Atomization agilawood device

A kind of technology of agarwood and atomization chamber, applied in the direction of atomizing substances, disinfection, etc., can solve the problems of increasing product cost and volume, difficulty in achieving visual effects, single shape, etc., and achieve the effect of simple structure, convenient assembly and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and example the present invention will be further described:

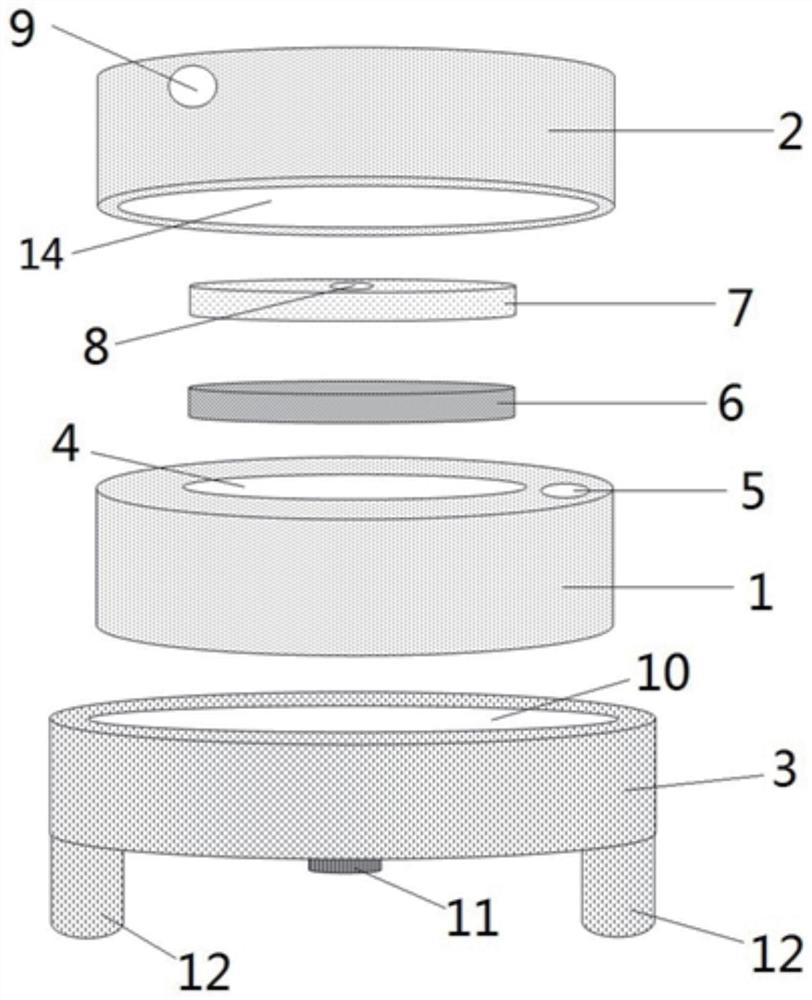

[0023] An atomized agarwood device such as figure 1 As shown, the atomized agarwood device can atomize liquids such as essential oil, water, perfume, smoke oil, etc. The top of the atomized agarwood device is the atomization chamber 2, and the middle of the atomization chamber 2 is used for atomization. The cavity 14, the side of the atomization chamber 2 is provided with an air inlet through hole 9 to assist the solution particles to quickly and continuously diffuse down to the external space along the transmission channel, and it can also be used as a liquid injection hole for adding the nebulizer that needs to be atomized. Liquid; the bottom is the mist outlet chamber 3, the mist outlet chamber 3 is provided with a hollow mist storage bin 10 and a mist outlet 11; the middle functional chamber 1 is provided with a groove 4, and the groove 4 is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com