Drainage valve capable of adjusting drainage speed

A drain valve, adjustable technology, applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of splashing water, unable to adjust the size, and loud noise, so as to avoid loud noise and splashing of water , the effect of avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

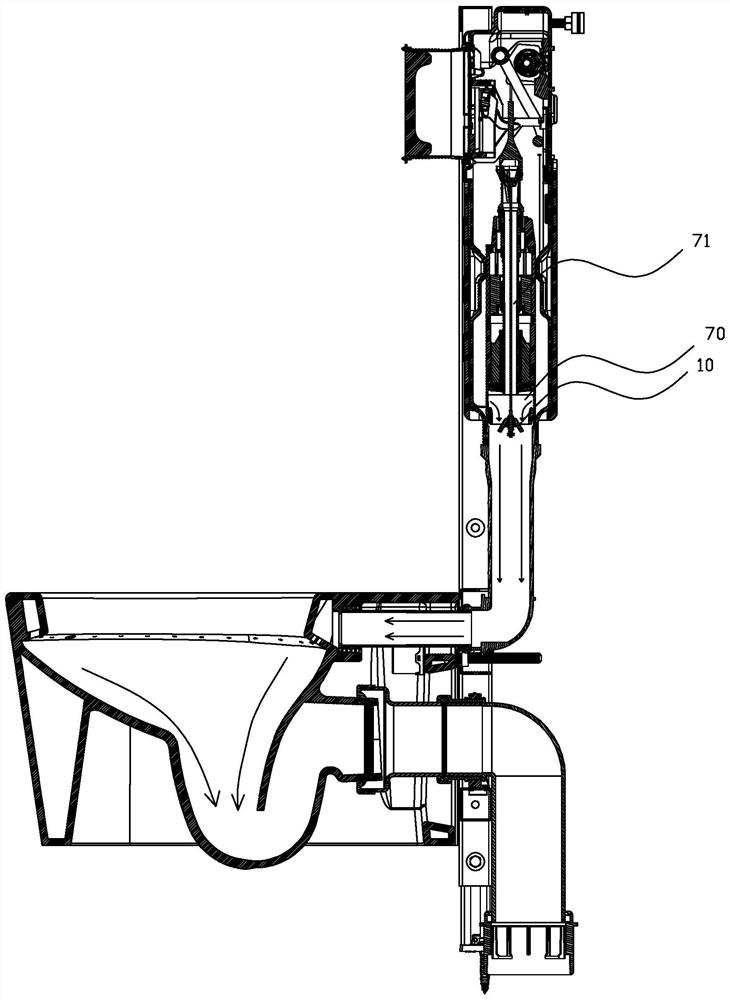

[0043] In the drain valve with adjustable drain speed according to the present invention, the position of the water outlet of the drain valve is controlled and adjusted by the adjustment mechanism to adjust the angle of the flap 10, adjust the opening size of the water outlet, and realize the adjustment of the drain speed. Furthermore, if figure 1 As shown, the implementation of the present invention makes it possible to adjust the flow rate of the water sprayed from the jet port of the toilet at the position of the drain valve, and then the jet port of the toilet retains a conventional size to ensure noise control and splash suppression during flushing.

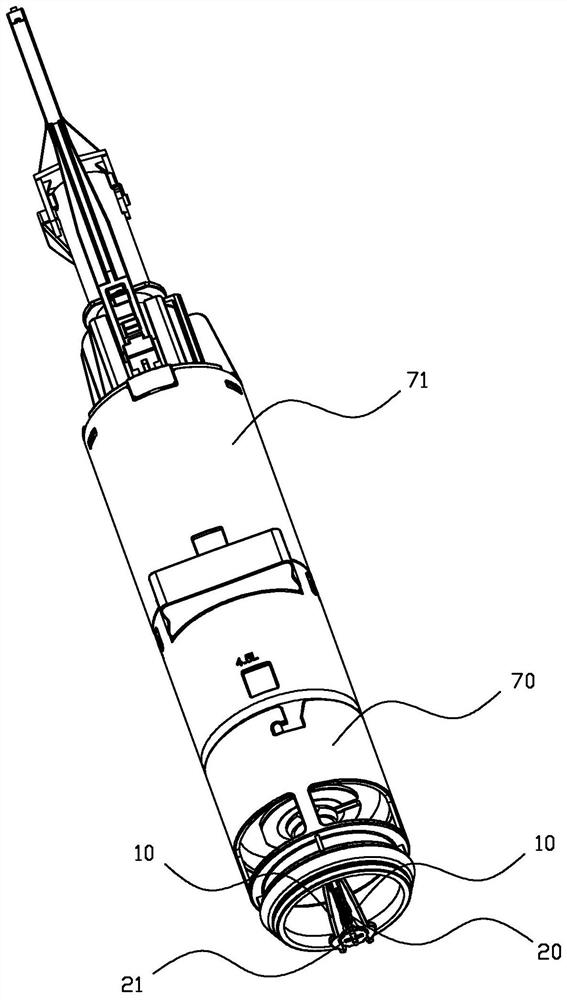

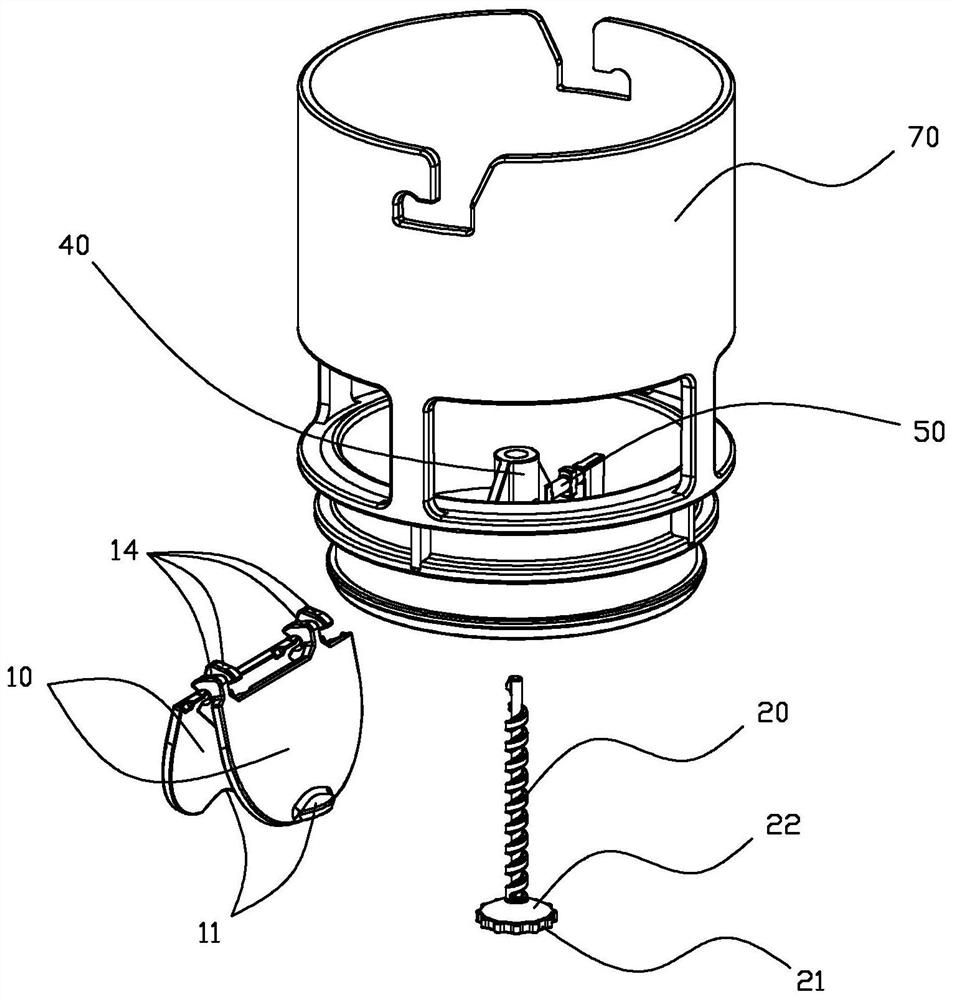

[0044] The present invention changes the water passing area of the water outlet of the drain valve by adjusting the posture change of the flap 10, so that under the same water displacement and water pressure, different water passing areas can obtain different drainage speeds. In the present invention, if Figure 2 to Figu...

Embodiment 2

[0055] Such as Figure 9 to Figure 15 As shown, in this embodiment, the adjustment mechanism includes a rotating rod 30 and a push assembly. The push assembly is a sleeve 31 provided with external threads. It rotates following the rotation of the rotation lever 30 . The inside of the drain valve near the water outlet is provided with an adjustment seat 40, the adjustment seat 40 is provided with an internal thread, the sleeve 31 is screwed on the adjustment seat 40, and the rise and fall of the sleeve 31 is controlled by rotating the rotating rod 30 to control the adjustment. The flip angle of the board 10 in the vertical direction. When adjusting the height of sleeve 31, turn rotating rod 30, sleeve 31 rotates with the rotation of rotating rod 30, because sleeve 31 rotates synchronously with rotating rod 30, and can slide on rotating rod 30, then sleeve 31 rotates process, that is, to move up and down along the rotating rod 30 , and then push or release the adjustment flap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com