Toner box

A toner cartridge and toner technology, applied in the field of toner cartridges, can solve problems such as defects, toner clogging, image quality, etc., to promote flow, reduce residual toner amount, and improve toner transfer performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

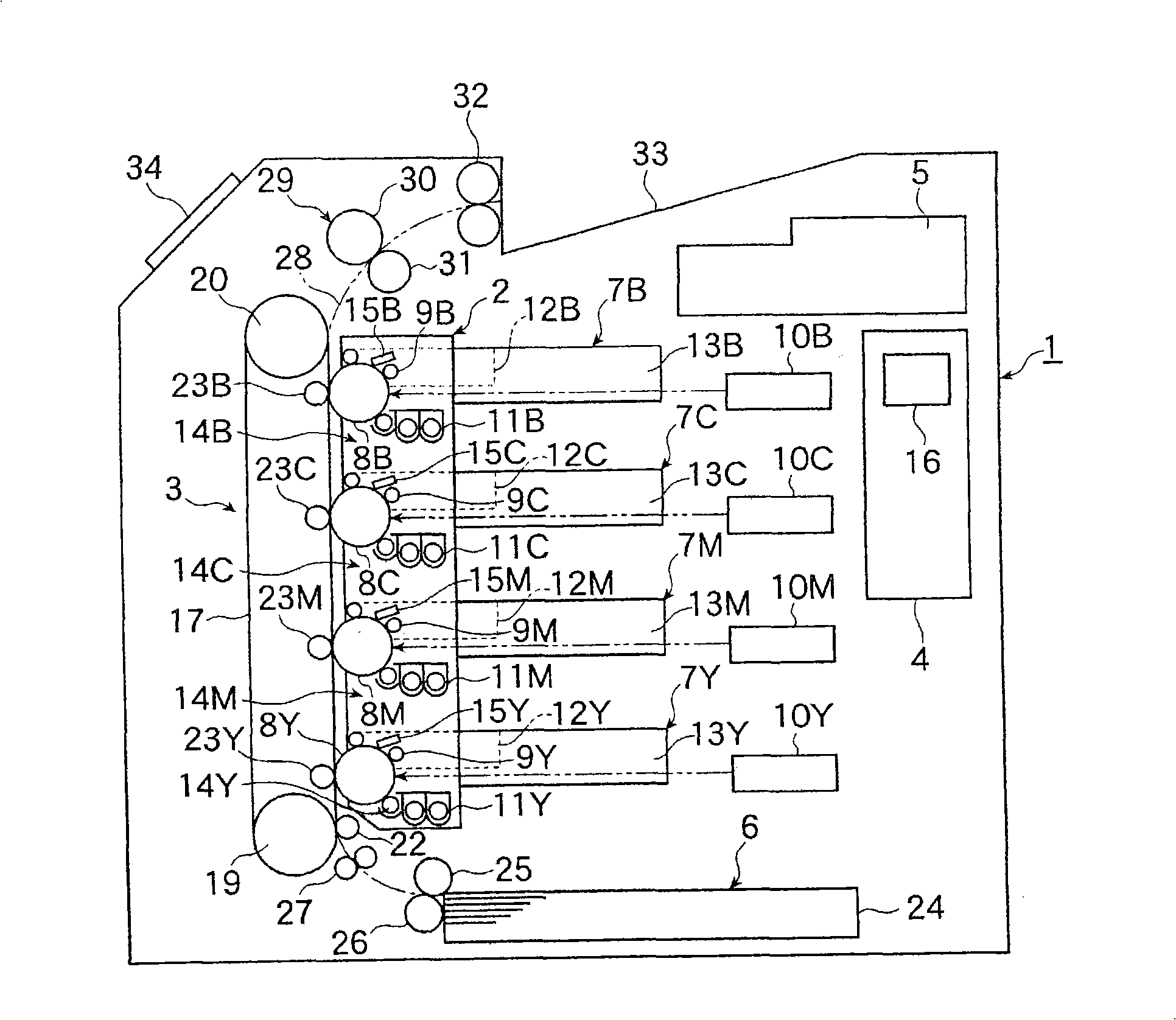

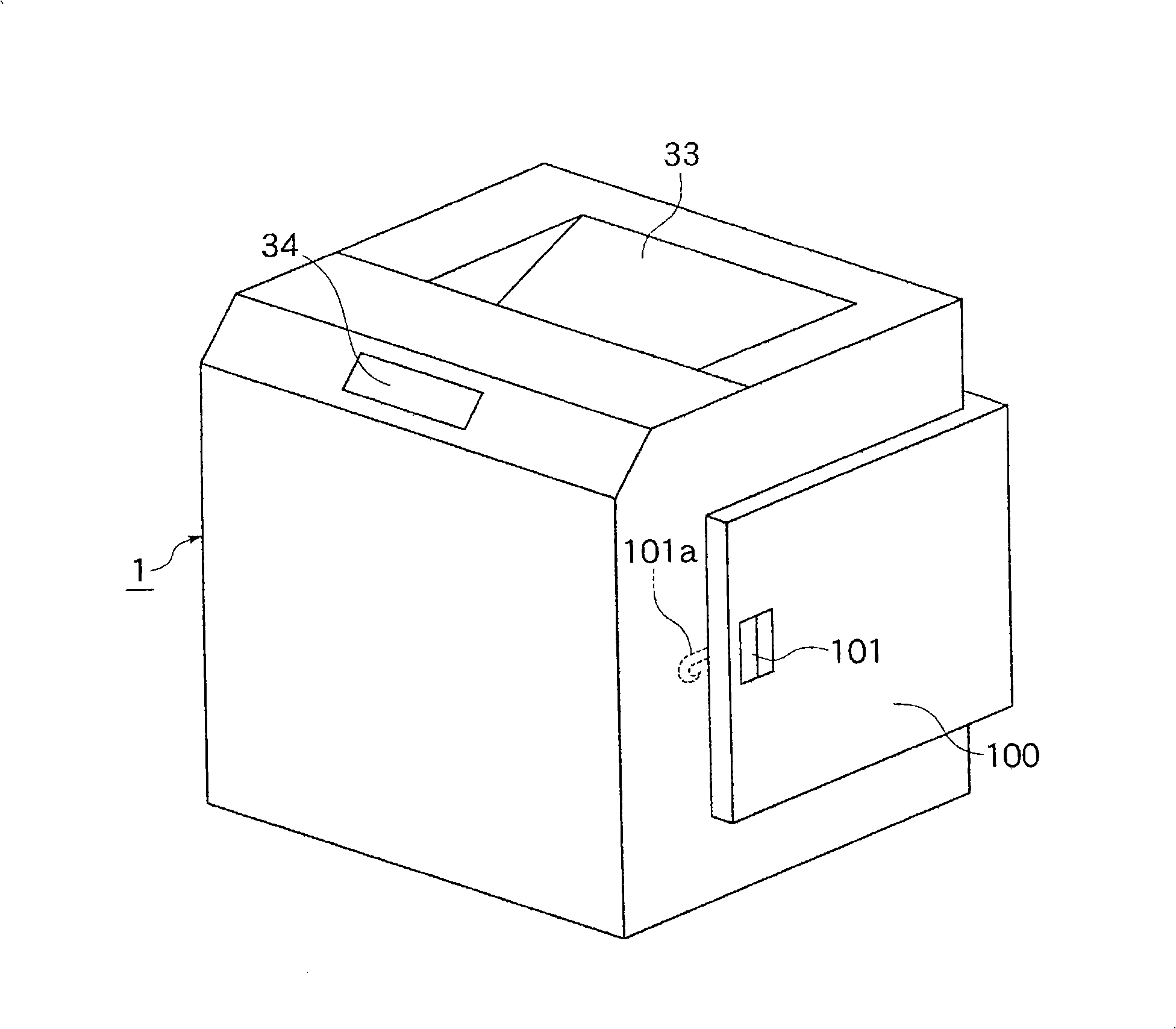

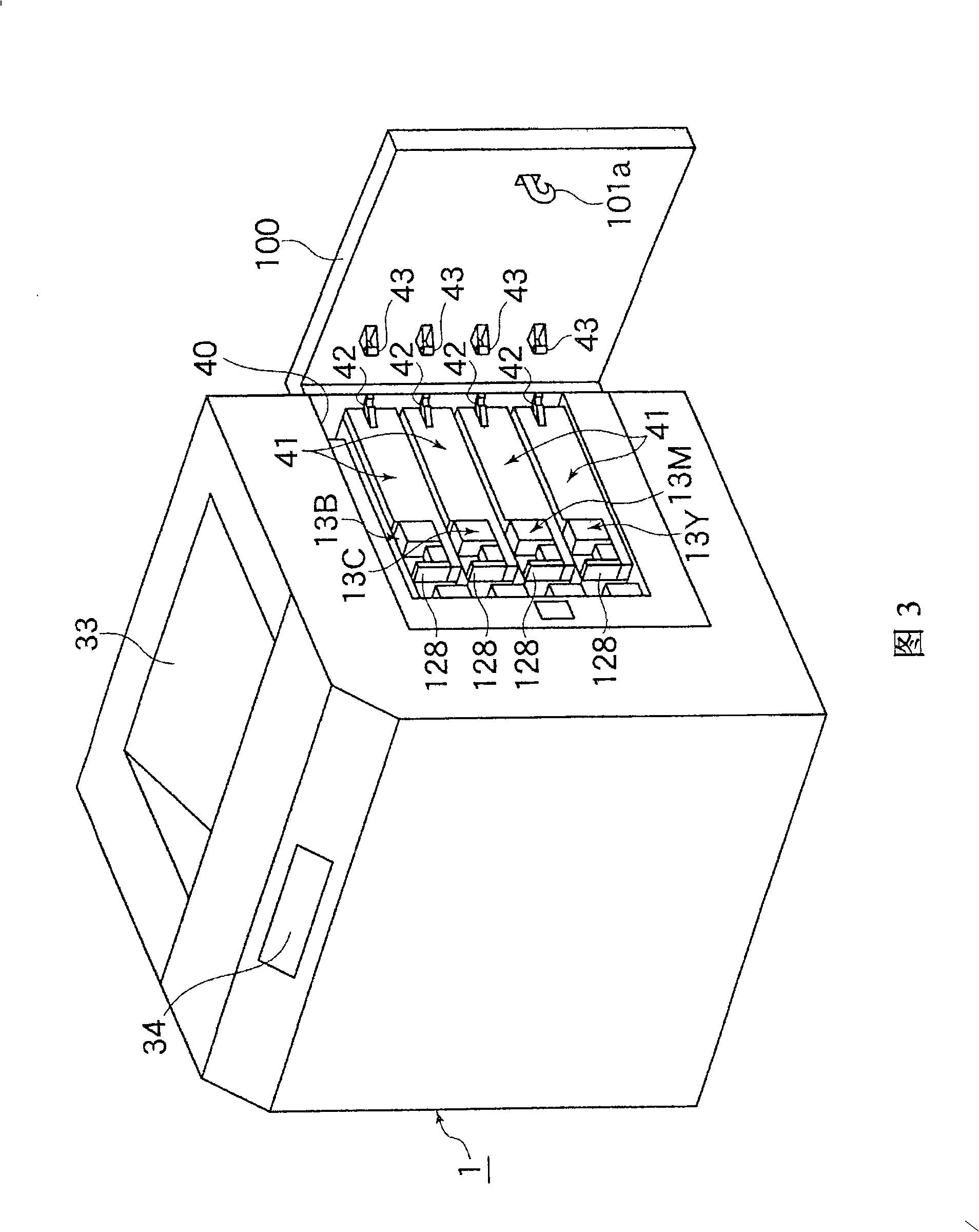

Method used

Image

Examples

example

[0161] Hereinafter, the present invention will be explained based on examples. Meanwhile, the present invention is not limited to these examples. In addition, "parts" in the following examples mean "parts by weight".

[0162] (1) Preparation of toner

manufacture example 1

[0164] 88 parts of polyester resin (polyester obtained from terephthalic acid, bisphenol A-ethylene oxide adduct and trimellitic anhydride: glass softening temperature 62°C, number average molecular weight 5,320, weight average molecular weight 24,500 , acid value 17, hydroxyl value 33), 7 parts of polyethylene wax (Polywax725: manufactured by Toyo-Petrolite Co., Ltd., DSC endothermic peak 102 ° C) and 5 parts of black pigment (carbon black #25B: manufactured by Mitsubishi Chemical Company Manufacture) Various ingredients are added and initially mixed, then kneaded using an extruder, and then the mixture is pulverized using a jet mill.

[0165] Then, the pulverized product was classified using a Coanda effect type classifier to obtain a classified product having a volume median particle diameter of 6.5 μm and 20 percent of the particles were not larger than 4 μm. 0.1 parts by weight of a hydrophobic titanium oxide compound and 1.2 parts by weight of silica treated with silicon...

manufacture example 2

[0167] A graded product having a volume median particle diameter of 6.5 μm was obtained by the same manufacturing method as in Manufacturing Example 1, and then the addition amount of silicon oil-treated silica as an external additive was changed to 0.8 parts by weight and the addition amount of the titanium compound was changed to 0.2 parts by weight to obtain Toner B. Toner B has a compression ratio of 0.38 and a shape factor SF of 142.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com