Oil baffle of dental milling machine

A dental milling machine and oil baffle technology, applied in dentistry, dental prosthesis, dentures, etc., can solve problems such as pollution, coolant splashing, and reduce limitations, so as to avoid pollution and corrosion, improve processing efficiency, and reduce limitations sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

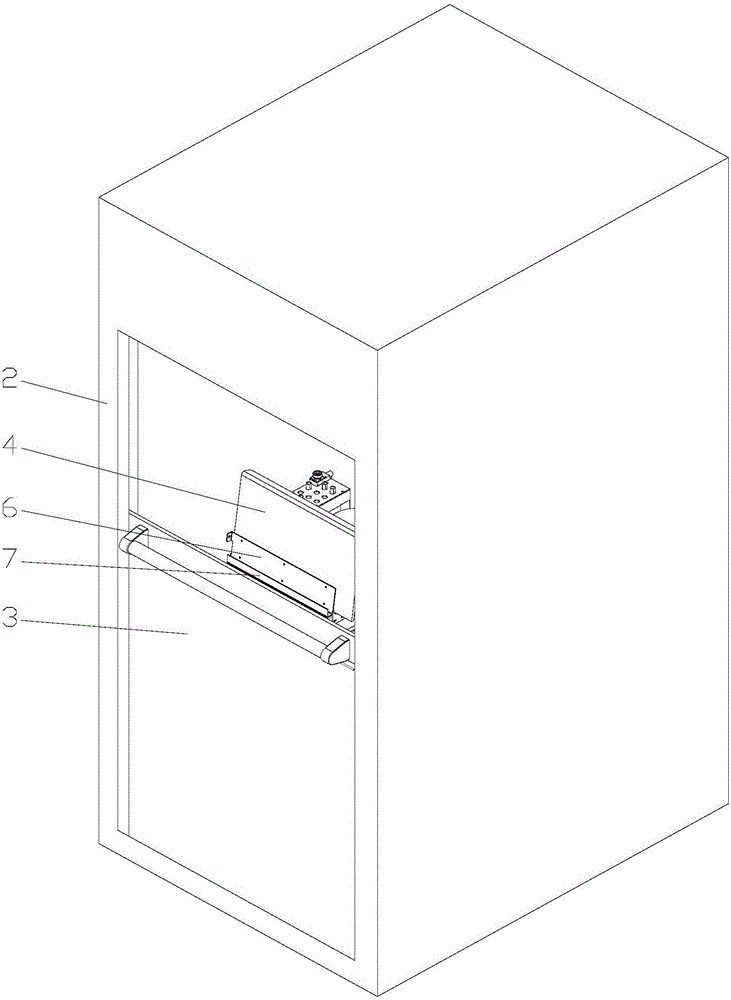

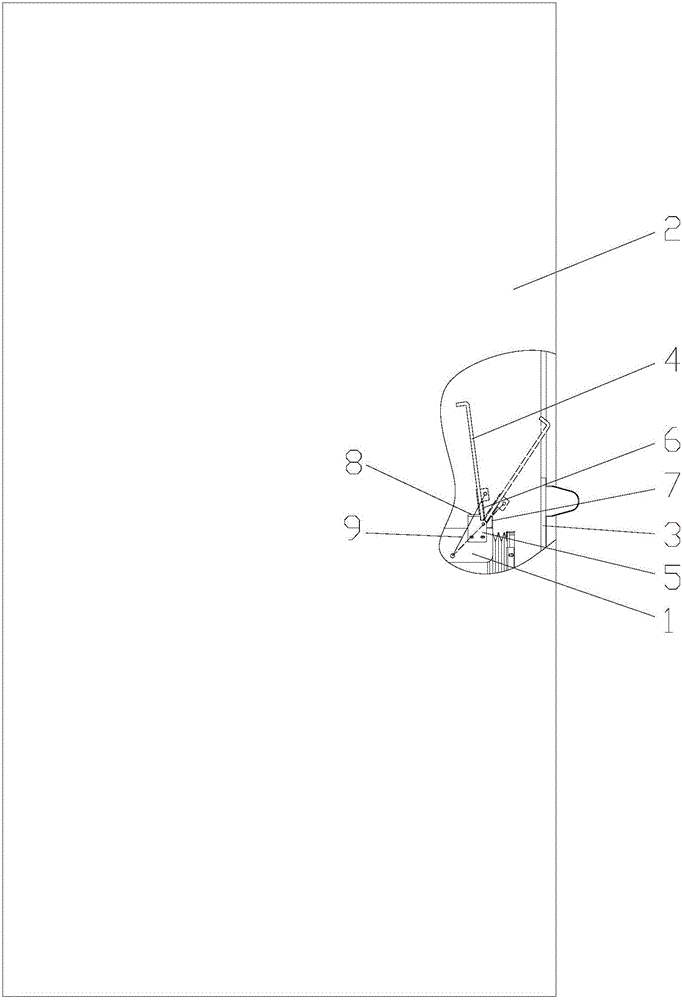

[0016] figure 1 Schematic diagram of the structure of the present invention; figure 2 It is a partial cross-sectional view of the present invention, as shown in the figure: the oil baffle of the dental milling machine of this embodiment, the dental milling machine includes a frame 1, a unit mounted on the frame 1, and a casing 2 covering the outside of the unit, on the casing 2 A protective door 3 is provided; the oil baffle plate of the dental milling machine includes an oil baffle body 4 arranged in the housing 2 of the dental milling machine; the oil baffle body 4 is arranged between the worktable of the dental milling machine and the protective door 3 and is installed in the dental The frame 1 of the milling machine is used to block the coolant splashing to the protective door 3, and the side where the protective door 3 is located is the front side, so the oil baffle body 4 is located on the front side of the worktable of the dental milling machine, and the oil baffle can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com