Nickel-based powder superalloy and its preparation method and application

A technology of superalloy and nickel-based powder, applied in the field of powder superalloy, can solve the problem of inability to meet long-lasting high performance, achieve uniform microstructure, uniform alloy composition, and improve the degree of alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of embodiment 1 nickel base powder superalloy

[0062] Prepare 1 with the ingredients listed in Table 1 and their contents as raw materials # ~5 # Nickel based powder superalloy.

[0063] Table 1 Composition and preparation conditions of nickel-based powder superalloy samples

[0064]

[0065]

[0066] The preparation method is as follows:

[0067] S1. Prepare raw materials according to the chemical composition and mass fraction of the powdered superalloy, and prepare alloy rods by using a 25kg vacuum induction melting process;

[0068] S2. Using the plasma rotating electrode method to prepare superalloy powder from the alloy bar, the alloy powder is screened and electrostatically treated to obtain a finished powder with a particle size of 50 μm to 150 μm;

[0069] S3. The alloy powder is put into a low-carbon steel ladle for vacuum degassing and sealing welding;

[0070] S4. Perform hot isostatic pressing to the alloy powder after sealing and...

experiment example 1

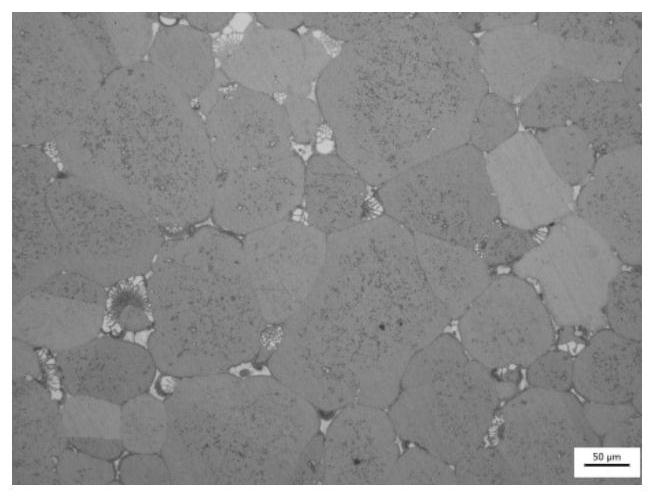

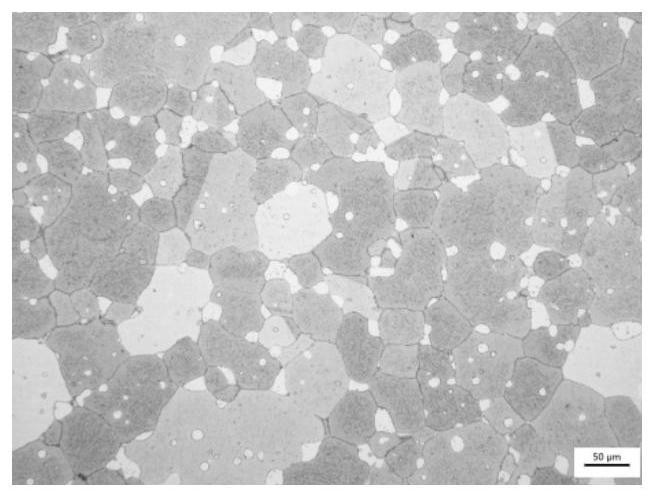

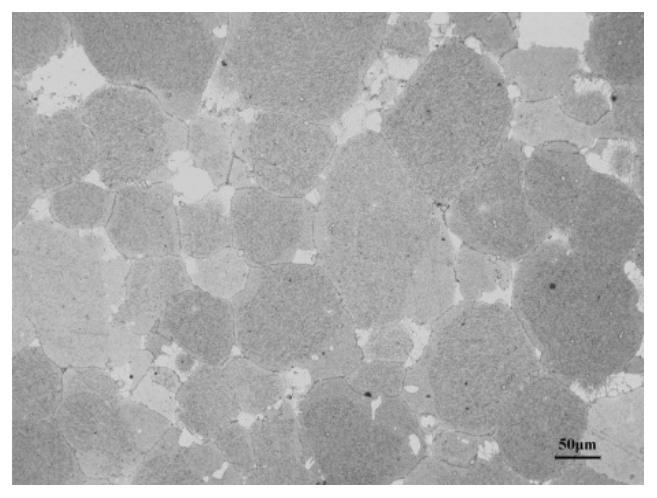

[0072] Experimental example 1 Metallographic structure characterization of nickel-based powder superalloy

[0073] Adopt Olympus GM-7 type metallographic microscope to observe the microstructure of alloy after heat treatment state and long-term aging, characterize the 1 prepared in embodiment 1 # ~5 # Metallographic structure of nickel-based powder superalloys.

[0074] to 4 # Nickel-based powder superalloy is typical, and its metallographic structure in the heat treatment state is as follows: figure 1 shown; 4 # The metallographic structures of nickel-based powder superalloy after aging at 815℃ / 3000h and after aging at 850℃ / 500h are as follows: figure 2 and image 3 shown.

[0075] The microstructure of the nickel-based powder superalloy provided by the present invention is mainly composed of γ, γ′, MC and M3B2 phases, and the composition of the γ′ phase is (Ni, Co) 3 (Al, Ti, Ta, Nb, Hf) type, the composition of MC type carbide is (Ti, Ta, Nb, Hf) C type.

[0076] 1...

experiment example 2

[0081] Performance Characterization of Experimental Example 2 Nickel-based Powder Superalloy

[0082] Adopt NCS GNT100 electronic tensile testing machine, GNCJ-30 mechanical type high temperature durable creep testing machine to test the 1 prepared in embodiment 1 # ~5 # Mechanical properties of nickel-based powder superalloys.

[0083] Among them, 1 # ~5 # The room temperature tensile properties, 760°C tensile properties, 815°C tensile properties, and 815°C / 450MPa durability properties of nickel-based powder superalloys are listed in Table 2, Table 3, Table 4, and Table 5, respectively.

[0084] Table 2 Room temperature tensile properties of nickel-based powder superalloys

[0085] Alloy No. σ b / MPa

σ 0.2 / MPa

δ / % ψ / % 1 #

1570 1210 11.0 12.5 2 #

1605 1240 10.0 11.5 3 #

1565 1205 11.5 12.5 4 #

1583 1225 11.0 12.0 5 #

1620 1260 9.0 10.5

[0086] Table 3 Tensile properties of nickel-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com