Low-cost calcium treatment method of ultralow-carbon high-aluminum steel

A carbon-high-aluminum steel, calcium treatment technology, applied in low-cost calcium treatment of ultra-low-carbon high-aluminum steel, calcium treatment process field of molten steel, can solve the burning RH furnace equipment production equipment accident, molten steel splashing and violent tumbling of molten steel , molten steel splashing and other problems, to achieve the effect of reducing the tumbling of molten steel, reducing production costs, and preventing the nitrogen increase of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

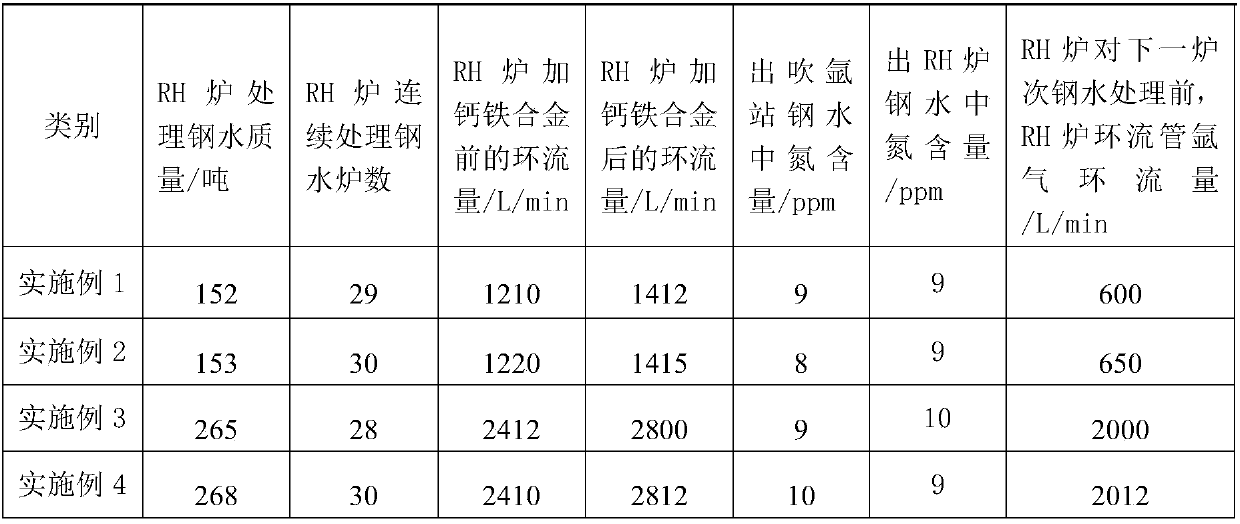

Examples

Embodiment Construction

[0021] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0022] A low-cost calcium treatment method for ultra-low-carbon high-aluminum steel, comprising the following steps:

[0023] 1) Decarburize the molten steel, and decarburize the molten steel entering the RH furnace at a vacuum degree of 270Pa or less for 10 to 20 minutes;

[0024] 2) Use silicon to deoxidize molten steel after decarburization, and cycle for more than 3 minutes; then add an appropriate amount of aluminum block to the composition design range, and after the last batch of alloy is added, cycle 4 at a circulating flow rate of 1600-3000L / min -6 minutes; Sampling and detection of Alt and Als in molten steel;

[0025] 3) Switch the molten steel treatment mode of the RH furnace to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com