Calcium adding method for deoxidation calcium treatment of liquid steel

A technology of calcium treatment and molten steel, applied in the field of calcium addition in molten steel deoxidation calcium treatment, can solve the problems of serious steel slag splashing, not feeding line speed, nitrogen increase of molten steel, etc., to improve utilization rate and recovery rate, and slow down heat transfer, solve the effect of nitrogen increase in molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: In this embodiment, the specification parameters of the calcium core wire with composite structure and the comprehensive parameters when feeding the wire are as follows:

[0040](1) The diameter D of the composite structure calcium core wire in this embodiment is 9mm;

[0041] (2) Outer cladding: steel strip thickness 0.5mm;

[0042] (3) Middle layer: steel strip thickness 0.8mm;

[0043] (4) Calcium core diameter: 6.4mm;

[0044] (5) Ladle inner diameter: 3010mm, molten steel depth: 3700mm;

[0045] (6) The incident angle α of the calcium core wire is 53°, and the feeding speed is 3m / s.

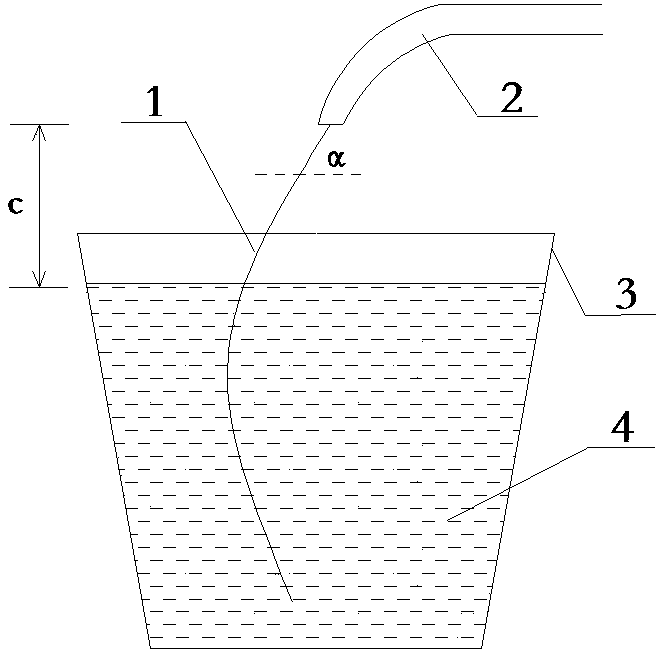

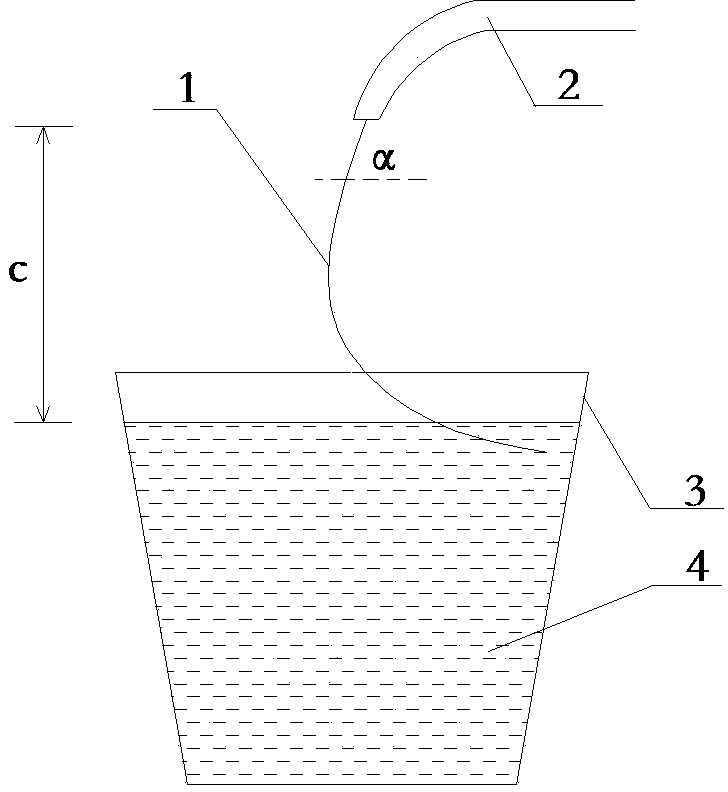

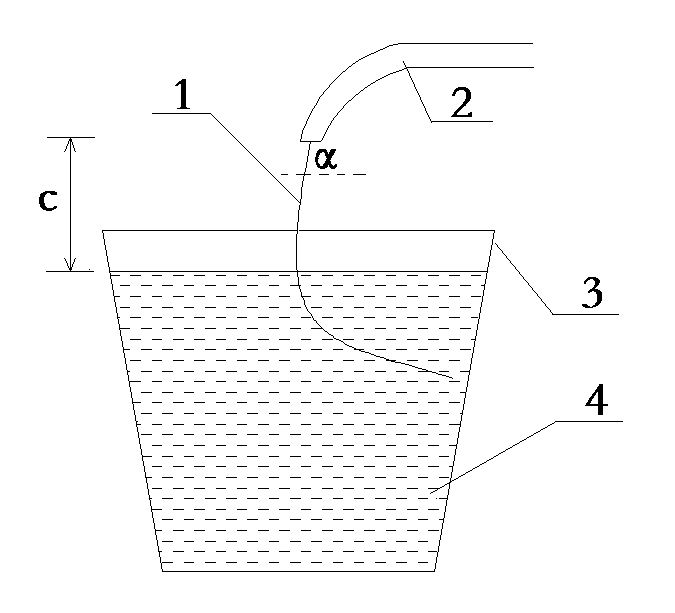

[0046] Such as figure 1 , 2 As shown, when the calcium core wire 1 is fed into the molten steel 4 in the ladle 3, except the incident height c of the calcium core wire 1 is different, all other parameters are the same; the use effect is shown in the following table:

[0047] Ca core incident height c (CM) 25 30 38 40 42 50 55 Calcium yield (%)...

Embodiment 2

[0049] Embodiment 2: In the present embodiment, the specification parameters of the composite structure calcium core wire and the comprehensive parameters during wire feeding are as follows:

[0050] (1) The diameter D of the composite structure calcium core wire in this embodiment is 9mm;

[0051] (2) Outer cladding: steel strip thickness 0.5mm;

[0052] (3) Middle layer: steel strip thickness 0.8mm;

[0053] (4) Calcium core diameter: 6.4mm;

[0054] (5) Ladle inner diameter: 3010mm, molten steel depth: 3700mm;

[0055] (6) The incident height of the calcium core wire is 40cm, and the feeding speed is 3m / s.

[0056] Such as figure 1 , 2 As shown, when the calcium core wire 1 is fed into the molten steel 4 in the ladle 3, except the incident angle α of the calcium core wire 1 is different, the other parameters are the same; the use effect is shown in the following table:

[0057] Ca core incident angle α 35 40 45 53 55 57 65 70 Calcium yield (%) ...

Embodiment 3

[0059] Embodiment three: the present embodiment will carry out the test of two batches, and the specification parameter of composite structure calcium core wire in the first batch and the comprehensive parameter when feeding wire are as follows:

[0060] (1) The diameter D of this batch of composite structure calcium core wire is 8.9mm;

[0061] (2) Outer cladding: steel strip thickness 0.5mm;

[0062] (3) Middle layer: steel strip thickness 0.8mm;

[0063] (4) Calcium core diameter: 6.3mm;

[0064] (5) Ladle inner diameter: 3400mm, molten steel depth: 4250mm;

[0065] (6) The incident height c of the calcium core wire is 40cm, and the incident angle α is 55°.

[0066] The specification parameters of the composite structure calcium core wire in the second batch and the comprehensive parameters when feeding the wire are as follows:

[0067] (1) The diameter D of this batch of composite structure calcium core wire is 10.1mm;

[0068] (2) Outer cladding: steel strip thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com