Construction method for achieving blowout prevention during drilling pressure relief of mine

A construction method and blowout prevention technology, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as inability to continue drilling construction, damage construction personnel, and drilling blowout holes, etc., and achieve a solution The effect of coal and rock particle splashing, improving safety, and solving gas impact problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

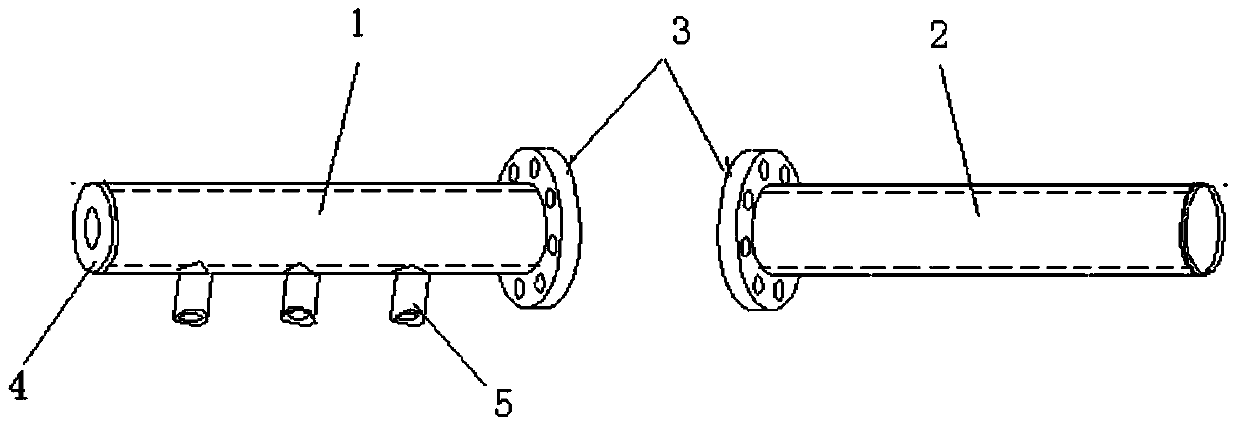

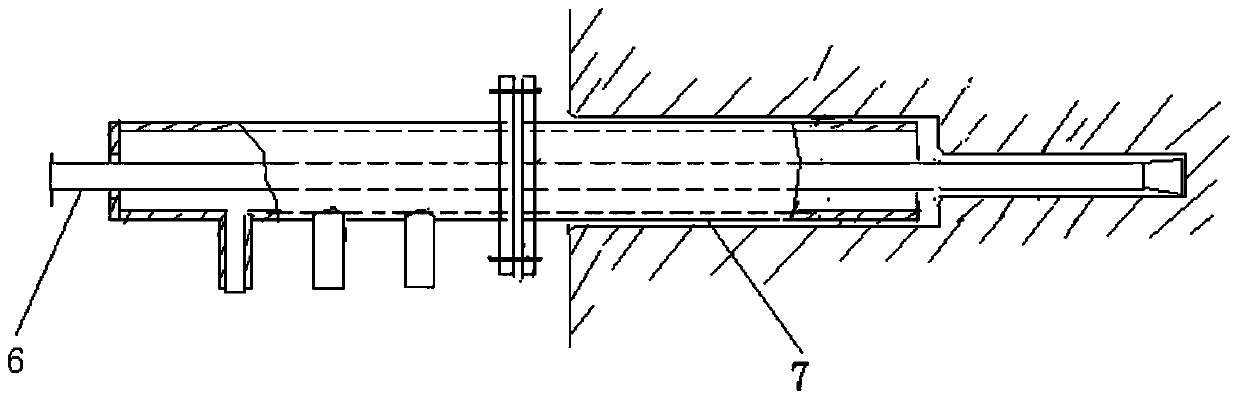

[0012] Such as figure 1 figure 2 The blowout prevention and anti-scouring construction method when the mine borehole pressure relief is shown, it includes:

[0013] The first step is to take two steel pipes with the same diameter. The diameter of the steel pipe is 2-3 times larger than the diameter of the drilled hole. The opposite ends of the two steel pipes are respectively welded to the corresponding flanges 3; one of them is used as the hole for inserting into the drilled hole The fixed pipe 2, the other section is used as the blowout preventer 1 outside the hole, and the circular plate 4 with a socket is welded on one end of the blowout preventer 1. It is required that the diameter of the hole should just pass through the drill bit, and the blowout preventer 1 faces downward. 2-4 pressure relief holes are processed on the side of each pressure relief hole, and a protective pipe 5 is welded on each pressure relief hole;

[0014] The second step is to open an installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com