Smoke-suppression non-cured rubber bitumen waterproof coating material

A technology of asphalt waterproof coating and non-curing rubber, applied in asphalt coatings, fire-retardant coatings, wax coatings, etc., can solve the problems of releasing a large amount of water, melting at high temperature, and affecting physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

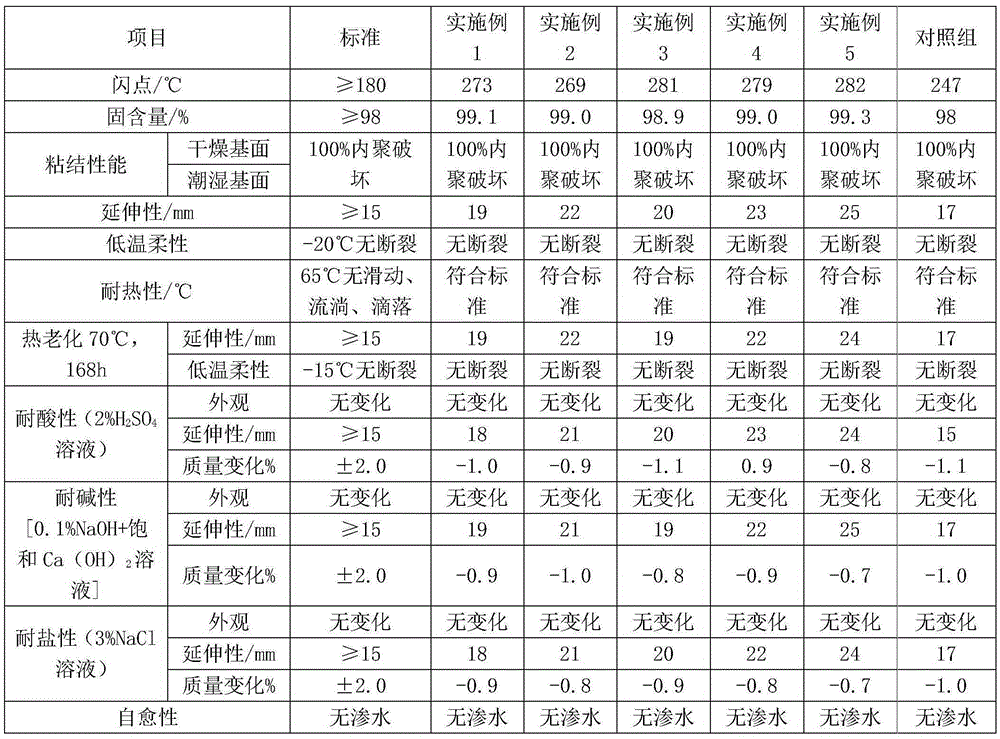

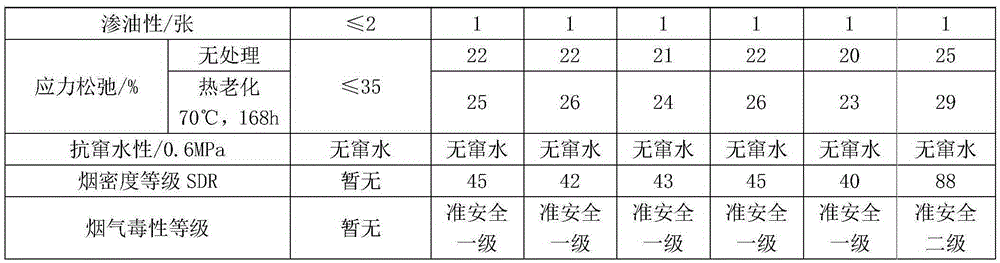

Examples

Embodiment 1

[0020] A smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include by weight: 28 parts of No. 10 construction asphalt, styrene-butadiene-styrene block ratio of styrene and butadiene is 30:70 3 parts of segment copolymer, 3.5 parts of styrene-butadiene rubber, 15 parts of paraffin oil, 3 parts of No. 200 solvent oil, 15 parts of 60 mesh reclaimed rubber powder, 25 parts of 200 mesh heavy calcium carbonate, 7 parts of 100 mesh asbestos wool, 150 mesh 8 parts of fly ash, 3 parts of terpene resin, 2 parts of epoxy resin, 1 part of epoxidized soybean oil, 10761.5 parts of antioxidant, 2920.1 parts of light stabilizer, 0.5 part of 2,4-dihydroxybenzophenone, 0.5 parts of ABS-g-MAH, 0.7 parts of dicumyl peroxide, 0.3 parts of vinyltriethoxysilane, 6 parts of microencapsulated red phosphorus, 1 part of modified smoke suppressant, and 1 part of C9 petroleum resin;

[0021] Among them, the preparation method of the modified smoke suppressant is: adding 800...

Embodiment 2

[0023] A smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include by weight: 20 parts of No. 100 road asphalt, styrene-butadiene-styrene block ratio of styrene and butadiene is 40:60 7 parts of segment copolymer, 2.5 parts of styrene-butadiene rubber, 20 parts of paraffin oil, 1 part of No. 200 solvent oil, 5 parts of 90 mesh reclaimed rubber powder, 20 parts of 300 mesh heavy calcium carbonate, 3 parts of 150 mesh asbestos wool, 200 mesh 4 parts of fly ash, 6 parts of terpene resin, 0.5 part of epoxy resin, 3 parts of epoxidized soybean oil, 10760.5 parts of antioxidant, 2920.3 parts of light stabilizer, 0.3 part of 2,4-dihydroxybenzophenone, 1 part of ABS-g-MAH, 0.3 part of dicumyl peroxide, 0.5 part of vinyltriethoxysilane, 4 parts of microencapsulated red phosphorus, 2 parts of modified smoke suppressant, 0.5 part of C9 petroleum resin;

[0024] Among them, the preparation method of the modified smoke suppressant is: adding 1000 mesh expand...

Embodiment 3

[0026]A smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include by weight: 26 parts of No. 10 construction asphalt, styrene-butadiene-styrene block ratio of styrene and butadiene is 30:70 4 parts of segment copolymer, 3.2 parts of styrene-butadiene rubber, 17 parts of paraffin oil, 2.5 parts of No. 200 solvent oil, 12 parts of 65 mesh reclaimed rubber powder, 24 parts of 230 mesh heavy calcium carbonate, 6 parts of 120 mesh asbestos wool, 160 mesh 7 parts of fly ash, 4 parts of terpene resin, 1.5 parts of epoxy resin, 1.5 parts of epoxidized soybean oil, 10761.3 parts of antioxidant, 2920.15 parts of light stabilizer, 0.45 part of 2,4-dihydroxybenzophenone, 0.7 parts of ABS-g-MAH, 0.6 parts of dicumyl peroxide, 0.35 parts of vinyltriethoxysilane, 5.5 parts of microencapsulated red phosphorus, 1.3 parts of modified smoke suppressant, and 0.8 parts of C9 petroleum resin;

[0027] Among them, the preparation method of the modified smoke suppressa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com