Ironing shoe with heat-conducting protruding structure

A technology that highlights the structure and ironing boots, and is applied in the field of ironing boots to achieve the effect of reducing heat transfer and reducing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

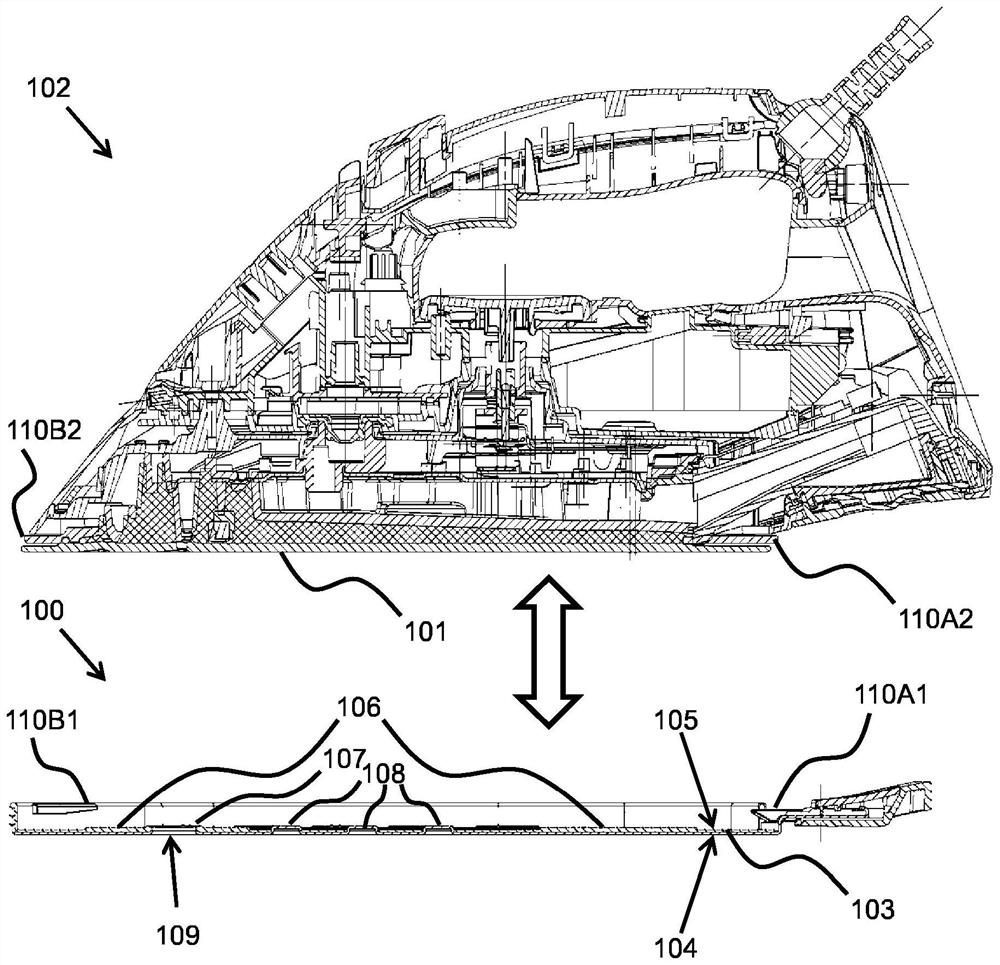

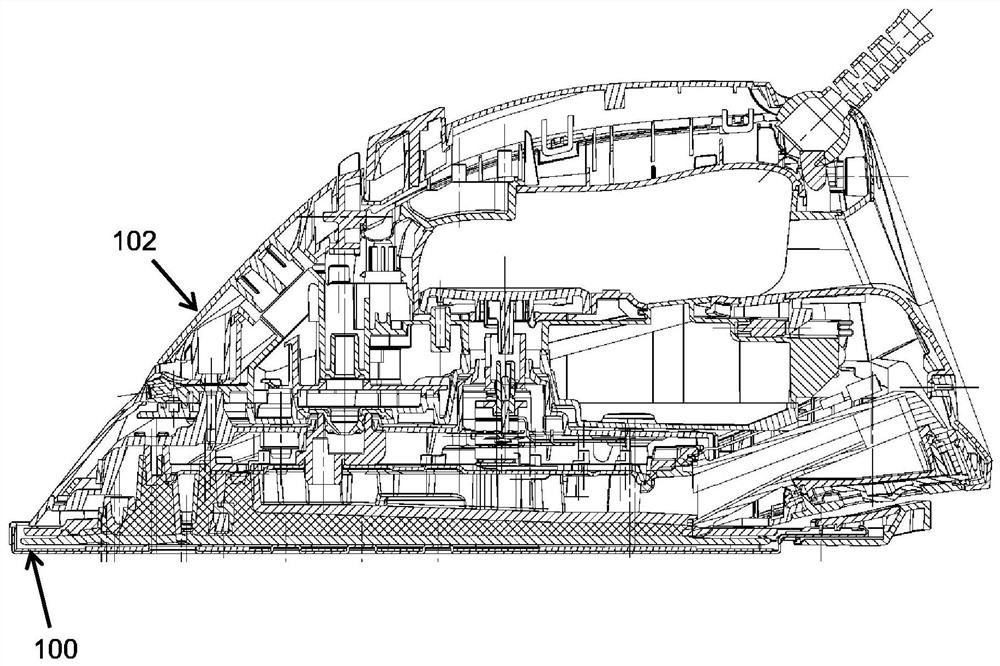

[0060] Figure 1A An ironing shoe 100 according to the present invention is depicted when detached from a soleplate 101 of a garment care appliance 102, such as a steam iron, as illustrated.

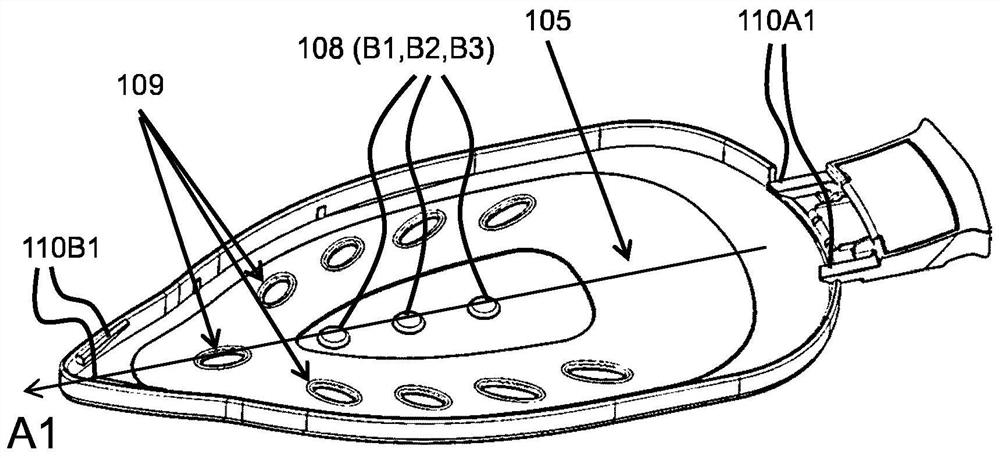

[0061] The ironing shoe 100 comprises a plate 103 comprising an outer face 104 intended to be in contact with the garment to be treated and an inner face 105 intended to face the soleplate when the ironing shoe 100 is attached to a garment care appliance.

[0062] Plate 103 is preferably made of metal such as aluminum or stainless steel.

[0063] Preferably, the plate 103 has a thickness in the range [0.6; 1.5] mm, preferably a thickness of 0.8 mm.

[0064] The outer 104 and inner 105 faces of the plate 103 are preferably flat so that when the ironing shoe is attached to the garment care appliance 102 they extend parallel to the surface of the sole plate 101 .

[0065] Figure 1B depicts the Figure 1A ironing boots.

[0066] Inner face 105 includes:

[0067] - thermal insulation 106...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com