Reciprocating water pumping vat

A reciprocating and water cylinder technology, which is applied in variable capacity pump components, liquid variable capacity machines, components of pumping devices for elastic fluids, etc., can solve the problems of single pumping, economic loss of production enterprises, High manufacturing cost and other issues, to avoid cooling water splashing, easy to use and move, and improve production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

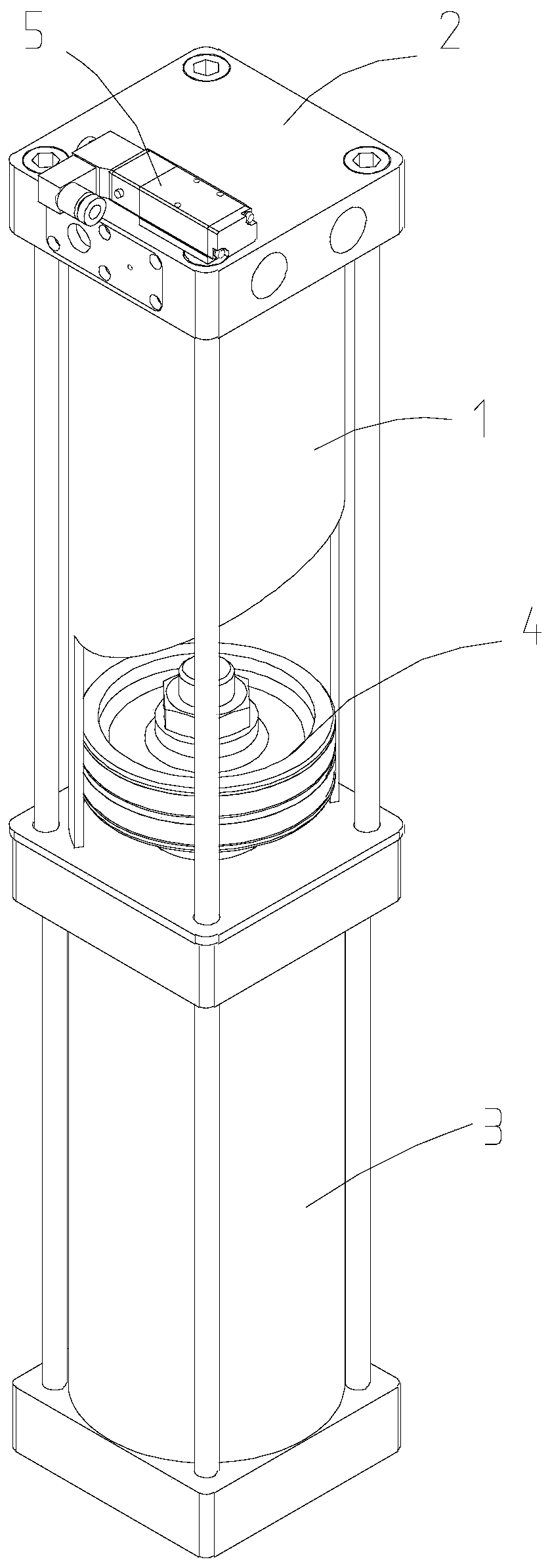

[0025] as attached figure 1 - attached Figure 4 The shown reciprocating pumping cylinder includes a water cylinder 1, the upper end of the water cylinder 1 is connected with an end cover assembly 2, and its lower end is connected with a cylinder 3, and the movable end of the cylinder 3 is fixed to the piston 4 located in the inner cavity of the water cylinder 1. Connection, the end cover assembly 2 is connected with a solenoid valve 5 .

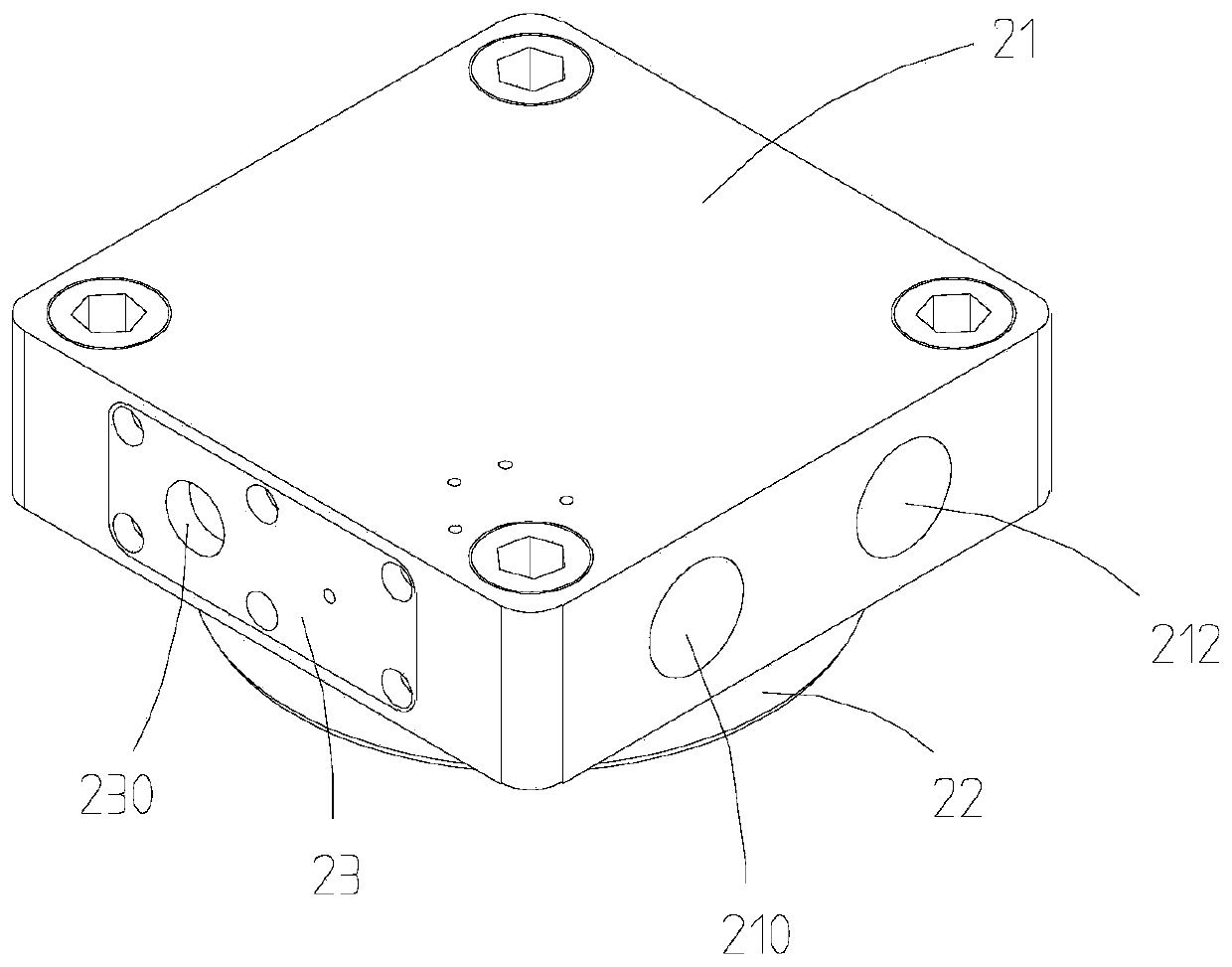

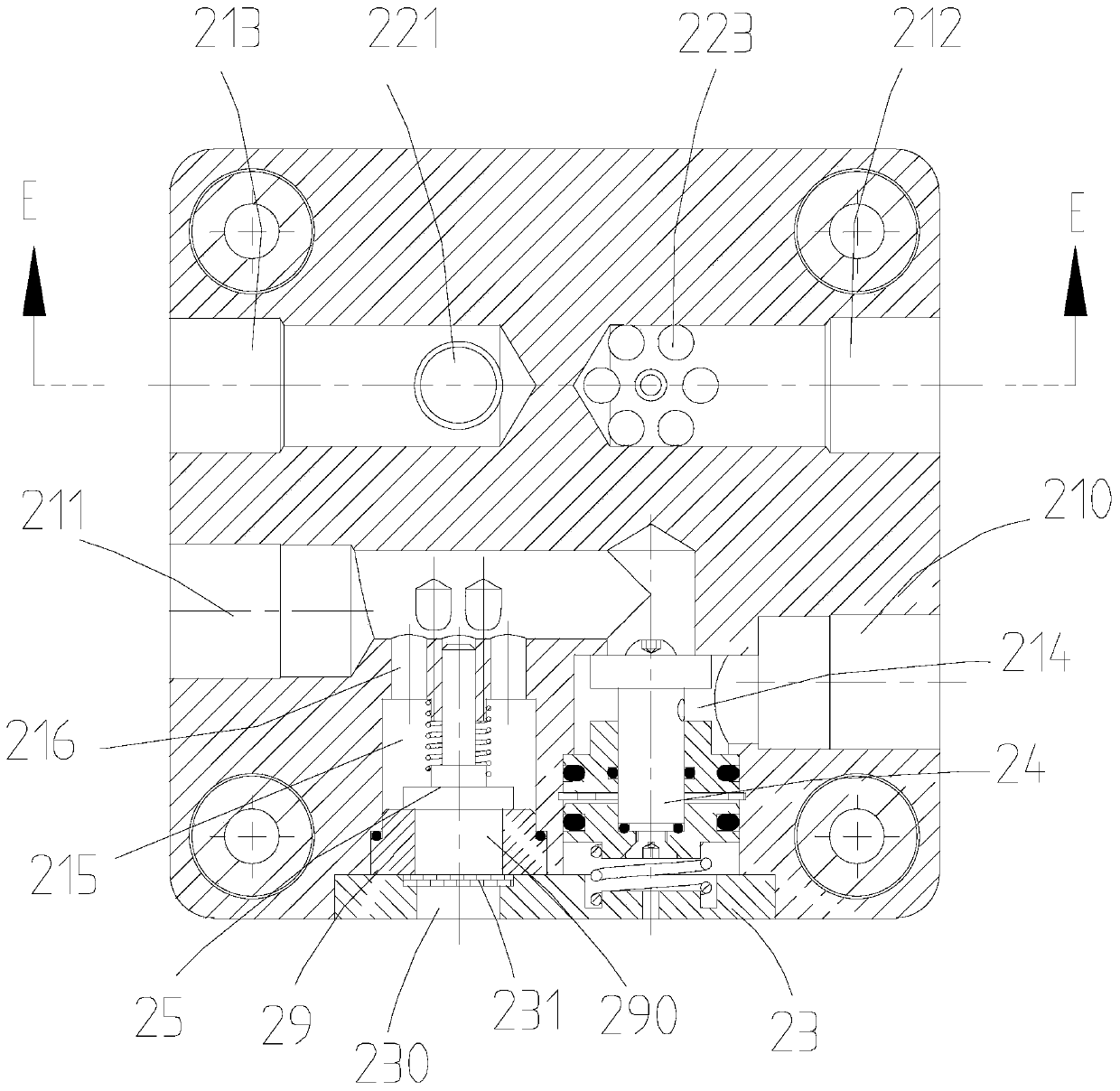

[0026] Please refer to figure 2 . image 3 and Figure 4 The above-mentioned end cover assembly 2 includes an end cover body, which includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com