A Dynamic Bottom Blowing Method of Converter Based on Audio Slagging

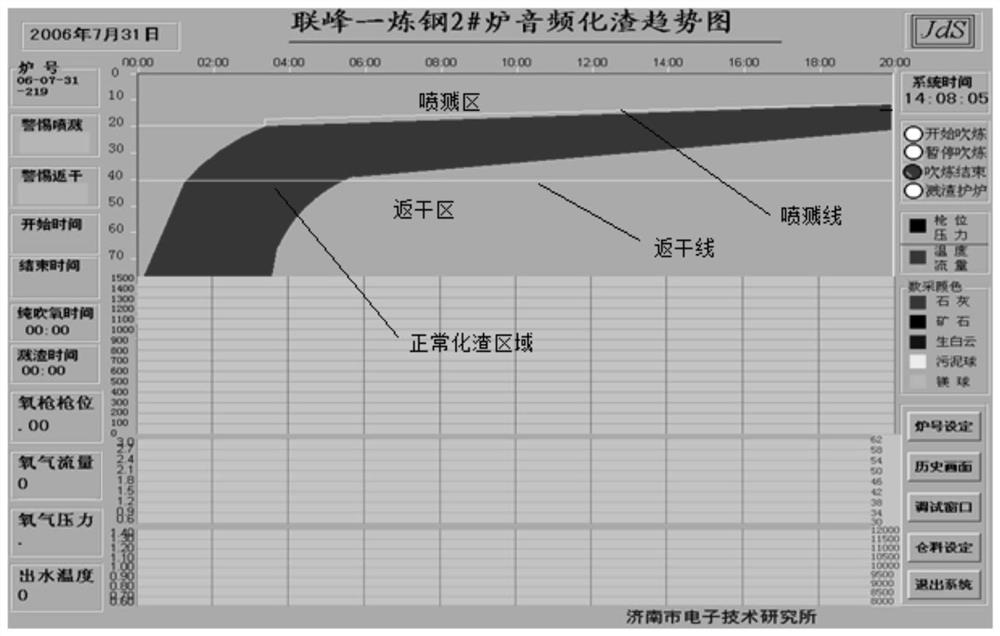

An audio frequency and converter technology, which is applied in the field of dynamic bottom blowing of converters based on audio frequency slag slag treatment, can solve the problems of poor improvement effect of bottom blowing, inability to adjust adaptively, and ineffective bottom blowing effect, so as to stabilize converter operation and solve the problems of bottom blowing. Untimely adjustment of splashing and back-drying, improving the effect of bottom blowing slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A dynamic bottom blowing method for converters based on audio frequency slag removal. In this embodiment, the steel type Q345R is produced. Taking a 120T converter as an example, add 130t of molten iron, 10t of scrap steel, 0.55% of silicon content in molten iron, 0.145% of phosphorus content, and a temperature of 1322°C , Q345R requires phosphorus content ≤ 0.020%.

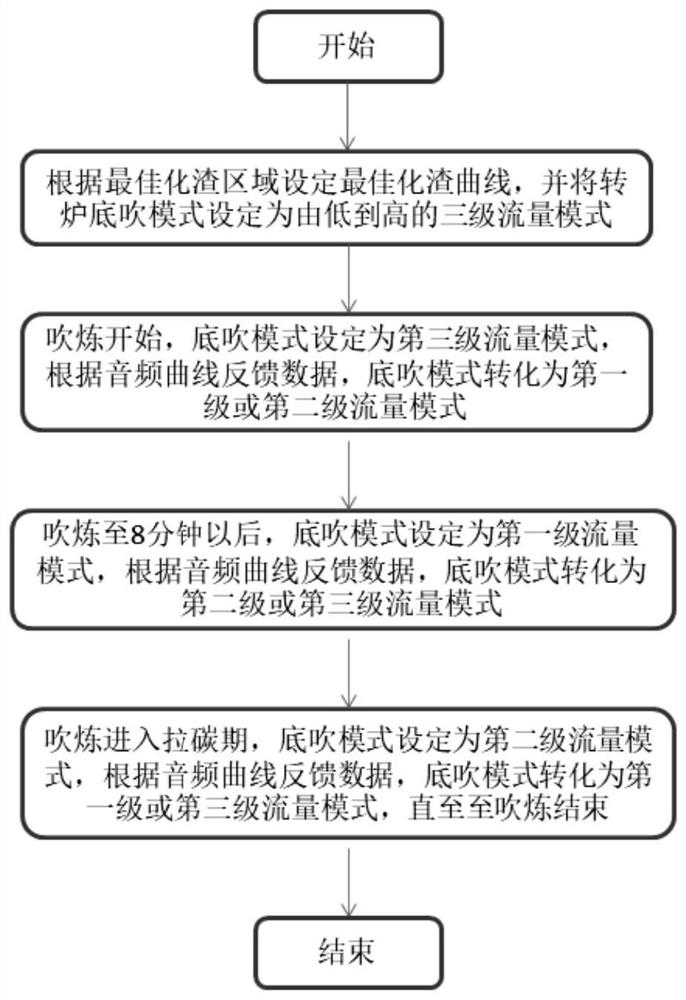

[0034] The control method is as follows:

[0035](1) When blowing starts, set the third-level flow mode (single gun 150L / min) for the bottom blower. If the audio curve approaches the back-drying area for more than 5 seconds, the bottom blower will automatically switch to the second-level flow mode (single gun 100L / min), until converted to the first level flow mode (single gun 60L / min).

[0036] (2) After 8 minutes of blowing, the reaction in the furnace enters the dry-back period, and the bottom blowing flow rate is set to the first-level flow mode. According to the audio frequency slag detection results...

Embodiment 2

[0042] Different from Example 1, the setting mode conversion time is 3 seconds, and the results are as follows:

[0043] Using this operation method, under the same operation model, the control of the smelting process is stable, there is no splashing and dry-back, the end-point determination of phosphorus is 0.025%, the steel output is 131.5t, the blowing loss is 6.2%, and the composition control is qualified.

Embodiment 3

[0045] Different from Example 1, the setting mode conversion time is 9 seconds, and the results are as follows:

[0046] With this operation method, the control of the smelting process is stable, there is no splashing and back-drying, the end-point determination of phosphorus is 0.023%, the steel output is 131.2t, the blowing loss is 6.5%, and the composition control is qualified.

[0047] In addition, the inventors have obtained through experiments of different mode conversion times that if the mode conversion time is lower than 3 seconds or higher than 10 seconds, the slag removal effect in the furnace cannot be improved in time, so the mode conversion time setting of 5 seconds is the best setting .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com