Third-generation nickle base monocrystal high temperature alloy with stable texture and preparation method

A nickel-based single crystal, high-temperature alloy technology, applied in the field of high-temperature alloys, can solve the problems of increasing the heat treatment temperature, increasing the heat treatment time, weakening the effect of alloy performance improvement, and destroying the continuity of the single crystal structure, so as to reduce the tendency of TCP precipitation and alloy segregation , the effect of improving the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation process of this embodiment is:

[0073] Step 1, prepare master alloy ingot:

[0074] Carry out batching according to the alloy composition described in Table 1. Master alloys were prepared by vacuum induction melting using conventional methods. The alloy is refined at 1540°C to 1580°C for 5 minutes. After refining, cool down to 1500°C to 1540°C and cast. get the size as master alloy ingots.

[0075] The obtained master alloy ingot was polished to remove scale, and was used to prepare single crystal rod after ultrasonic cleaning with alcohol.

[0076] Step 2, prepare single crystal test rod:

[0077] The single crystal test rod was prepared in a directional solidification furnace by adopting the seed crystal method + spiral crystal selection method in the prior art.

[0078] The cleaned master alloy block is placed in the crucible, the draft tube is placed under the crucible, and the mold shell with the pre-seed crystal is fixed on the crystallizati...

Embodiment 1

[0096] The instantaneous tensile properties of the alloy in Example 1 and the alloy in Example 11 at different temperatures are shown in Table 5.

[0097] table 5

[0098]

[0099] The instantaneous tensile properties at different temperatures of typical third-generation nickel-based single crystal superalloys in the prior art are shown in Table 6.

[0100] Table 6

[0101]

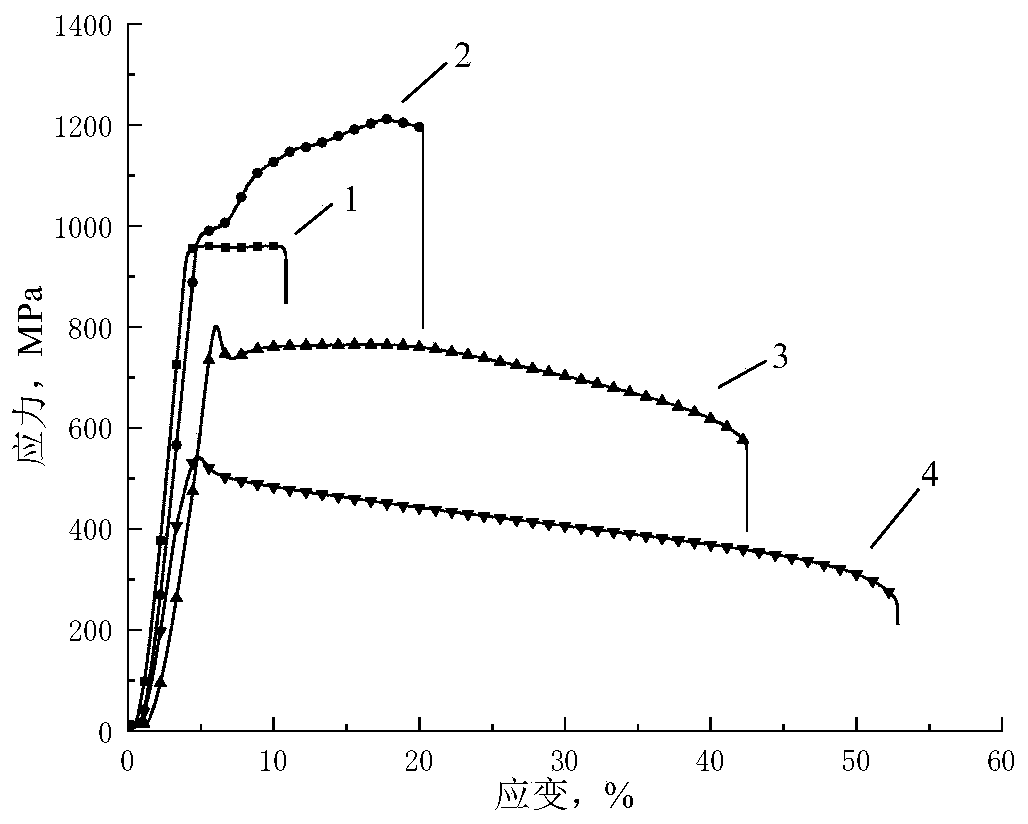

[0102] Comparing the tensile properties of the alloys in Table 5 and Table 6, it can be seen that the alloy of Example 1 with high W content has effectively improved the yield strength and tensile strength of the alloy compared with Example 11. At room temperature, the tensile properties of the alloys of Example 1 and Example 11 are better than those of TMS-75 alloy. At 760 ° C, the yield strength and tensile strength of the alloy in Example 1 reached the highest as figure 2 As shown, the performance of the Example 1 alloy at this temperature is close to that of the TMS-75 alloy at 750°C. At 98...

Embodiment 11

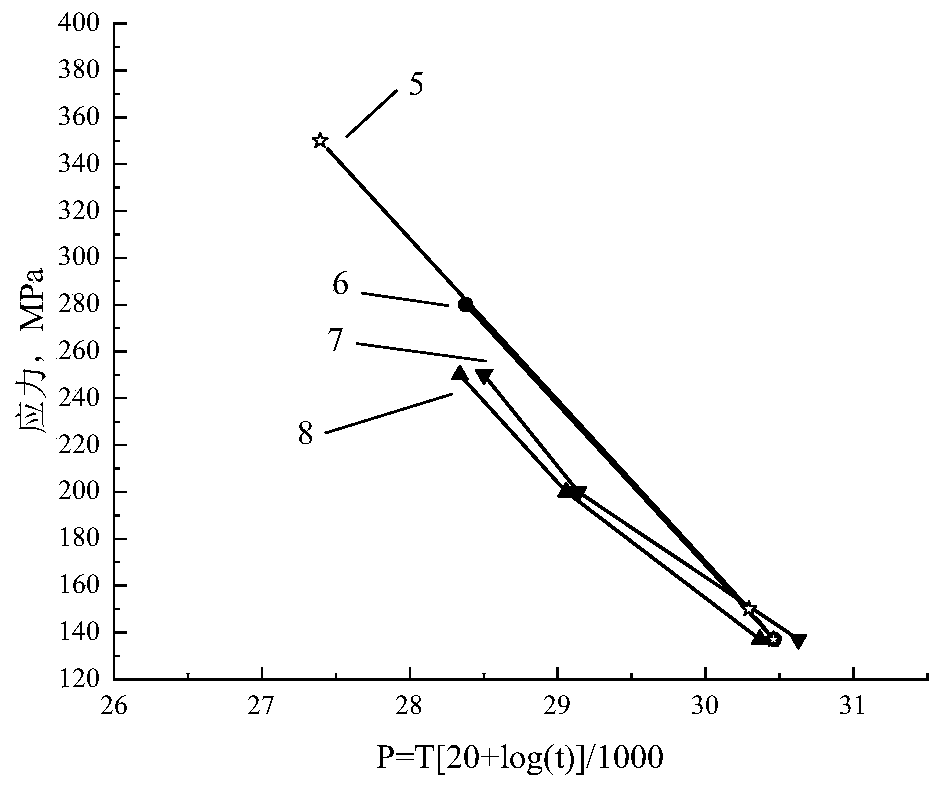

[0109] The performance data of Example 11 under different creep conditions are shown in Table 8.

[0110] The creep performance of table 8 embodiment 11 alloy

[0111] Creep condition Creep life h Elongation% Larson-Miller parameter P 1100℃ / 150MPa 83.6 24.91 30.10 1100℃ / 150MPa 86.2 22.34 30.12 1100℃ / 150MPa 89.4 26.57 30.14 1100℃ / 137MPa 93.1 18.75 30.16 980℃ / 350MPa 68.8 39.42 27.36

[0112] For comparison of the creep curves of Example 1 and Example 11 at 1100°C / 150MPa, see Figure 4 . Comparing the creep curve Curve 9 of the alloy in Example 1 at 1100°C / 150MPa with the creep curve 10 of the alloy in Example 11 at 1100°C / 150MPa, it can be seen that when the Re content is 4wt.%, the W element is added to the alloy , the high temperature mechanical properties of the alloy are significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com