High-W-content high-Mo-content nickel-base high-temperature alloy and preparation method thereof

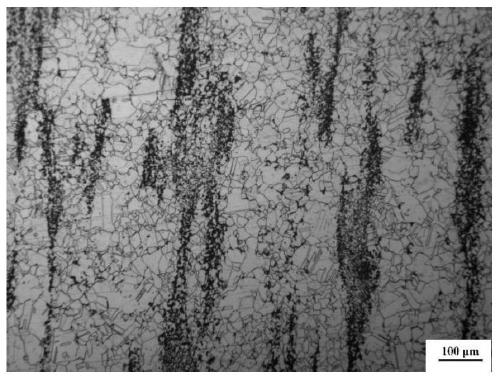

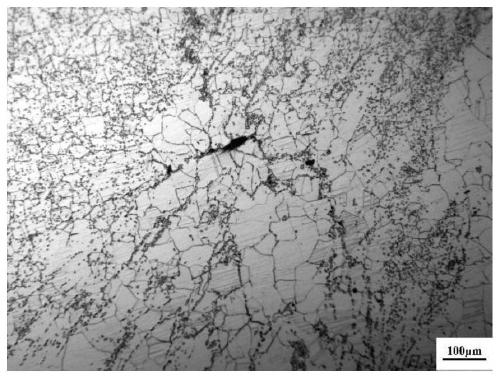

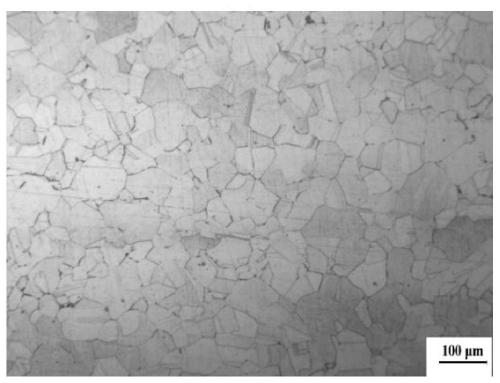

A nickel-based superalloy and content technology, applied in the direction of improving energy efficiency and process efficiency, can solve problems such as unevenness and abnormal aggregation structure, achieve uniform distribution of carbides, reduce the fluctuation range of melting parameters, reduce Effect of Precipitation Tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A nickel-based high-temperature alloy with high W and Mo content. In terms of mass percentage, the composition content of elements in the alloy is: C0.013wt%, Cr 20wt%, W 7.9wt%, Mo 7.9wt%, Al 0.6wt%, Ti 0.6wt%, Mn 0.28wt%, Si 0.15wt%, P 0.002wt%, S 0.001wt%, Fe 0.11wt%, B 0.002wt%, Ce 0.02wt%, Zr 0.02wt%, the balance being Ni.

[0029] 2. a kind of preparation method of high W, Mo content nickel base superalloy, it is characterized in that: comprise the following steps:

[0030] 1) The composition of the nickel-based superalloy alloy is calculated by mass percentage: C 0.013wt%, Cr 20wt%, W7.9wt%, Mo 7.9wt%, Al 0.6wt%, Ti 0.6wt%, Mn 0.28wt%, Si 0.15wt%, P 0.002wt%, S 0.001wt%, Fe 0.11wt%, B 0.002wt%, Ce 0.02wt%, Zr 0.02wt%, the balance is Ni; C, Cr, W, Mo, Si , P, S, Fe, and Ni are added to the crucible, and the crucible is put into a vacuum induction furnace for vacuum melting. The working vacuum degree during vacuum melting is ≤15Pa, and the melting temperature of t...

Embodiment 2

[0034] A nickel-based high-temperature alloy with high W and Mo content. In terms of mass percentage, the composition content of elements in the alloy is: C0.015wt%, Cr 20.5wt%, W 8.0wt%, Mo 8.0wt%, Al 0.65wt% , Ti 0.68wt%, Mn0.30wt%, Si 0.19wt%, P 0.010wt%, S 0.010wt%, Fe 0.15wt%, B 0.003wt%, Ce0.03wt%, Zr 0.04wt%, the balance is Ni .

[0035] A kind of preparation method of high W, Mo content nickel base superalloy, wherein: comprise the following steps:

[0036] 1) The composition of the nickel-based superalloy alloy is calculated by mass percentage: C 0.015wt%, Cr 20.5wt%, W8.0wt%, Mo 8.0wt%, Al 0.65wt%, Ti 0.68wt%, Mn 0.30wt% , Si 0.19wt%, P0.010wt%, S 0.010wt%, Fe 0.15wt%, B 0.003wt%, Ce 0.03wt%, Zr 0.04wt%, the balance is Ni; C, Cr, W, Mo, Si, P, S, Fe, Ni are added to the crucible, and the crucible is put into a vacuum induction furnace for vacuum melting. The working vacuum degree during vacuum melting is ≤15Pa, and the melting temperature of raw materials is 1480°C. ...

Embodiment 3

[0040] A nickel-based superalloy with high W and Mo content: calculated by mass percentage, the composition content of elements in the alloy is: C0.018wt%, Cr 21wt%, W 8.1wt%, Mo 8.1wt%, Al 0.75wt% , Ti 0.75wt%, Mn 0.33wt%, Si 0.20wt%, P 0.013wt%, S 0.013wt%, Fe 0.19wt%, B 0.005wt%, Ce 0.05wt%, Zr0.06wt%, the balance is Ni .

[0041] A kind of preparation method of high W, Mo content nickel base superalloy, comprises the following steps:

[0042] 1) The components of the nickel-based superalloy alloy are calculated by mass percentage: C 0.018wt%, Cr 21wt%, W8.1wt%, Mo 8.1wt%, Al 0.75wt%, Ti 0.75wt%, Mn 0.33wt%, Si 0.20wt%, P0.013wt%, S 0.013wt%, Fe 0.19wt%, B 0.005wt%, Ce 0.05wt%, Zr 0.06wt%, the balance is Ni; C, Cr, W, Mo, Si , P, S, Fe and Ni are added to the crucible, and the crucible is put into a vacuum induction furnace for vacuum melting. , the refining vacuum degree is ≤5Pa, the refining temperature is 1520°C, and the refining time is 120min, then add B, Ce, Zr, Mn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com