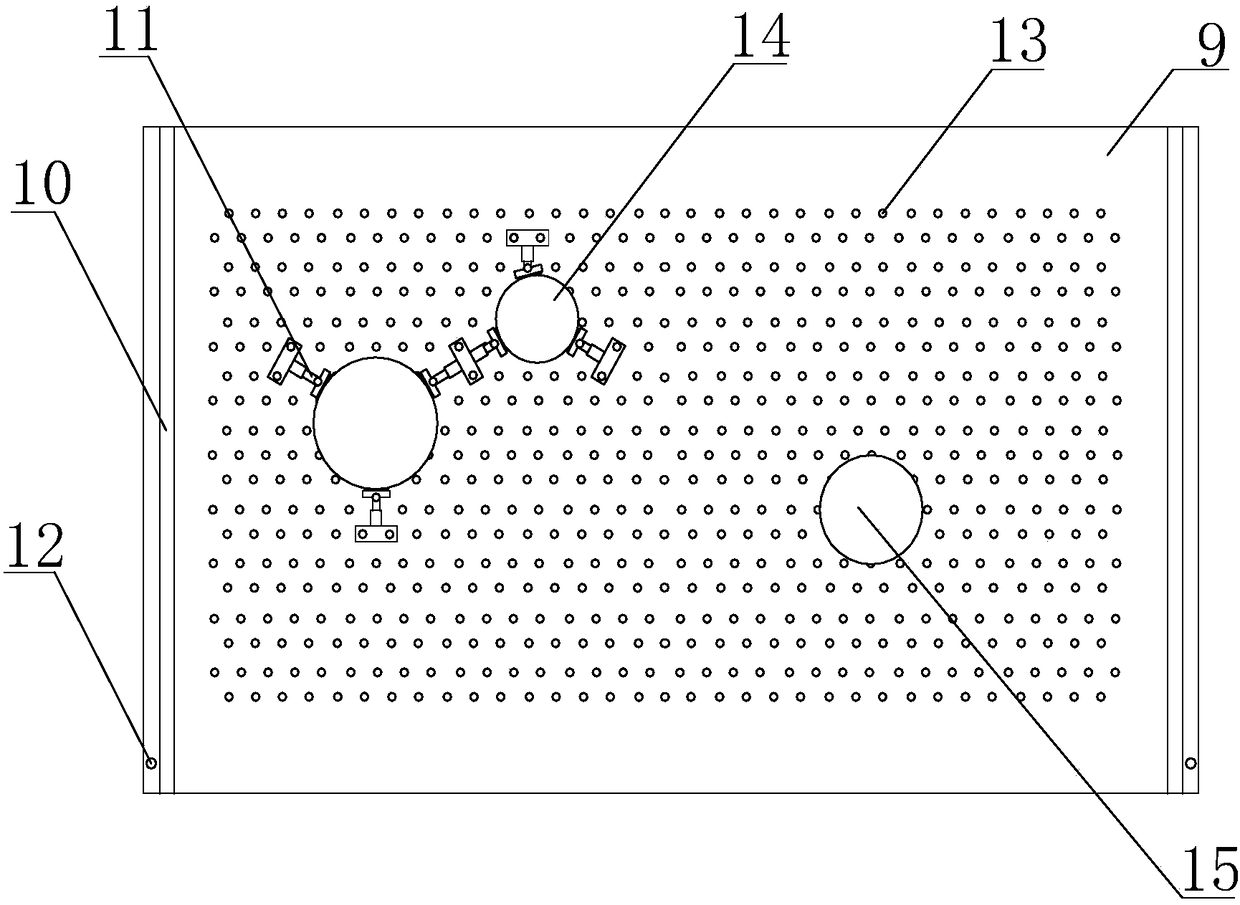

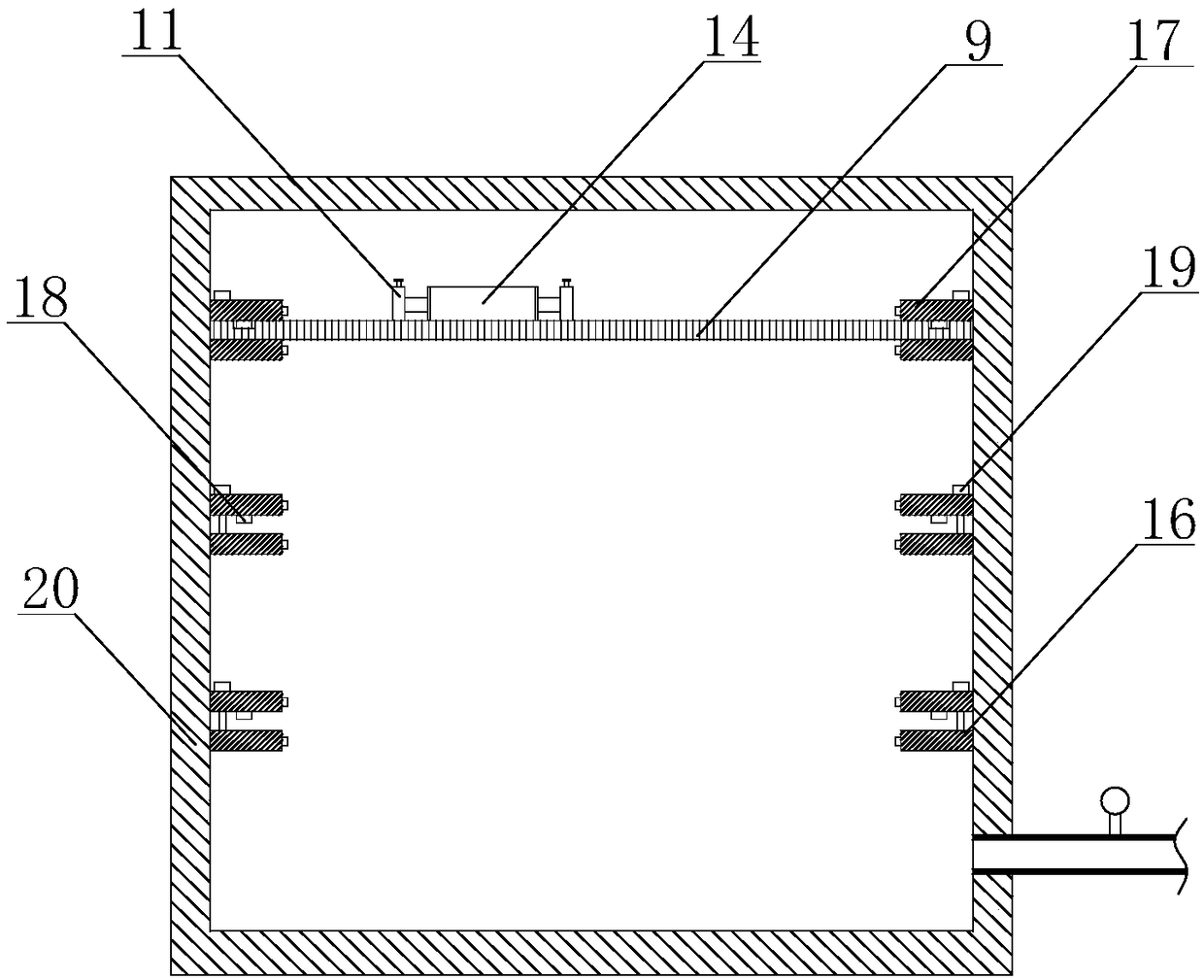

Biological specimen storage device

ActiveCN107914969AReduce lossReduce or eliminate the impactDomestic cooling apparatusLighting and heating apparatusEngineeringBio-Specimen

The invention discloses a biological specimen storage device which comprises a specimen storage cabinet, a specimen transferring tank and a specimen storage box, wherein the specimen storage cabinet comprises a cabinet body and a cabinet gate; the cabinet body comprises a shell, a heat-preservation layer and a thermal insulating plate; the heat-preservation layer is wrapped by the shell; the shellis fixedly connected with the outer wall of the heat-preservation layer; and the thermal insulating plate is fixedly connected with the inner wall of the heat-preservation layer and is used for partitioning a cavity of the inner layer of the heat-preservation layer into a low-temperature storage cavity and a normal-temperature storage cavity. By adopting the biological specimen storage device, the phenomenon that external air is fed into the cabinet body when specimens are stored or taken out by specimen storage operators is avoided, furthermore the gas environment inside the cabinet body isslightly changed, the influence upon temperatures inside the cabinet body is reduced when biological specimens are stored and taken out by specimen operators, and meanwhile bacteria in environments outside the cabinet body can be prevented from entering the cabinet body.

Owner:崔洋

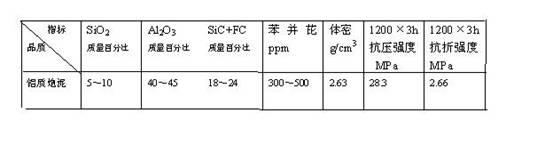

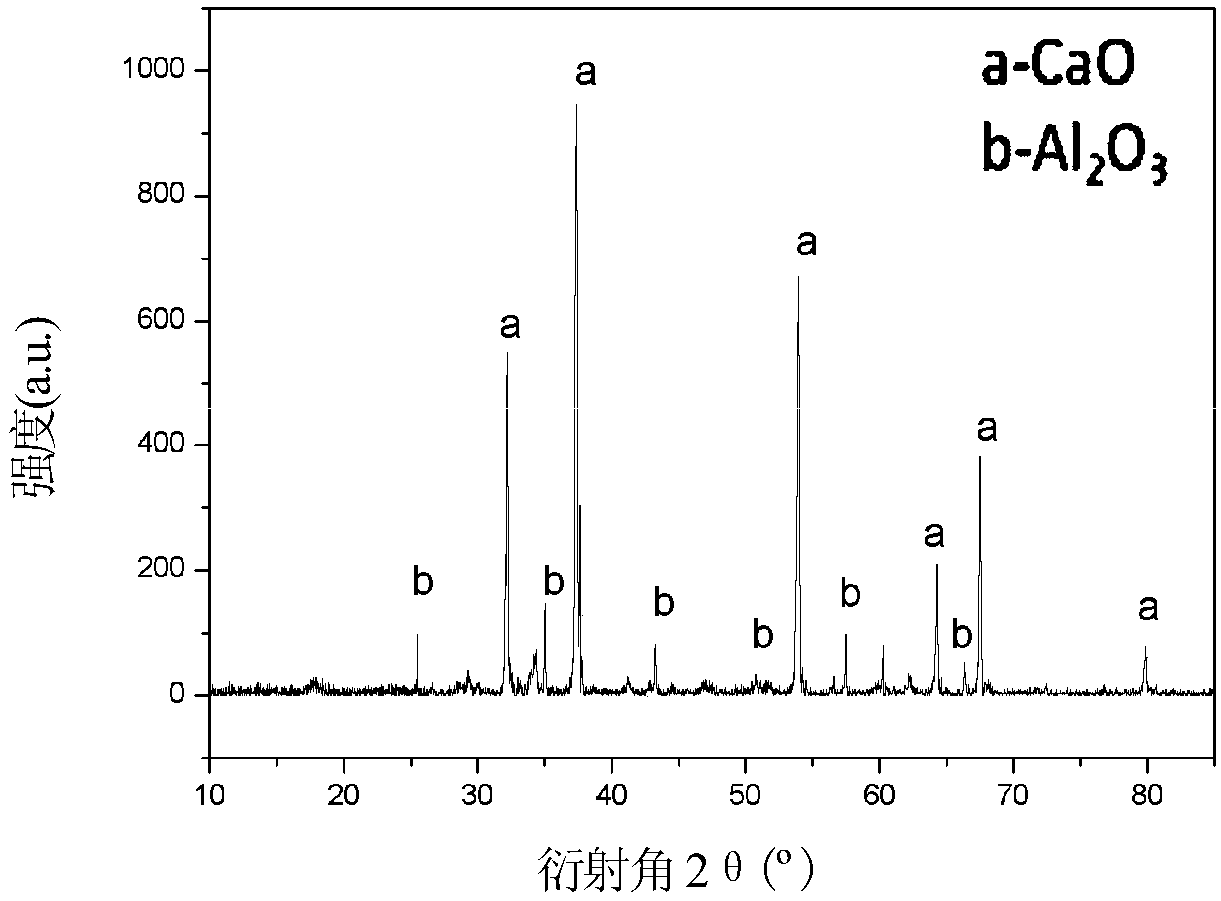

Blast furnace taphole filled aluminum stemming and preparation method thereof

The invention relates to blast furnace taphole filled aluminum stemming and a preparation method thereof and belongs to the field of high-temperature metallurgical fireproof materials. The preparation method comprises the following steps of: premixing 40 to 50 mass percent of corundum, 12 to 30 mass percent of silicon carbide, 3 to 5 mass percent of micropowder, 8 to 12 mass percent of ball clay,1 to 3 mass percent of plasticizer, 2 to 4 mass percent of graphite, 3 to 5 mass percent of expanding agent aluminium silicate, 3 to 5 mass percent of metal powder, 3 to 5 mass percent of titanium corundum and 3 to 5 mass percent of modified asphalt powder for later use; adding the mixture into a wheel roller, and pre-rolling for 5 minutes; adding 15 to 20 mass percent of modified liquid tar; performing high-speed wheel rolling for 30 to 35 minutes, so that the Marshall value is 4 to 16 MPa; and measuring the Marshall value again after 3 days, wherein if the Marshall value is 8 to 24 MPa, theproduct is qualified. By the blast furnace taphole filled aluminum stemming and the preparation method thereof, problems of low high-temperature strength, low high-temperature toughness and environmental pollution of the stemming are solved; and problems of shallow iron notch, broken iron notch and spattering are solved at the same time.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

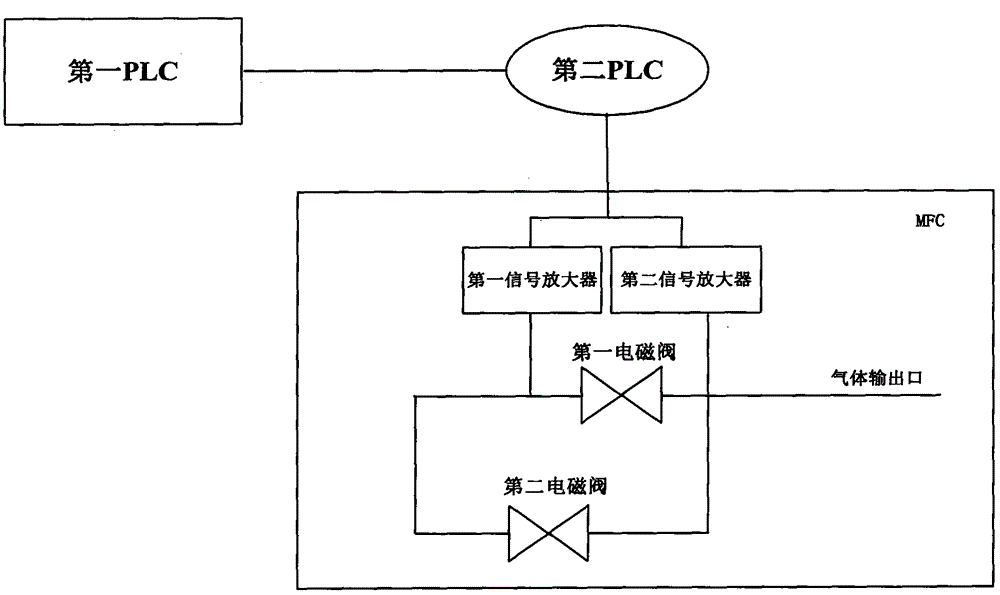

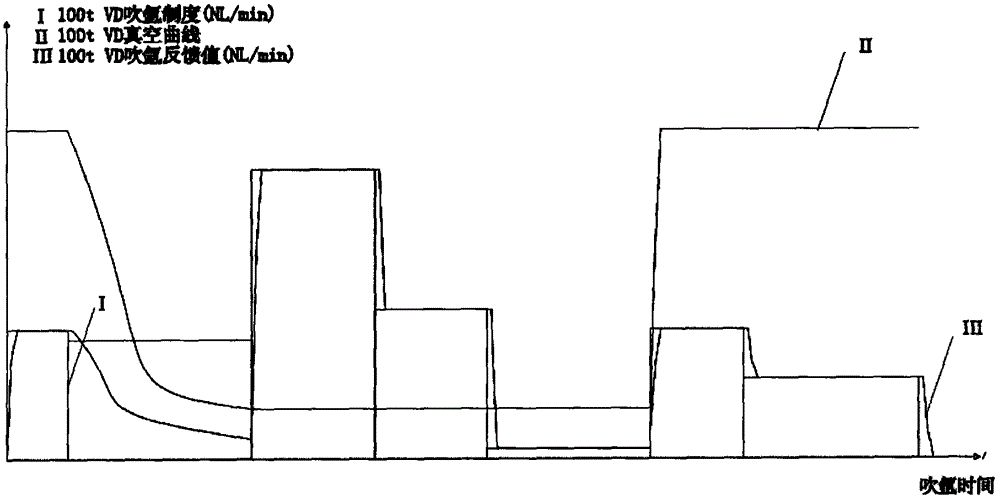

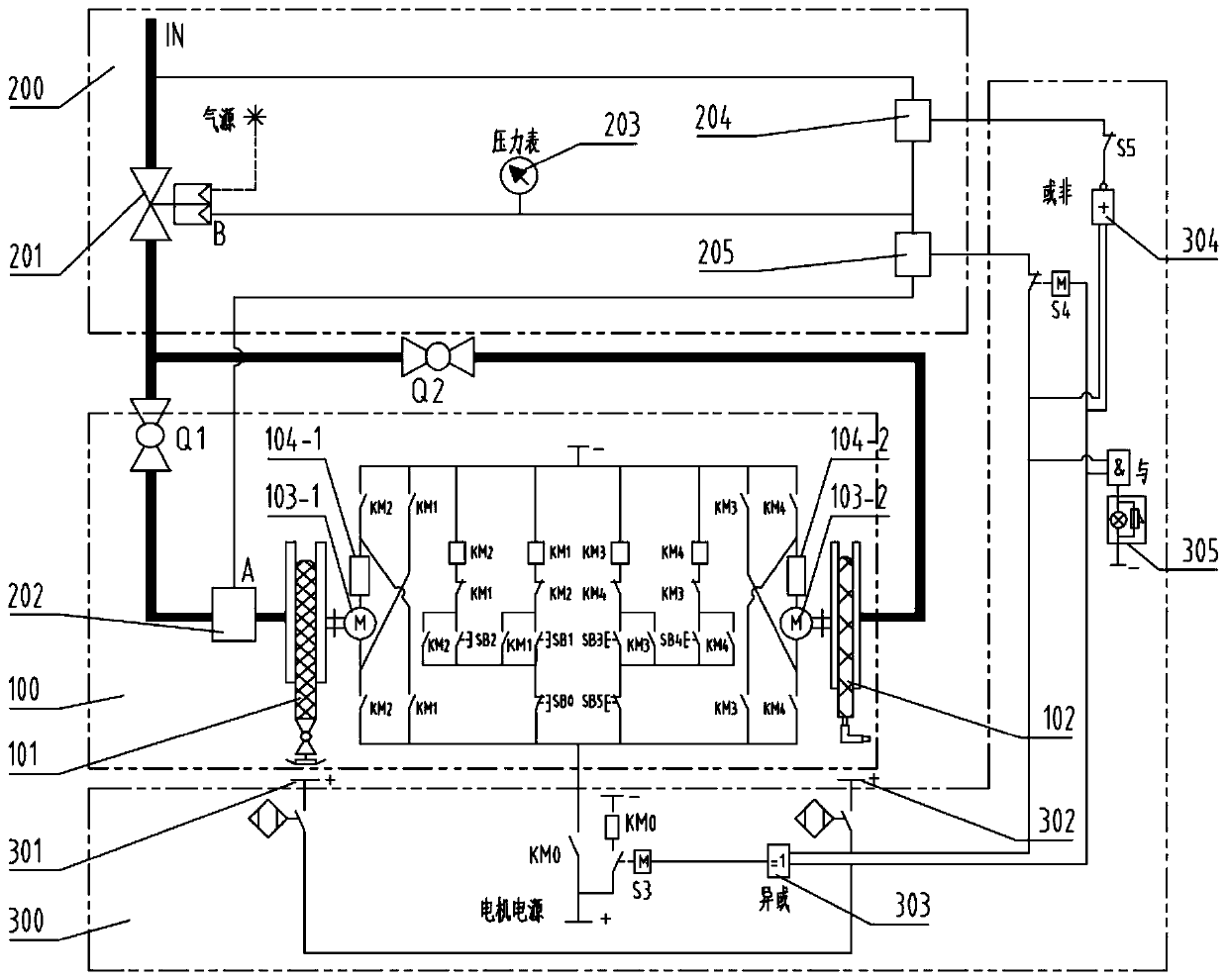

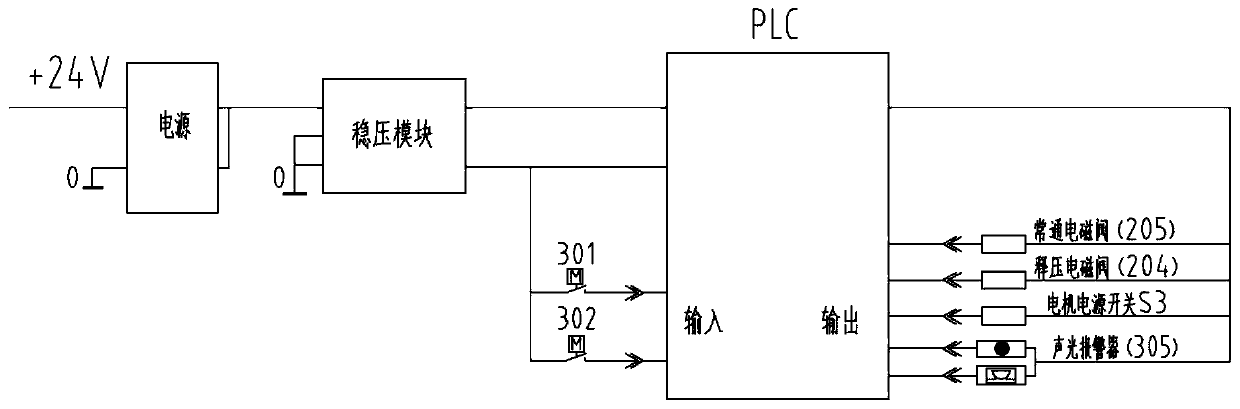

Control method capable of realizing precise control of bottom-blowing gas during refining and vacuumizing in VD furnace

InactiveCN104593549ARealize intelligent controlSolve the splatter problemProgrammable logic controllerControl system

The invention discloses a control method of realizing the precise control of bottom-blowing gas during refining and vacuumizing in a VD furnace. The control method comprises the following steps of reading real-time process parameters by virtue of a programmable logic controller (PLC) of a VD furnace control system and transmitting the real-time process parameters of the VD furnace to a programmable logic controller (PLC) of a VD furnace bottom-blowing gas control system through an industrial communication module; setting a definite specific stirring power value according to the process needs, calculating the output bottom blowing argon flow based on the calculation formula epsilon is equal to 6.18*10<-3>QT / W*[(1-273 / T)+ln(P1 / P2)] and finally transmitting the bottom blowing argon flow to an implementation element so that the intelligent control of the bottom blowing argon flow is achieved. The invention provides a method for implementing the real-time intelligent control of the bottom blowing argon flow through PLC, good real-time property is achieved, the flow value is accurately regulated and the bottom blowing argon flow can be automatically and rapidly adjusted according to changes in the degree of vacuum.

Owner:西安宝科流体技术有限公司

Slag removing and furnace protecting agent

InactiveCN101054611ASolve erosionSolve the problem of adsorption of molten steel inclusionsManufacturing convertersRheniumSlag

A slag-adjusted furnace-protected agent is composed by the following substances in percentage, 45-80% MgO2, 6-22% CaO, 6-22% C, 5-12% Al2O3 and 1-4% rhenium. The agent is prepared by taking the above raw materials in proportion, mixing them uniformly and molding and forming particles in a granulator to produce spheroids with the diameter of 10-13mm. The invention has the advantages of (1) solving the problem of spraying before smelting; (2) solving the problem of corroding to the furnace lining of the slag during smelting; (3) solving the problem of absorbing liquid steel impurities of the slag; (4) prolonging the service life of the steel-tapping hole bushing and (5) improving the efficiency of slag adjusting and furnace protecting.

Owner:江西华东实业有限公司

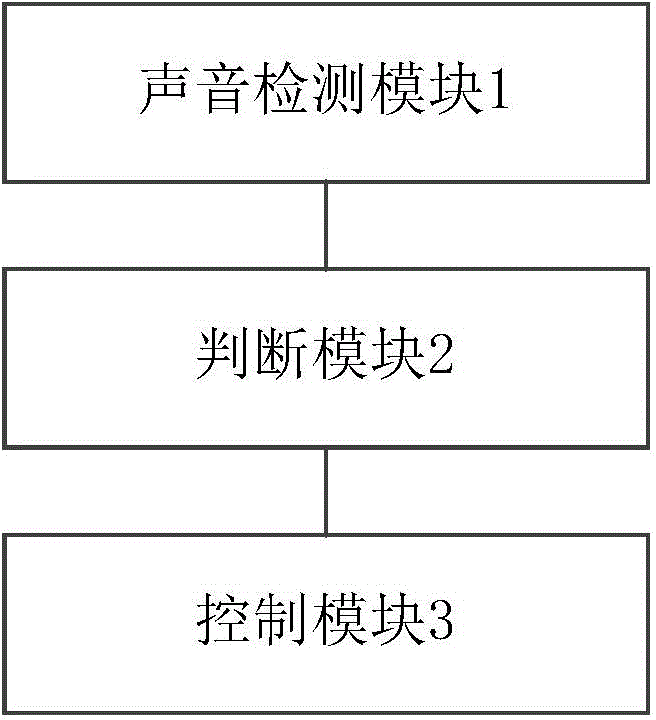

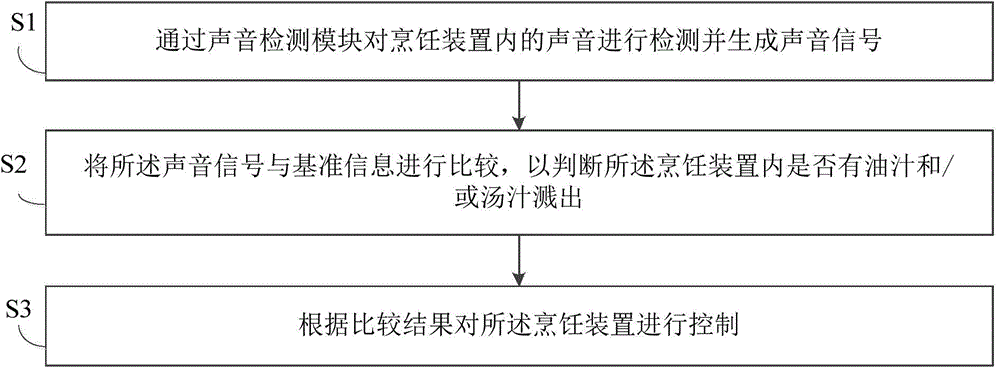

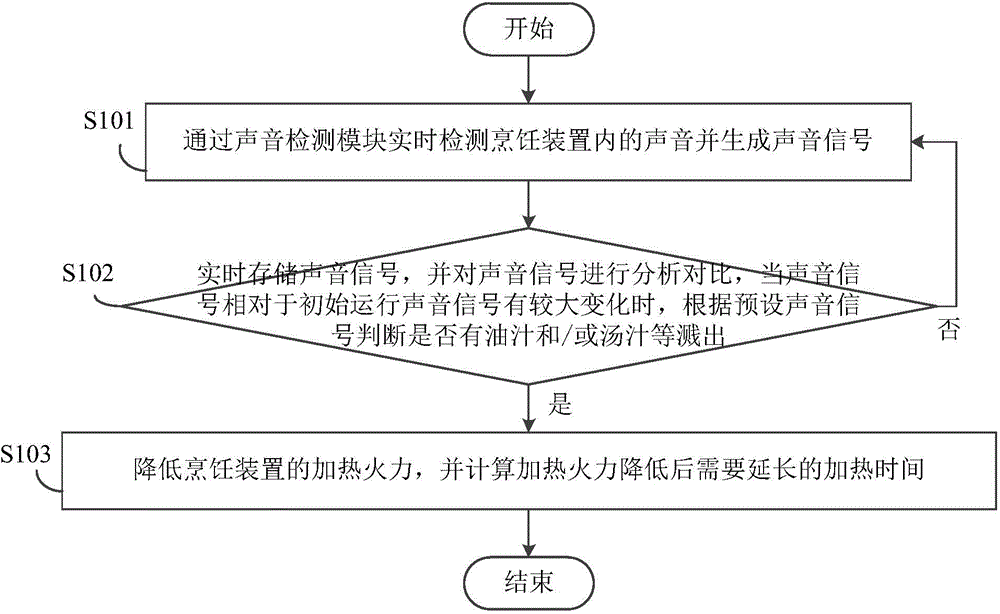

Cooking device and control method thereof

The invention discloses a cooking device and a control method thereof. The cooking device comprises a sound detecting module, a judging module and a control module, wherein the sound detecting module is used for detecting sound inside the cooking device and generating sound signals; the judging module is used for comparing the sound signals with reference signals to determine whether oil and / or cooking liquor splashing occurs inside the cooking device; the control module is used for controlling the cooking device according to comparing results. Therefore, the cooking device can reduce splashing of oil and / or cooking liquor, solve the problem of splashing of oil and / or cooking liquor at the source, avoid pollution of a cavity, save a user from cleaning the cavity after every usage, facilitate usage for the user and greatly improves the willingness to repeatedly use the cooking device.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Siliceous stemming for filling blast furnace taphole and preparation method thereof

The invention relates to siliceous stemming for filling a blast furnace taphole and a preparation method thereof, and belongs to the field of high-temperature metallurgical fireproof materials. The method comprises the following steps of: pre-mixing 35 to 45 mass percent of diaspore silicate, 16 to 27 mass percent of silicon carbide, 3 to 5 mass percent of micro powder, 10 to 18 mass percent of ball clay, 2 to 4 mass percent of graphite, 1 to 3 mass percent of plasticizer, 6 to 10 mass percent of ferrosilicon nitride, 2 to 4 mass percent of metal powder, 3 to 5 mass percent of modified asphalt powder and 3 to 5 mass percent of expanding agent aluminum silicate fine powder for later use, putting into a wheel roller and pre-rolling for 5 minutes; adding 15 to 20 mass percent of modified liquid tar, performing wheel rolling at a high speed for 30 to 35 minutes to ensure that a Marshall value is between 4 and 16MPa; and packaging, and measuring the Marshall value 3 days later, wherein the product is qualified when the Marshall value is between 8 and 24MPa. The problems of low high-temperature strength and high-temperature toughness of the stemming are solved, and the problems of a shallow iron notch, a broken iron notch and splashing are solved simultaneously.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

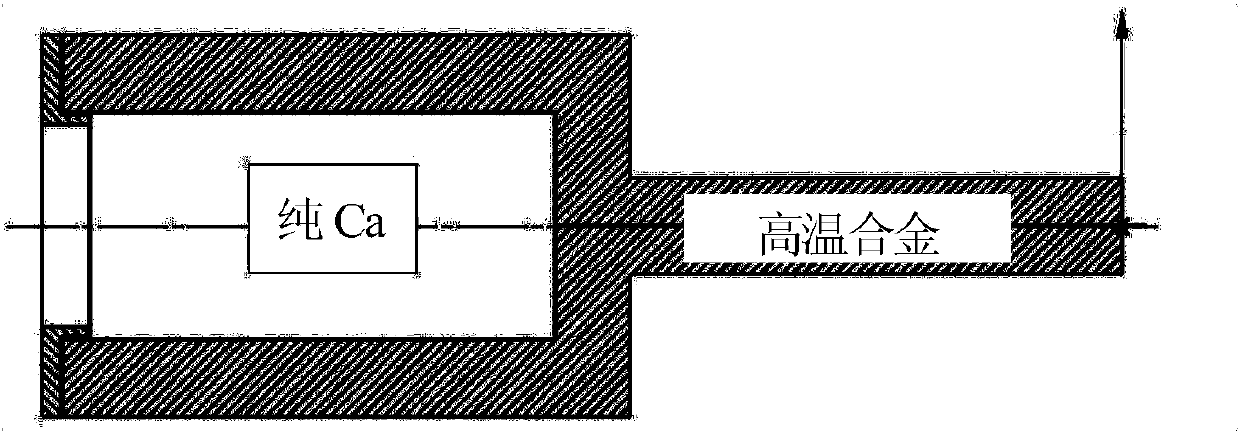

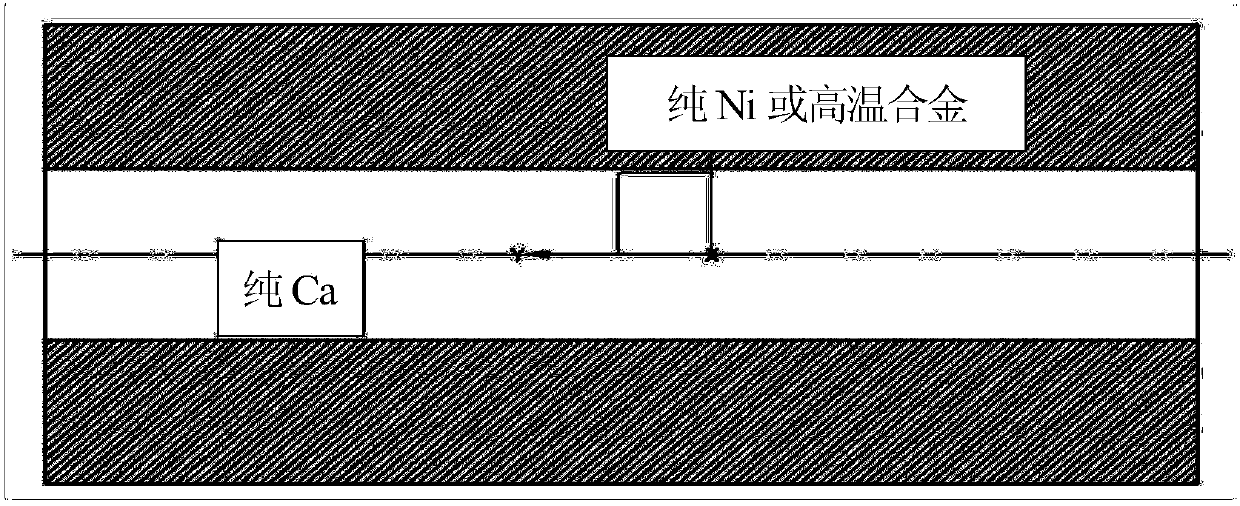

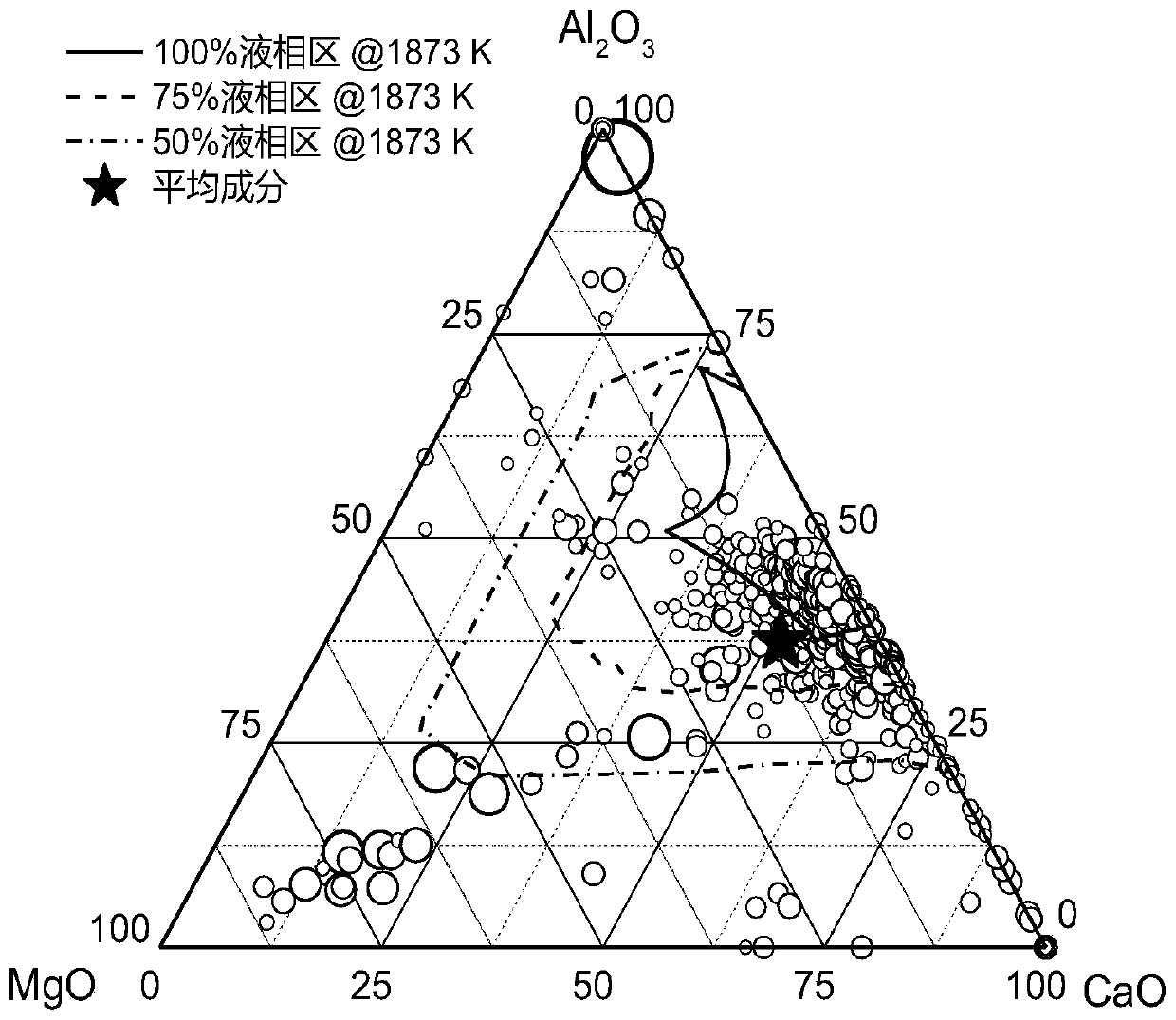

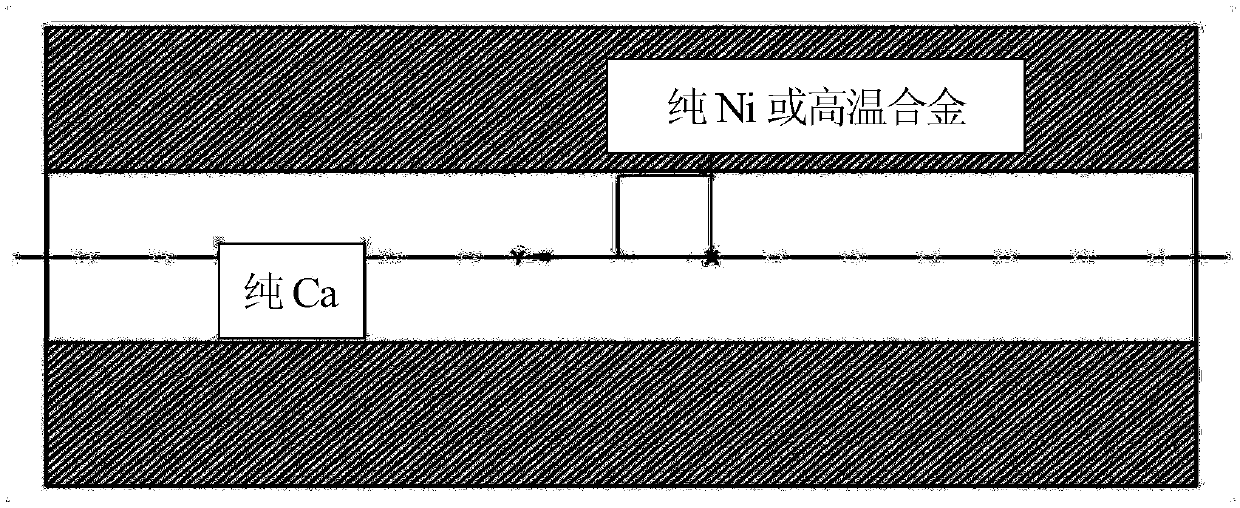

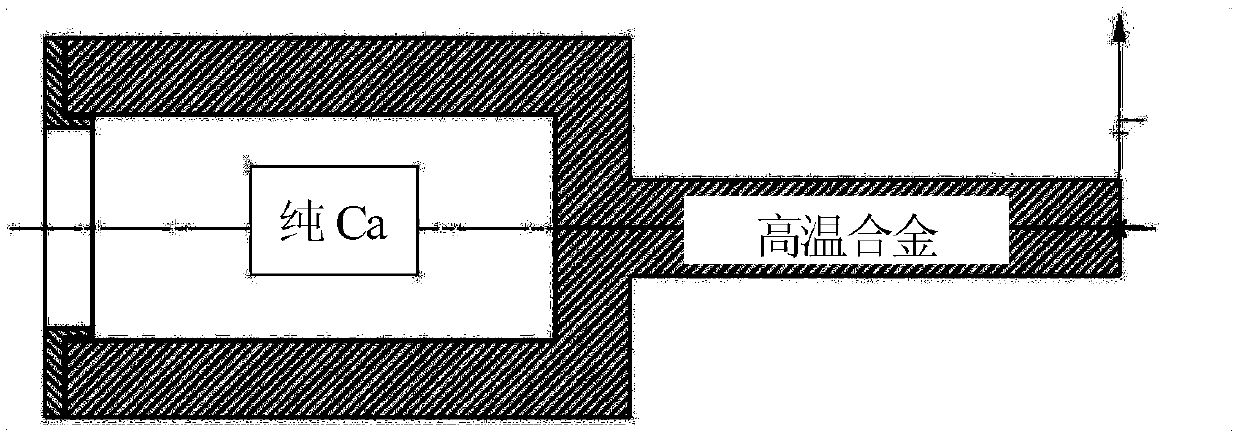

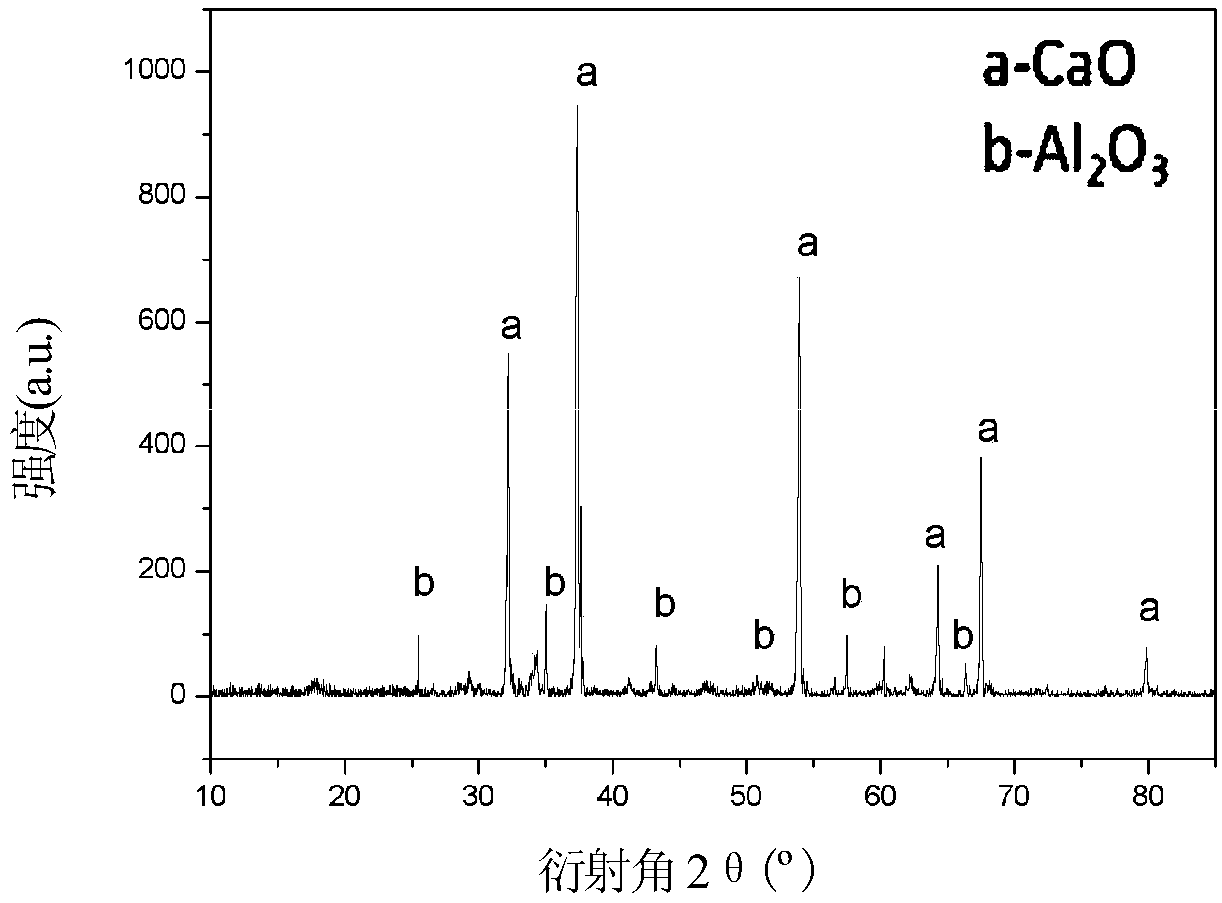

Pure-calcium-line-adopted high-purity nickel or high-temperature alloy smelting method

The invention relates to the field of high-temperature alloy smelting, in particular to a high-purity nickel based high-temperature alloy smelting technology, and in particular to a pure-calcium-line-adopted high-purity nickel or high-temperature alloy smelting method. The method includes the following steps that (1) a vacuum induction smelting furnace is adopted for smelting, and vacuum pouring is carried out; (2) metal bath is subject to metal liquid boiling under the vacuum state, and the oxygen content in an alloy is reduced through a carbon oxygen reaction; (3) cooling and film formationare carried out, and a self-made pure calcium line is added; and (4) low temperature stirring and standing are carried out, and then vacuum pouring is carried out. By means of the method, the problemsof silicon increasing and iron pollution on the alloy in the using process of commercial silicon-calcium lines and iron-calcium lines are solved; through structural design of the pure calcium line, the sufficient line feeding depth is guaranteed, spraying and splashing in the using process of the pure calcium line is prevented, the problem about purification of the nickel based high-temperature alloy produced in a large-scale and batched manner is solved, and the smelting cost is reduced; and calcium is adopted for conducting modification on impurities in the high-temperature alloy, the sizeof occluded foreign substance is reduced, the number of the occluded foreign substance in the alloy is decreased, and an effective way is provided for pure smelting of the high-temperature alloy.

Owner:辽宁红银金属有限公司

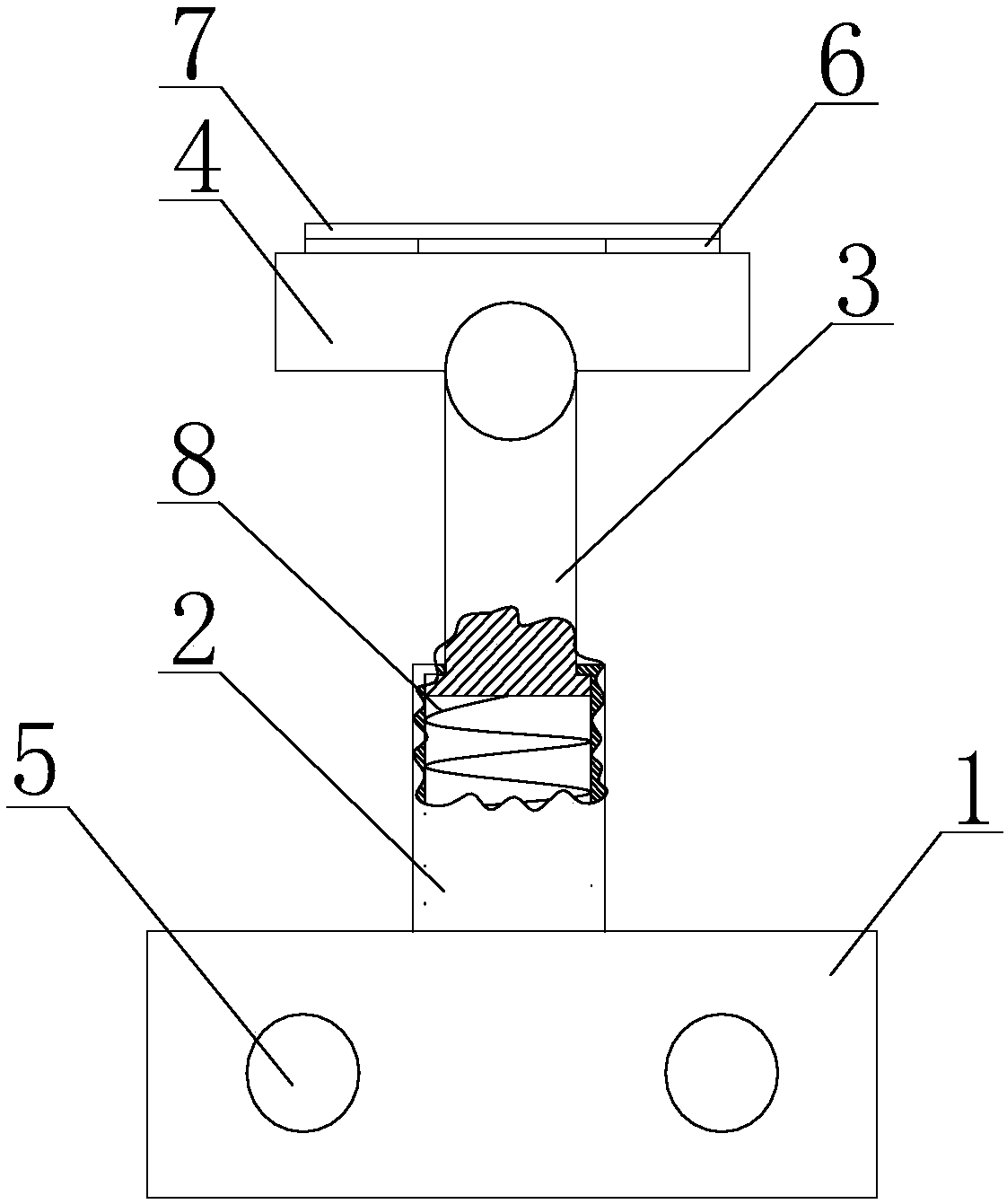

Oil baffle of dental milling machine

InactiveCN105796198ASolve the splatter problemAvoid pollutionArtificial teethEngineeringCooling fluid

Owner:CHONGQING ZHUOTIAN TECH CO LTD

Kitchen washbasin capable of preventing water from being splashed out

The invention discloses a kitchen washbasin capable of preventing splashing of water, which comprises a basin body, a wash mouth, a curved groove, and a water outlet pipe. The bottom of the basin body is rectangular, and the top is a curved groove, which is more The smaller the size, the outlet pipe hangs above the basin, and the handwashing port is arranged on the side of the basin. At present, the washbasins used in the kitchen are all washbasins with a wide opening at the top. During the process of washing hands, water droplets are prone to splash, which can easily cause people to slip. The basin body adopted in the present invention becomes smaller and smaller from bottom to top, and is in a shrinking shape, and the water drops are not easy to splash out. There is a special hand washing port from the side for washing hands, and there is no need to wash hands directly from the upper opening, which greatly reduces the The splash of water droplets.

Owner:德耳曼家居用品成都有限公司

Method for carrying out molten steel silicon alloying and calcium treatment by using metal-calcium-containing silicon-iron alloy

The invention discloses a method for carrying out molten steel silicon alloying and calcium treatment by using metal-calcium-containing silicon-iron alloy, and belongs to the field of steel metallurgyrefining. The method is characterized in that in the tapping process after converter smelting, silicon alloying is not carried out or partial silicon alloying is carried out, the steel liquid aluminum deoxidation treatment and slag adding pre-refining are carried out at the same time, and the aluminum content is controlled according to the steel type requirement upper limit; and the metal-calcium-containing silicon-iron alloy is added into molten steel after secondary refining to carry out silicon alloying and calcium treatment, then argon is blown at a larger flow for stirring for 1-3 minutes so as to promote melting of the alloy, and then the argon is blown at a smaller flow for stirring so as to out low-flow argon blowing stirring to uniformize molten steel components and promote modification and floating of inclusions. According to the method for carrying out molten steel silicon alloying and calcium treatment by using the metal-calcium-containing silicon-iron alloy, the metal calcium contained in the silicon-iron alloy is utilized, and the targets of molten steel silicon alloying and calcium treatment are achieved at the same time by adjusting the silicon alloying time, so that the conventional calcium feeding line operation is reduced or even eliminated, and the production cost is reduced; and meanwhile, the situation of molten steel splashing caused by a calcium feedingline is avoided, oxygen increasing and nitrogen increasing of the molten steel are reduced, the operation stability and the yield of the calcium are improved, and then the cleanliness of the molten steel is also improved.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of newly-constructed taphole duct

The invention relates to a preparation method of a newly-constructed taphole duct. The preparation method comprises the steps of (1), cleaning reserved holes of the newly-constructed taphole duct by using compressed air; (2), sealing a ceramic duct wall of thetaphole duct in a furnace hearth with a casting template with a thickness of 15mm - 25mm; (3), carrying out one-time casting on the reservedholes of the taphole channel by adopting refractory casting materials, and vibrating bubbles in the refractory casting materials by using a vibrating rod, wherein the vibration time is 1 min - 2 min;(4), naturally drying the reserved holes of the taphole channel for 24h - 36h, no contact with water vapor during drying; and (5), determing the position of a center line opening of a taphole, and drilling the refractory casting materials in a duct to form the taphole duct by using a drill bit with the diameter being the same as the diameter of the taphole duct. Compared with the duct manually filled with steeming, the integral casting has the advantages that the compactness of the duct is higher, no gap exists, and ring cracking is not easy to occur; the integrity of the duct filling is ensured, the phenomenon of gas string in the taphole duct is controlled, and the problem of taphole splashing is solved; the method has the advantages that the formation of a mud drum is facilitated, thelong service life of the furnace hearth is ensured, and the labor intensity is reduced.

Owner:ANGANG STEEL CO LTD

Low-cost calcium treatment method of ultralow-carbon high-aluminum steel

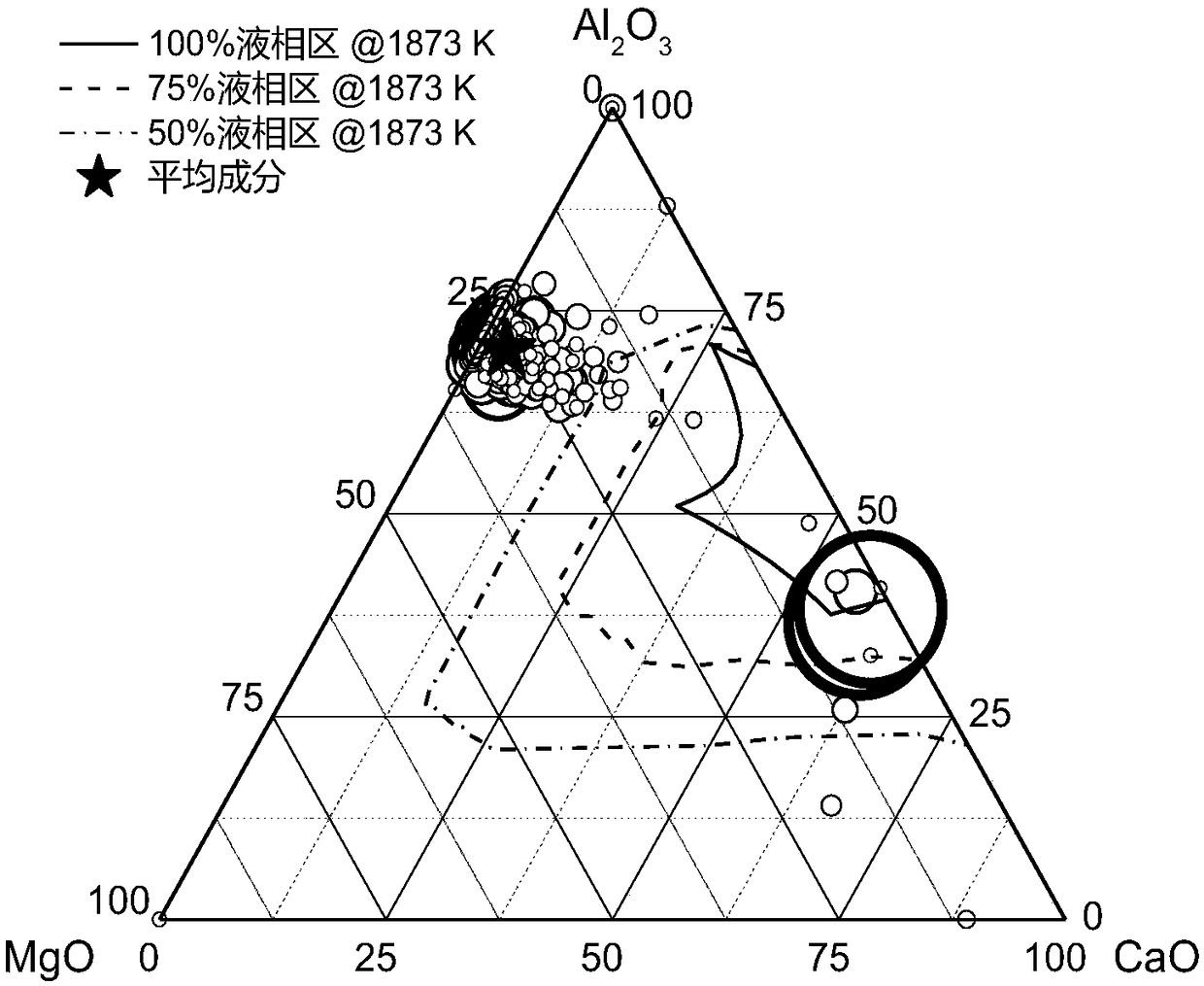

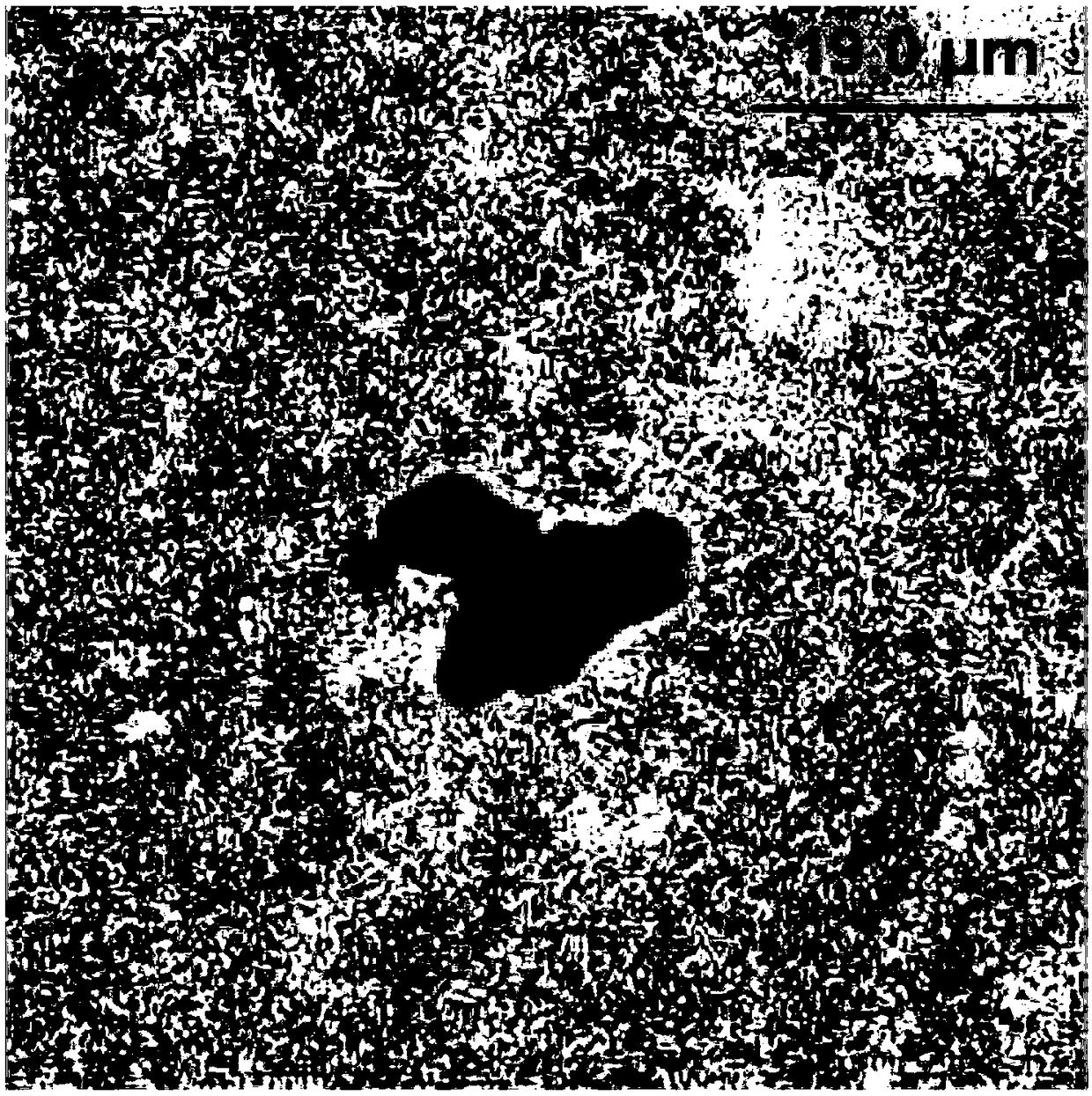

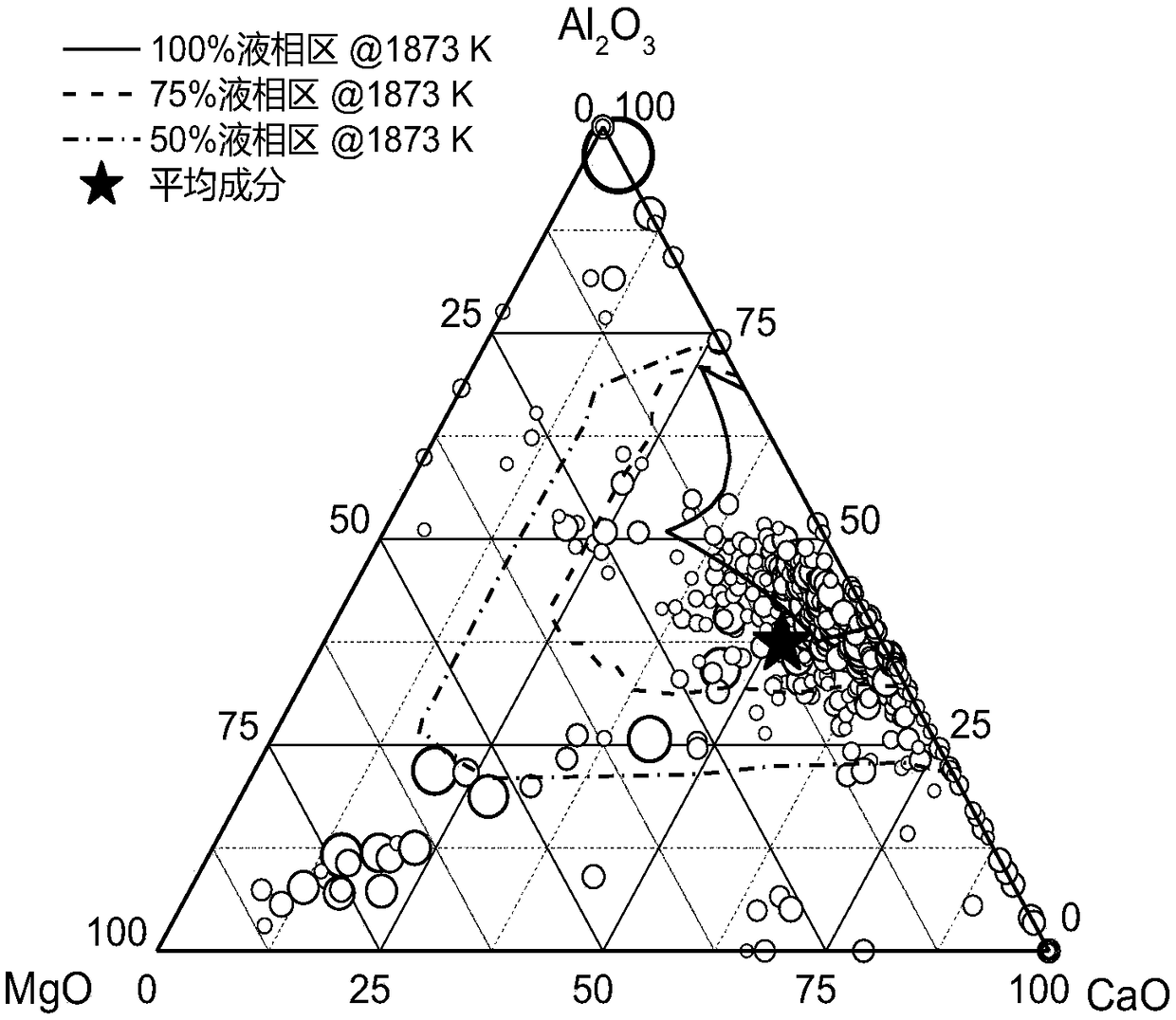

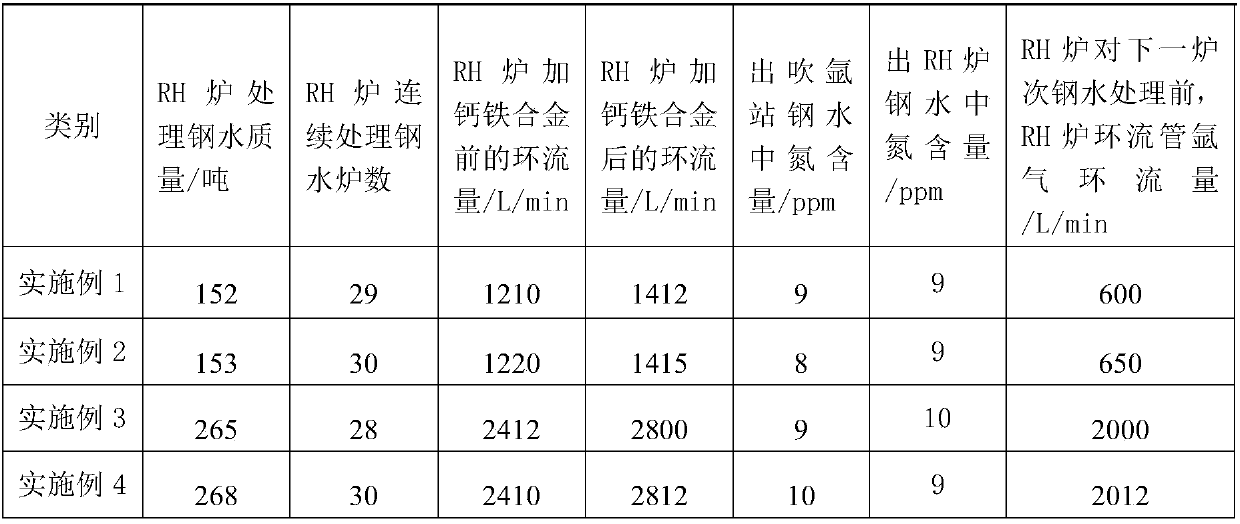

InactiveCN110317927ASolve the splatter problemSolve the fierce industry problemsLight treatmentNitrogen

The invention discloses a low-cost calcium treatment method of ultralow-carbon high-aluminum steel. The technical problems of high cost, molten steel splashing and molten steel nitrogen increasing ofthe calcium treatment conducting on the ultralow-carbon high-aluminum steel by an RH furnace in the prior art are solved. According to the technical scheme, the low-cost calcium treatment method for the ultralow-carbon high-aluminum steel comprises the following steps that decarbonizing is conducted on molten steel; deoxidizing is conducted the decarburized molten steel by adopting silicon; controlling a molten steel treatment mode of the RH furnace to be switched into a light treatment mode; conducting the calcium treatment on the molten steel; introducing argon into a RH furnace circulationpipe before the RH furnace finishes the next-furnace molten steel treatment, circulating the argon in the RH furnace circulation pipe, and the argon circulating flow rate is 500-2400 L / min. Accordingto the method, the cost for conducting the calcium treatment on the ultralow-carbon high-aluminum steel in the RH furnace is reduced, and the production cost of the ultralow-carbon high-aluminum steelis reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

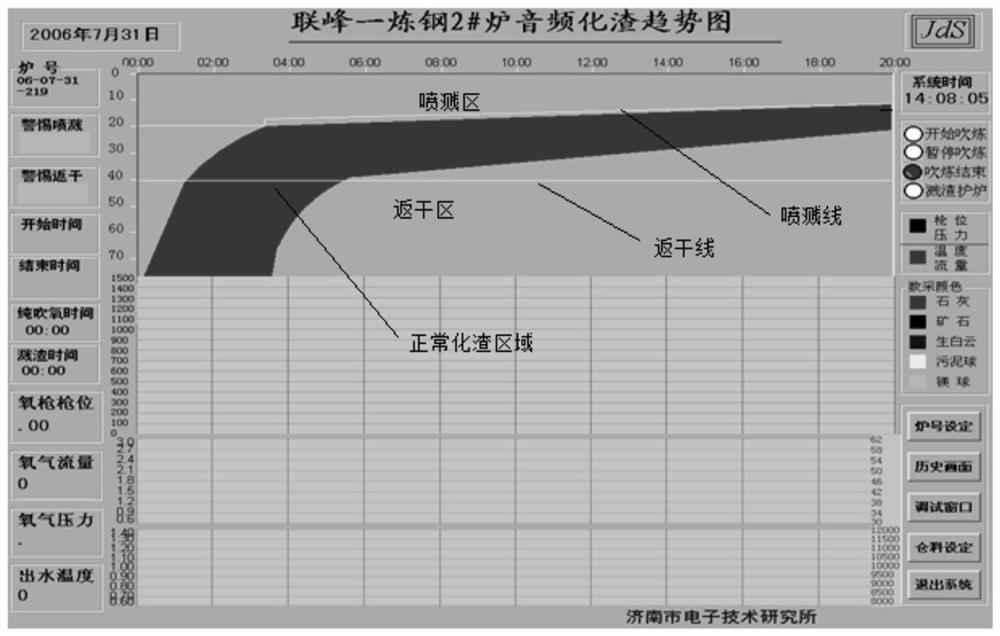

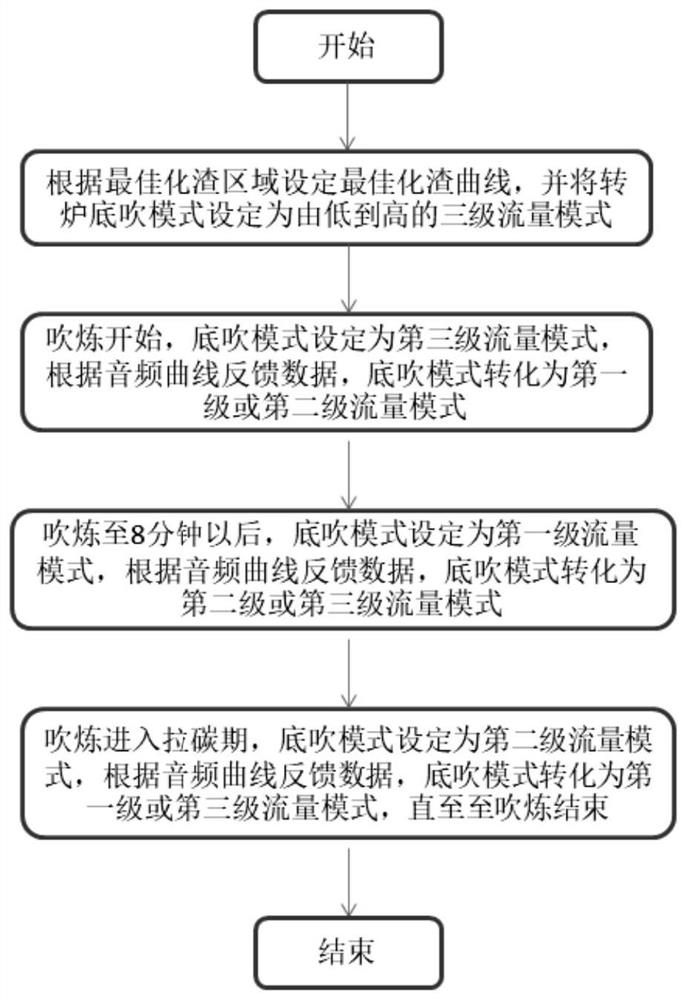

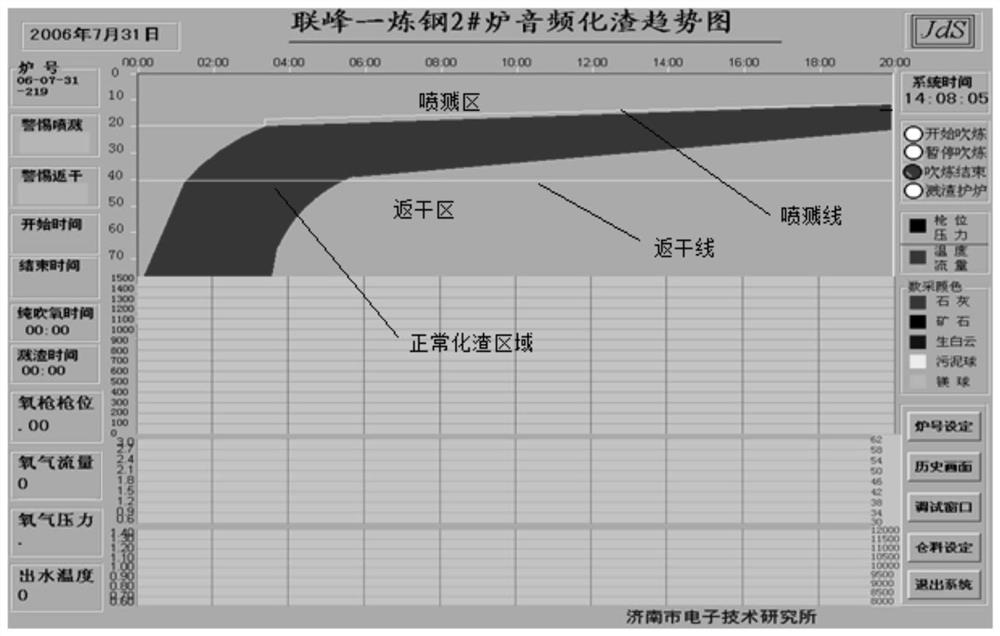

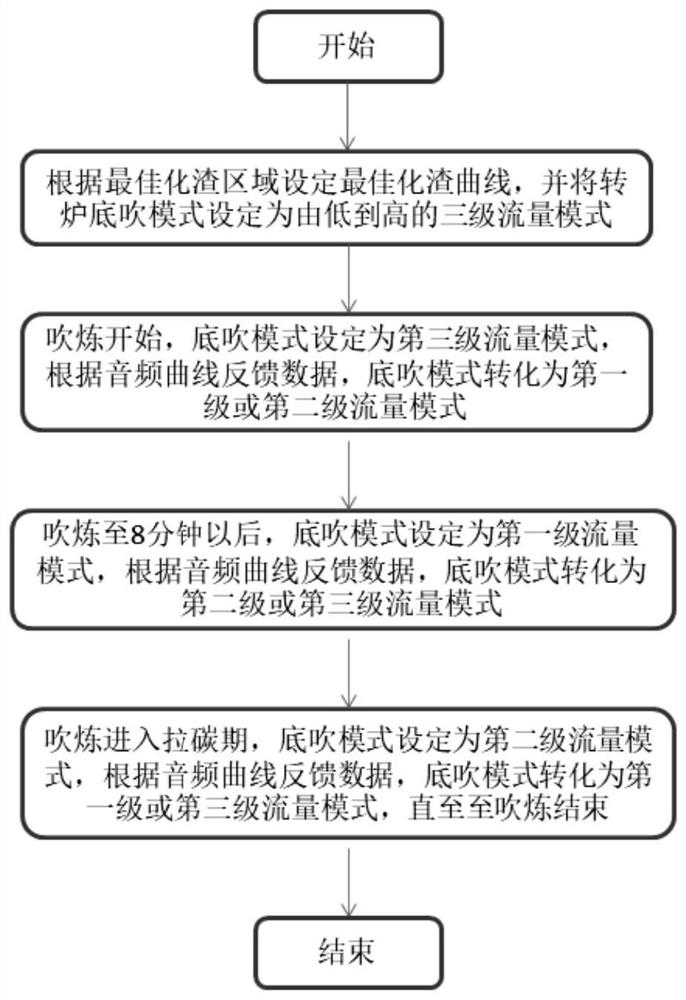

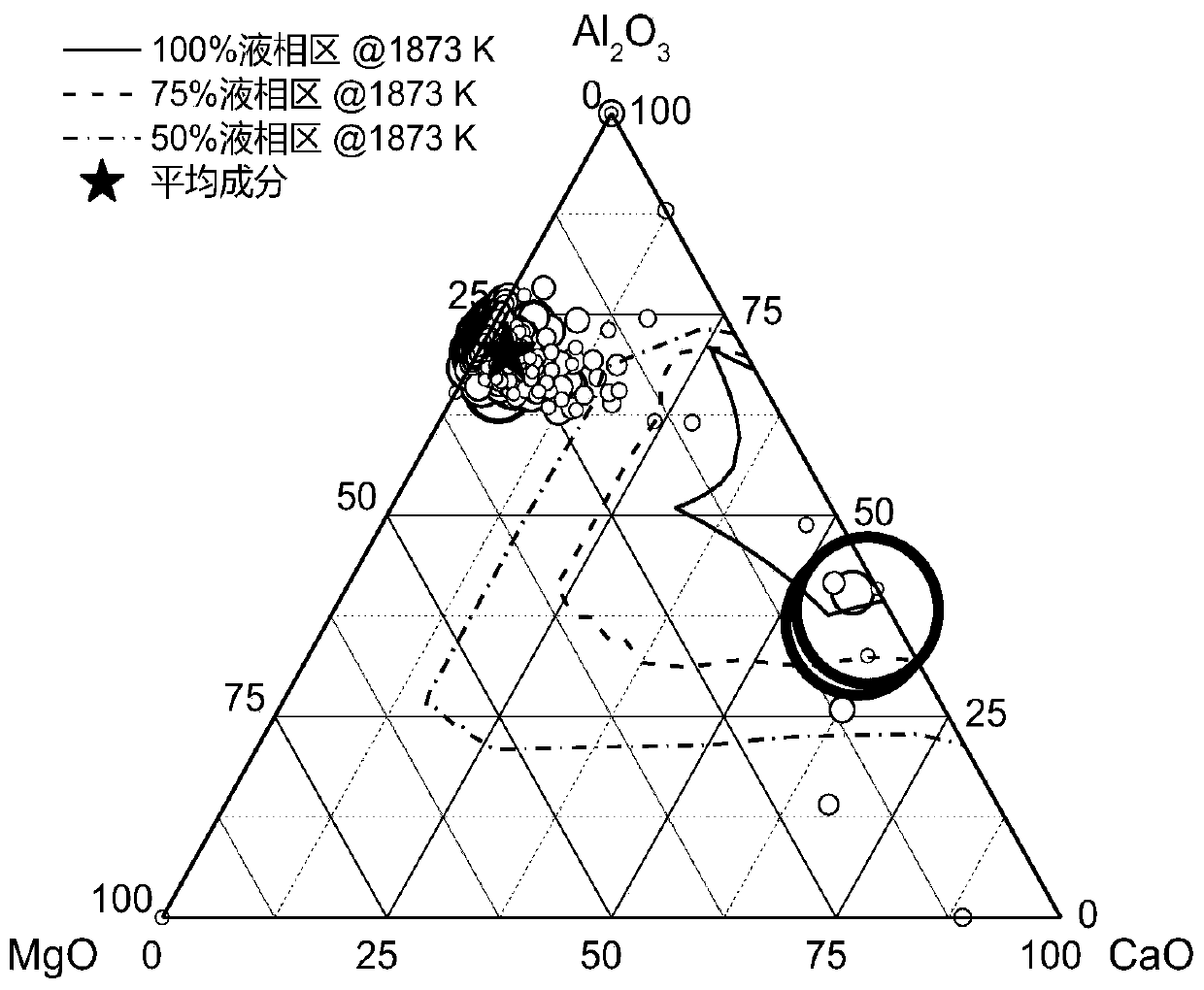

Converter dynamic bottom blowing method based on audio frequency slag melting

ActiveCN113061684AImprove bottom blowing slag effectSolve the problem of splashing and back-drying adjustment not in timeSteel manufacturing process aspectsIncreasing energy efficiencyProcess engineeringAudio frequency

The invention provides a converter dynamic bottom blowing method based on audio frequency slag melting. The converter dynamic bottom blowing method comprises the following steps that (1), an optimal slag melting curve is set according to an audio frequency slag melting system; (2), the converter bottom blowing flow quantity is set to be in a three-stage flow quantity mode from low flow quantity to high flow quantity; (3), blowing refining is started, the bottom blowing mode is set as the third-stage flow quantity mode, and the corresponding bottom blowing mode is converted according to the audio frequency curve deviation condition; (4), after the blowing refining is performed for 8 minutes, the bottom blowing mode is set as the first-stage flow quantity mode, and the corresponding bottom blowing mode is converted according to the audio frequency curve deviation condition; and (5), the blowing refining enters a carbon catching period, the bottom blowing mode is set as the second-stage flow quantity mode, and the corresponding bottom blowing mode is converted according to the audio frequency curve deviation condition. According to the converter dynamic bottom blowing method based on the audio frequency slag melting, timely adjustment can be performed before an audio frequency curve reaches a back-dry line or a splashing line, the top-bottom combined blowing converter bottom blowing slag melting effect can be improved, the problem that splashing and back-dry adjustment of a converter is not timely is solved, and converter operations are greatly stabilized.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

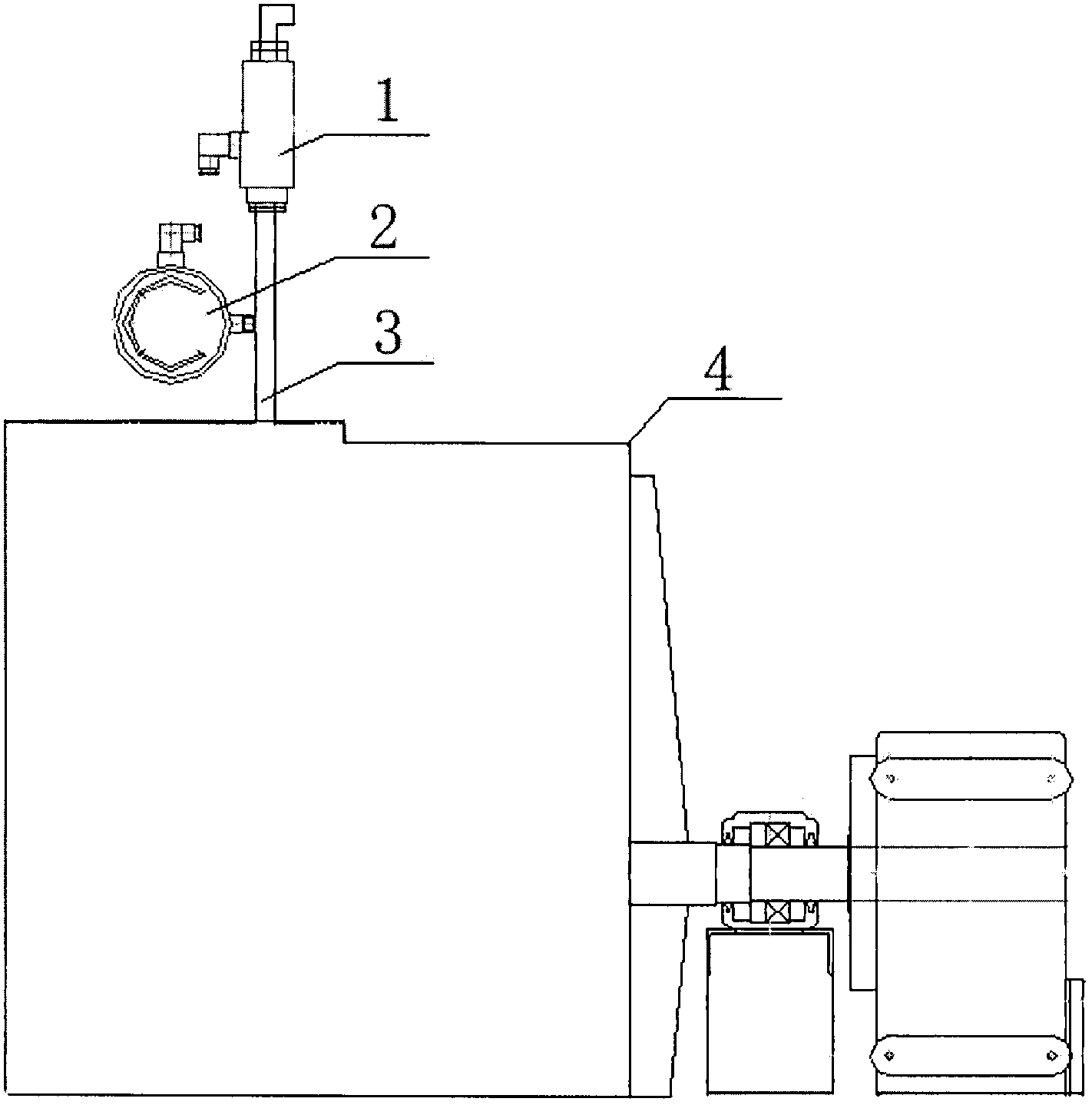

Electric reel aircraft fueling system

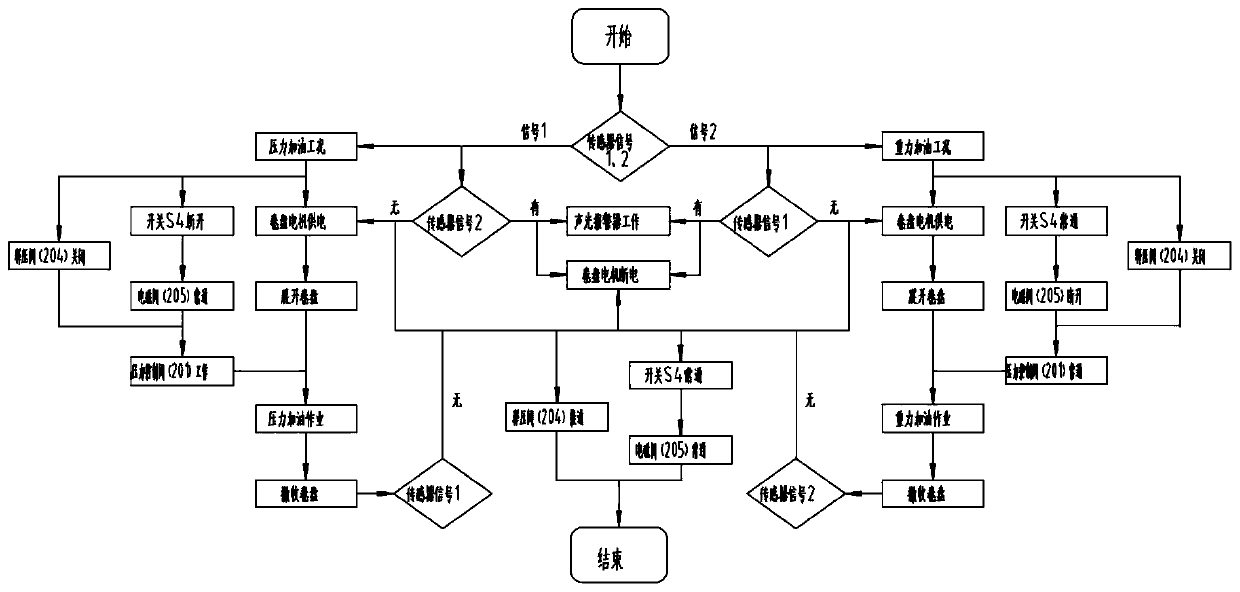

PendingCN110723306APrevent leakageEnsure safetyLiquid handling installationsAircraft fuel systemElectric machinery

The invention discloses an electric reel aircraft fueling system, and belongs to the aircraft fueling technology field. The electric reel aircraft fueling system comprises an electric reel, a pressurecontrol module and an interlock control module, wherein the electric reel comprises a pressure fueling hose reel and a gravity fueling hose reel, the pressure control module comprises a pressure control valve and a pressure feedback device, the operation interlock control module comprises a first position sensor and a second position sensor, signal output ends of the first position sensor and thesecond position sensor are connected with a power supply controlled end of a motor through exclusive-or interlock circuits, and connected with a controlled end of a relief valve through nor control circuits, and the signal output ends of the first position sensor and the second position sensor are connected with a controlled end of a normal open electromagnetic valve respectively through a collocated control circuit and a non-collocated control circuit. The electric reel aircraft fueling system not only can meet requirements for pressure fueling, but also can meet requirements for gravity fueling, and meanwhile due to the fact that the electric reel aircraft fueling system solves the tail end overpressure spattering problem properly and guarantees interlocking of the pressure fueling andthe gravity fueling, the electric reel aircraft fueling system is convenient and quick, and safe and reliable.

Owner:AEROSUN CORP

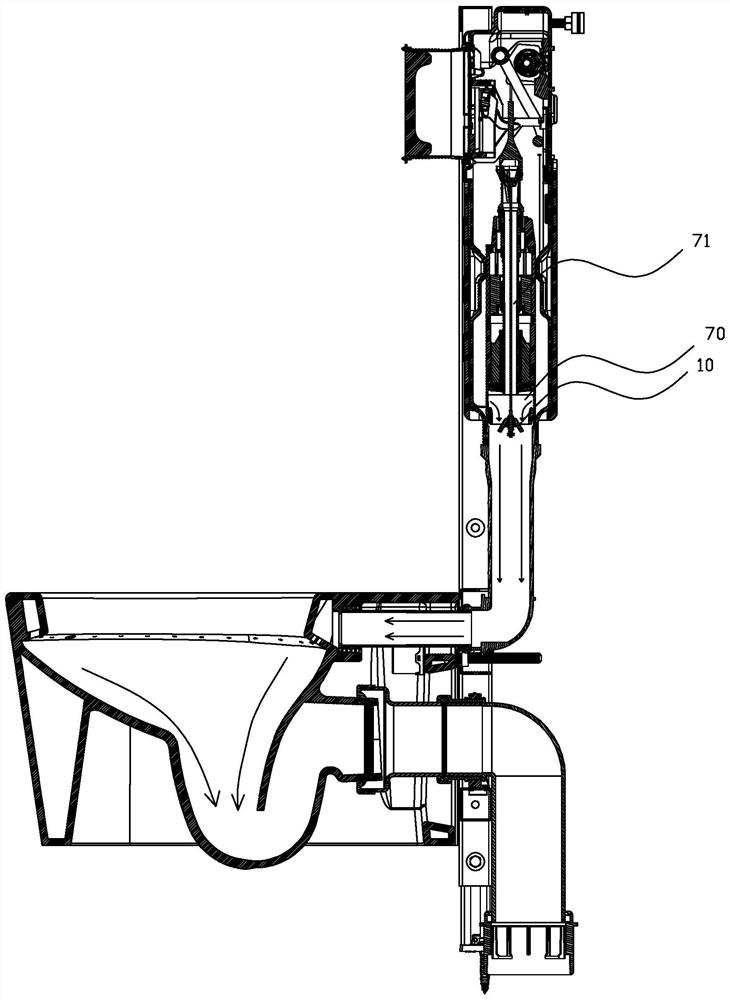

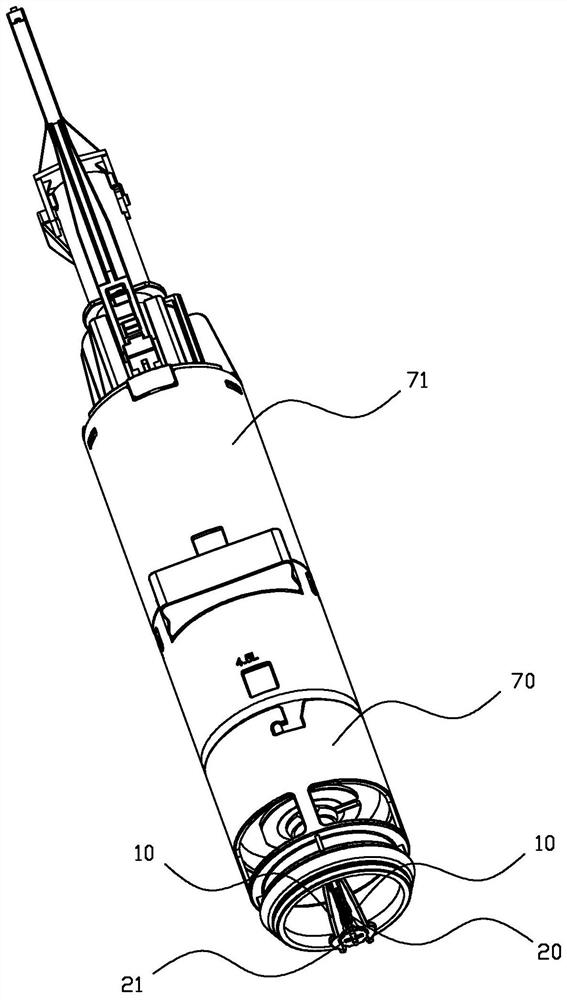

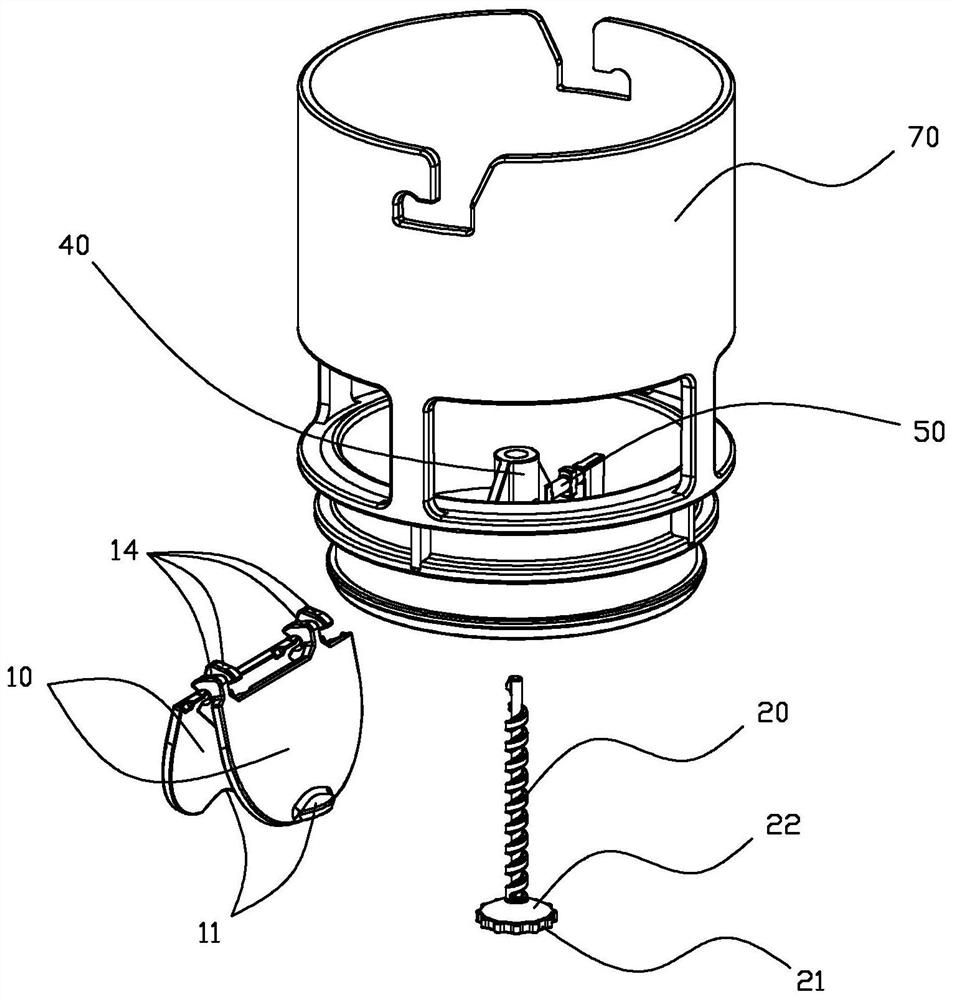

Drainage valve capable of adjusting drainage speed

PendingCN111622314AAdjust the drainage speedSpeed up drainageWater closetsFlushing devicesWater dischargeOutfall

The invention relates to a drainage valve capable of adjusting the drainage speed. The size of an outlet of a water outlet of the drainage valve is controlled through a turnover adjusting turning plate, namely, the water passing area of the water outlet of the drainage valve is adjusted, then the drainage speed of the drainage valve is controlled, and finally the drainage speed of a closestool isadjusted. According to the implementation of the invention, the drainage speed is improved without changing the size of the jet orifice of the closestool, so that the corresponding problems of high noise, water splashing and the like are avoided. Drainage speed adjustment is achieved at the position of the water outlet of the drainage valve, noise can be effectively avoided, the jet orifice of theclosestool can be implemented to be in the optimal size, and the problem that water splashes in the flushing process is avoided. The drainage speed of the drainage valve is adjustable, and the drainage valve can be matched with different toilets and different water tanks to cooperate with the drainage amount, the jet orifice size and the drainage speed of the drainage valve to obtain the flushingeffect required by a user.

Owner:ECO XIAMEN TECH INC

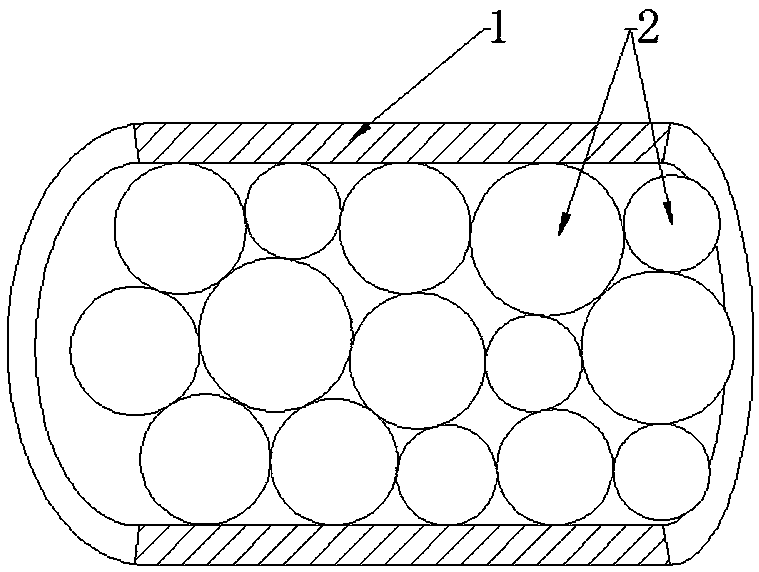

Ball milling technology

InactiveCN103752376ASolve the problem of excessive internal pressure and material splashingSolve the splatter problemGrain treatmentsElectricityInternal pressure

The invention discloses a ball milling technology. The ball milling equipment comprises a ball milling equipment body, and a cavity of the ball milling equipment body is connected with a pressure gauge with electric contact (2) and a solenoid valve (1) in series by an exhaust pipe (3), and the pressure gauge with electric contact is connected with a control circuit of the solenoid valve. According to the technology scheme, the pressure gauge with electric contact of the ball milling equipment monitors pressure of the cavity of the ball mill; when the internal pressure is higher than the setting pressure, the control circuit of the solenoid valve opens the solenoid valve, thereby positioning the solenoid valve in an exhaust state in order to reduce internal pressure of the cavity, solving the material spraying problem caused by excessive pressure in the existed ball milling equipment, effectively preventing equipment damage, improving safety of the equipment, guarantying accuracy of lithium iron phosphate ingredient, and finally improving product quality of the lithium iron phosphate cathode material.

Owner:魏宇

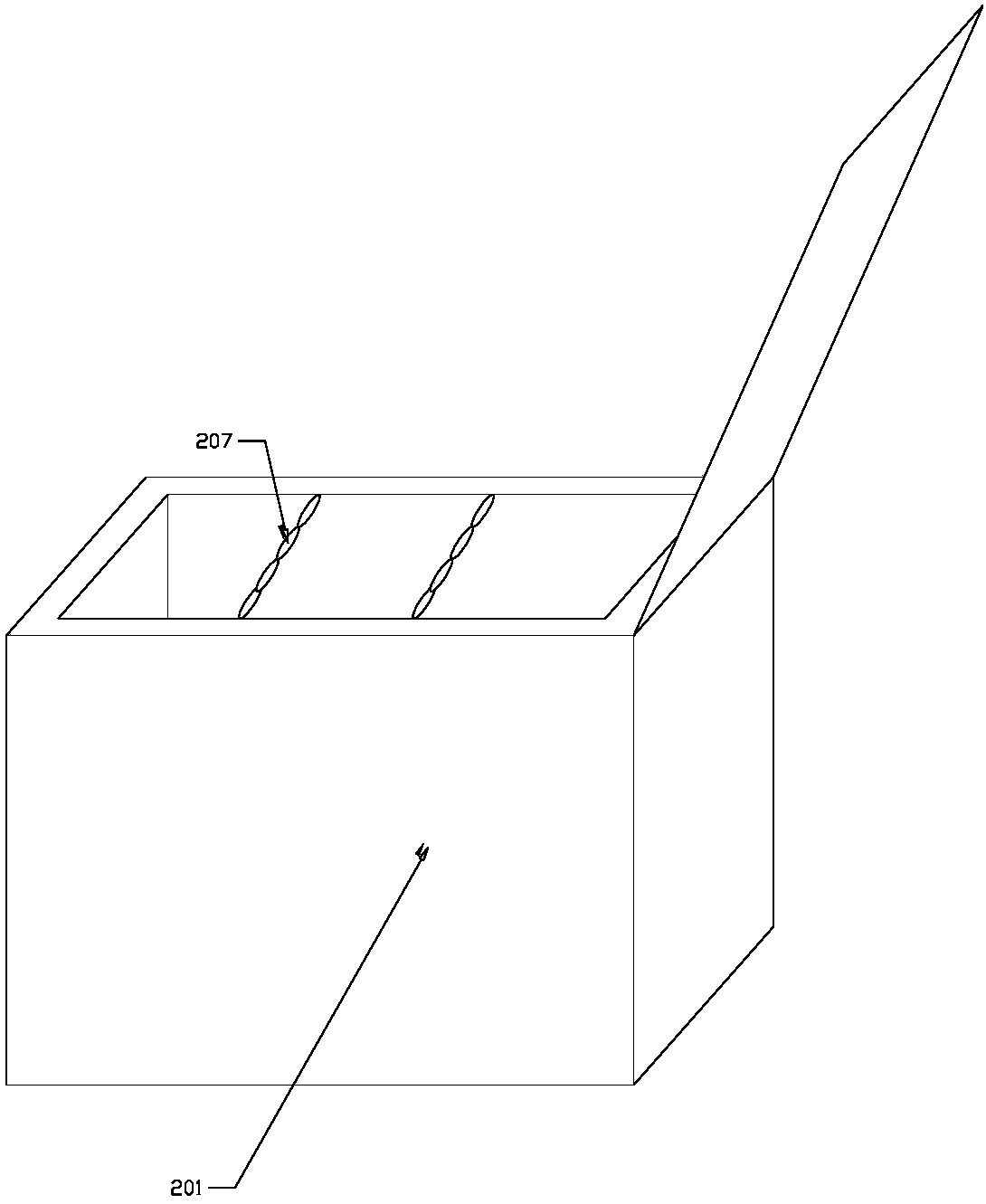

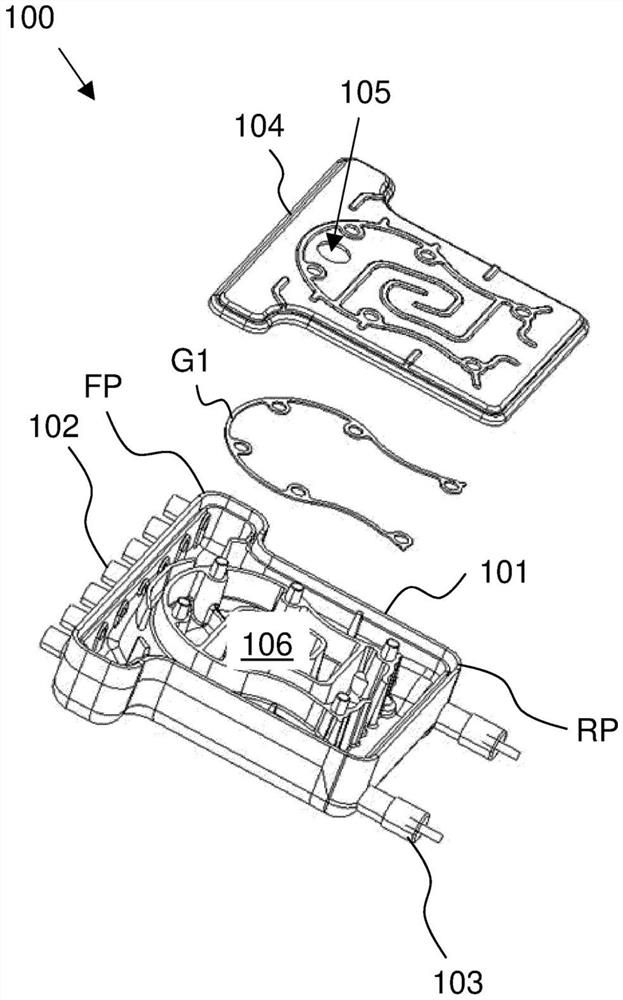

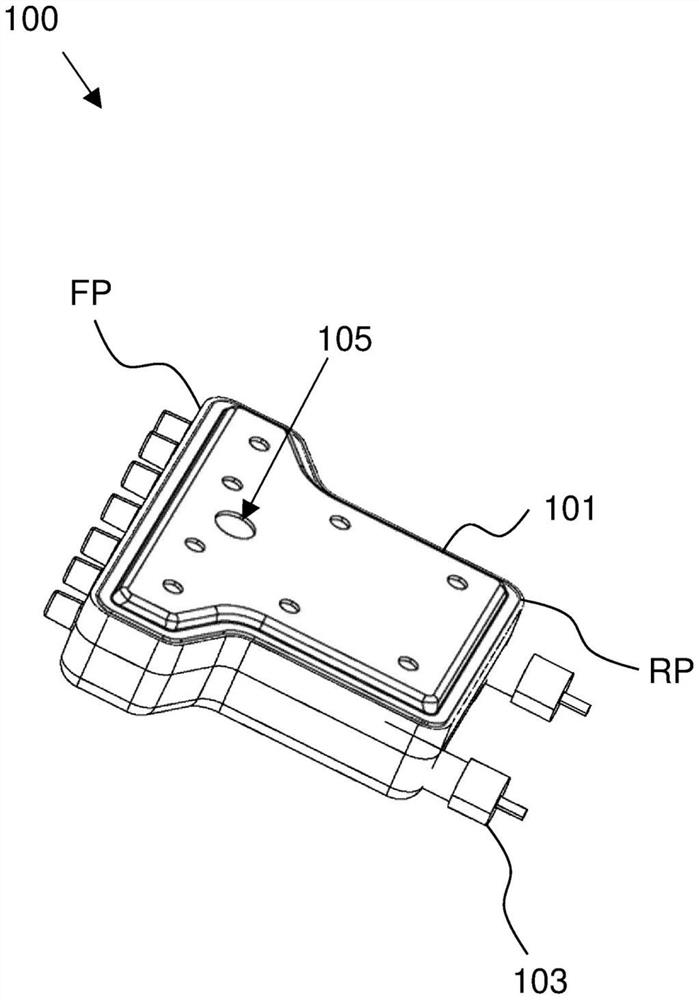

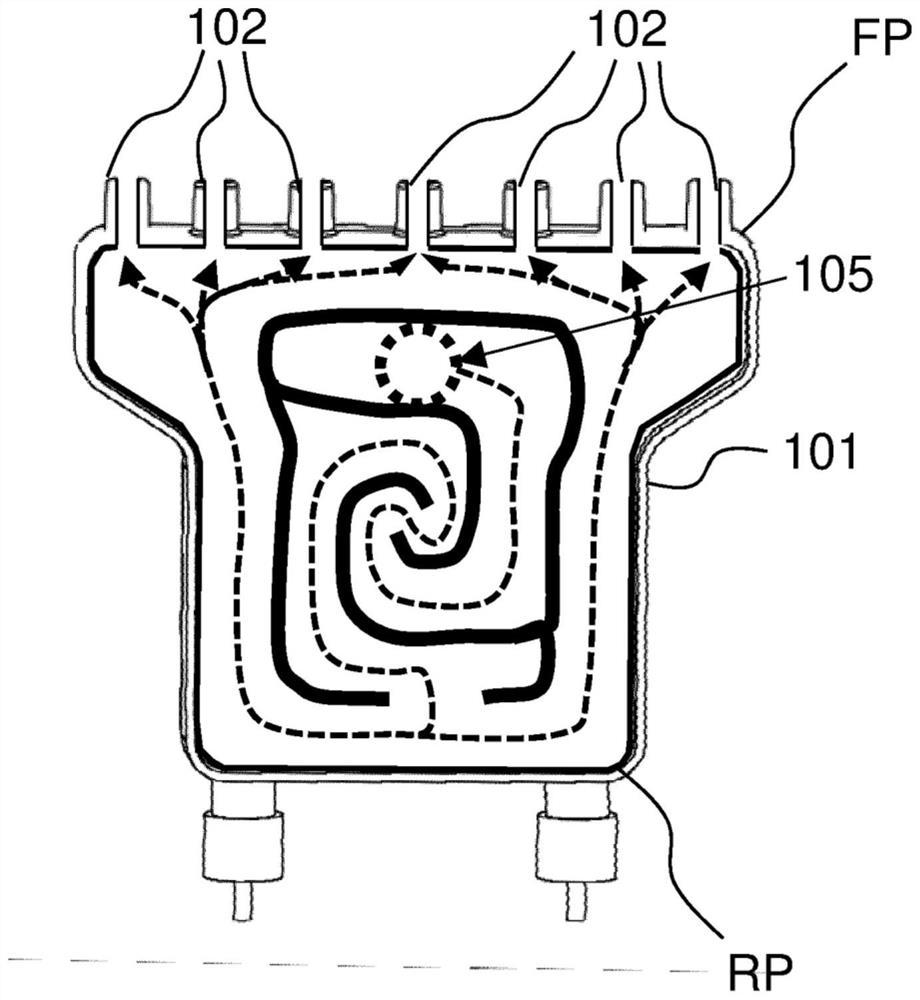

Steam generator having steam chamber and metering orifice arranged near rear of steam chamber

PendingCN114222887APrevent from reachingImprove experienceSteam generation heating methodsOther washing machinesThermodynamicsEngineering

The invention relates to a steam generator (200) comprising a steam chamber (201) for generating steam, said steam chamber (201) extending between a front portion (FP) and a rear portion (RP). The steam generator (200) further comprises at least one steam outlet (202) arranged at the front portion (FP) and receiving steam from the steam chamber (201). The steam generator (200) further comprises a heating element (203) for heating the steam chamber (201) and a cover (204) adapted to be in a closed position to close the steam chamber (201). The steam generator (200) further comprises a metering orifice (205) arranged in said cover (204) for receiving water and / or steam from outside said steam generator (200), said metering orifice (205) being arranged near said rear (RP) when said cover (204) is in said closed position.

Owner:KONINKLJIJKE PHILIPS NV

A Dynamic Bottom Blowing Method of Converter Based on Audio Slagging

ActiveCN113061684BGood effectSolve the splatter problemSteel manufacturing process aspectsManufacturing convertersEngineeringAudification

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Technology for processing steel liquid calcium by adopting hard high-purity calcium wire

InactiveCN106636541ASolve the silicon increase problemSolve the splatter problemSteel millSteel belt

The invention provides a technology for processing steel liquid calcium by adopting a hard high-purity calcium wire and belongs to the technical field of steel making. According to the technology for processing the steel liquid calcium by adopting the hard high-purity calcium wire, technology parameters such as the steel strip thickness, the wire feeding speed and the wire feeding depth in the wire feeding process are optimized, so that the steel liquid splash problem is solved, the yield of the calcium element is increased, the yield of Ca is larger than 40%, the finished Ca content is stably controlled, the proportion of nozzle blocking in the continuous casting process is decreased, the current problems existing in steel mills are solved, and the smelting cost is reduced.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL

Method for silicon alloying and calcium treatment of molten steel by using metal-containing calcium-silicon-iron alloy

The invention discloses a method for carrying out molten steel silicon alloying and calcium treatment by using metal-calcium-containing silicon-iron alloy, and belongs to the field of steel metallurgyrefining. The method is characterized in that in the tapping process after converter smelting, silicon alloying is not carried out or partial silicon alloying is carried out, the steel liquid aluminum deoxidation treatment and slag adding pre-refining are carried out at the same time, and the aluminum content is controlled according to the steel type requirement upper limit; and the metal-calcium-containing silicon-iron alloy is added into molten steel after secondary refining to carry out silicon alloying and calcium treatment, then argon is blown at a larger flow for stirring for 1-3 minutes so as to promote melting of the alloy, and then the argon is blown at a smaller flow for stirring so as to out low-flow argon blowing stirring to uniformize molten steel components and promote modification and floating of inclusions. According to the method for carrying out molten steel silicon alloying and calcium treatment by using the metal-calcium-containing silicon-iron alloy, the metal calcium contained in the silicon-iron alloy is utilized, and the targets of molten steel silicon alloying and calcium treatment are achieved at the same time by adjusting the silicon alloying time, so that the conventional calcium feeding line operation is reduced or even eliminated, and the production cost is reduced; and meanwhile, the situation of molten steel splashing caused by a calcium feedingline is avoided, oxygen increasing and nitrogen increasing of the molten steel are reduced, the operation stability and the yield of the calcium are improved, and then the cleanliness of the molten steel is also improved.

Owner:UNIV OF SCI & TECH BEIJING

A high-purity nickel or superalloy smelting method using pure calcium wire

The invention relates to the field of high-temperature alloy smelting, in particular to a high-purity nickel based high-temperature alloy smelting technology, and in particular to a pure-calcium-line-adopted high-purity nickel or high-temperature alloy smelting method. The method includes the following steps that (1) a vacuum induction smelting furnace is adopted for smelting, and vacuum pouring is carried out; (2) metal bath is subject to metal liquid boiling under the vacuum state, and the oxygen content in an alloy is reduced through a carbon oxygen reaction; (3) cooling and film formationare carried out, and a self-made pure calcium line is added; and (4) low temperature stirring and standing are carried out, and then vacuum pouring is carried out. By means of the method, the problemsof silicon increasing and iron pollution on the alloy in the using process of commercial silicon-calcium lines and iron-calcium lines are solved; through structural design of the pure calcium line, the sufficient line feeding depth is guaranteed, spraying and splashing in the using process of the pure calcium line is prevented, the problem about purification of the nickel based high-temperature alloy produced in a large-scale and batched manner is solved, and the smelting cost is reduced; and calcium is adopted for conducting modification on impurities in the high-temperature alloy, the sizeof occluded foreign substance is reduced, the number of the occluded foreign substance in the alloy is decreased, and an effective way is provided for pure smelting of the high-temperature alloy.

Owner:辽宁红银金属有限公司

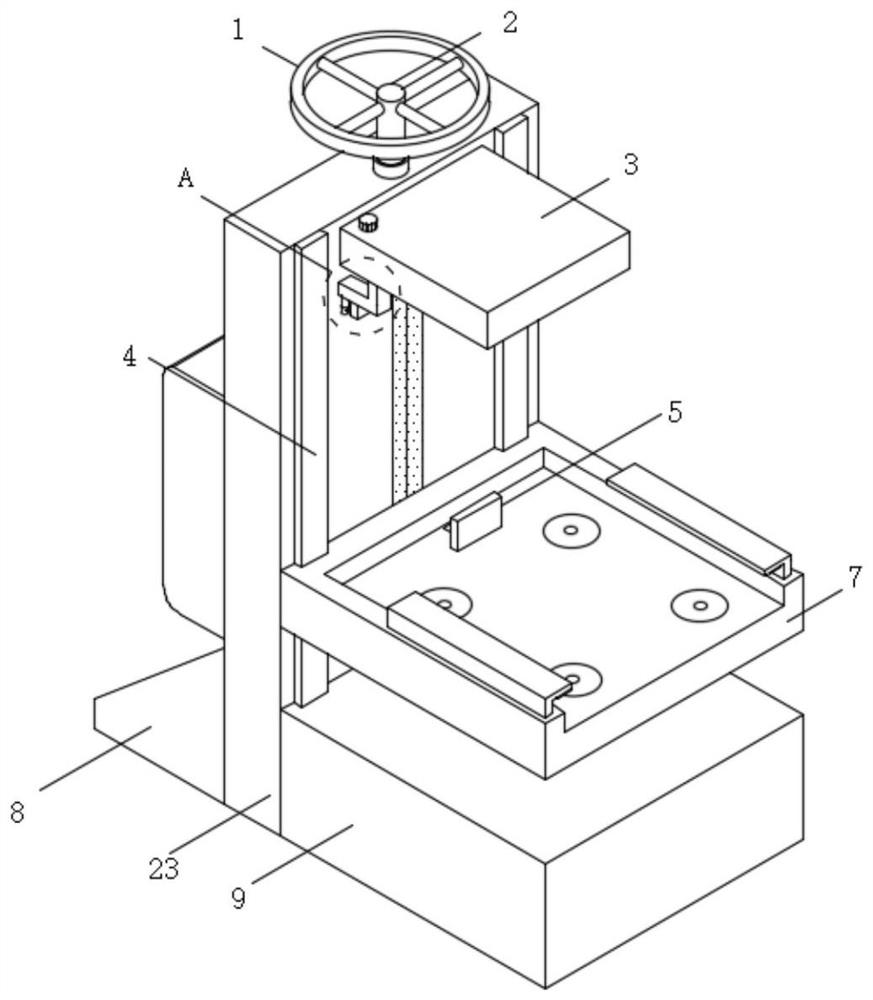

Coating vacuum cavity welding auxiliary equipment for LOW-E glass production

The invention discloses coating vacuum cavity welding auxiliary equipment for LOW-E glass production, and belongs to the technical field of glass production and manufacturing. The coating vacuum cavity welding auxiliary equipment comprises a glass mounting base and a main mounting frame, and side supporting bases and a base are fixedly mounted on the outer walls of the two sides of the main mounting frame correspondingly; an air bag and a material storage assembly are arranged on the side supporting bases and the base and located on the outer surface of the main mounting frame correspondingly, an air guide pipe is arranged at the top of the air bag, and a square guide pipe is fixedly mounted at the top end of the air guide pipe; according to the equipment, the material storage assembly and the air bag are arranged outside, through the design, no electronic structure is used, automatic timing spraying of the welding anti-splashing agent is achieved, the problem of splashing of some materials in a high-temperature welding area can be effectively solved, the construction safety of workers is effectively guaranteed, meanwhile, the connection tightness of the welding area is higher, the welding surface is not prone to erosion, the welding effect is improved, the step of manually adding a welding splash-proof agent is omitted, the process efficiency is improved, and operation is easy.

Owner:南京苏洋玻璃有限公司

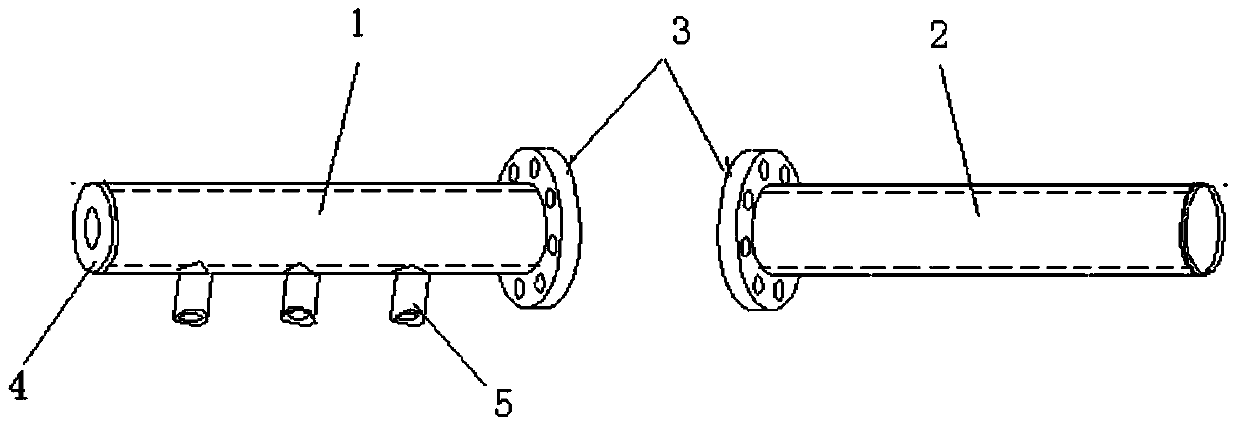

Construction method for achieving blowout prevention during drilling pressure relief of mine

The invention discloses a construction method for achieving blowout prevention during drilling pressure relief of a mine. According to the construction method for achieving blowout prevention during drilling pressure relief of the mine, firstly, two steel pipes with the same diameter are combined together through a flange plate, one steel pipe serves as a hole mouth fixing pipe which is inserted into a drilled hole, the other steel pipe serves as a blowout prevention pipe arranged outside the hole, a circular plate with an insertion hole is welded to one end of the blowout prevention pipe, the diameter of the insertion hole needs to meet the requirement that a drill bit can right pass through the insertion hole, two to four pressure relief holes are machined in the side face, facing downwards, of the blowout prevention pipe, and a protection pipe is welded to each pressure relief hole; an installation hole is firstly formed in the position where a hole needs to be drilled, and the hole mouth fixing pipe is installed and fixed in the installation hole; a drill stem of a drilling machine is inserted into an insertion hole of a blowout prevention device and extends to the bottom of the insertion hole, and then the drilling machine can be started normally to conduct drilling; in this way, coal and rock particles and gas are splashed into the blowout prevention pipe from the drilled hole at a high speed, and impact pressure of the gas is relieved through the pressure relief holes. According to the construction method for achieving blowout prevention during drilling pressure relief of the mine, through the blocking function and the buffering function of the blowout prevention device, the problems of coal and rock particle splashing and gas impact are effectively solved during drilling pressure relief of the mine.

Owner:XINWEN MINING GROUP +1

Internal oil baffles for dental milling machines

InactiveCN105798699BSolve the splatter problemAvoid pollutionMaintainance and safety accessoriesEngineeringMechanical engineering

Owner:CHONGQING ZHUOTIAN TECH CO LTD

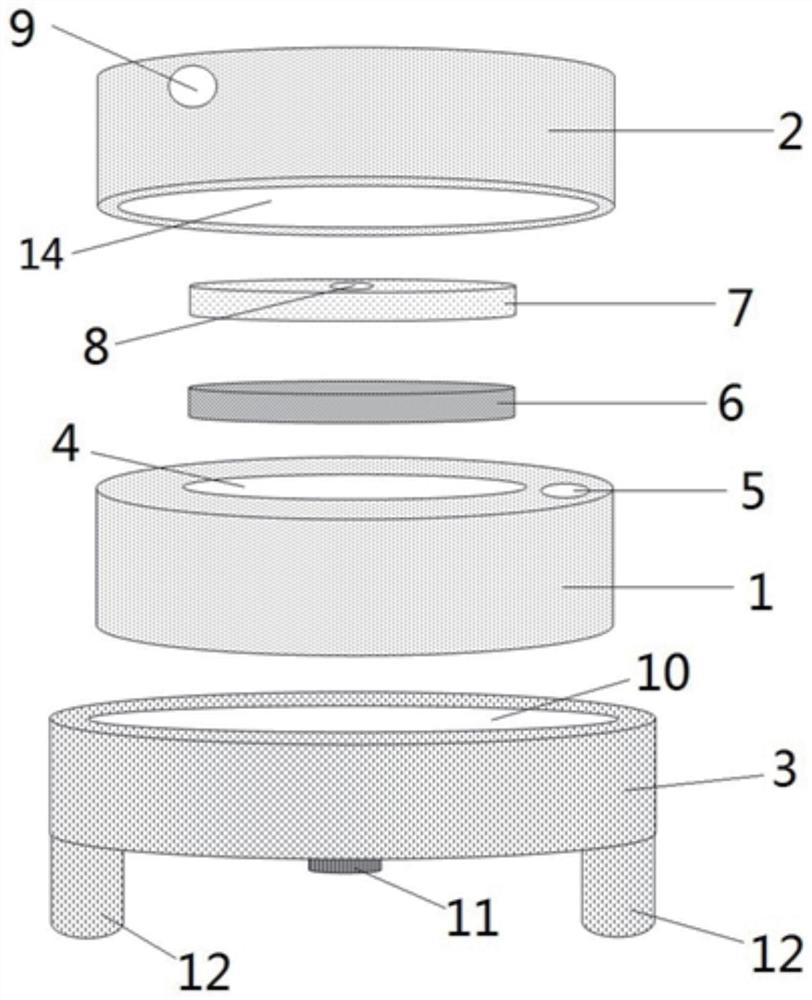

Atomization agilawood device

The invention relates to an atomization agilawood device, and belongs to the technical field of atomization application. The atomization agilawood device particularly comprises a functional cavity anda mist outlet cavity; an atomization cavity comprises a hollow cavity which is formed by ensclosure, and air inlet through holes formed in the side surface; a groove is formed in the middle of the functional cavity; a gas flow through hole is formed in the side face of the groove; and a liquid storage material and a piezoelectric ceramic atomization piece are sequentially arranged in the groove from top to bottom, wherein the mist outlet cavity is provided with a hollow mist storage bin formed by enclosure and a mist outlet, and the airflow through hole communicates upwards with the cavity and communicates downwards with the mist storage bin.

Owner:HUNAN JIAYEDA ELECTRONICS

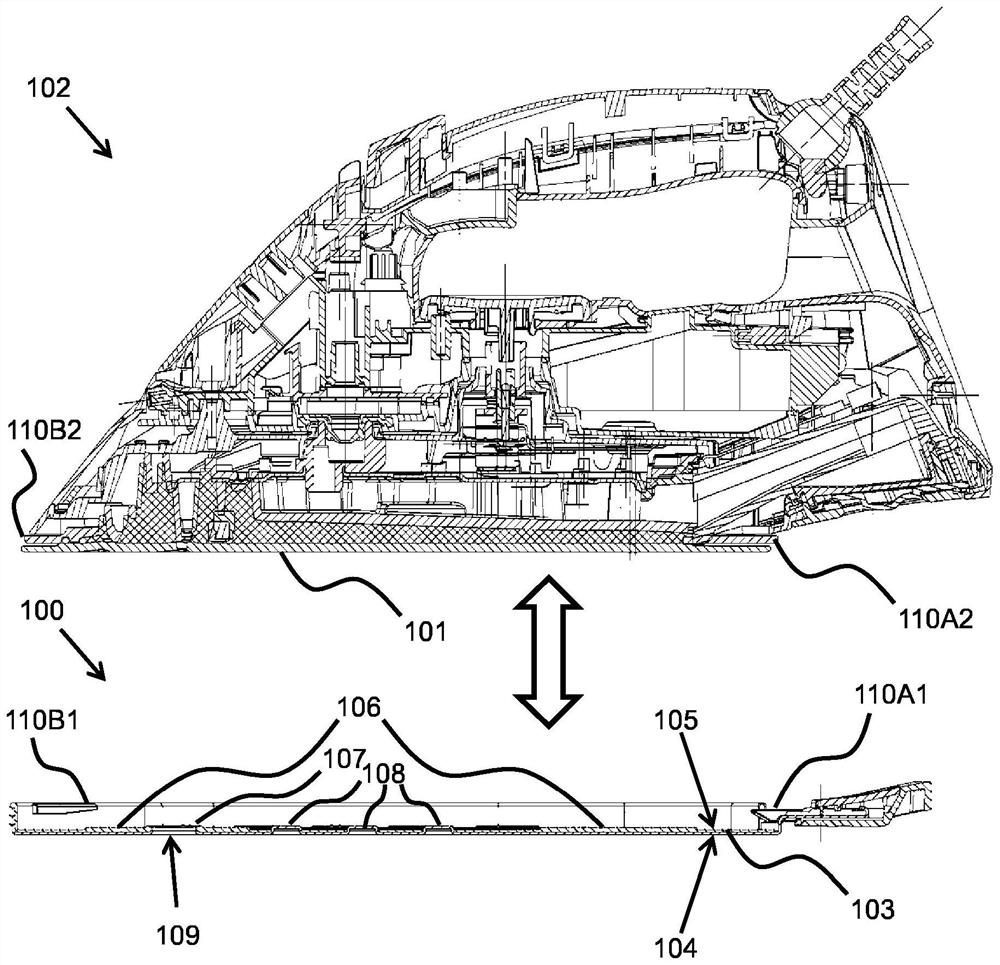

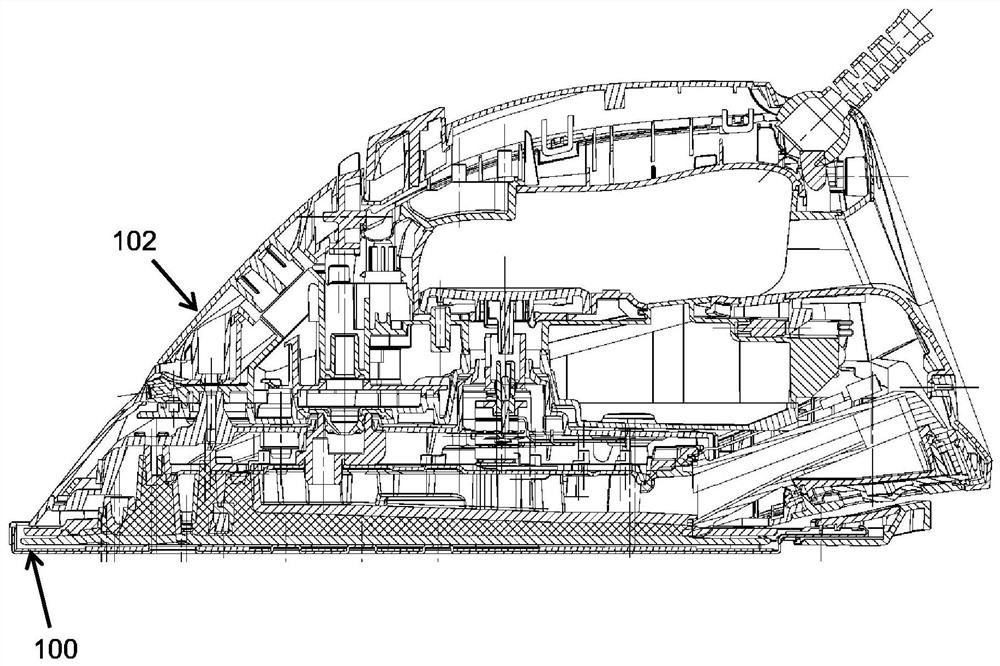

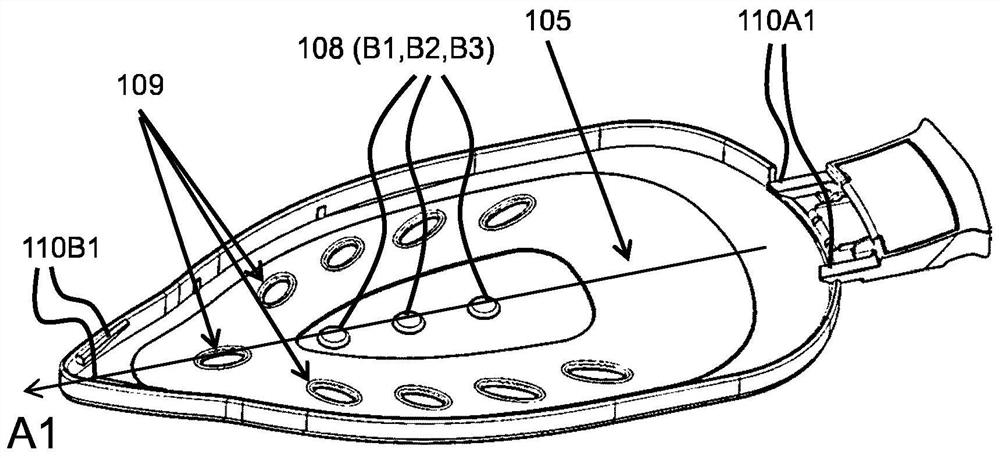

Ironing shoe with heat-conducting protruding structure

The invention relates to an ironing shoe (100) adapted to be removably attached to a soleplate (101) of a garment care appliance (102). The ironing shoe (100) includes a plate (103). The plate (103) comprises an outer face (104) intended to come into contact with the garment to be treated. The plate (103) comprises an inner face (105) intended to face the sole plate when the ironing shoe (100) is attached to the garment care device. The inner face (105) includes: an insulating layer (106); insulating protrusions (107) for forming between the insulating layer (106) and the soleplate when the ironing shoe (100) is attached to the garment care appliance an air gap (AG); and a thermally conductive protrusion (108) for conducting heat from the soleplate to the plate (103) when the ironing shoe (100) is attached to the garment care appliance. The ironing shoe improves the problem of steam condensation when the ironing shoe is attached to the soleplate.

Owner:KONINKLJIJKE PHILIPS NV

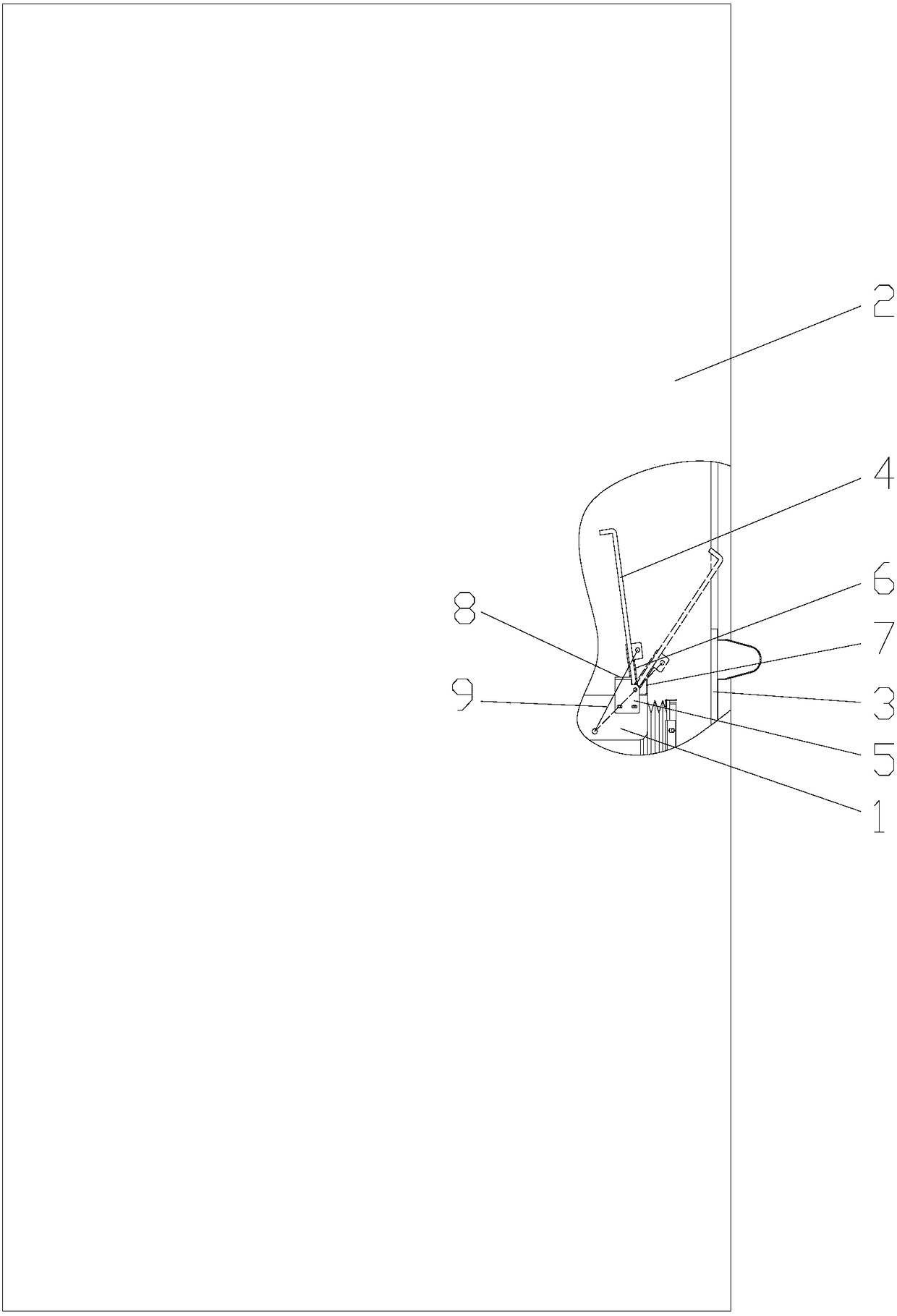

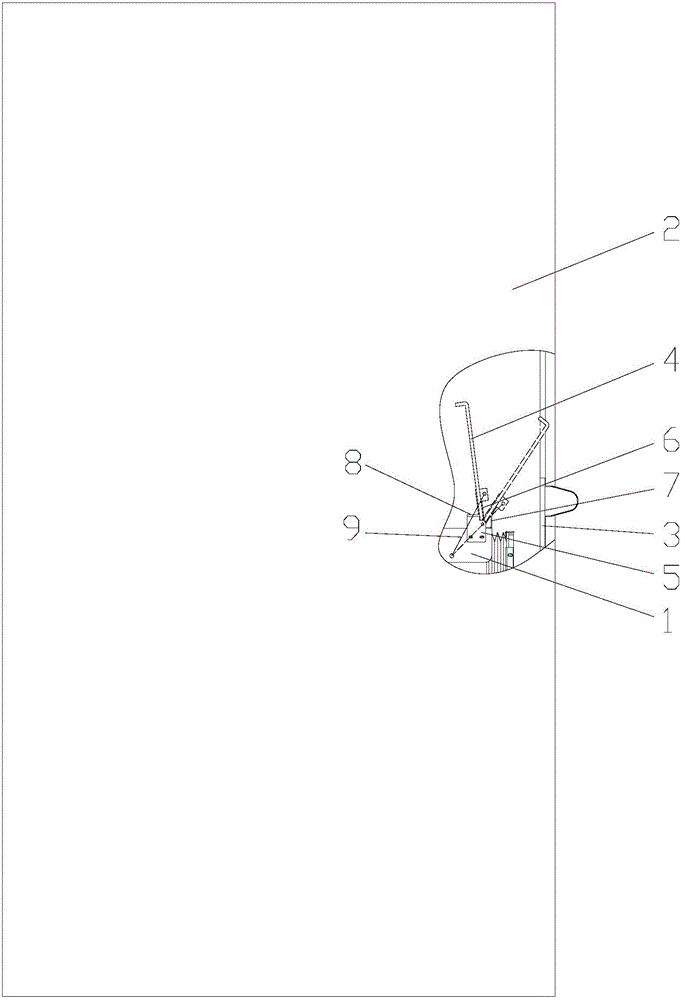

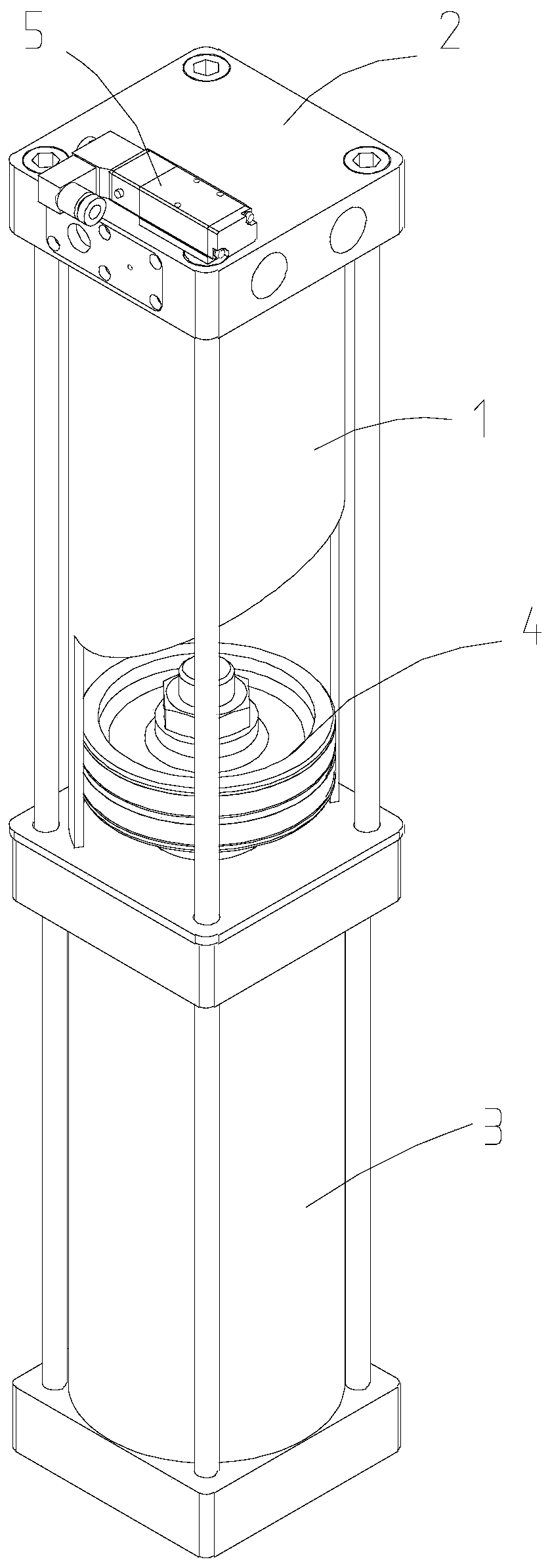

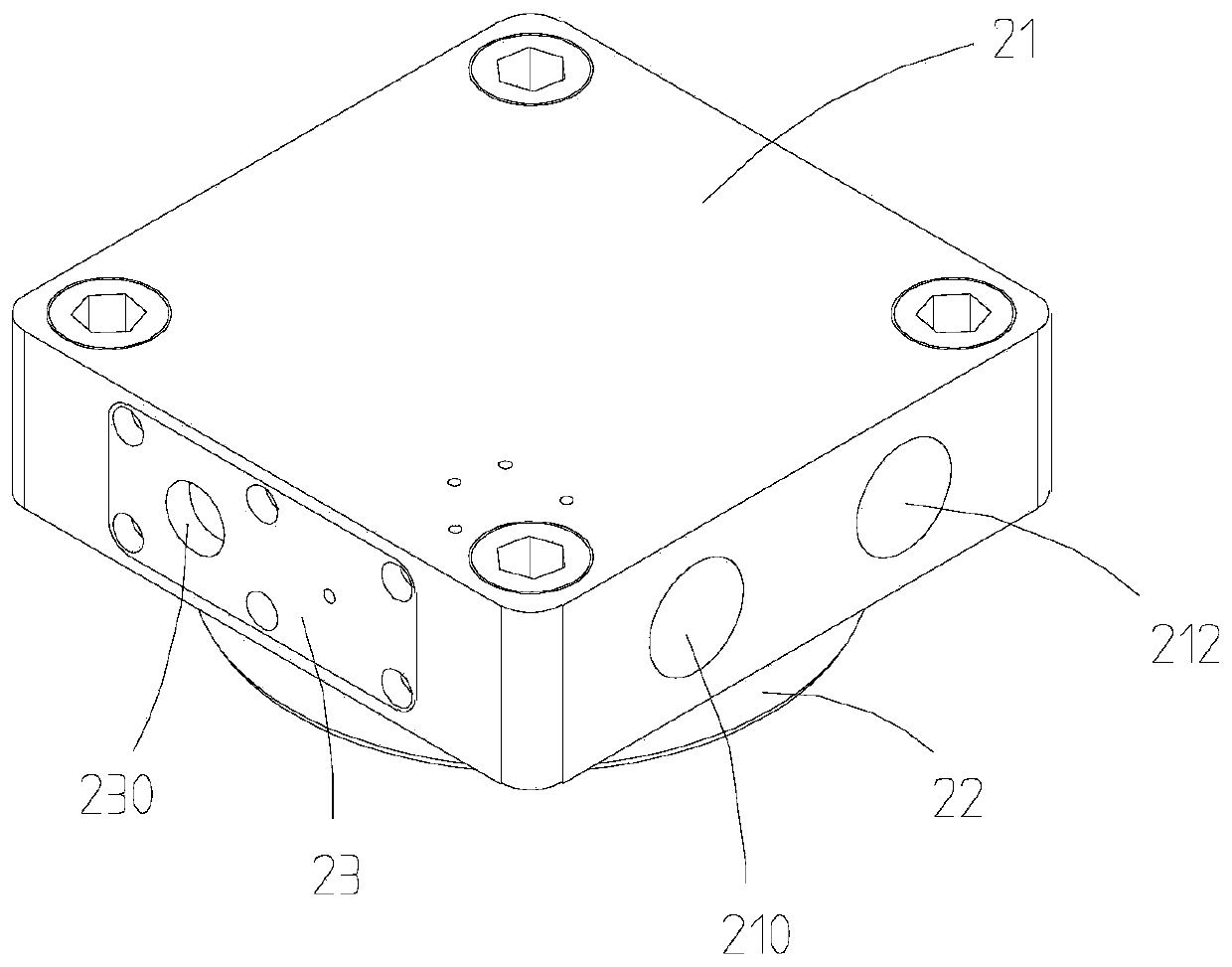

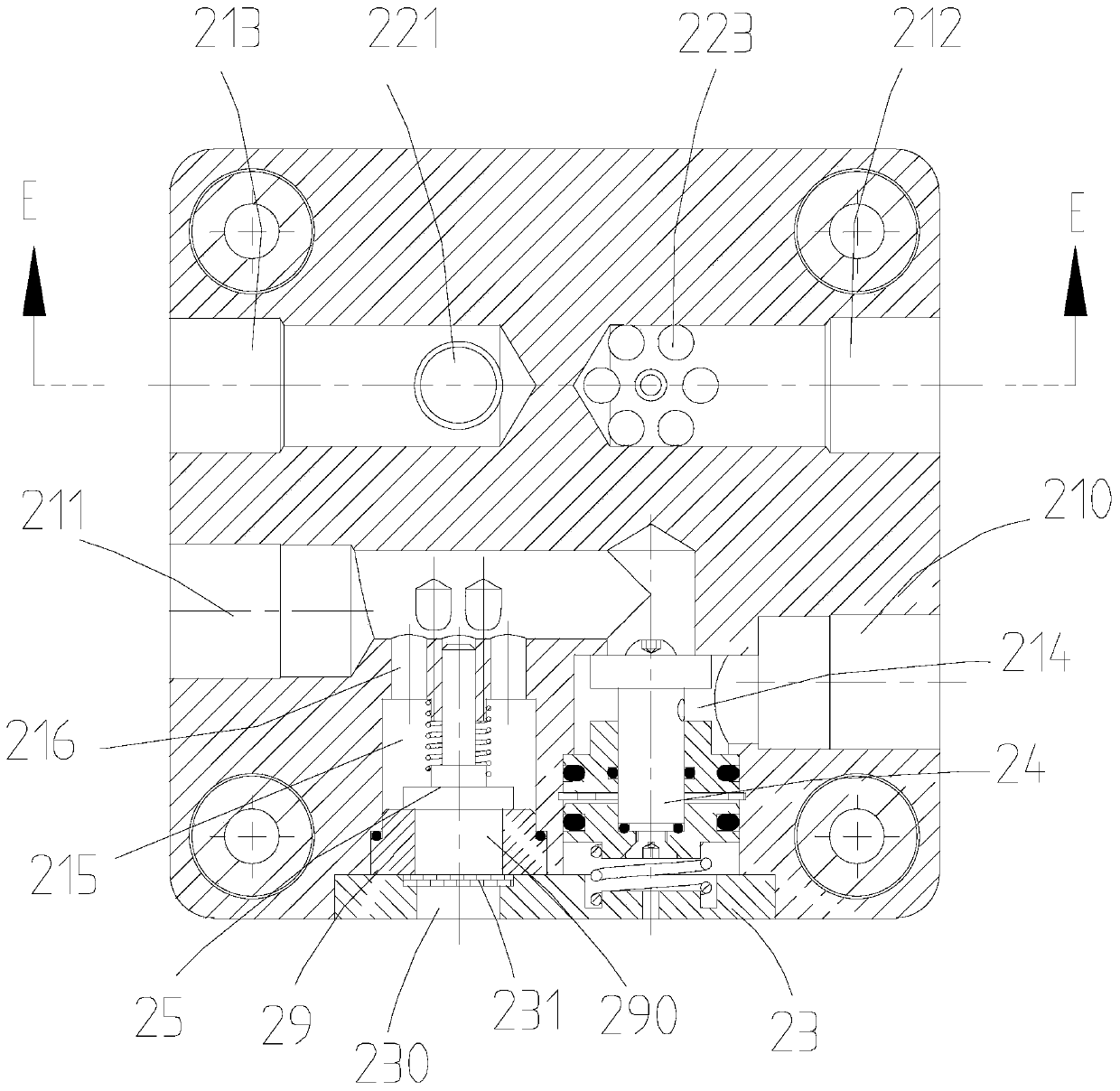

Interior oil baffle plate for milling machine in dentistry

InactiveCN105798699ASolve the splatter problemAvoid pollutionMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses an interior oil baffle plate for a milling machine in the dentistry. The milling machine in the dentistry comprises a rack, a unit installed on the rack and a shell arranged outside the unit in a covering manner, and a protection door is arranged on the shell; the interior oil baffle plate for the milling machine in the dentistry comprises an oil baffle plate body arranged in the shell of the milling machine in the dentistry; the oil baffle plate body is distributed between a working table and the protection door of the milling machine in the dentistry, installed on the rack of the milling machine in the dentistry and used for stopping cooling liquid splashed to the protection door; and the oil baffle plate body is movably connected to the rack of the milling machine in the dentistry and used for giving out operation space for dismounting and mounting of workpieces. By means of the interior oil baffle plate for the milling machine in the dentistry, the cooling liquid splashed to the protection door can be stopped, pollution and corrosion of the cooling liquid to the protection door and a connecting piece between the protection door and the shell are avoided, and the service life is prolonged; and in addition, the problem that the cooling liquid is splashed out when the protection door is opened is effectively solved, the using limitation is reduced, and the machining efficiency is better improved.

Owner:CHONGQING ZHUOTIAN TECH CO LTD

Reciprocating water pumping vat

PendingCN109854473ASolve the splatter problemImprove production safetyPositive displacement pump componentsPiston pumpsInlet valveElectromagnetic valve

The invention discloses a reciprocating water pumping vat. The reciprocating water pumping vat comprises a water vat; the upper end of the water vat is connected with an end cover module, and the lower end is connected with a cylinder; the end cover module is connected with an electromagnetic valve; the end cover module comprises an end cover main body, and is provided with a first water inlet hole, a first water outlet hole, a second water inlet hole, a second water outlet hole and a stop valve mounting hole; a stop valve is mounted in the stop valve mounting hole; the end cover main body isprovided with a water inlet valve element mounting hole, a water outlet valve element mounting hole and a water inlet and outlet valve base; a water inlet valve element is mounted in the water inlet valve element mounting hole; a water outlet valve element is mounted in the water outlet valve element mounting hole; first communicating holes are distributed on the water inlet and outlet valve baseand located around the water inlet valve element; the water inlet valve element mounting hole communicates with an inner cavity of the water vat through the first communicating holes; a first valve base via hole is formed in the water inlet and outlet valve base and corresponds to the water outlet valve element; second communicating holes are distributed on the end cover main body and located around the water outlet valve element; and the water outlet valve element mounting hole communicates with the second water outlet hole through the second communicating holes.

Owner:重庆特博智能装备有限公司

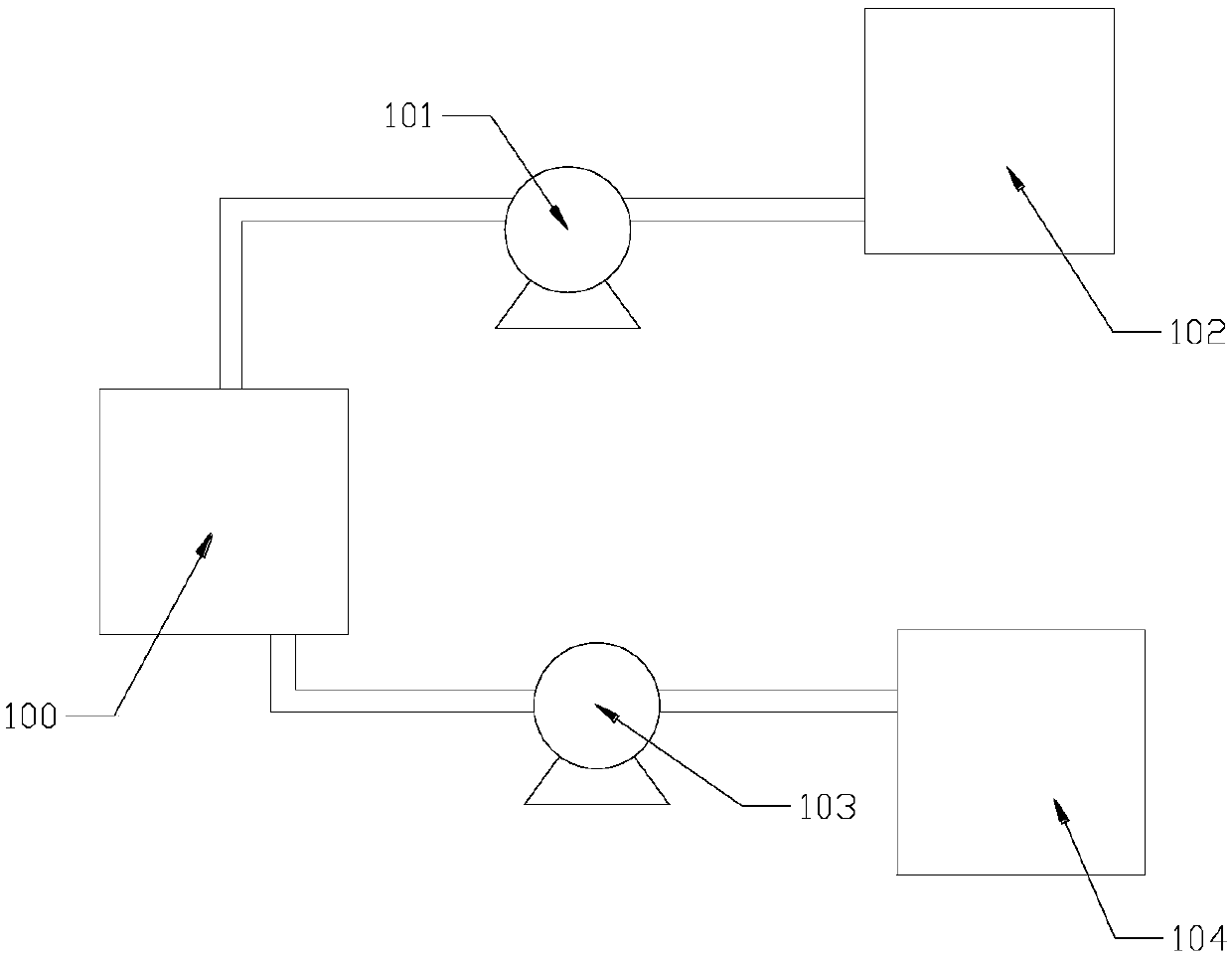

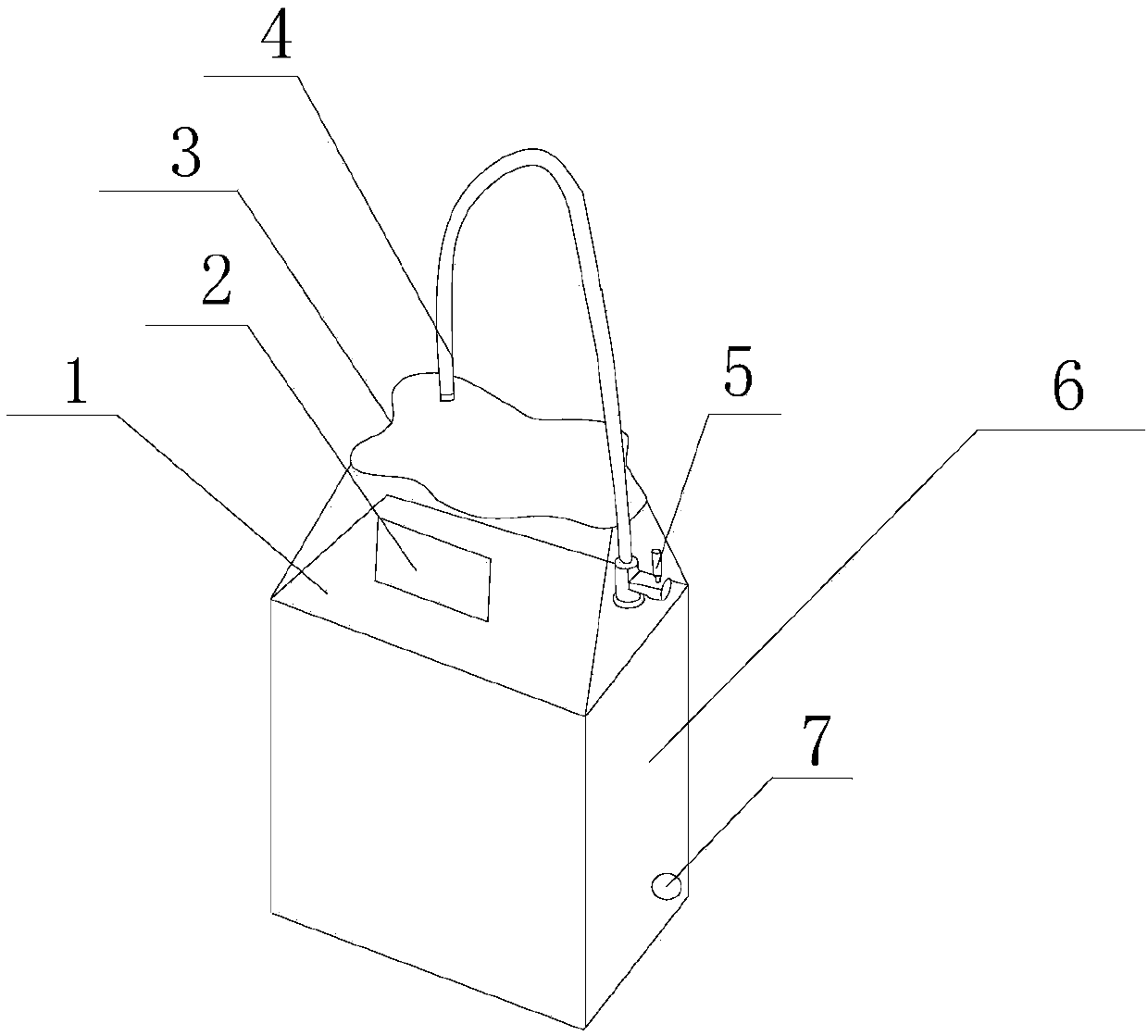

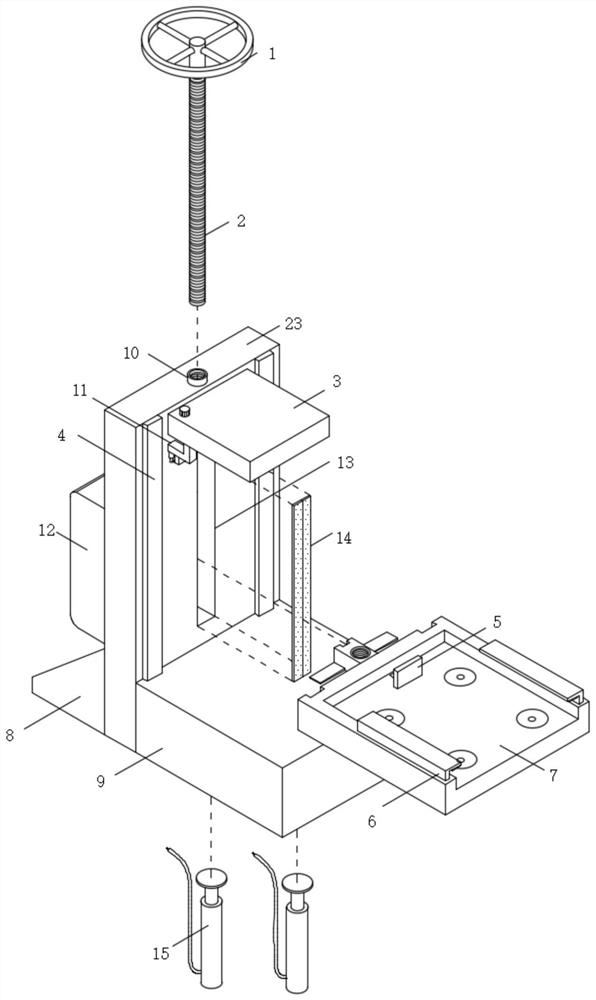

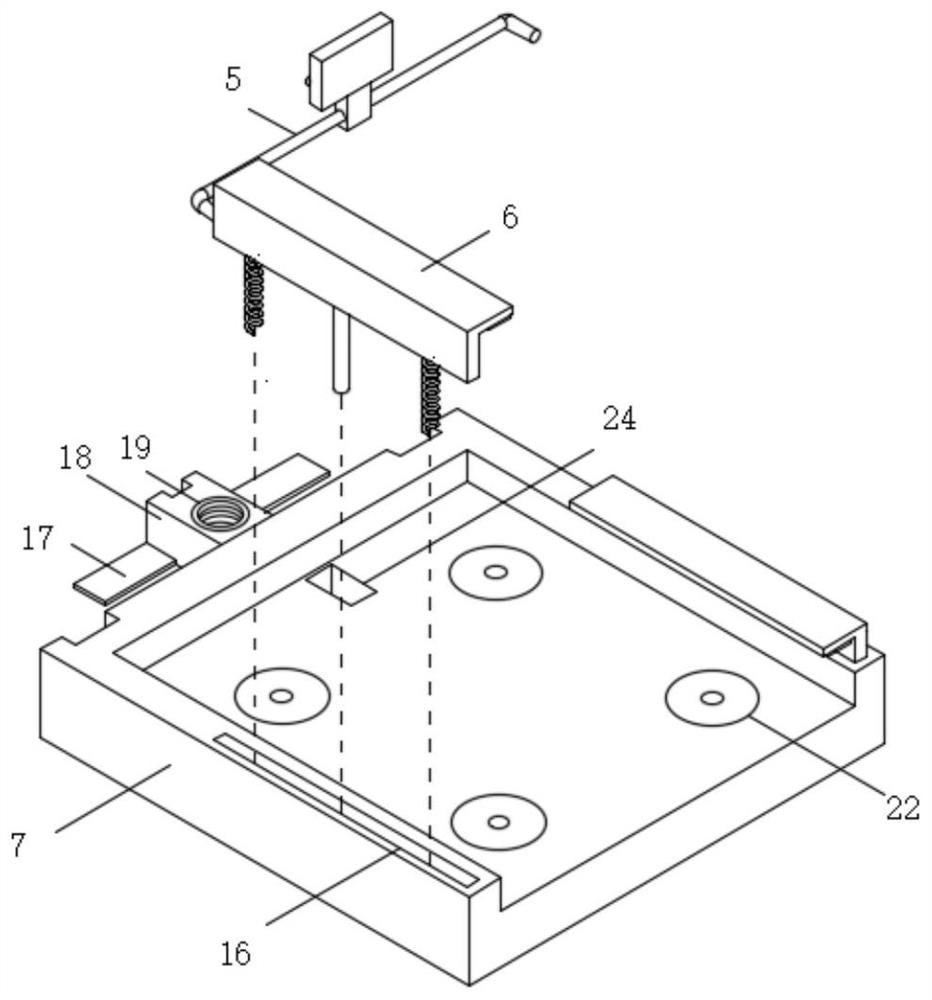

Medium storage device

PendingCN108410693AIncrease profitEasy to placeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineering

The invention discloses a medium storage device, which comprises a shell, further comprises limiting pins, further comprises a placing tray and further comprises a plurality of fixing mechanisms, wherein a plurality of lower support frames are arranged on the shell; upper support frames are arranged above the lower support frames; rolling wheels and upper limiting holes are arranged on the upper support frames; lower limiting holes are formed in the lower support frames; a plurality of mounting holes are formed in the placing tray; two rolling grooves are formed in the upper surface of the placing tray; the rolling wheels are arranged in the rolling grooves; limiting holes are additionally formed in the placing tray; the plurality of fixing mechanisms are arranged on the limiting placing tray; the fixing mechanisms comprise fixed seats; two fixed holes and fixed pins, which are matched with the two fixed holes, are arranged on each fixed seat, and the fixed holes are identical to the mounting holes in diameter; sleeves are arranged on the side faces of the fixed seats; connecting rods are arranged in the sleeves; a spring is connected to one end of each connecting rod; and a laminating plate is connected to the other end of the connecting rod. According to the medium storage device provided by the invention, universality is improved; the reasonable utilization of the space of the placing tray can be achieved; and the fixing mechanisms can closely fit to a culture dish.

Owner:成都源泉生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com