Environment-friendly alloying method of metal bismuth for free-cutting steel

A free-cutting steel and alloying technology, applied in the alloying field of environmentally friendly free-cutting steel metal bismuth, can solve the problems of injury to production personnel and equipment, difficulty in reaching the lower part of molten steel, environmental dust pollution, etc., and achieve standardized and uniform operation. Good performance and stable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Smelting 20Cr free-cutting ferritic stainless steel with a target bismuth content of 0.5%.

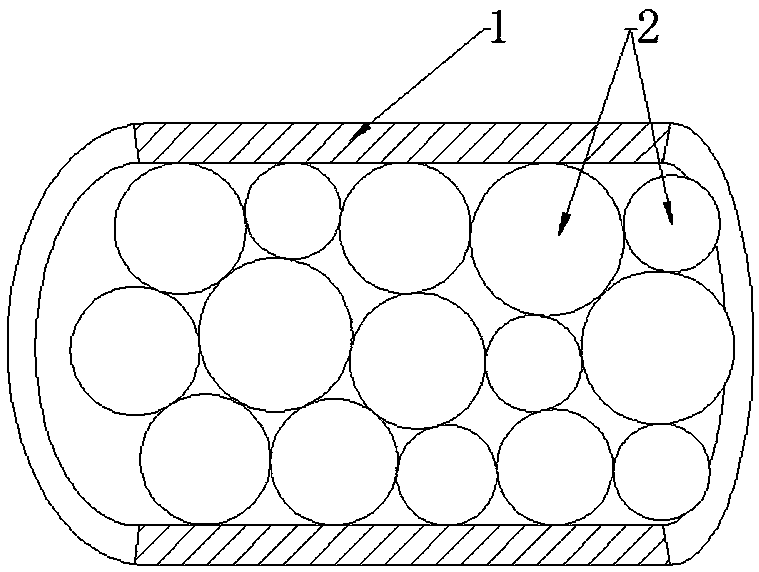

[0033] Such as figure 1 As shown, the thickness of the steel sheath 1 of the bismuth cored wire is 1.0 mm, the diameter of the bismuth element particles 2 is not greater than 2 mm, and the diameter of the cored wire is 13 mm. The wire feeding temperature is 1650°C. Use the wire feeding machine to feed the bismuth cored wire into the ladle, adjust the feeding position through the catheter to be above the blowing hole, the feeding rate is 110m / min, use a single machine for single wire feeding, after the wire feeding is completed, continue to stir for 8 minutes, and take samples The detection yield of bismuth metal was 53.4%.

Embodiment 2

[0035] Smelting 17Cr free-cutting ferritic stainless steel with a target bismuth content of 0.25%.

[0036] The thickness of the steel sheath 1 of the bismuth cored wire is 1.2 mm, the diameter of the bismuth element particles 2 is not greater than 3 mm, and the diameter of the cored wire is 12.8 mm. The wire feeding temperature is 1660°C. Use the wire feeding machine to feed the bismuth cored wire into the ladle, adjust the feeding position through the catheter to be above the blowing hole, the feeding rate is 80m / min, use a single machine for double wire feeding, after the wire feeding is completed, continue to stir for 4 minutes, The recovery rate of metal bismuth was 58.2%.

Embodiment 3

[0038] Smelting 13Cr free-cutting ferritic stainless steel with a target bismuth content of 0.15%.

[0039] The thickness of the steel sheath 1 of the bismuth cored wire is 0.8 mm, the diameter of the bismuth element particles 2 is not greater than 2.5 mm, and the diameter of the cored wire is 13.3 mm. The wire feeding temperature is 1680°C. Use the wire feeding machine to feed the bismuth cored wire into the ladle, adjust the feeding position through the catheter to be above the blowing hole, the feeding rate is 100m / min, use a single machine for double wire feeding, after the wire feeding is completed, continue to stir for 6 minutes, The recovery rate of metal bismuth was 60.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com