Steam generator having steam chamber and metering orifice arranged near rear of steam chamber

A technology of a steam generator and a steam chamber, which is applied to the steam generator field of a garment steamer, can solve problems such as splashing at the outlet of the steam chamber, and achieve the effect of preventing the splashing problem and improving the user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

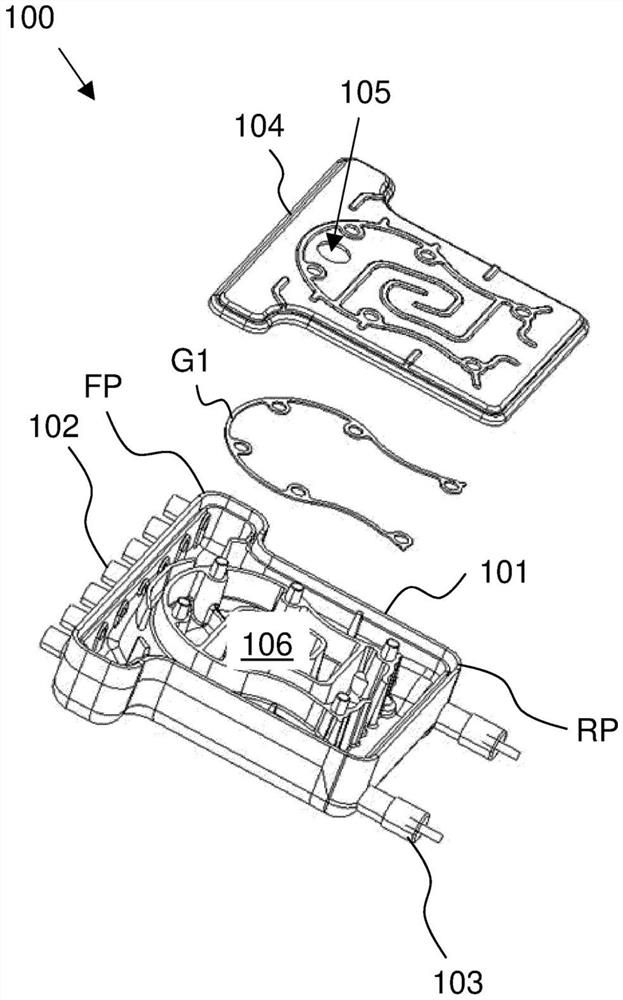

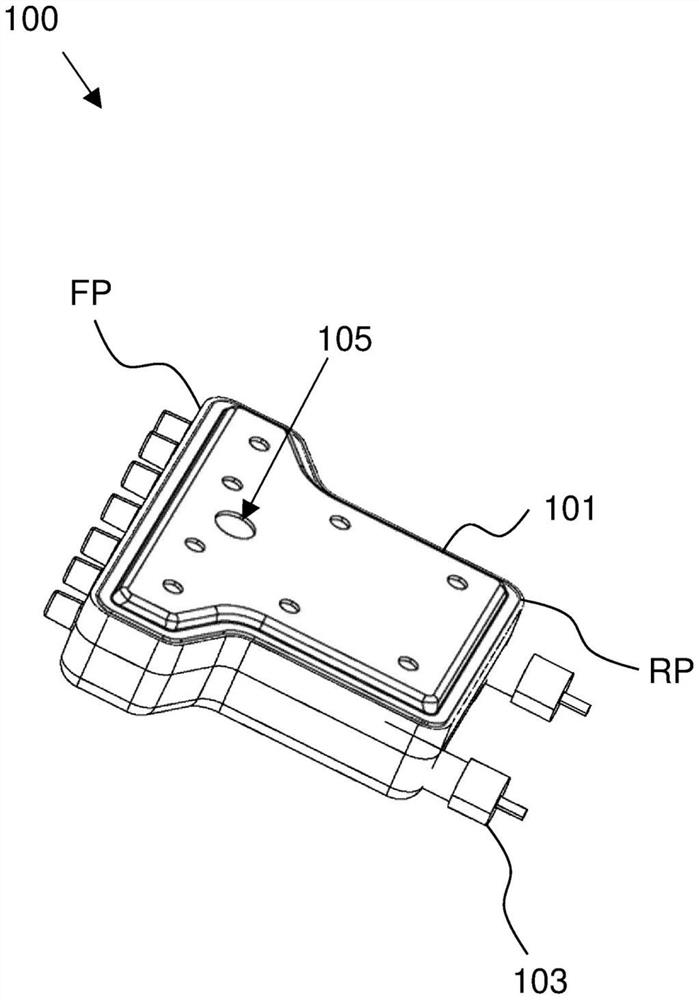

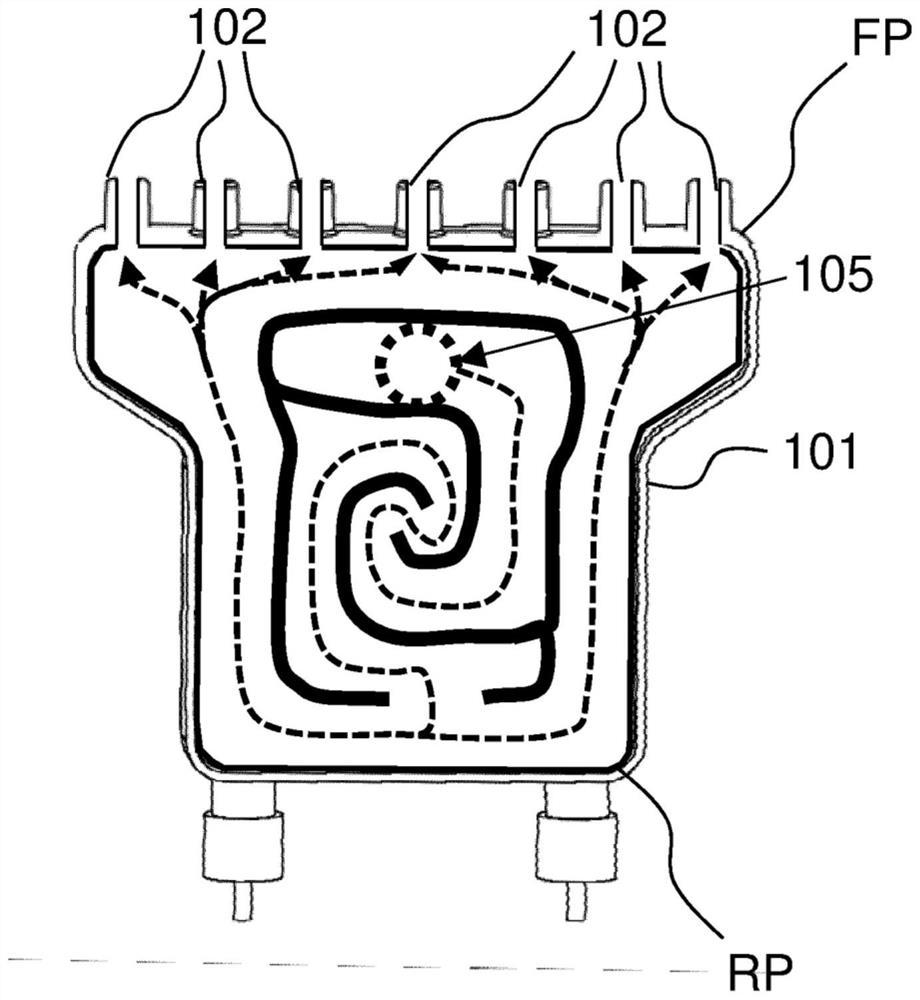

[0040] Figure 2A A first (exploded) view of a steam generator 200 according to the invention is shown, Figure 2B shows as Figure 2A Second (assembled) view of the steam generator shown.

[0041] The steam generator 200 includes a steam chamber 201 for generating steam. The steam chamber 201 extends between the front FP and the rear RP. The steam generator 200 also includes at least one steam outlet 202 arranged at the front FP and receiving steam from the steam chamber 201 .

[0042] The steam generator 200 further includes: a heating element 203 for heating the steam chamber 201 .

[0043] The steam generator 200 also includes a cover 204 adapted to be in a closed position to close the steam chamber 201 . The closed position is Figure 2B shown in .

[0044] The steam generator 200 further includes: a dosing hole 205 arranged in the cover 204 for receiving water and / or steam from the outside of the steam generator 200 . Such as Figure 2B As shown, the dosing aper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com