Ball milling technology

A ball milling and technical technology, applied in the direction of grain processing, etc., can solve the problems of destroying the product quality of lithium iron phosphate cathode material, changing lithium iron phosphate ingredients, and destroying equipment, etc., to prevent equipment damage, improve product quality, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

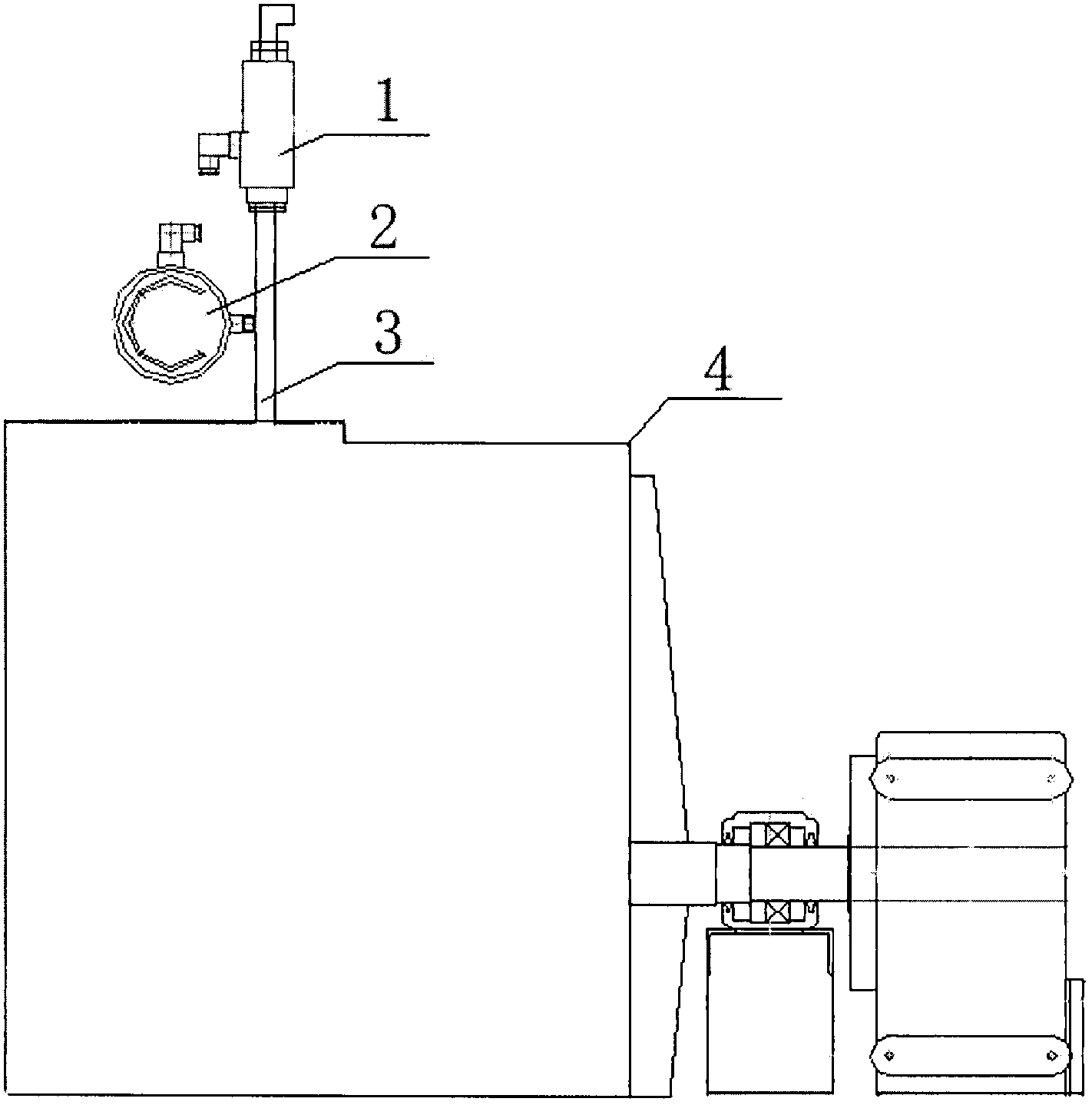

[0012] As shown in the figure, a ball milling technology includes a ball milling technology body, the cavity 4 of the ball milling technology body is connected in series with an electric contact pressure gauge 2 and a solenoid valve 1 through an exhaust pipe 3, and the electric contact pressure gauge and the solenoid valve control circuit connection. The electric contact pressure gauge monitors the cavity pressure of the ball mill. When the internal pressure is higher than the set pressure, the control circuit of the solenoid valve opens the solenoid valve and is in the exhaust state to reduce the internal pressure of the cavity and effectively solve the internal pressure of the existing ball mill technology. If it is too large, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com