A kind of high alkali resistance basalt fiber composition and its application method

A technology of basalt fiber and application method, which is applied in the field of basalt fiber materials, can solve problems such as polluted air, unsatisfactory alkali resistance, and hazards of surrounding biological growth, and achieves a small loss rate of tensile strength, avoiding phase separation defects, and wire drawing operations The effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

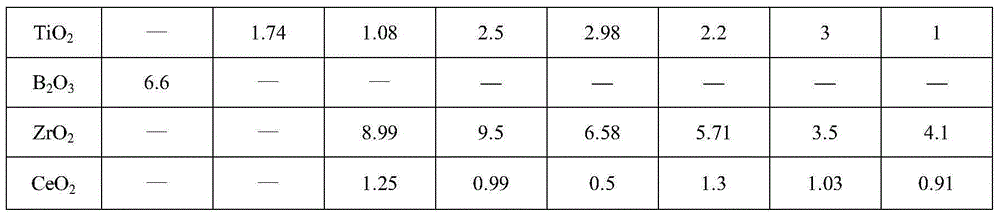

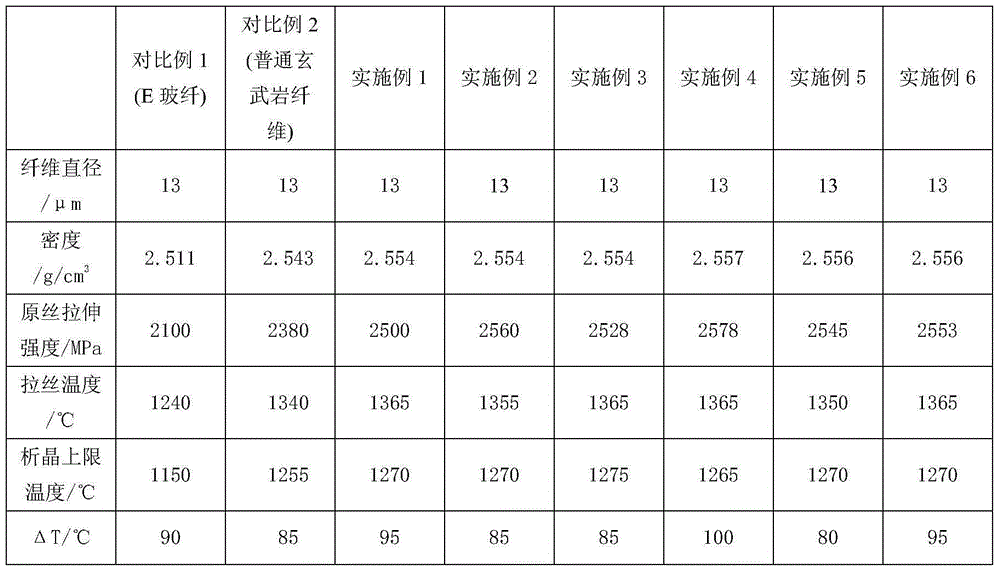

[0105] The alkali-resistant basalt fibers of Examples 1 to 6, under the same alkali corrosion conditions, the mass loss rate of the basalt fibers of Comparative Example 1 and Comparative Example 2 is greatly reduced. For example, when the etching time is 2 hours and the etching temperature is 25°C, the mass loss rate of Comparative Example 1 is 6.3%, the mass loss rate of Comparative Example 2 is 4.2%, and the mass loss rate of Example 1 is 1.3%. The mass loss rate of Example 1 was reduced by 79% compared with Comparative Example 1, and by 69% compared with Comparative Example 2. When the etching time is 4 hours and the etching temperature is 100°C, the mass loss rate of Comparative Example 1 is 9.7%, the mass loss rate of Comparative Example 2 is 7.3%, and the mass loss rate of Example 6 is 2.9%. The mass loss rate of Example 6 was reduced by 70% compared to Comparative Example 1, and 60% compared with Comparative Example 2. This indicates that the basalt fiber composition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com