Galvanizing bake hardening steel plate with timeliness being larger than 6 months and production method of galvanizing bake hardening steel plate

A baking hardening and production method technology, applied in the field of metallurgy, can solve problems such as insufficient aging resistance, achieve the effects of solving insufficient aging resistance, improving aging resistance, and reducing precipitation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

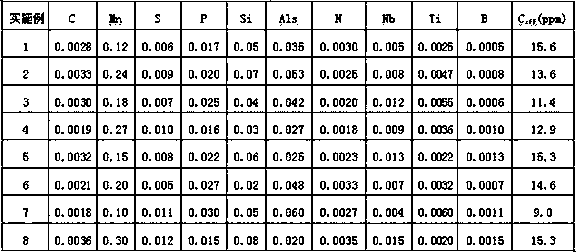

[0019] In this embodiment, the specification of the galvanized bake-hardened steel plate with a timeliness of more than 6 months is 0.6mm*1200mm, and its chemical composition and mass percentage are shown in Table 1.

[0020] The production method of the galvanized bake-hardened steel plate with a timeliness of more than 6 months in this embodiment includes molten iron pretreatment, decarburization converter, RH vacuum treatment, continuous casting, slab hot charging, hot rolling, acid continuous rolling, continuous hot dipping Zinc, post-plating finishing process, the specific process steps are as follows:

[0021] (1) Decarburization converter process: After the molten iron is pretreated, it is decarburized to 0.035% by decarburization converter;

[0022] (2) RH vacuum treatment process: RH outbound B content is controlled at 0.0008%;

[0023] (3) Continuous casting process: the continuous casting process protects the casting, and controls N at 0.0030%;

[0024] (4) Slab h...

Embodiment 2

[0031] In this embodiment, the specification of the galvanized bake-hardening steel plate with a timeliness of more than 6 months is 1.0 mm*1325 mm in thickness, and its chemical composition and mass percentage are shown in Table 1.

[0032] The production method of the galvanized bake-hardened steel plate with a timeliness of more than 6 months in this embodiment includes molten iron pretreatment, decarburization converter, RH vacuum treatment, continuous casting, slab hot charging, hot rolling, acid continuous rolling, continuous hot dipping Zinc, post-plating finishing process, the specific process steps are as follows:

[0033] (1) Decarburization converter process: After the molten iron is pretreated, it is decarburized to 0.040% by decarburization converter;

[0034] (2) RH vacuum treatment process: RH outbound B content is controlled at 0.0010%;

[0035] (3) Continuous casting process: the whole process of continuous casting is protected and casted, and N is controlled...

Embodiment 3

[0043] In this embodiment, the specification of the galvanized bake-hardening steel plate with a timeliness of more than 6 months is 0.8mm*1300mm, and its chemical composition and mass percentage are shown in Table 1.

[0044] The production method of the galvanized bake-hardened steel plate with a timeliness of more than 6 months in this embodiment includes molten iron pretreatment, decarburization converter, RH vacuum treatment, continuous casting, slab hot charging, hot rolling, acid continuous rolling, continuous hot dipping Zinc, post-plating finishing process, the specific process steps are as follows:

[0045] (1) Decarburization converter process: After the molten iron is pretreated, it is decarburized to 0.045% by decarburization converter;

[0046] (2) RH vacuum treatment process: RH outbound B content is controlled at 0.0012%;

[0047] (3) Continuous casting process: the whole process of continuous casting is protected and casted, and N is controlled at 0.0032%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com