Patents

Literature

93results about How to "Reduce gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

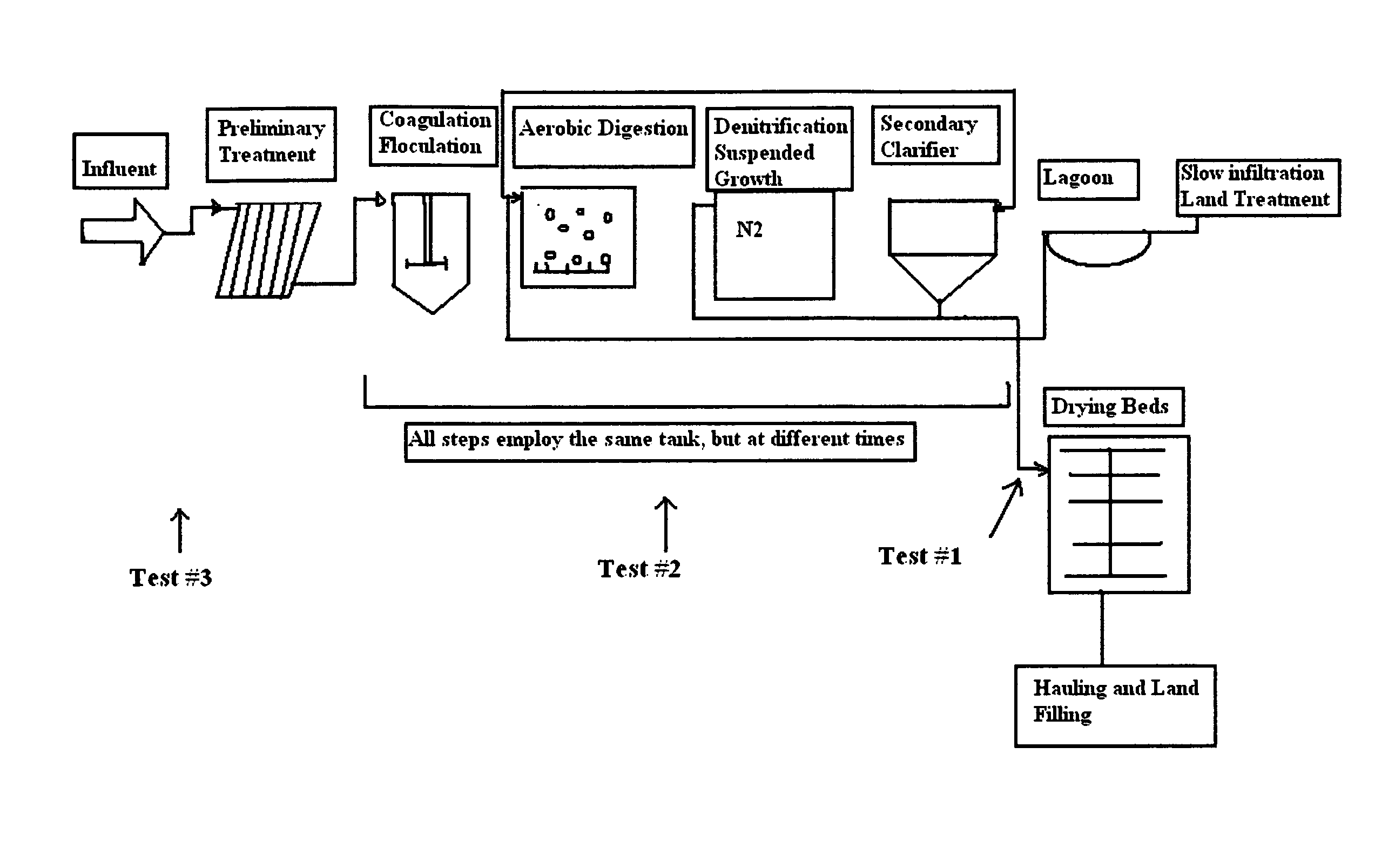

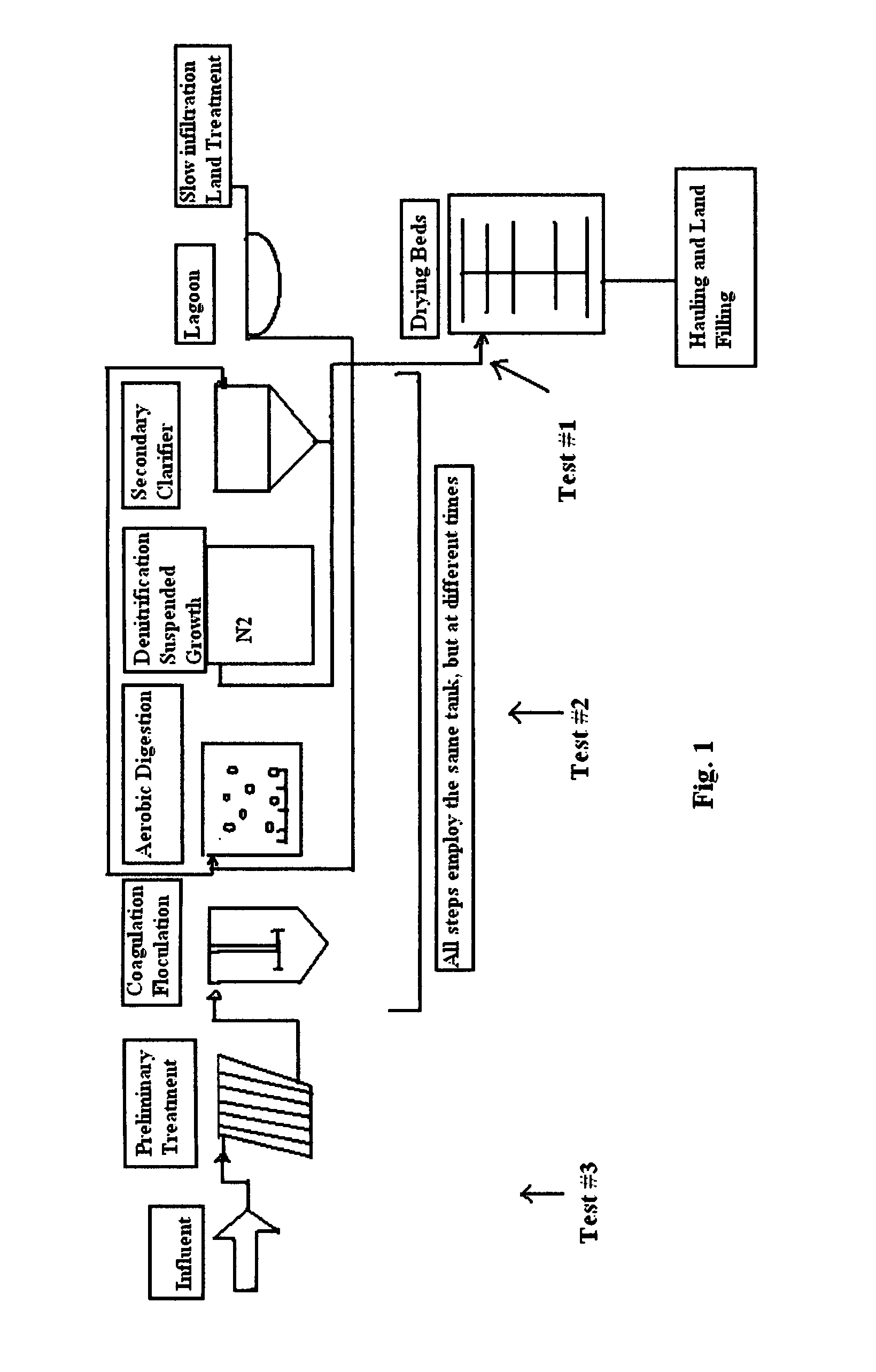

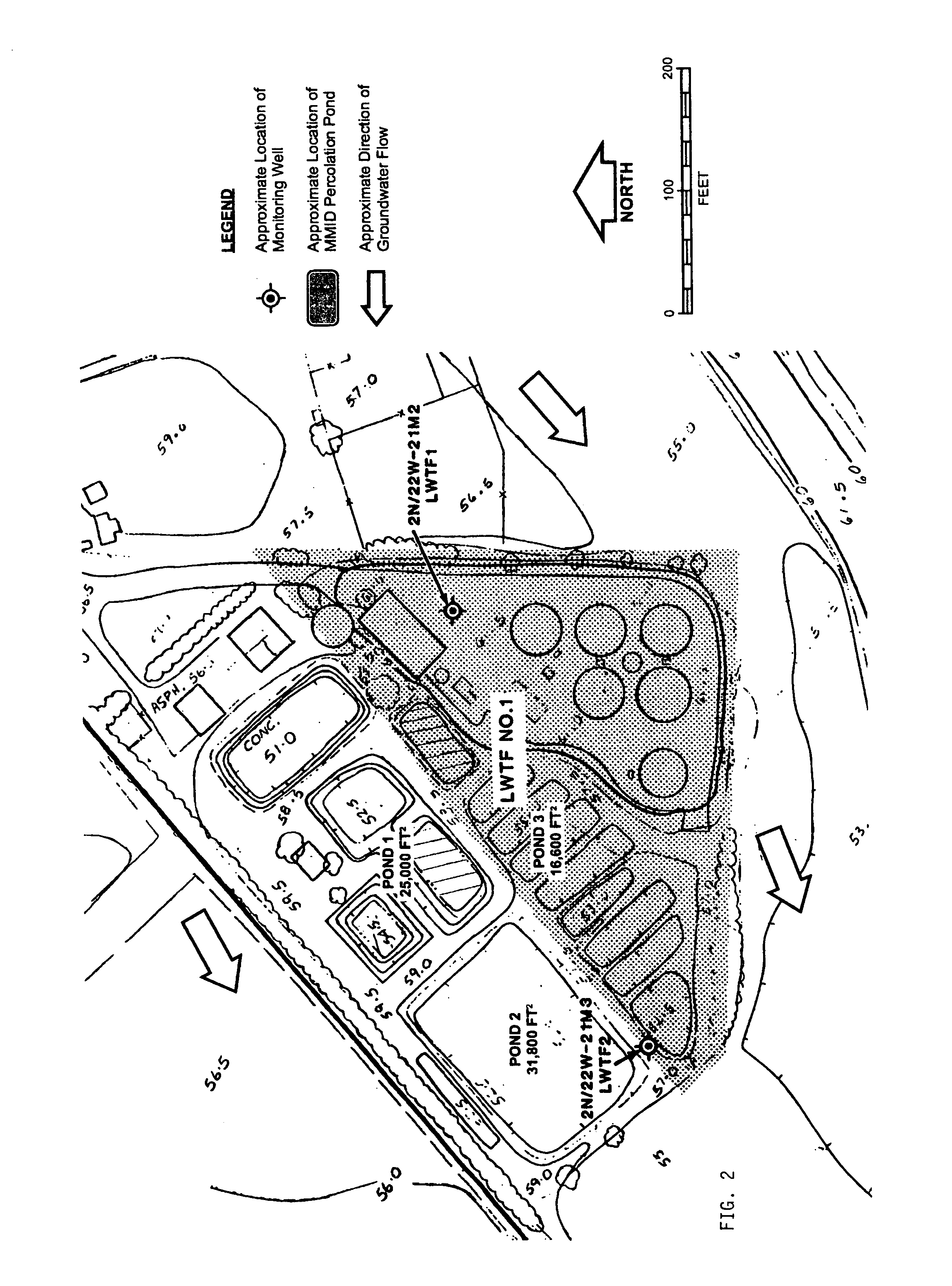

Wastewater chemical/biological treatment plant recovery apparatus and method

ActiveUS7416668B1Minimal capital cost expenditureLand cost is not prohibitiveBio-organic fraction processingSedimentation separationSludgeWastewater

A chemical / biological wastewater treatment plant method and apparatus employing rapid sludge chemical dewatering technology in conjunction with an environmental biological system for treating the separated treated wastewater by land applying it for plant consumption, and / or passing it through aqueous plant or microbial reduction of the dissolved solids and ammonia for BOD compliance to produce water of sufficient quality to meet open stream and ocean effluent discharge requirements; and disposing of the high BTU low moisture solids.

Owner:EARTH RENAISSANCE TECH

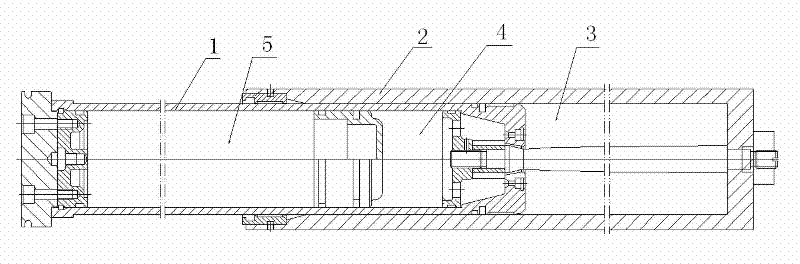

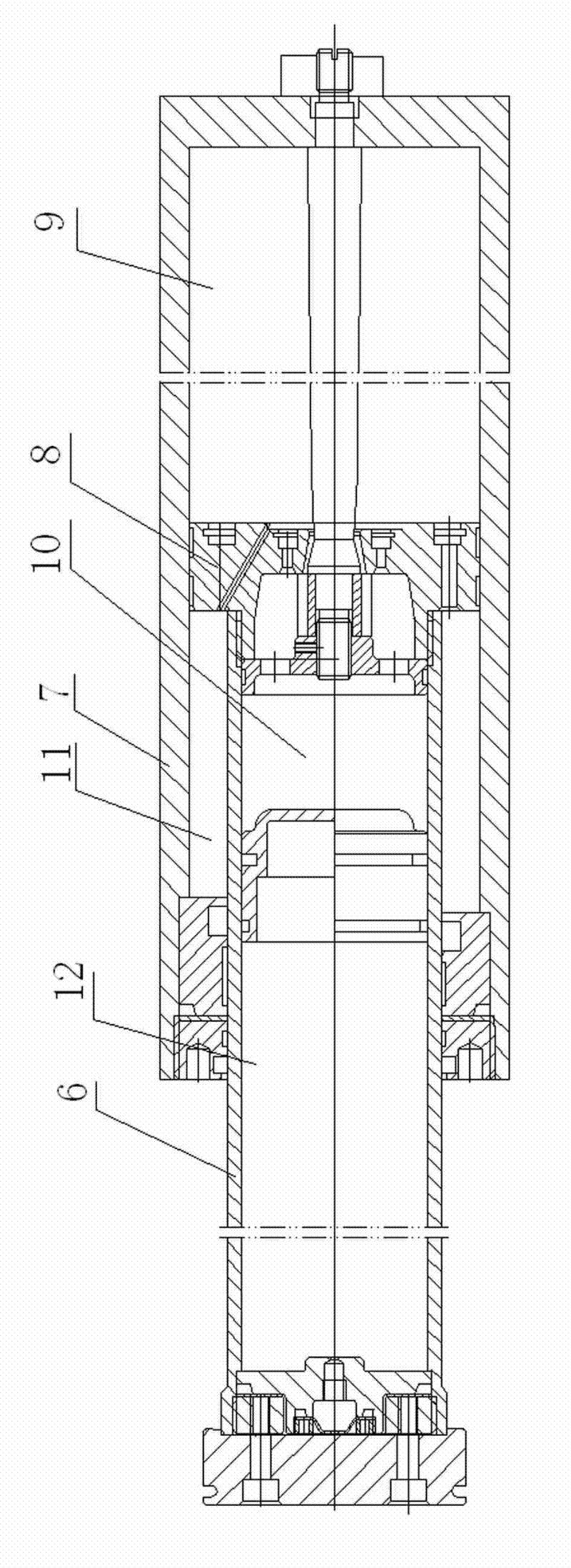

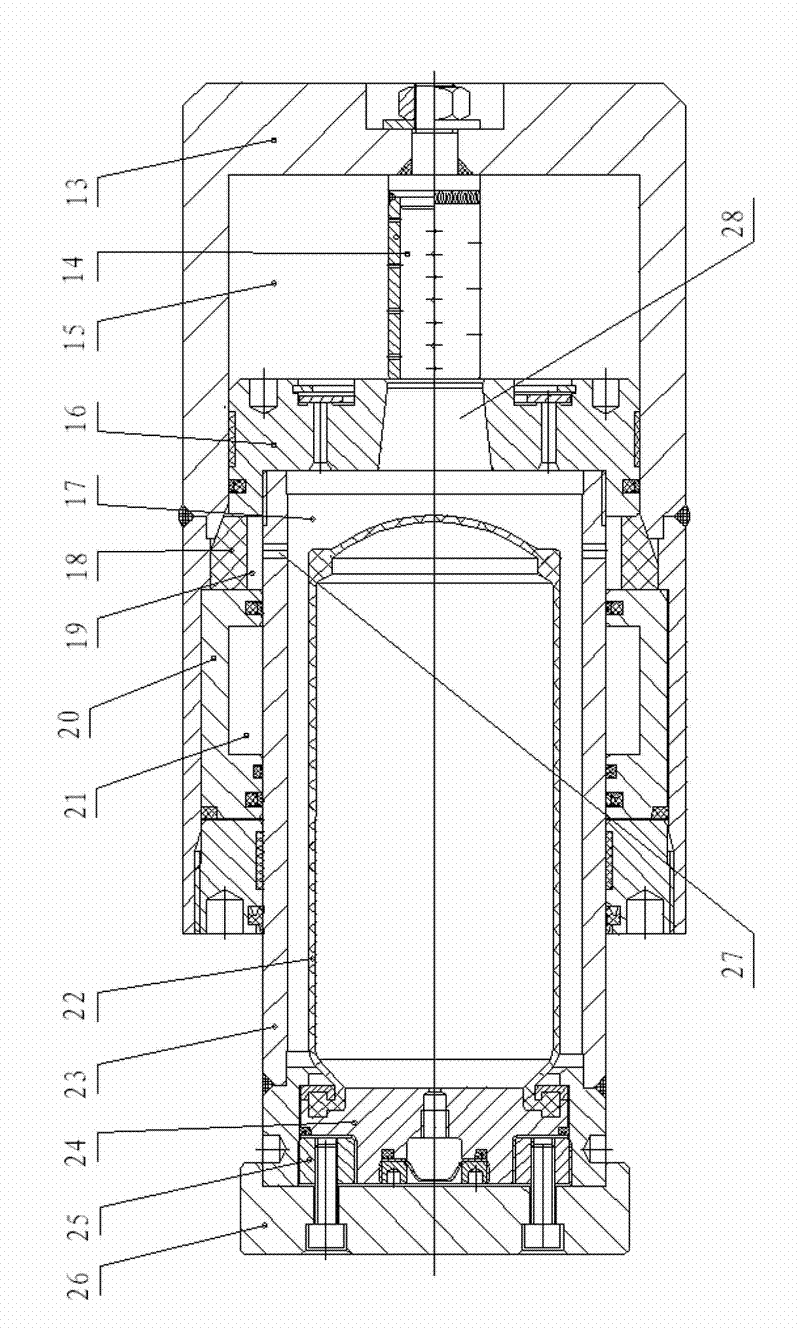

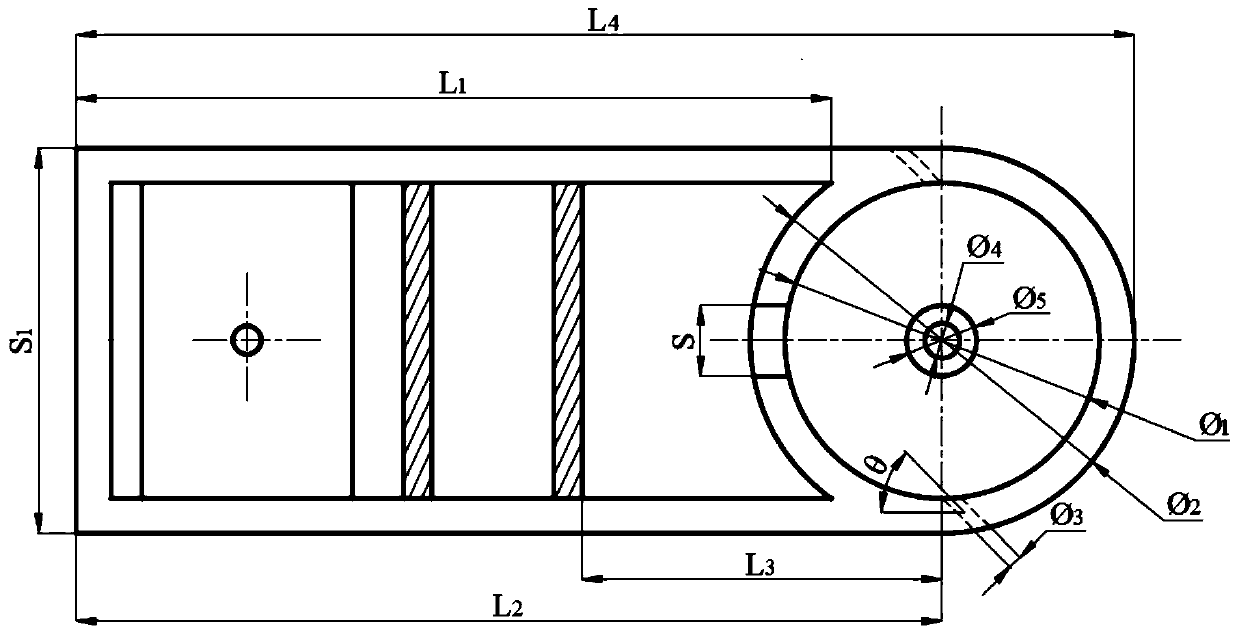

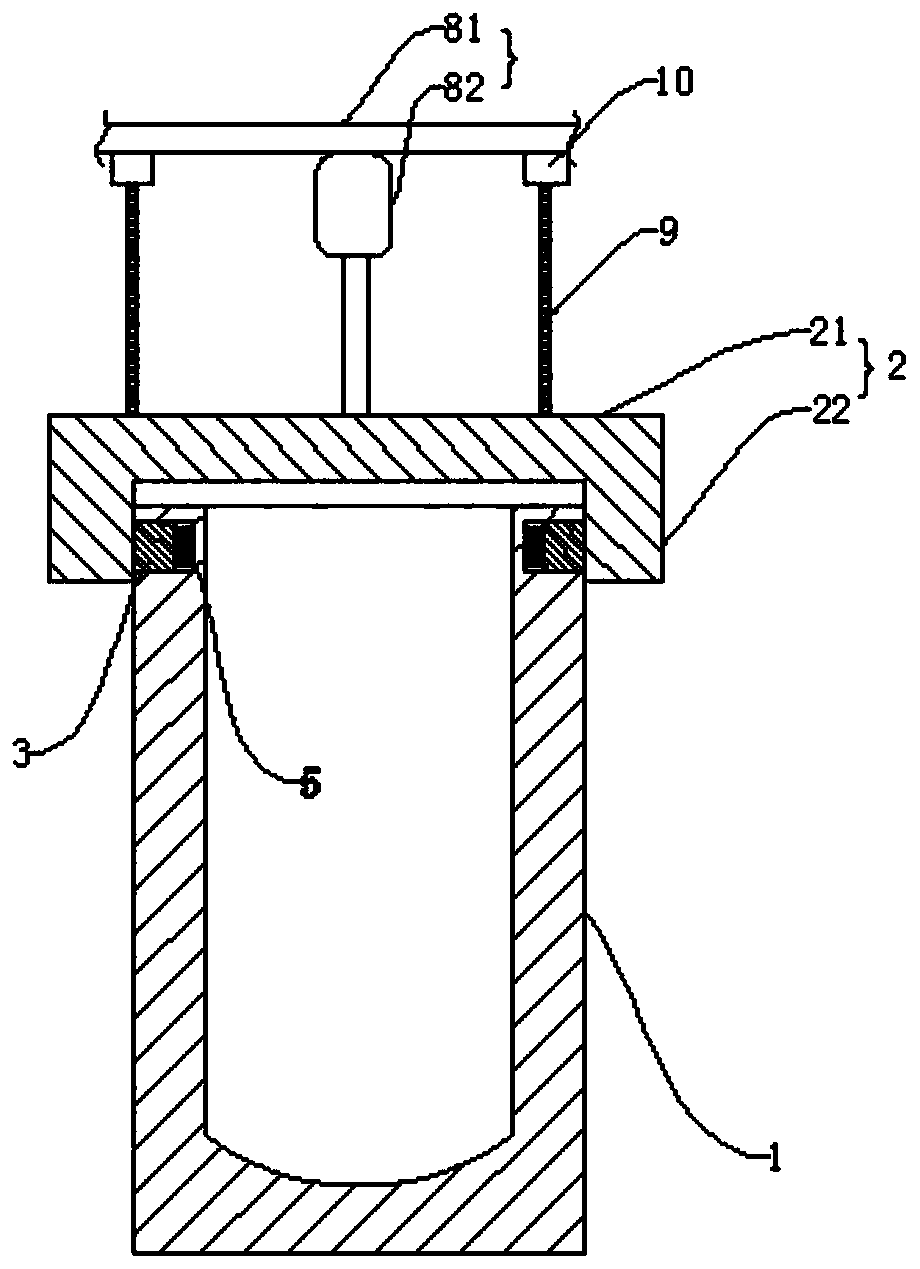

Piston type hydropneumatic buffer

InactiveCN102359529AReliable separationSolve the problem of severe air leakageSpringsShock absorbersCylinder blockAir tightness

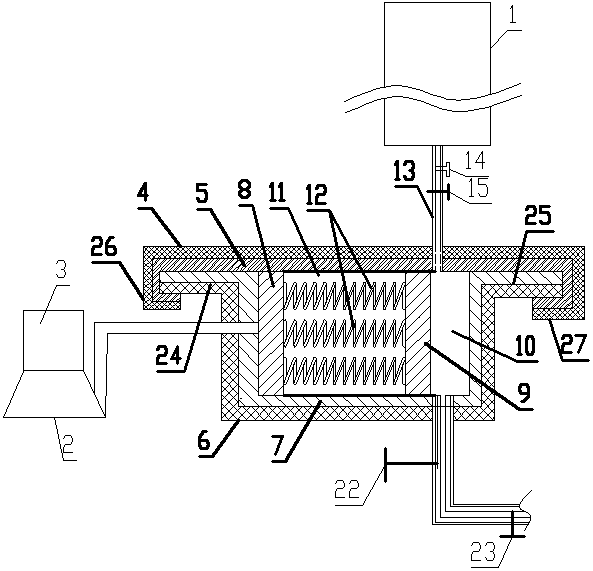

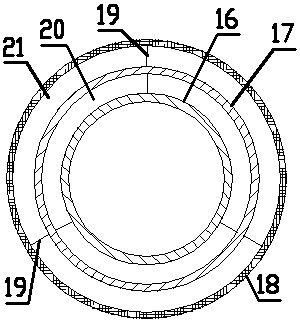

The invention provides a piston type hydropneumatic buffer which can be used for improving the sealing performance, maintaining the buffering performance and prolonging the service life. The technical scheme of the invention is as follows: the buffer comprises a cylinder body, a hollow piston rod and a piston fixedly connected with the piston rod, wherein a first oil cavity is formed between the bottom of the piston and the cylinder body, the piston rod is internally equipped with an air bag, an air tightness device is arranged outside a plug of the air bag, a second oil cavity is formed between the bottom of the air bag and the inner end face of the hollow piston rod, and a first throttling channel is arranged between the first oil cavity and the second oil cavity; a cavity is formed among the excircle of the piston rod, the outer end face of the piston and the cylinder body, a polyurethane limited block is arranged in the cavity, the outer end of the polyurethane limited block is provided with a guide seat which can partition the cavity into a third oil cavity and a fourth oil cavity, and a second throttling channel is arranged between the third oil cavity and the second oil cavity; and the first oil cavity, the second oil cavity and the third oil cavity are filled with low viscosity oil, the fourth oil cavity is filled with high viscosity oil and the air bag is filled with air.

Owner:吕再昌

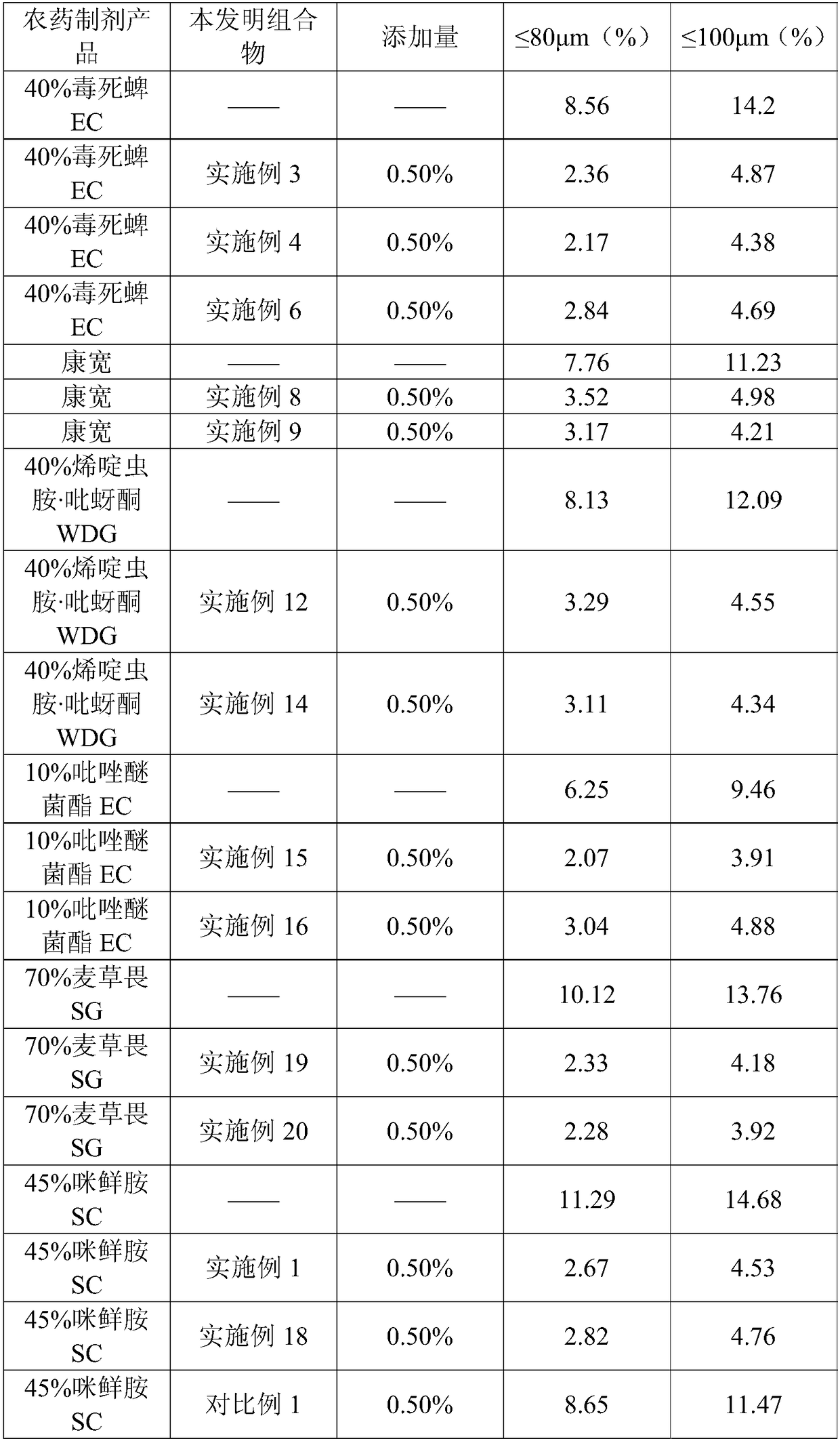

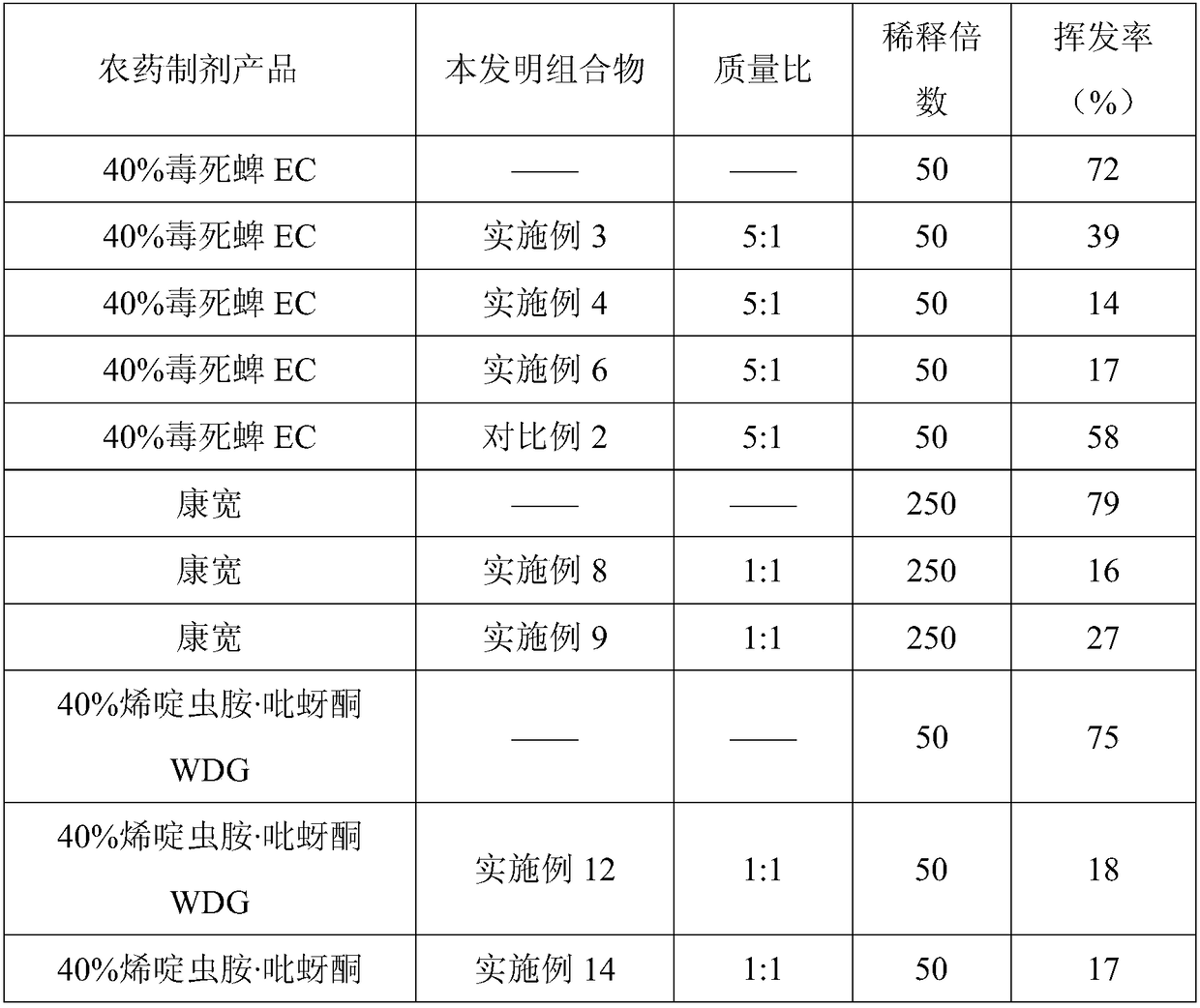

Anti-volatile spray additive as well as preparation method and application thereof

The invention provides an anti-volatile spray additive. The anti-volatile spray additive is prepared from the following components in percentage by mass: 20 to 48 percent of vegetable oil, 8 to 40 percent of surfactant, 8 to 40 percent of anti-volatile agent, 3 to 15 percent of sedimentation promoting agent and 0 to 61 percent of solvent. According to the anti-volatile spray additive disclosed bythe invention, the problems that medicinal liquid is easily volatilized in processes of plant protection of unmanned aerial vehicles and spray fog droplet sedimentation of large-sized machines and absorption of the medicinal liquid are solved, and the problems that the sedimentation velocity is low in a spraying process and the sprayed medicinal liquid are easily drifted are improved.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

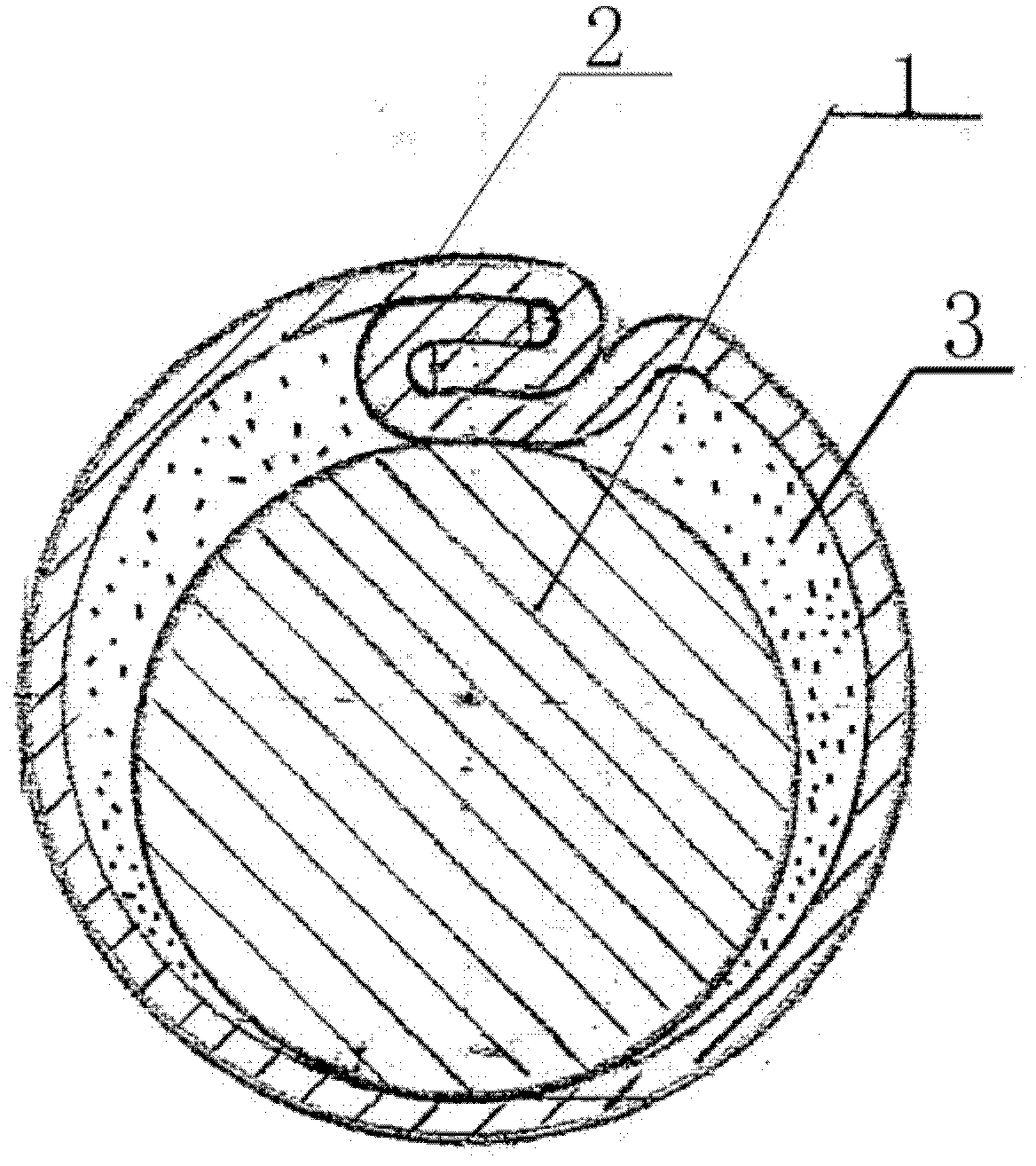

Metal calcium core composite cored wire and preparation method thereof

InactiveCN102586542AReduce gasificationImproved ability to penetrate molten steelCompound aHeat resistance

The invention discloses a metal calcium core composite cored wire, which consists of an inner core material and an outer coat, wherein the inner core material is formed by compounding a solid-core calcium wire and metal particle powder. The invention also provides a method for manufacturing the cored wire. The method comprises the following steps of: (1) processing metal calcium into a metal calcium wire; (2) preparing metal into the metal particle powder or metal alloy granules; (3) tightly wrapping the metal calcium wire and the metal particle powder by using strip steel on a cored wire machine to obtain the wire, wherein the metal calcium core is wrapped in the metal particle powder or the metal alloy granules; and (4) coiling the wire into a roll. The metal calcium core composite cored wire has high molten steel penetrability; the metal particle powder is introduced, so that the molten steel is cooled locally, the heat resistance of the metal calcium wire is increased, the gasification of the metal calcium is reduced, and the dissolubility of the calcium in molten steel is improved; therefore, the N absorption of the molten steel is greatly reduced and the calcium yield is further improved.

Owner:上海马腾新型材料厂

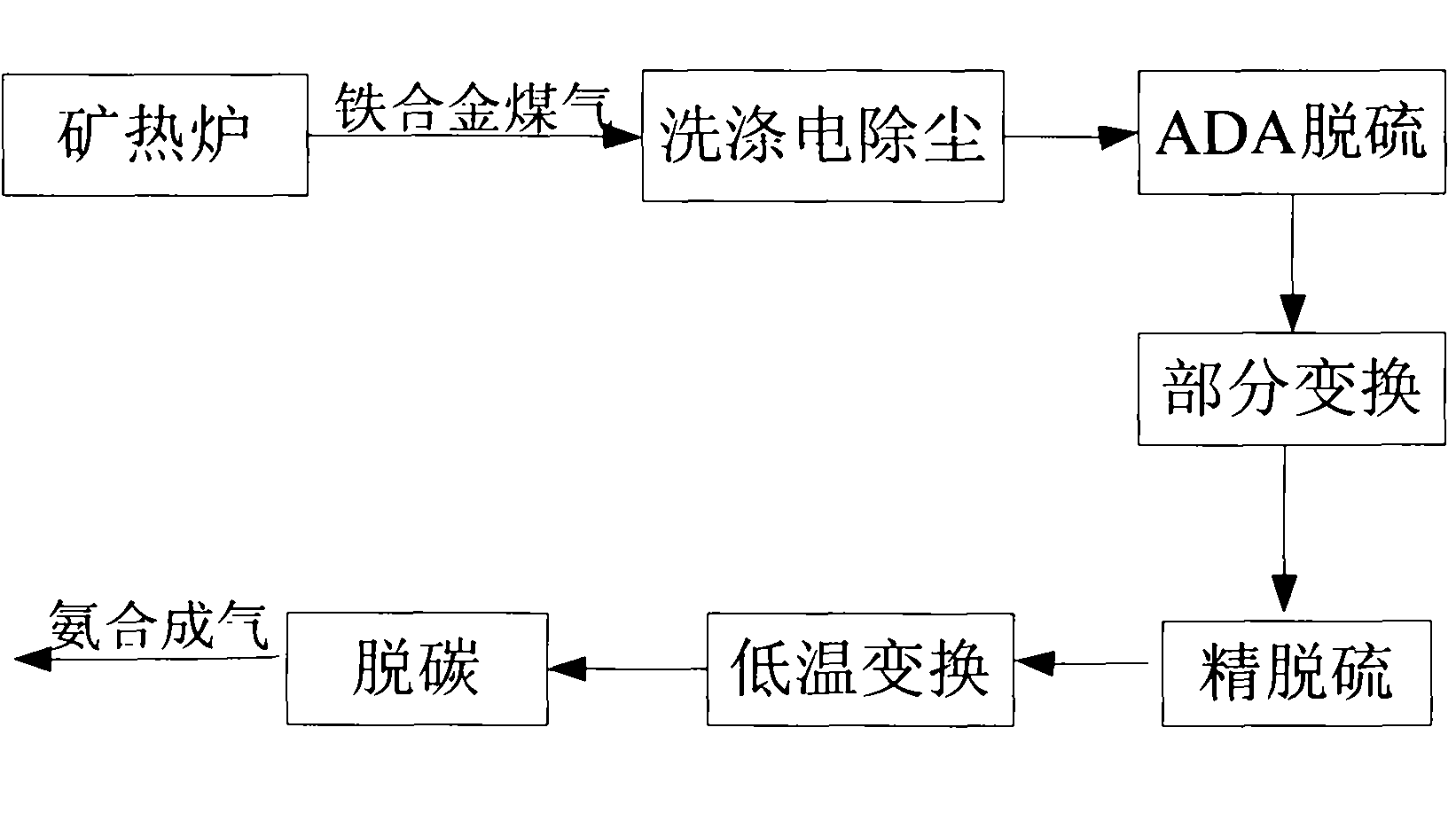

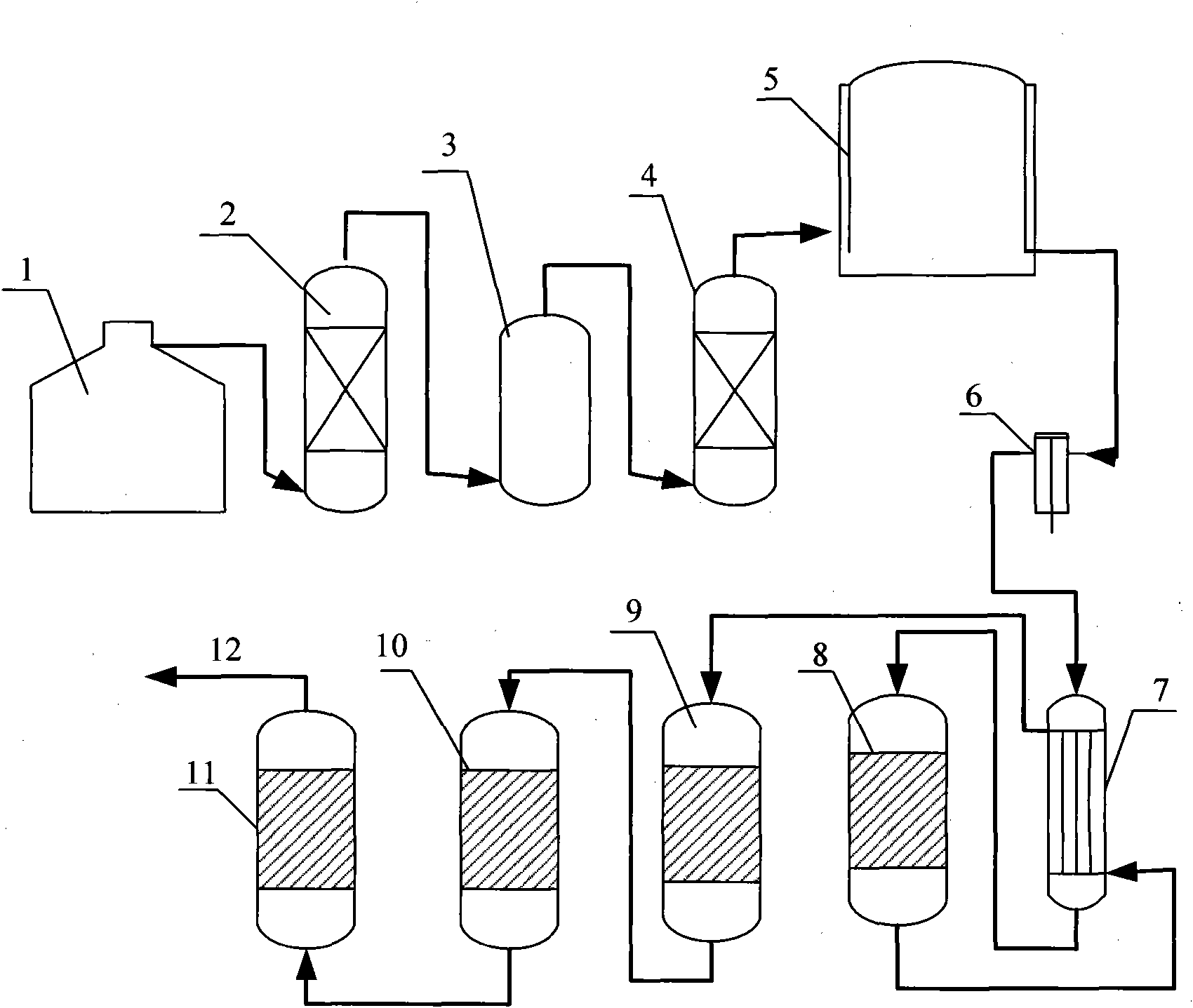

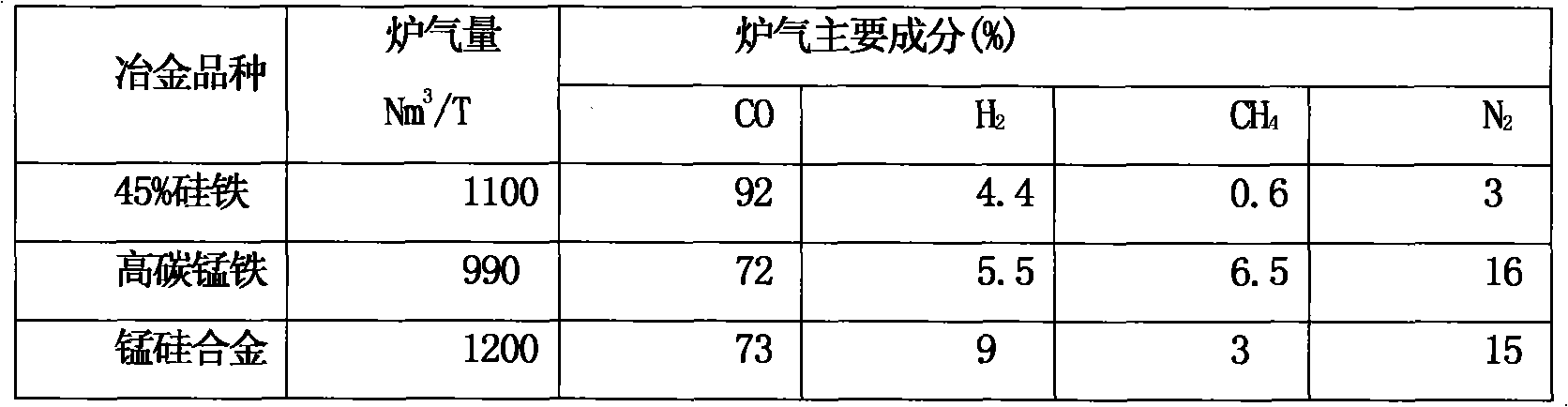

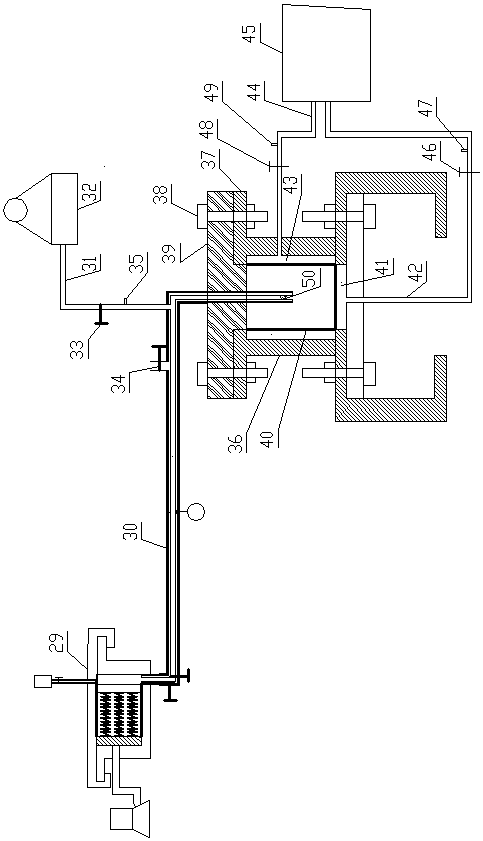

Method for preparing ammonia synthesis gas from iron alloy smoke

InactiveCN102101644AShort processLow costHydrogen separation using solid contactAmmonia preparation/separationDust controlFuel oil

The invention relates to a method for preparing ammonia synthesis gas from iron alloy smoke. The method comprises the following steps: carrying out scrubbing dust collection, desulfurization and nitrogen complement on the iron alloy smoke so as to ensure the ratio of nitrogen to carbon monoxide (CO) to hydrogen (H2) in the iron alloy smoke to achieve the requirement of the ammonia synthesis gas; converting the CO to the H2 through partial conversion and low temperature conversion; and removing carbon dioxide and trace CO in order to meet the requirement of the ammonia synthesis gas, thereby constituting an iron alloy-synthesis ammonia comprehensive utilization combo to achieve the purposes of energy conservation and emission reduction. By using the method, iron alloy and synthesis ammonia are produced to constitute the utilization combo, thereby shortening the synthesis ammonia process flow, improving the resource utilization rate, greatly lowering the cost, reducing the raw material transportation and gasification during ammonia synthesis, saving the investment, saving coke, coal and heavy oil consumed during ammonia synthesis and supplying short natural gas; and the economic benefits and energy conservation and emission reduction effects are obvious.

Owner:KUNMING UNIV OF SCI & TECH

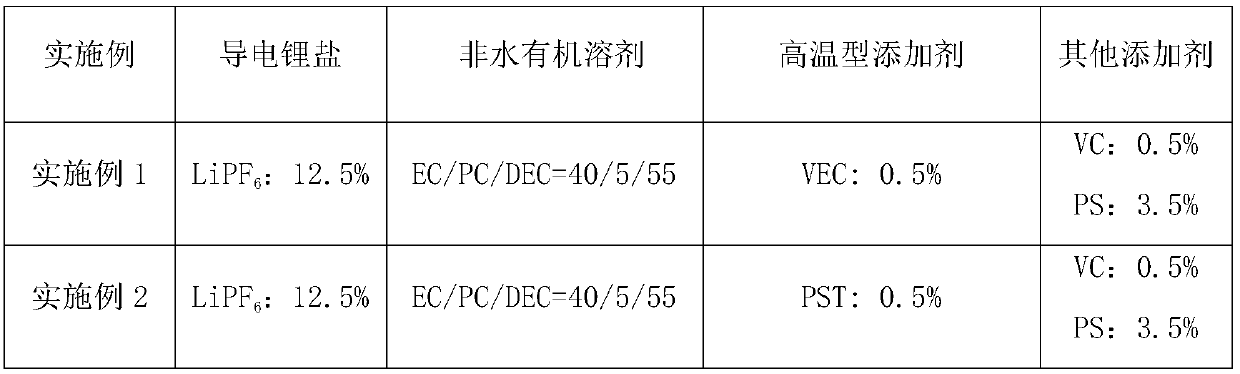

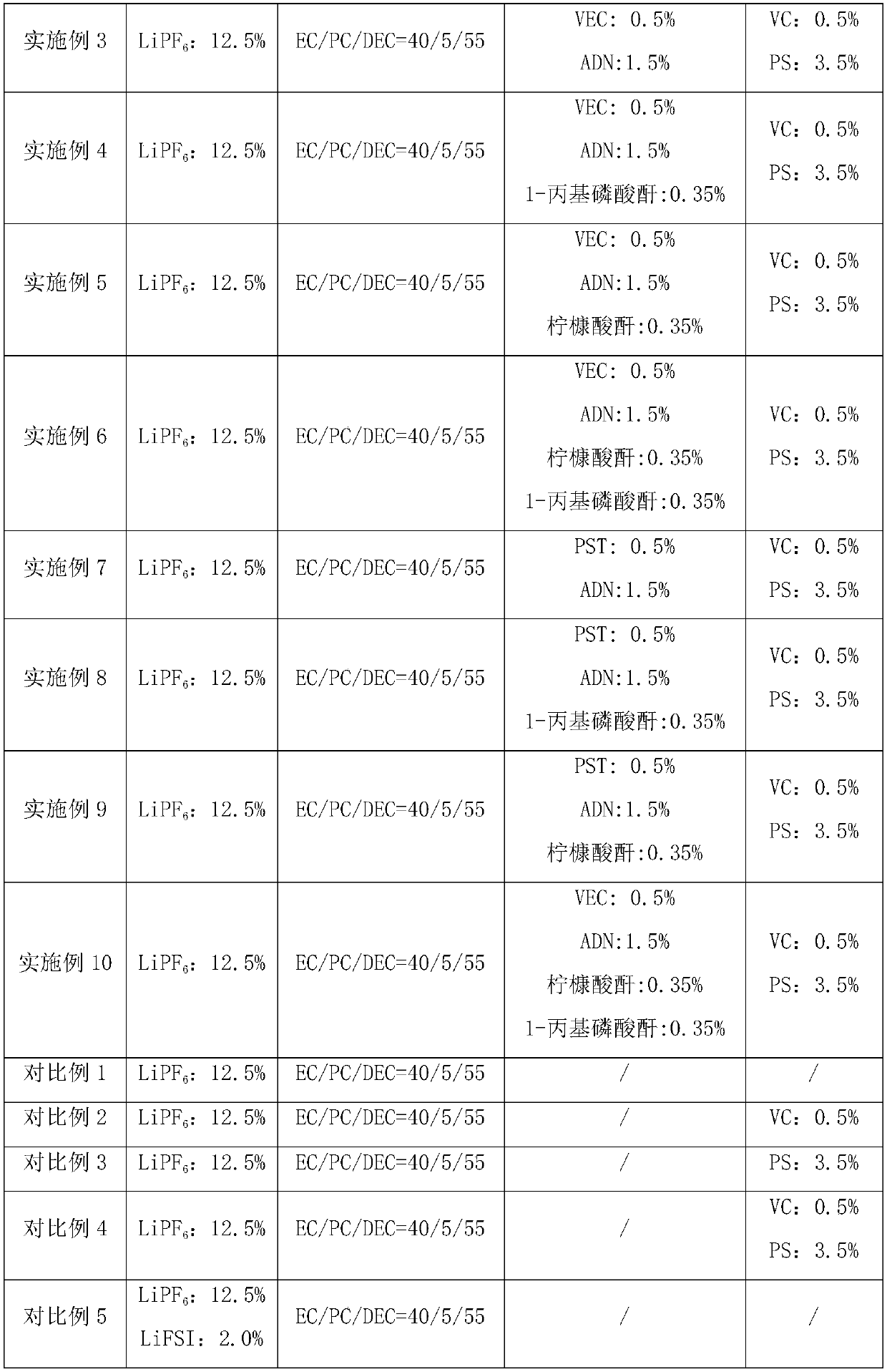

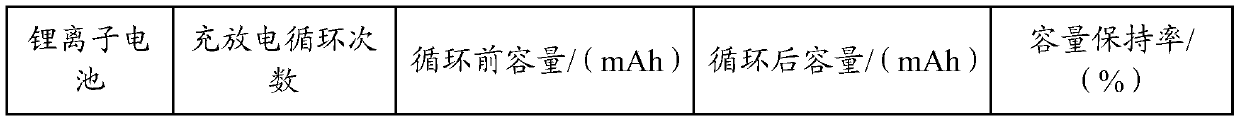

Non-aqueous electrolyte of high-temperature resistant lithium ion battery

ActiveCN109687021AReduced responseDissolution inhibitionSecondary cellsOrganic electrolytesLithium-ion batteryNon aqueous electrolytes

The invention discloses a non-aqueous electrolyte for a high-temperature resistant lithium ion battery and relates to the technical field of lithium ion batteries. The non-aqueous electrolyte of the high-temperature-resistant lithium ion battery contains an electrolyte lithium salt, a non-aqueous organic solvent and a film-forming additive, wherein the film-forming additive contains a negative electrode film-forming additive and a high-temperature additive, and the high-temperature additive is one or more of methylene methane disulfonate, 1,3-propane sultone, citraconic anhydride, adiponitrile, succinic anhydride, maleic anhydride, 1-propylphosphonic anhydride and vinyl ethylene carbonate. The non-aqueous electrolyte for the high-temperature resistant lithium ion battery effectively improves high-temperature (85 DEG C) storage performance and high-temperature (80 DEG C) cycle stability of the lithium ion battery. On the basis of the additive and the non-aqueous organic solvent, the high-temperature performance and long cycle performance of the power battery can be improved only the conventional lithium salt LiPF6, the cost is low, and the electrolyte is conductive to industrialization.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

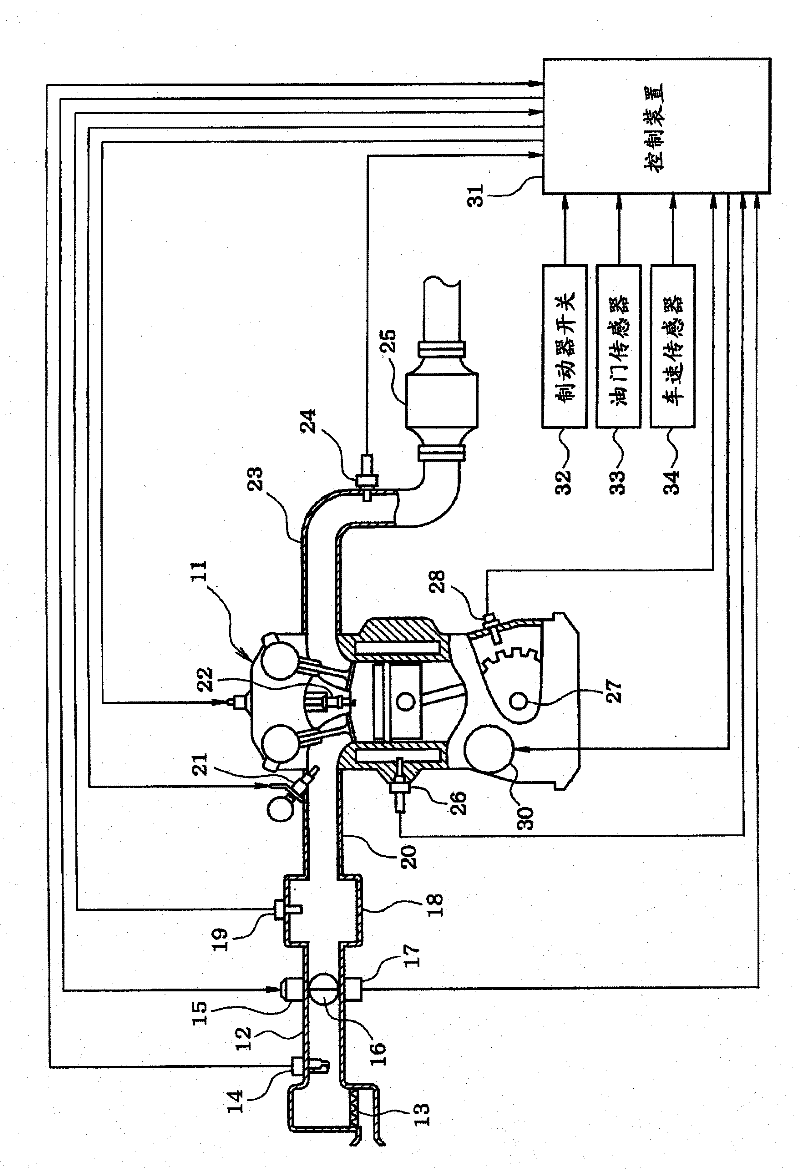

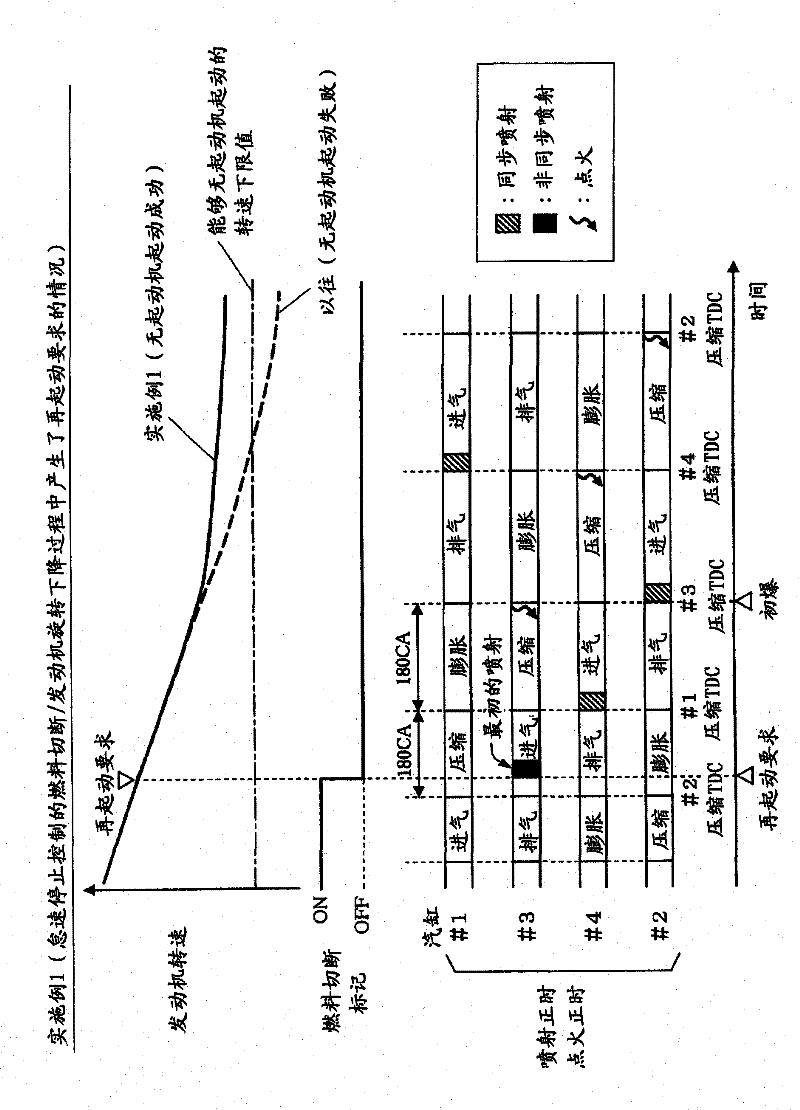

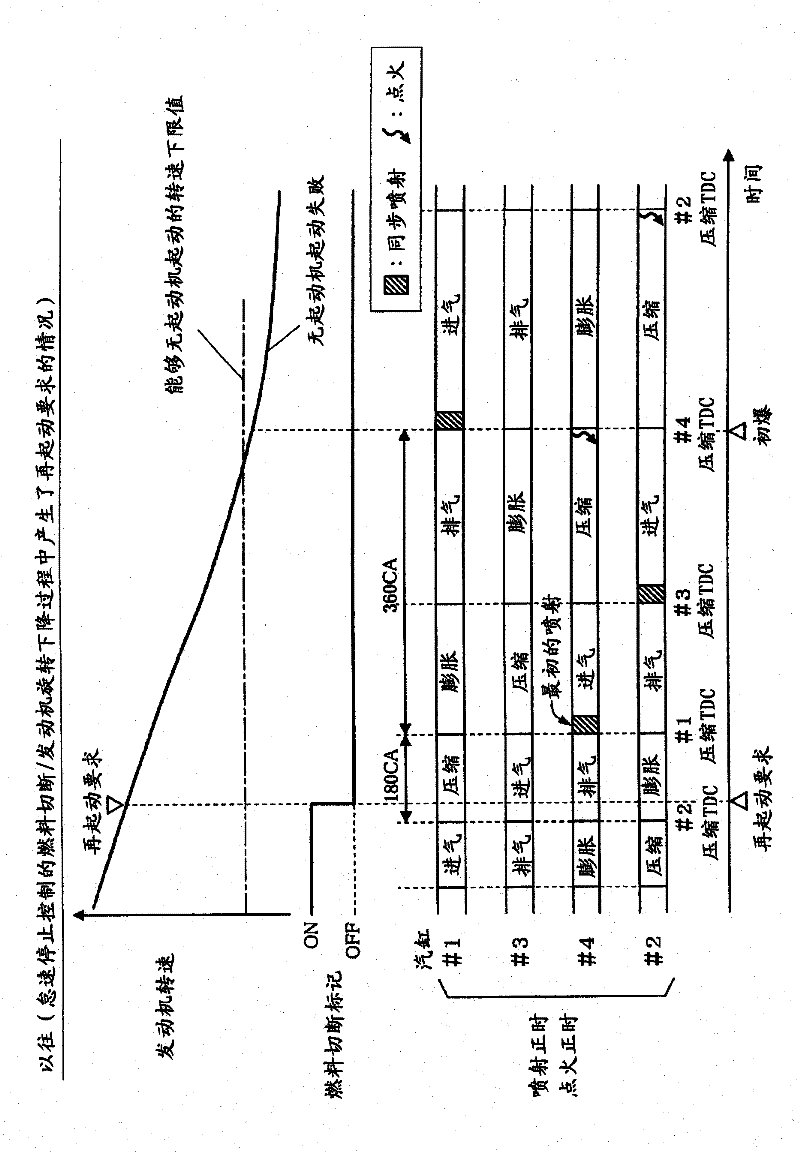

Automatic start-stop control device for internal combustion engine

ActiveCN102356225AIncrease frictionReduce gasificationElectrical controlInternal combustion piston enginesCombustionStart stop

When a restart is requested in a period wherein the rotation speed of an engine descends within a rotation speed range in which the engine can be restarted without a starter (the engine can be restarted by only a fuel injection), during a fuel cutoff for an idling stop control, an independent return control is performed, i.e., an initial fuel injection is performed immediately and asynchronously before being returned to a synchronous fuel injection, and a starter-less start by which the engine is restarted by only a fuel injection without using a starter, is performed. Thus, when a request for restart arises, the asynchronously injected fuel is sucked to a cylinder in an air intake stroke, and is ignited in the vicinity of a subsequent compression TDC, to generate an initial combustion (initial ignition). Accordingly, the initial ignition can be generated one stroke earlier than ever before.

Owner:TOYOTA JIDOSHA KK

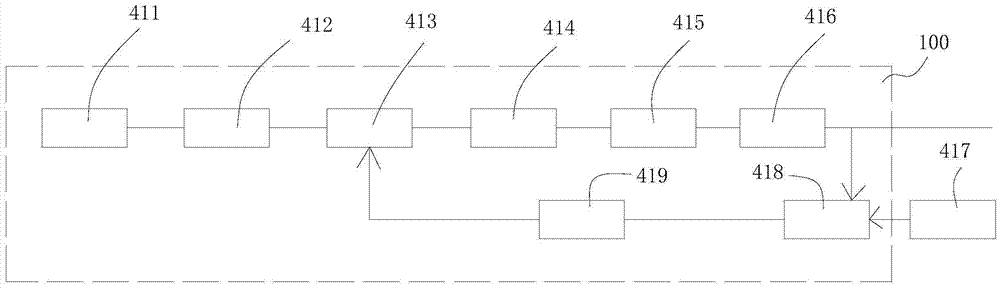

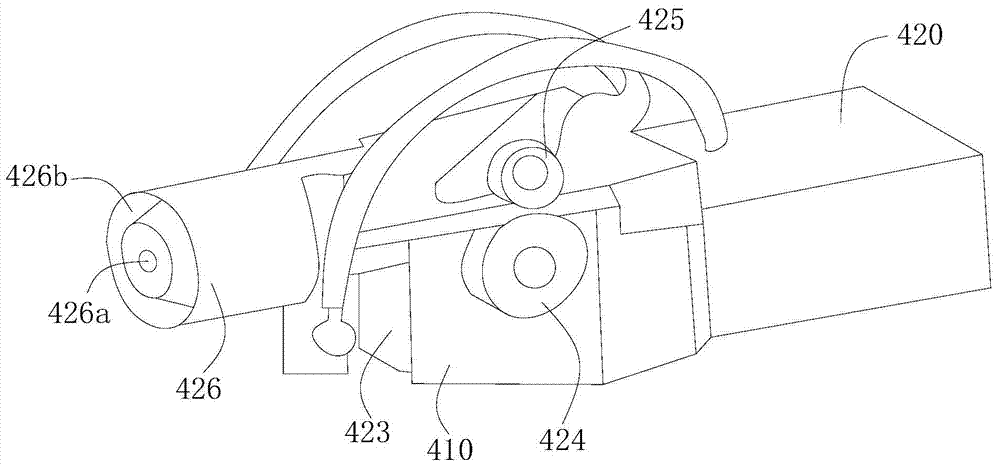

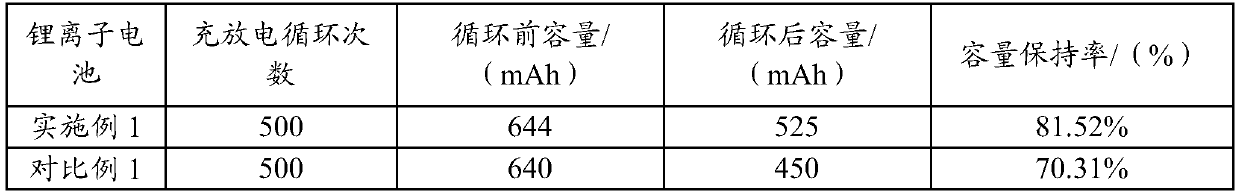

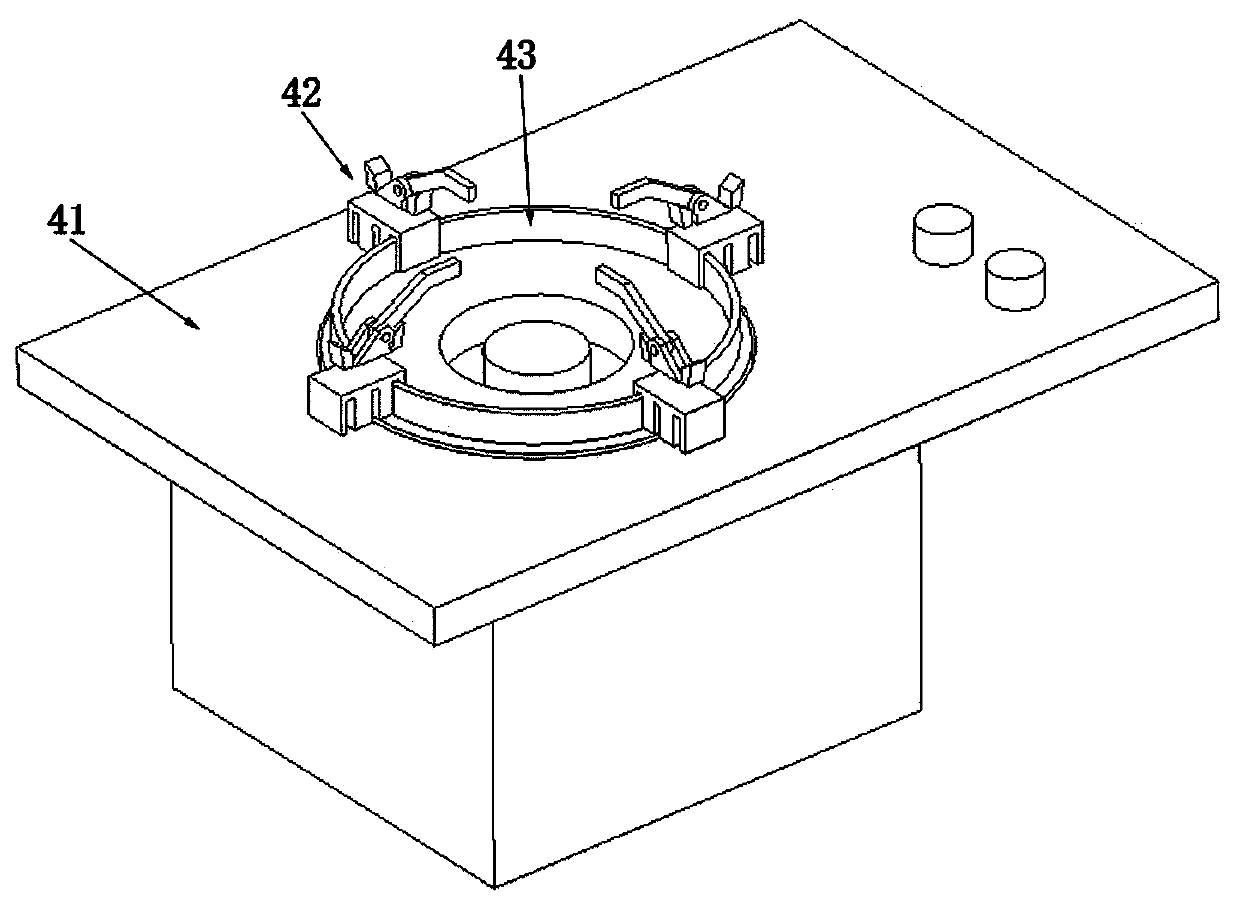

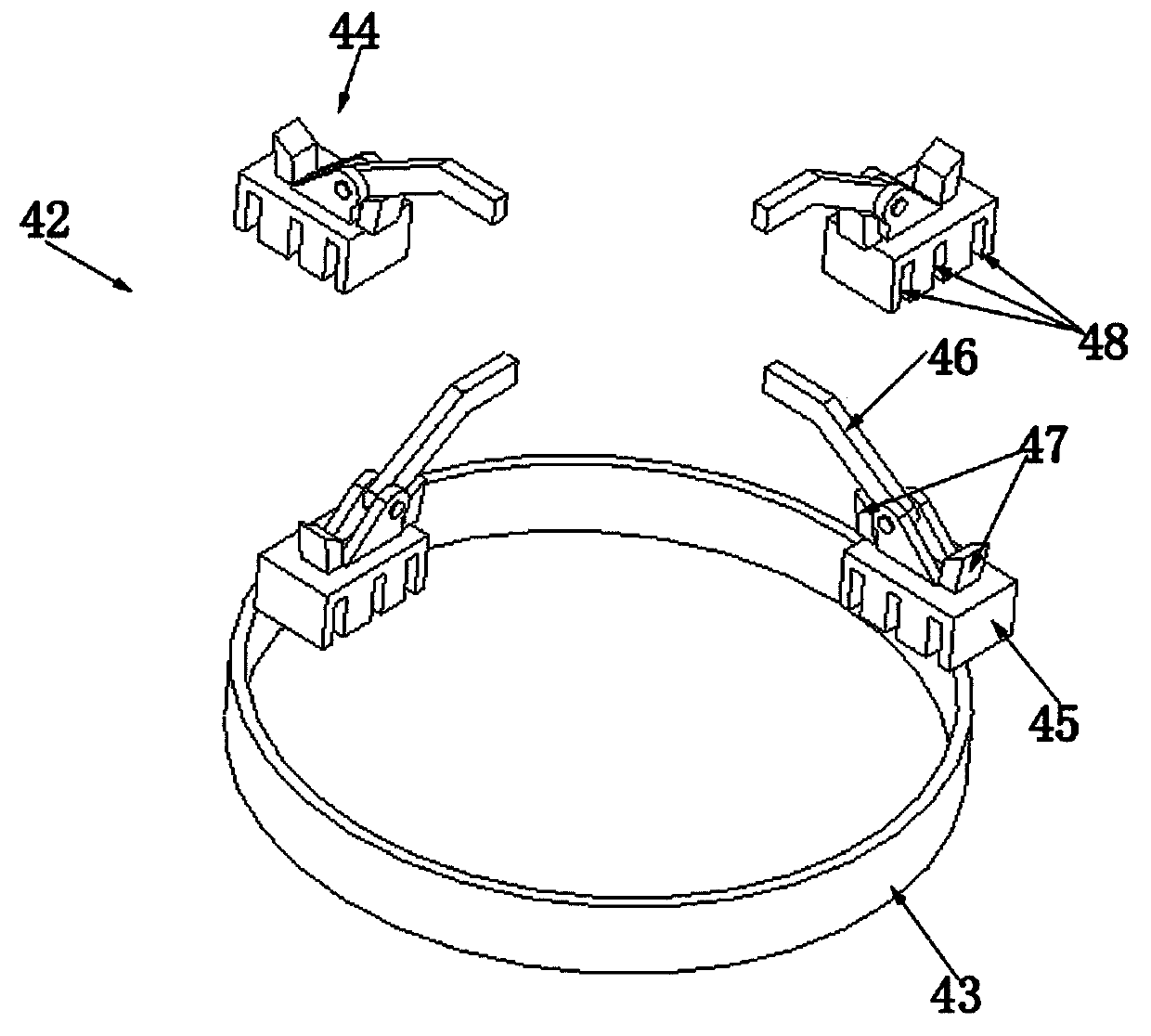

Simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes

ActiveCN103938146ADoes not affect setpointImprove anti-interference abilityCombination devicesMolten spray coatingPower flowEngineering

The invention discloses a simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes. The simultaneous online zinc spraying and dust removal device comprises spraying equipment, a spraying cabinet and a dust removal device, wherein the spraying equipment is arranged in the spraying cabinet, and an air outlet of the spraying cabinet is connected to the dust removal device; the multiple microchannel aluminium flat pipes enter into the spraying cabinet from one side of the spraying cabinet in parallel and exit out of the spraying cabinet from the other side of the spraying cabinet; the spraying equipment comprises a spraying main machine and a plurality of melting injection spray guns, the electric current parts of the plurality of melting injection spray guns are connected to the electric current output end of the spraying main machine, each melting injection spray gun is used for carrying out zinc spraying operation on each microchannel aluminium flat pipe, and the spraying main machine is provided with a power source part which comprises an input rectifying circuit, an input filter circuit, a power switch circuit, a voltage conversion and isolation circuit, an output rectifying circuit, an output filter circuit, an electric arc zone temperature detection sensor, a comparison circuit and a control circuit. The simultaneous online zinc spraying and dust removal device has a good spraying effect and low pollution to environments.

Owner:SHANGHAI LIANGSHI BLASTING & COATING EQUIP

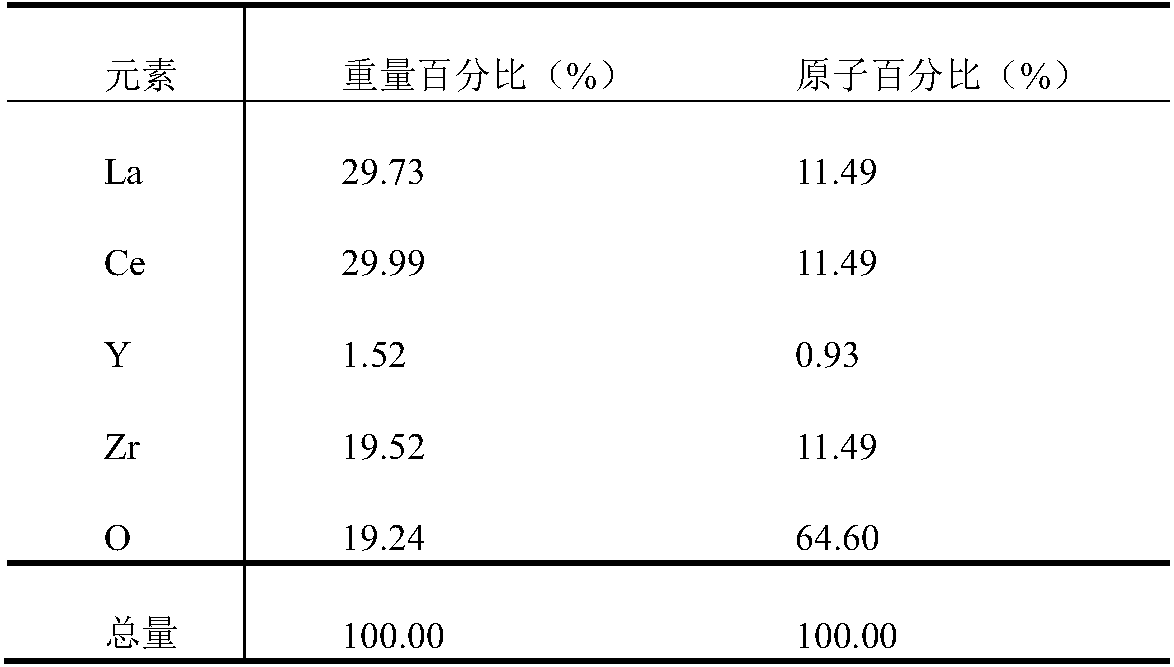

Yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for plasma physical vapor deposition and preparation method thereof and application

ActiveCN108546907AGood mechanical propertiesImprove fracture toughnessMolten spray coatingGas phaseLanthanum

The invention discloses yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for plasma physical vapor deposition and a preparation method thereof and application, and relates to the technical field of thermal barrier coating. The preparation method comprises the followings steps that lanthanum oxide, cerium oxide, yttrium oxide and zirconia are mixed in a molar ratio of (0.8-1.3):1:0.08:1 for ball-milling treatment, and ball-milling products are obtained; the products are filtered and dried, the products is performed ball milling with deionized water, binders and dispersants after drying to be mixed uniformly, and sizing agents are obtained; the sizing agents are performed spraying and drying treatment to obtain aggregates; and the aggregates are performed screening treatment after sintering to obtain the yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for the plasma physical vapor deposition. When a coating is prepared, the powder is heatedin a powder feeder to start plasma physical gas phase deposition equipment, and the vacuum is pumped to the pressure less than 0.08mbar and the vacuum chamber is filled with argon to 130mbar; and thenspraying is performed to obtain the coating. The yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for the plasma physical vapor deposition and the preparation method thereof and the application have simple steps and save cost, improve material performance and can be used in mass industrial production.

Owner:BEIHANG UNIV

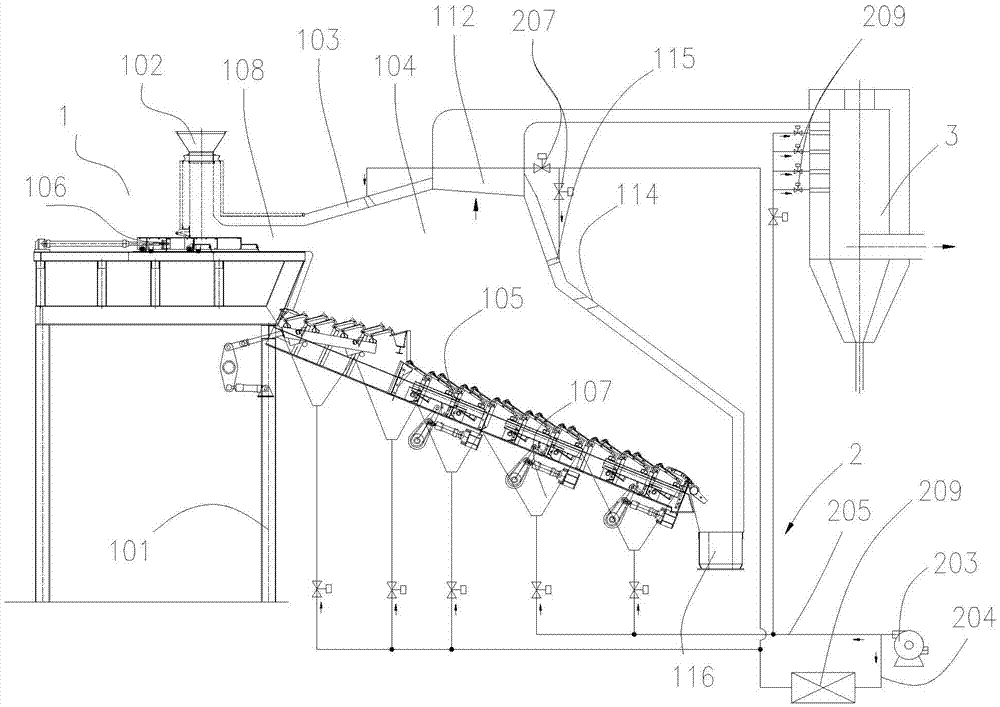

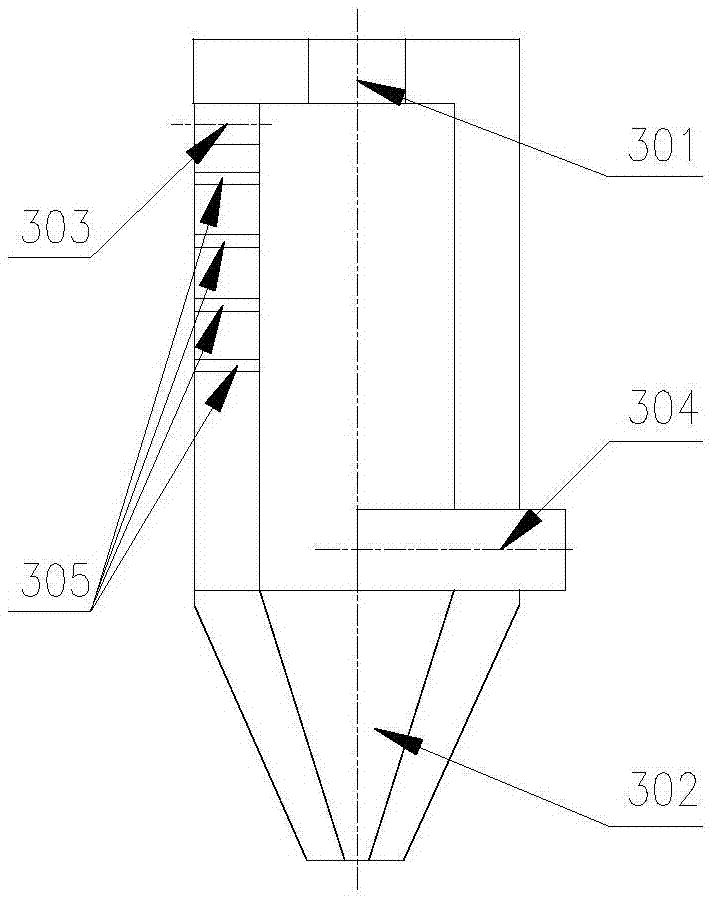

Mechanical grate type single-furnace garbage gasifying incineration system and disposal method thereof

ActiveCN105444183AImprove recycling efficiencyEmission reductionIncinerator apparatusCombustion chamberFlue gas

The invention discloses a mechanical grate type single-furnace garbage gasifying incineration system which comprises a gasifying incinerator, a cyclone combustion chamber and an air supply system, wherein the gasifying incinerator comprises a feed hopper and a furnace body; a stockpile sealing segment is arranged between the feed hopper and the furnace body; the upper end of the furnace body is arched and provided with a first flue gas outlet; and the cyclone combustion chamber is used for secondary combustion and is provided with a flue gas inlet connected with the first flue gas outlet. A garbage disposal method comprises the following steps: Step A, starting and drying the incinerator; Step B, burning garbage in a furnace chamber; Step C, realizing continuous garbage gasifying incineration disposal; and Step D, shutting down the mechanical grate type single-furnace garbage gasifying incineration system after the garbage and garbage residues burn out. By the use of the mechanical grate type single-furnace garbage gasifying incineration system, large-scale continuous garbage gasifying incineration disposal can be realized, the garbage disposal capacity and the garbage transport capacity are higher, the heat recovery efficiency is high, and the emission of pollutants is effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

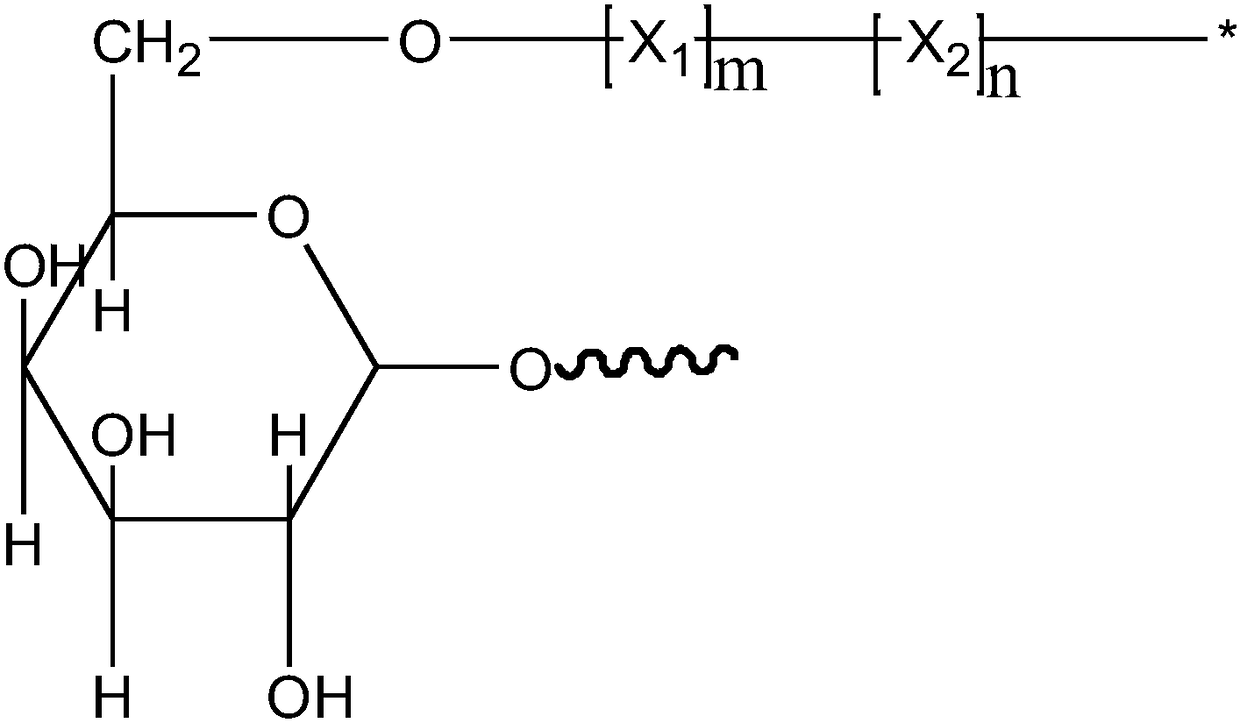

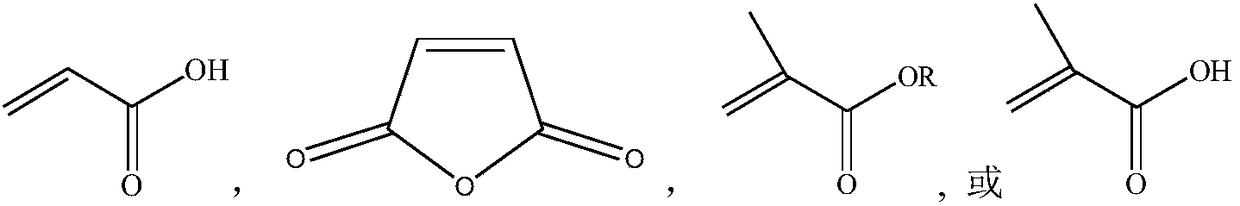

Saponin-grafted copolymer water-coal-slurry dispersing agent and preparation method thereof

InactiveCN108456282AImprove stabilityReduce gasificationLiquid carbonaceous fuelsEmulsionRoom temperature

The invention relates to a saponin-grafted copolymer water-coal-slurry dispersing agent and a preparation method thereof. The preparation method comprises the following steps: completely dissolving all saponin in a three-neck flask by using an appropriate amount of deionized water, forming a 5 to 20 percent aqueous solution, then adding an oxidant in an initiator, heating, and stirring for a giventime at a constant temperature; cooling the reaction system, adjusting the pH, adding a given amount of X2 and reducing agent into the system, dropwise adding the remaining oxidant and a given amountof X1, keeping the temperature after the addition, polymerizing for a given time, and cooling a mixed product to the room temperature; and adjusting the pH of the cooled mixed product by using a NaOHaqueous solution, and obtaining the synthesized grafted copolymer water-coal-slurry dispersing agent. The saponin-grafting copolymer water-coal-slurry dispersing agent is brown clear emulsion. The slurry viscosity can be apparently reduced, and the stability of the slurry can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

Antimony wire for RH refining and adding method thereof

The invention discloses an antimony wire for RH refining and an adding method thereof. An antimony ingot is added in molten steel by using a wire feeding mode; such factors as antimony wire adding position and adding speed and ladle bottom blowing are synchronously controlled to guarantee most antimony elements to be molten in the molten steel as far as possible, so that the gasification quantity of the antimony elements is largely reduced, and the yield of the antimony elements is obviously increased; and compared with the prior art, the adding method is a process with the advantages of simple, easiness in operation and environmental protection.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Deep overcooling solidification process for preparing superconductive MgB2 material

The present invention relates to deeply overcooling solidification process for preparing superconductive MgB2 material. The process includes the following steps: smelting the mixture of Mg and Cu of purity 99.9 % in the atom ratio of 52-65 to 35-48 and the mixture of Cu and B in purity of 97 % in the atom ratio of 82-95 to 5-18 separately in high frequency inducing furnace at 1000-1500 deg.c for 5-10 min to obtain eutectic Mg-Cu alloy and Cu-B alloy; mixing Mg-Cu alloy and Cu-B alloy in the weight ratio of 0.2-1.5 to 1 and smelting similarly to obtain ternary Mg-Cu-B alloy; cutting the ternary Mg-Cu-B alloy into small blocks and deeply overcooling solidification at 10-320 K in a quick liquid quenching apparatus to obtain deeply overcooling solidified ternary Mg-Cu-B alloy. The process can lower the smelting point of metals and avoid the evaporization of Mg, and MgB2 monocrystal separation and growth of ternary Mg-Cu-B alloy at relatively low temperature.

Owner:TIANJIN UNIV

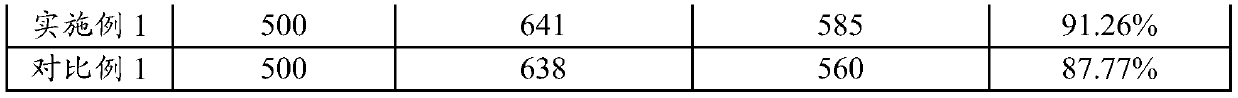

Electrolyte and lithium ion battery

ActiveCN111162315ALow melting pointImprove high temperature stabilitySecondary cellsComposite electrolytesPropanoic acidHigh energy

The invention relates to the field of lithium ion batteries, and discloses an electrolyte which comprises a high-temperature organic solvent, a positive and negative electrode protection additive andan electrolyte lithium salt, wherein the high-temperature organic solvent comprises the following components in parts by weight of 5-30 parts of ethylene carbonate, 5-30 parts of propylene carbonate,5-30 parts of diethyl carbonate, 5-50 parts of propyl propionate and 1-10 parts of fluorobenzene; the positive and negative electrode protection additive comprises the following components in parts byweight of 0.2 to 5 parts of ethylene sulfate, 0.2 to 5 parts of fluoroethylene carbonate, 0.2 to 5 parts of difluoroethylene carbonate, 0.2 to 5 parts of a dinitrile organic matter, 0.2 to 3 parts oflithium difluorophosphate, 0.2 to 5 parts of diethylene glycol dipropionitrile ether, 0.2 to 3 parts of lithium fluorosulfonyl imide, 0.1 to 2 parts of 1-propyl phosphoric anhydride, 0.5 to 20 partsof 1, 1, 2, 2-tetrafluoroethyl-2, 2, 3, 3-tetrafluoropropyl ether, 0.1 to 2 parts of lithium oxalyldifluoroborate and 0.1 to 1 part of methylene methanedisulfonate. The electrolyte is excellent in high-temperature resistance, enables the lithium ion battery with high energy density to normally work at the temperature of 70 DEG C or above, and can keep the relatively better endurance.

Owner:EVE ENERGY CO LTD

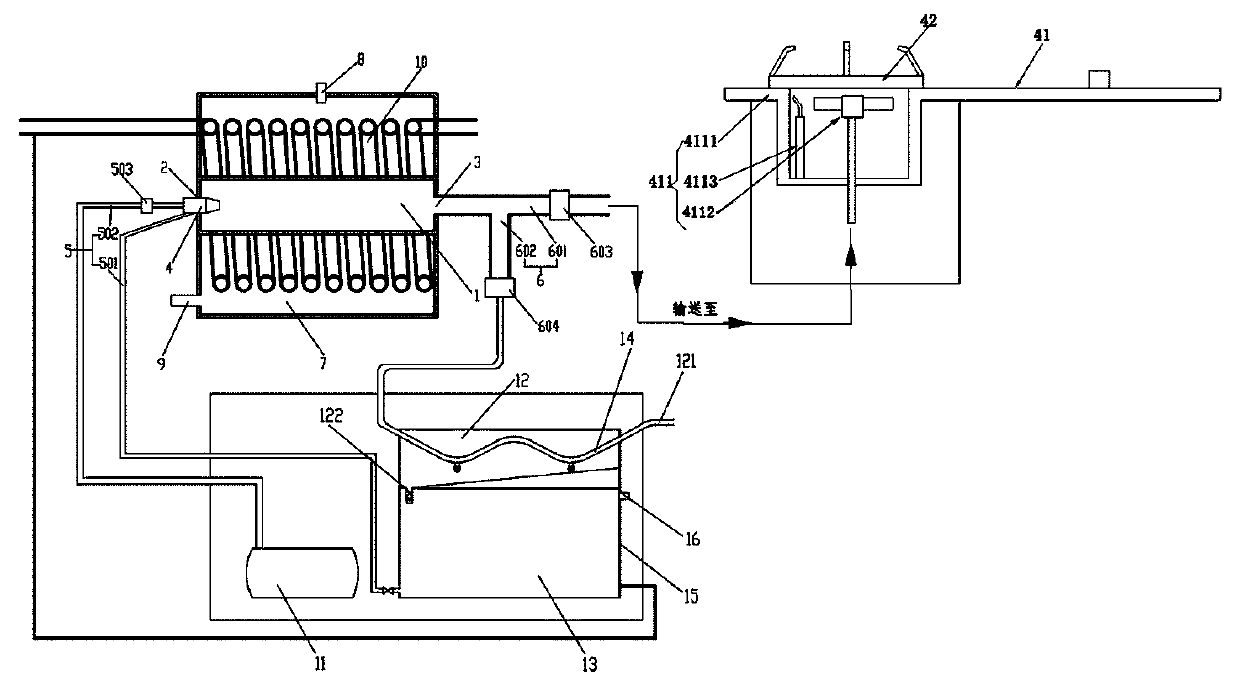

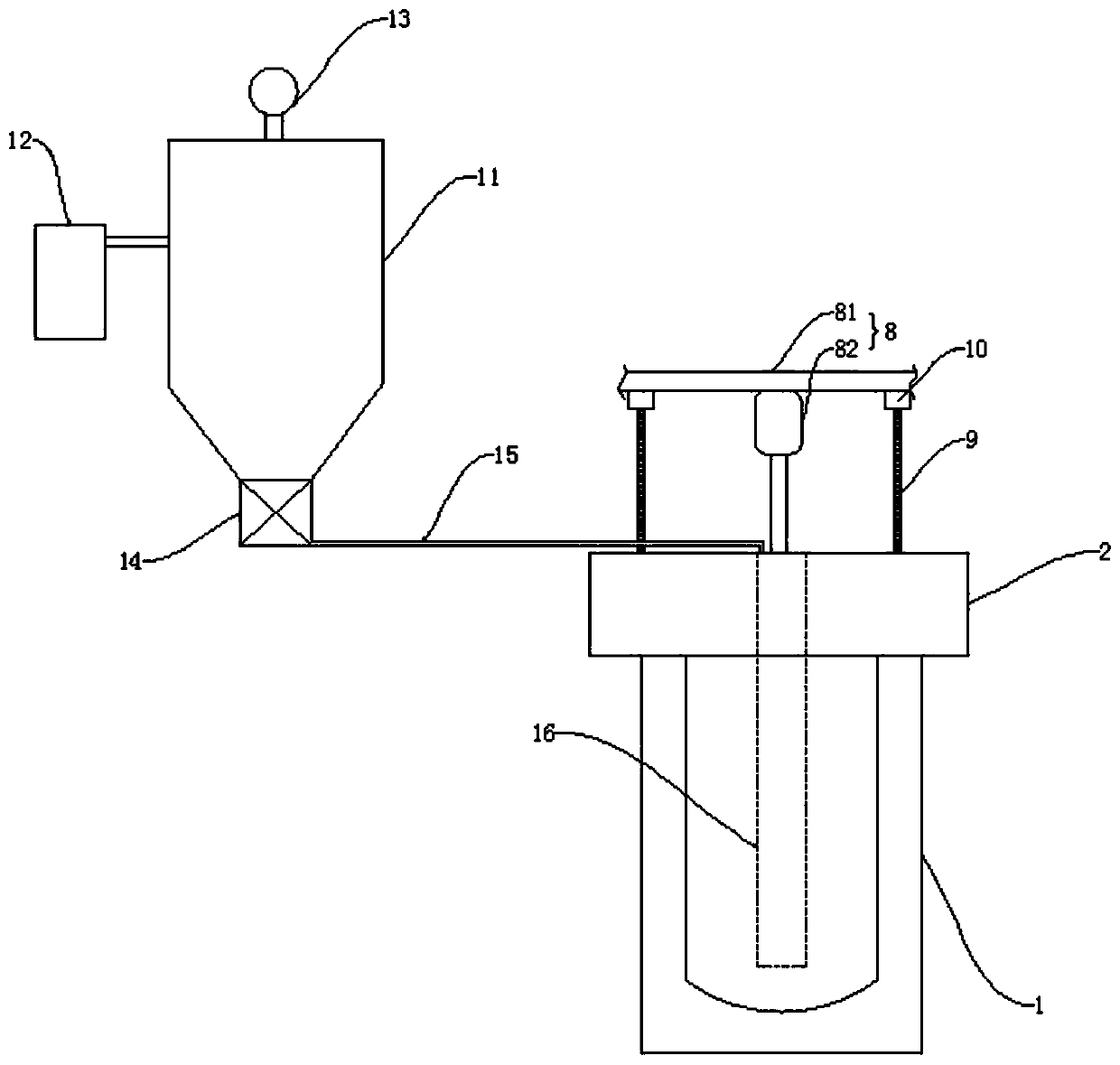

Gas system

PendingCN109855111AImprove separation efficiencyReduce gasificationLiquid fuel feeder/distributionDomestic stoves or rangesProcess engineeringGas separation

The invention belongs to the technical field of combustion devices, and particularly relates to a gas system. The gas system comprises a fission gasification terminal, a gasification base station anda gas furnace, wherein the fission gasification terminal comprises a fission tube and a resonance box; the gasification base station comprises a liquid fuel tank and an air compressor; the liquid fueltank comprises an oil-gas separation device and an oil storage device; the gas furnace comprises a gas stove panel and a burner; the burner is arranged on the gas stove panel and comprises a stove cavity, a stove head and an ignition needle; the stove head and the ignition needle are both arranged at the bottom of the stove cavity; the stove head is communicated with an outlet of a flow regulating pump; and an adjustable pot rack is arranged on the gas stove panel. Recovery of fuel at an outlet of a gasification terminal and stable storage of liquid fuel are achieved synchronously by the liquid fuel tank; and a breather valve is arranged on the oil storage device, so that the internal stability of the oil storage device is guaranteed. The fission gas-liquid conversion system is simple instructure, stable in operation and low in energy consumption.

Owner:万荣金坦能源科技有限公司

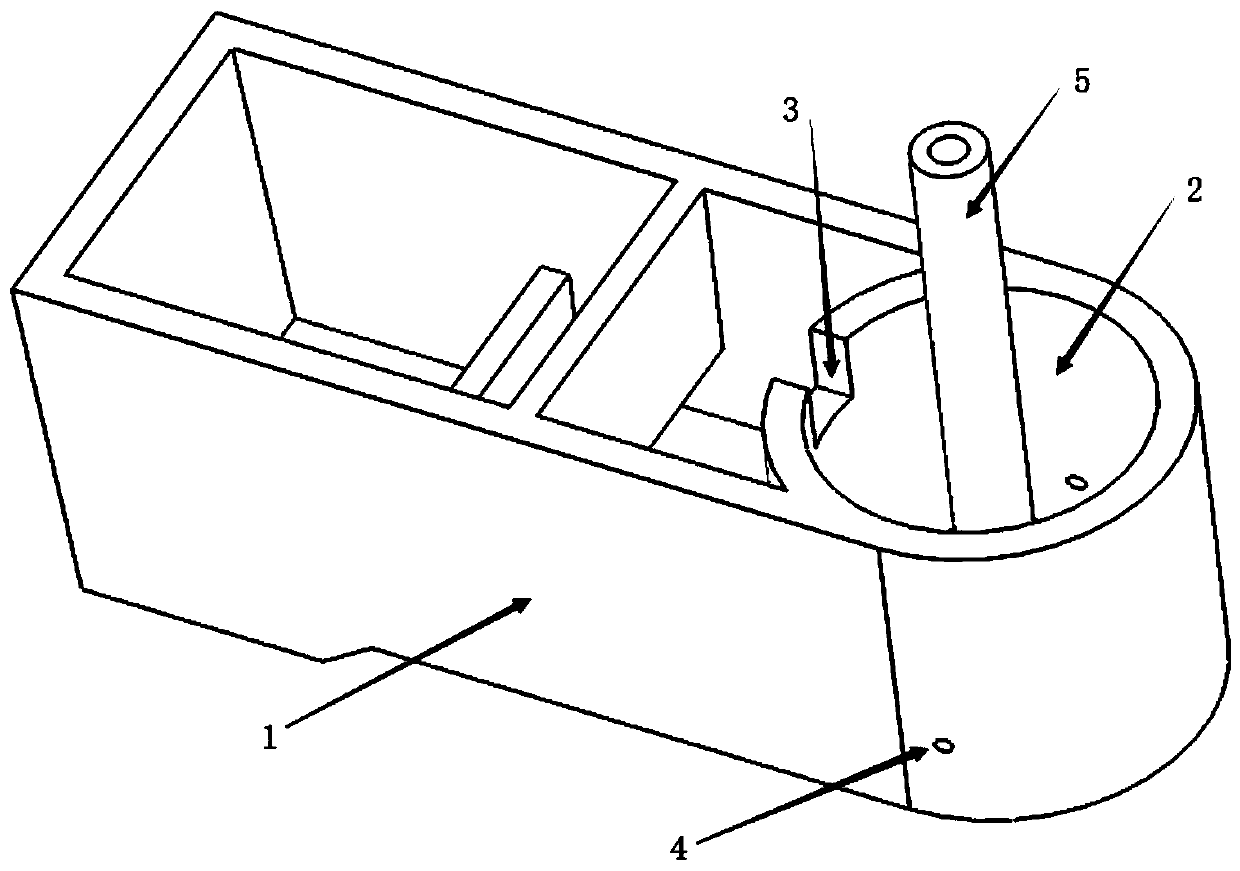

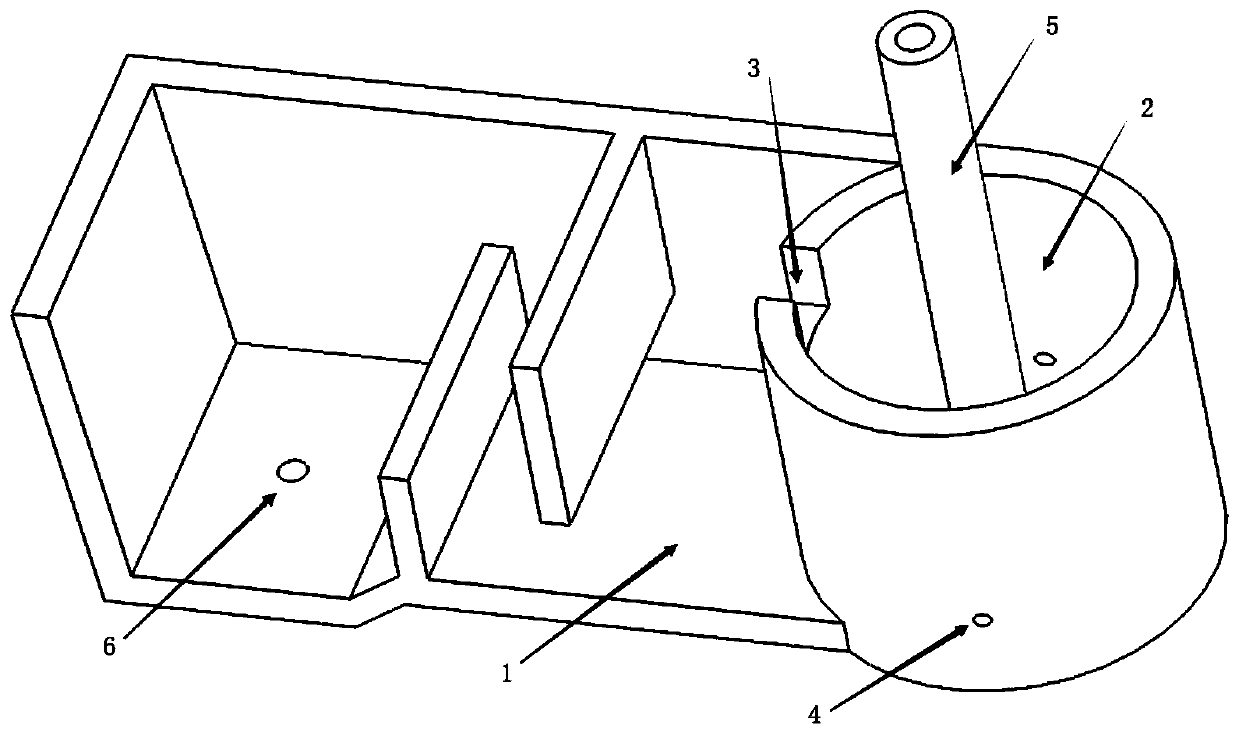

Device and method for fine adjustment of molten steel components and for modification of inclusions in continuous casting tundish

The invention provides a device and method for fine adjustment of molten steel components and for modification of inclusions in a continuous casting tundish. The device mainly consists of a tundish rectangular chamber and a tundish rotational flow chamber, wherein the tundish rotational flow chamber is located at one side of the tundish, is provided with an independent reaction chamber and is fixedly connected with the tundish rectangular chamber to form a main structure of the device; a molten steel outlet is formed in the upper side wall of the tundish rotational flow chamber; and a plurality of blowing holes are circumferentially formed in the side wall at a certain height from the bottom of the tundish rotational flow chamber. According to the device and the method, alloy powder is blown into the tundish rotational flow chamber by blowing in carrier gas through the blowing holes, and the fine adjustment of the molten steel components and the modification treatment of the inclusions in the tundish are preliminarily finished inside; and due to the driving action of the blown-in gas, the molten steel rotatably flows, the interaction time of the blown-in alloy powder and the molten steel is prolonged, and the alloy powder and the molten steel are fully blended, so that the yield and the utilization rate of alloy elements are improved, and the alloy components in the molten steel are uniform.

Owner:NORTHEASTERN UNIV

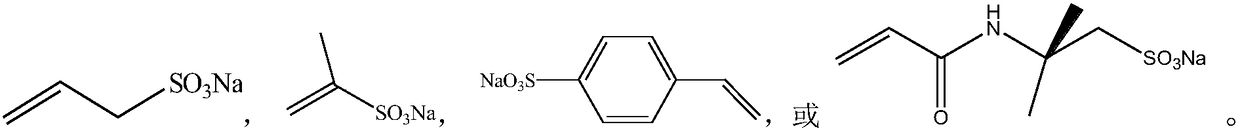

Seamless aluminum-containing core-spun yarn

The invention belongs to a refining technique outside a steelmaking furnace, and particularly relates to a seamless aluminum-containing core-spun yarn for molten steel disoxidation calcium treatment. The core-spun yarn is composed of an outer cladding and an inner core, wherein the outer cladding is coated on the external surface of the inner core; the outer cladding is composed of a steel belt which is 0.3-0.8mm thick; and the inner core is prepared from one or both of aluminum and calcium. The thickness of the outer cladding steel belt can be adjusted according to the size of the ladle, so that the calcium metal can be fed to the depth of molten steel, and the static pressure on the calcium metal is increased; and since the aluminum metal and the calcium metal can form an aluminum-calcium complex element in the molten steel, the mutual protection enhances the oxidation resistance. The introduction of the aluminum enhances the boiling point of the calcium metal and reduces the gasification of the calcium metal, thereby increasing the yield of the calcium metal and aluminum metal, and thoroughly solving the problem of splashing in the molten steel calcium treatment process.

Owner:上海盛宝冶金科技有限公司

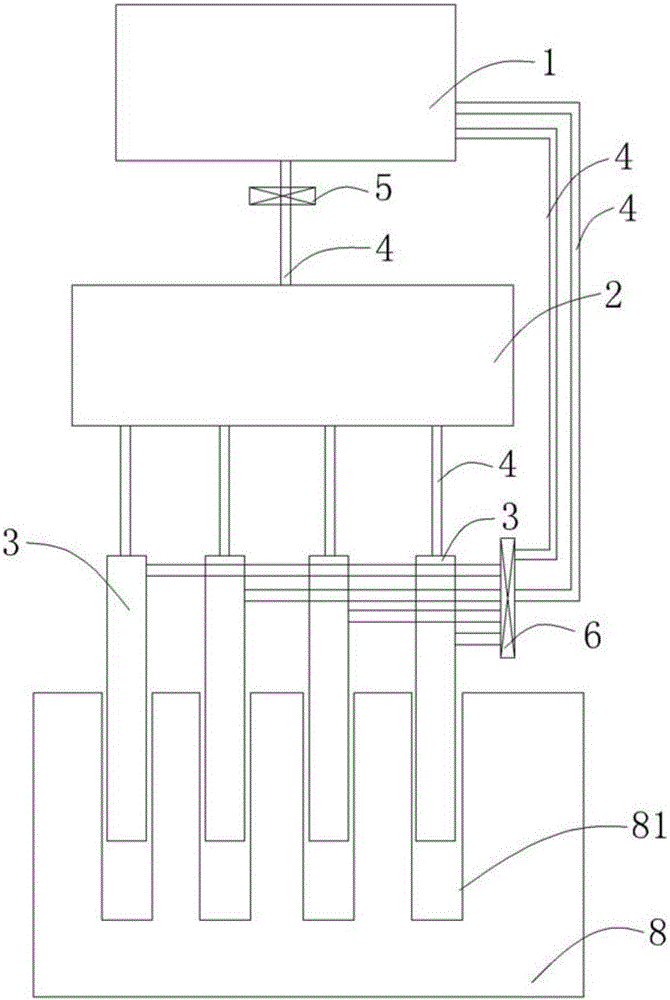

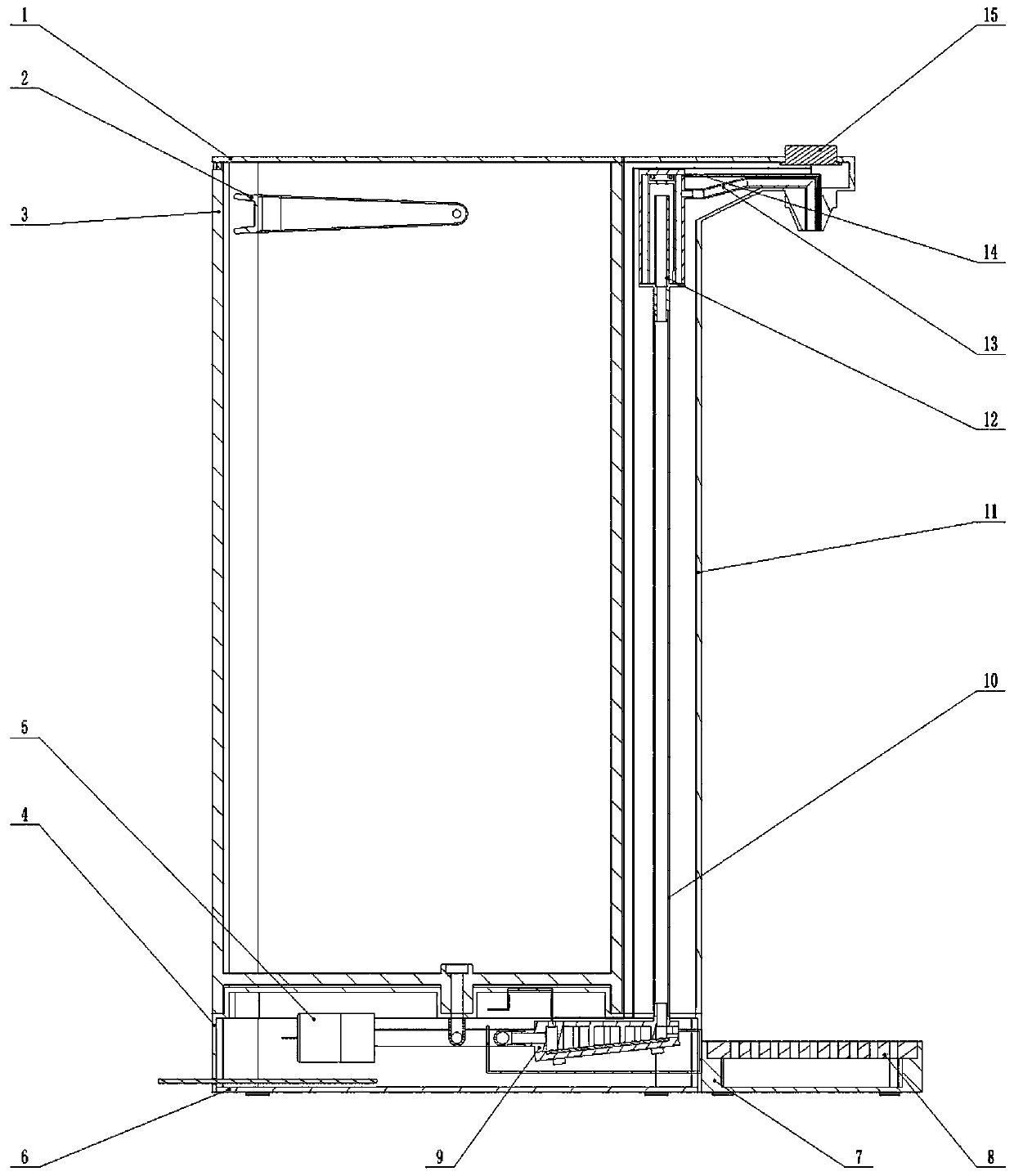

Full-automatic stone cracking machine

ActiveCN105864129AEasy to operateEasy constructionDisloding machinesServomotor componentsHydraulic pumpEngineering

The invention discloses a full-automatic stone cracking machine which is simple in structure, convenient to control, higher in work efficiency, better in stone cracking effect, higher in continuity and free of pollution and noise, and a pressure relief valve is controlled more conveniently and rapidly. The full-automatic stone cracking machine comprises a hydraulic station, multiple stone cracking bars, hydraulic pipes, a one-way valve and the pressure relief valve. The hydraulic station communicates with the one-way valve through the corresponding hydraulic pipe. The one-way valve communicates with the stone cracking bars through the corresponding hydraulic pipes so that oil liquid in the hydraulic station can be conveyed out to each stone cracking bar in the single direction. The stone cracking bars communicate with the pressure relief valve through the corresponding hydraulic pipes. The pressure relief valve communicates with the hydraulic station through the corresponding two hydraulic pipes; when each stone cracking bar is ejected out, the pressure relief valve is in a closed state; and when each stone cracking bar contracts, the oil liquid in the hydraulic station can control opening and closing of the pressure relief valve through one hydraulic pipe, and the oil liquid in each rock cracking bar flows back to the hydraulic station through the other hydraulic pipe.

Owner:GUANGDONG NACRE HYDRAULIC CO LTD

Plasma window windowless seal-based liquid-state metal spallation neutron target device

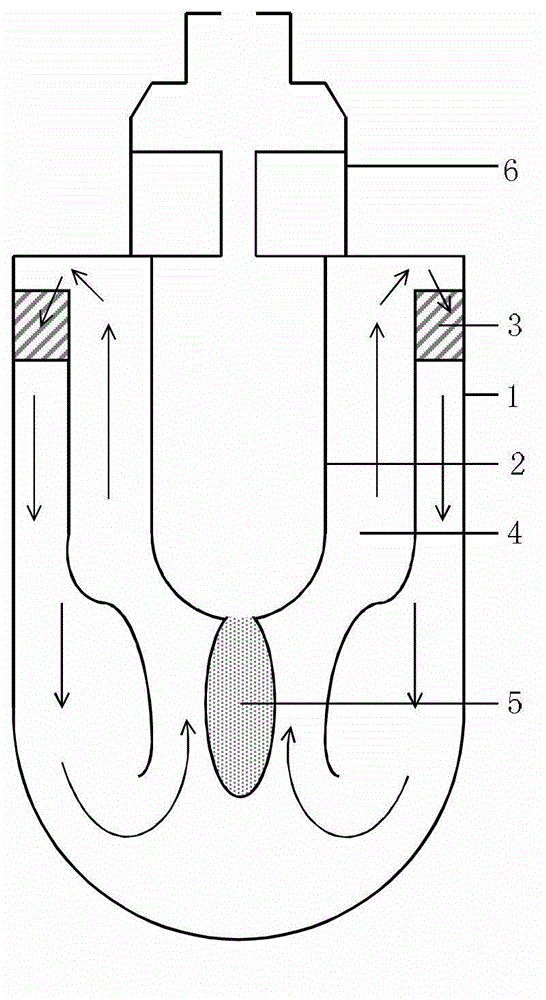

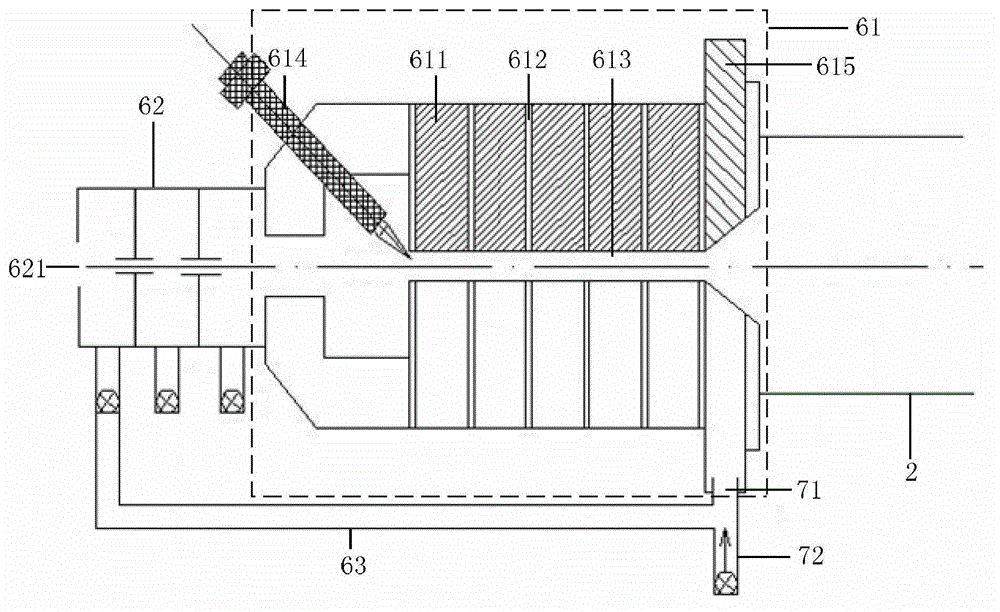

ActiveCN102946686AAchieve continuous coolingSimple designDirect voltage acceleratorsNuclear targetsLiquid stateParticle beam

The invention discloses a plasma window windowless seal-based liquid-state metal spallation neutron target device. The liquid-state metal spallation neutron target device comprises a plasma window and a liquid-state metal target, wherein the plasma window is arranged at the front end of the liquid-state metal target; the liquid-state metal target further comprises a liquid container; a liquid-state metal target material is held in the liquid container; a high-pressure cavity, a heat exchanger and a liquid-state metal circulating pipeline are arranged in the liquid container; the high-pressure cavity is arranged on the top of the liquid container; an opening is formed in the center of the bottom of the high-pressure cavity; a particle beam is in contact with a part bombarded by the beam through the opening; the heat exchanger is arranged on the inner wall of the liquid container to discharge heat to the exterior; and the metal liquid circulates in the liquid container through the liquid-state metal circulating pipeline. According to the plasma window windowless seal-based liquid-state metal spallation neutron target device, windowless seal of the liquid-state metal target is realized; the beam loss of the particle beam in a passage of the plasma window is reduced; the gasification of the liquid-state metal is reduced; and the steam of the metal entering a vacuum pipeline is reduced.

Owner:PEKING UNIV

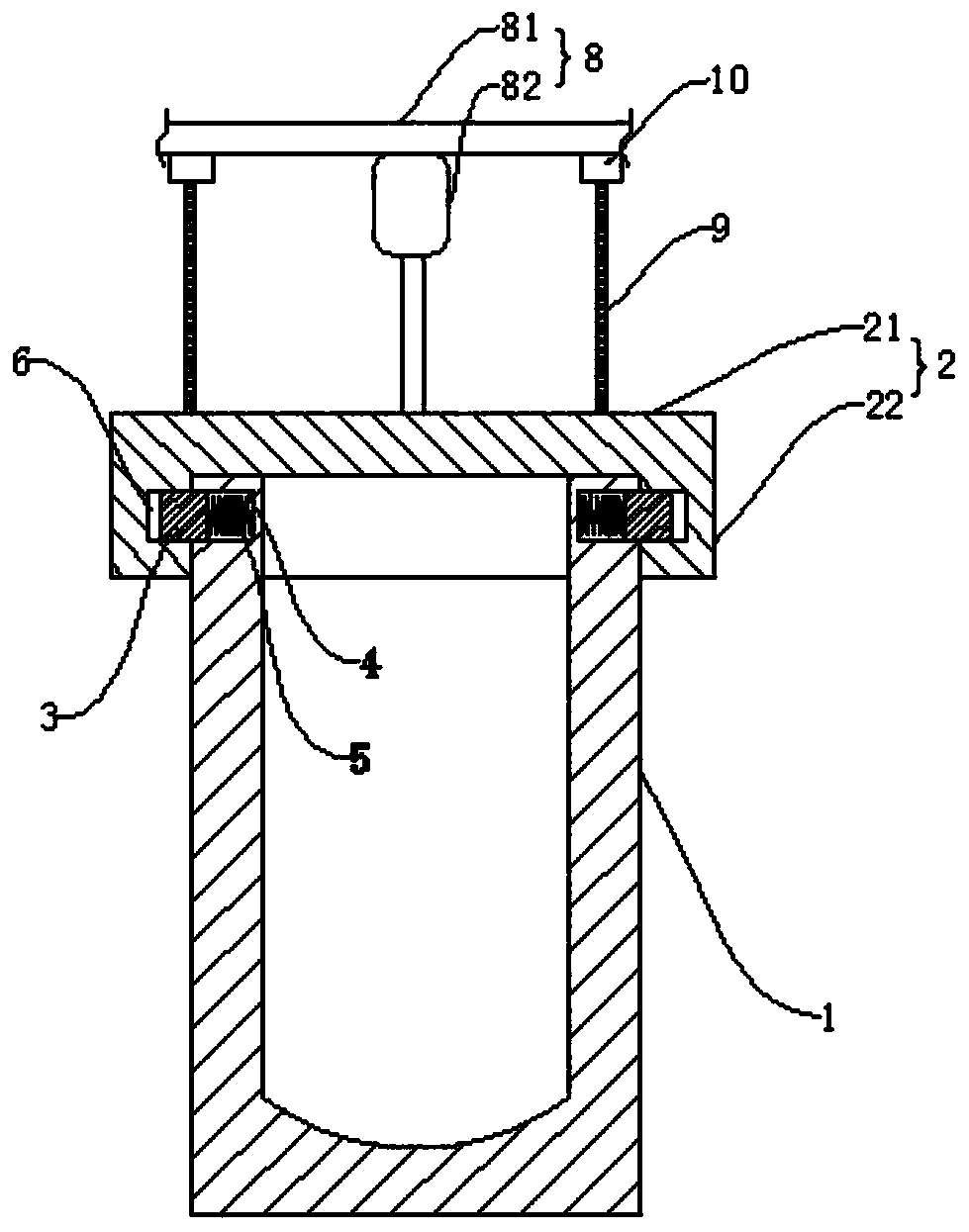

Liquid nitrogen pressurizing device, anti-reflection experiment system using same and experiment method

PendingCN110080764AIncrease pressureSimple structureMining devicesDisloding machinesLiquid nitrogen containerPressure system

The invention discloses a liquid nitrogen pressurizing device which comprises a liquid nitrogen container, an electric control device, a top cover and a liquid nitrogen tank used for pressurizing liquid nitrogen, and the electric control device is connected with a display screen. The invention further discloses an anti-reflection experiment system using the liquid nitrogen pressurizing device. Theanti-reflection experiment system comprises the liquid nitrogen pressurizing device and a confining pressure system. The invention also discloses an experiment method using the anti-reflection experiment system. The experiment method comprises the following steps: step one, system inspection; step two, putting a coal sample; step three, applying predetermined circumferential pressure and axial pressure to the coal sample; step four, vacuumizing a nitrogen supply inner pipe; step five, injecting liquid nitrogen into a liquid nitrogen thermal preservation cavity; and step, injecting high-pressure liquid nitrogen into the coal sample to carry out a cracking and anti-reflection experiment. According to the device, adverse effects caused by liquid nitrogen evaporation in the nitrogen supply pipeline are greatly relieved, the technical cost is reduced, and it is guaranteed that a liquid nitrogen fracturing anti-reflection experiment is conducted on the coal sample stably and smoothly.

Owner:HENAN POLYTECHNIC UNIV

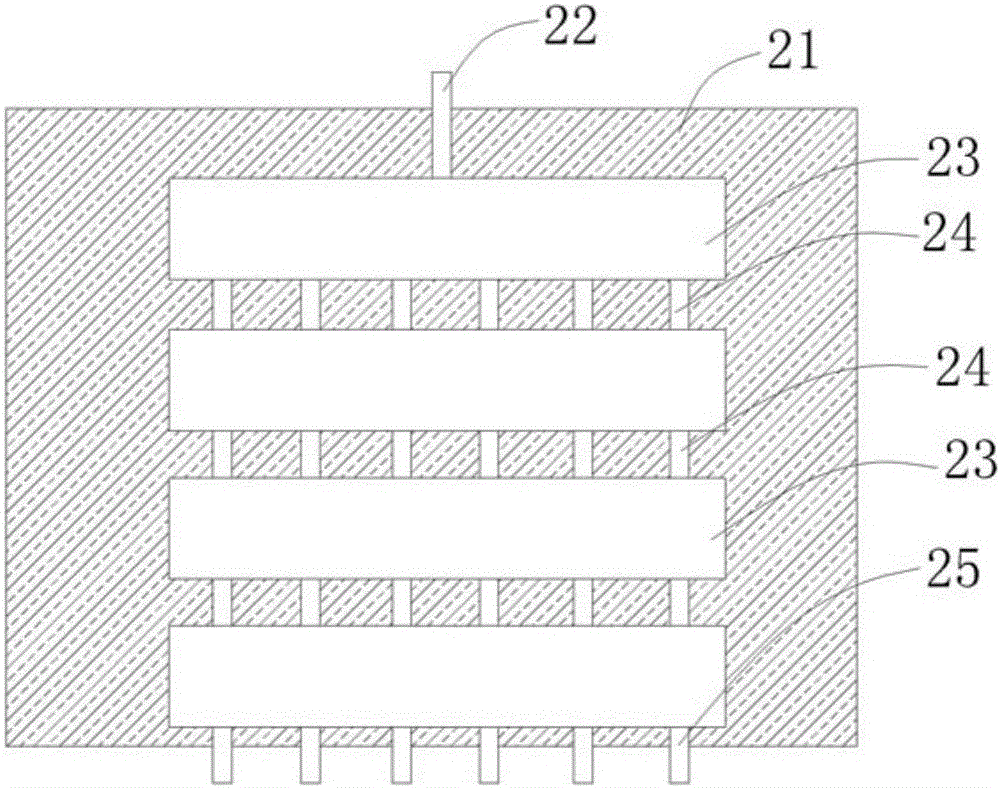

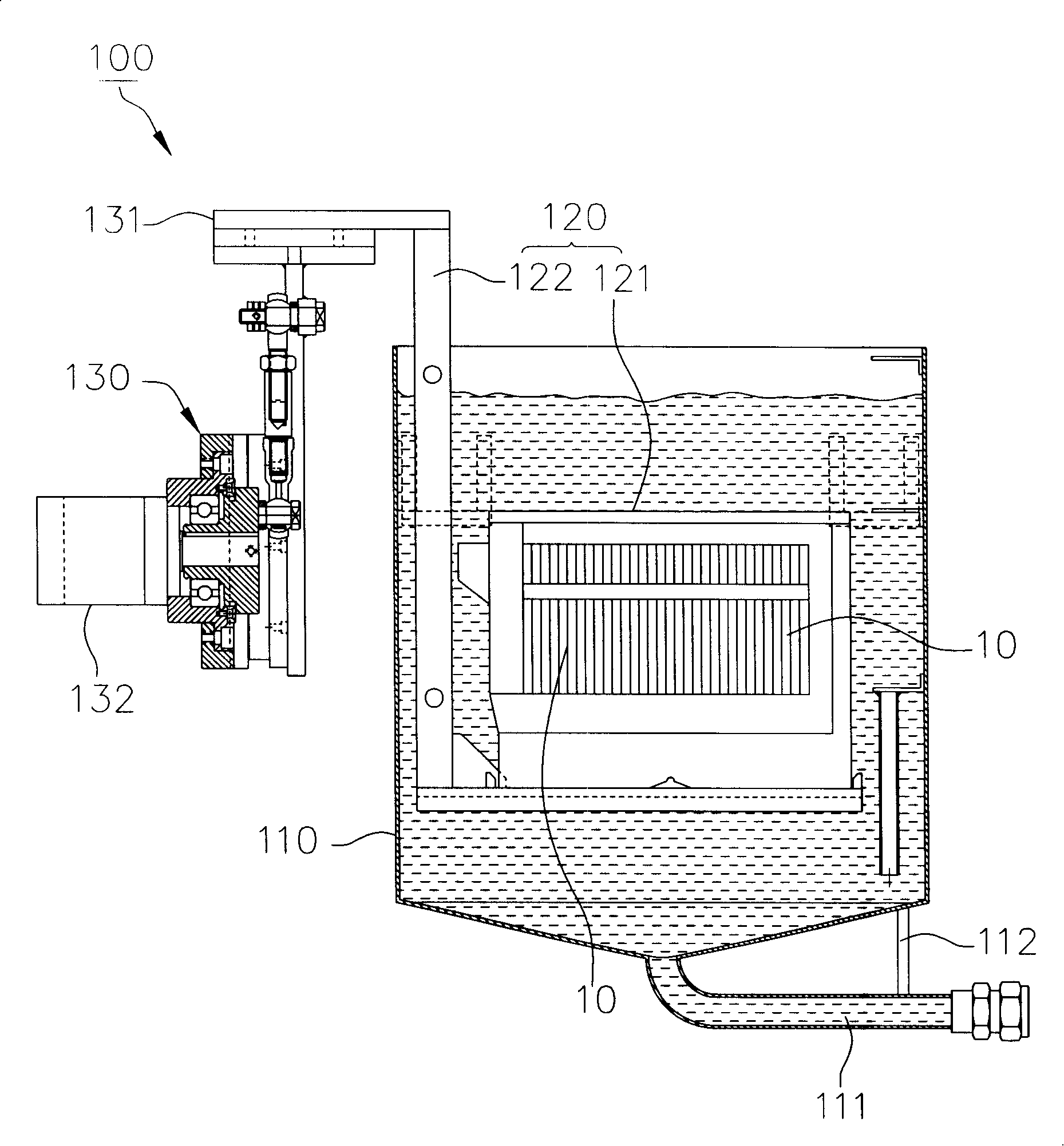

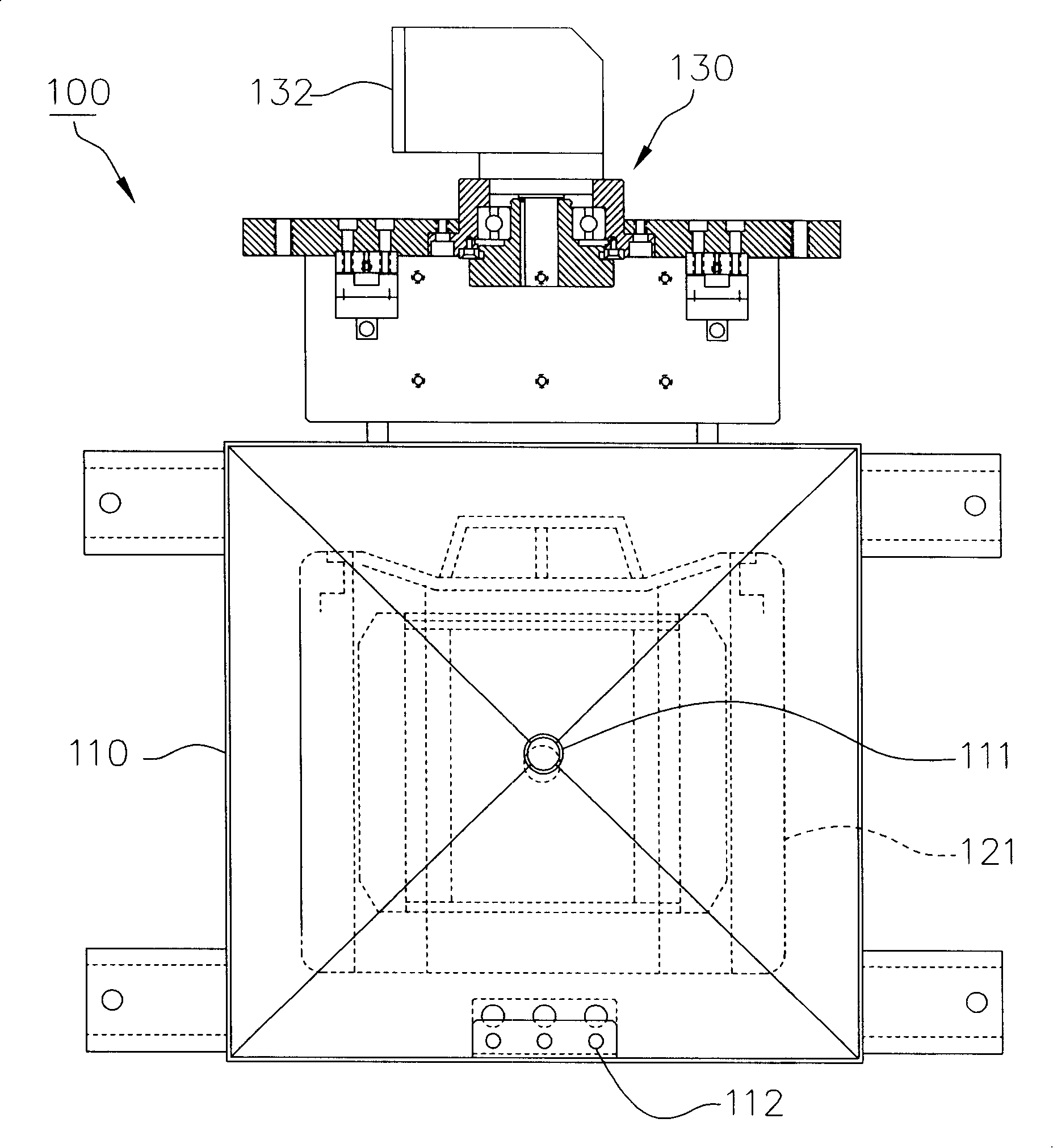

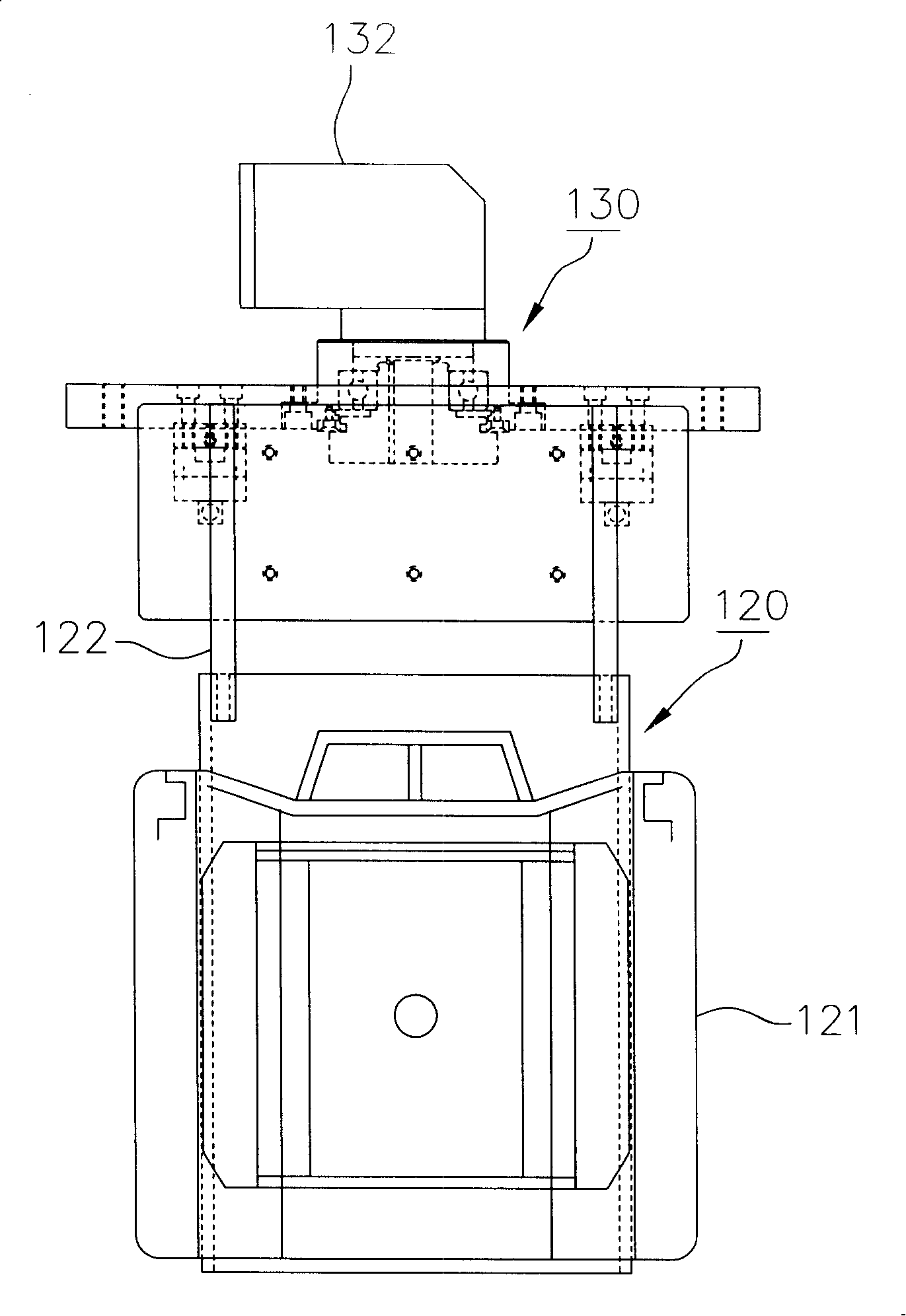

Glass substrate homogenizing and thinning device

This invention relates to an equipment for thinning glass substrate evenly. It is composed of: an etching circulation trough, a mechanism for fixing the substrates and a Bynuli oscillation mechanism. The etching circulation trough is used for holding or replacing etchant; said fixing mechanism is used for fixing several sheets of glass substrates in said trough; said oscillation mechanism, linked with said trough, makes the substrates acting in oscillation. This invention makes even etching of glass substrates and lower the gasification of hydrofluoric acid.

Owner:SAN FU CHEM CO LTD

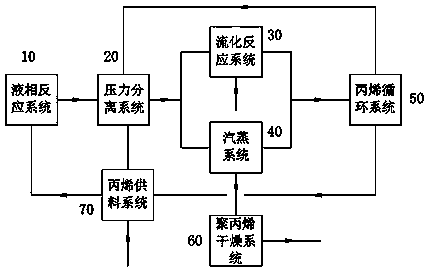

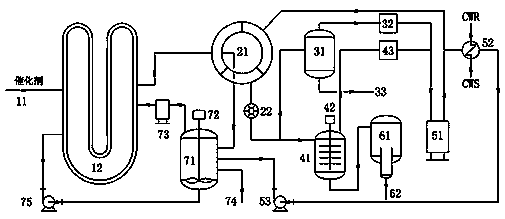

Polypropylene production process and production device

InactiveCN110606905AChange separation methodImprove separation efficiencyMoving filtering element filtersPolypropyleneChemistry

The invention relates to a polypropylene production process and a polypropylene production device. The production process comprises the following steps: polymerizing liquid-phase propylene in a liquid-phase reaction system under the action of a catalyst; introducing a solid-liquid mixture generated by the polymerization reaction into a pressure separation system for solid-liquid separation under the condition of not carrying out other solid-liquid separation; feeding filtrate obtained by solid-liquid separation into a liquid-phase reaction system to be used as a propylene raw material; feedinga solid separated material obtained by the solid-liquid separation into a steaming system and a drying system for steaming liquid removal and drying to form homo-polypropylene powder. The productiondevice comprises the corresponding liquid phase reaction system, the pressure separation system, a propylene feeding system, the steaming system, the drying system and the like. The process and the production device have the advantages of being small in equipment number, short in flow and high in process operability, one-time investment of project construction is reduced, and meanwhile the problemof huge energy consumption caused by liquid phase reactor discharging gasification, flash evaporation, propylene recompression and condensation liquefaction in a traditional process is solved.

Owner:北京泽阳天成化工技术有限公司

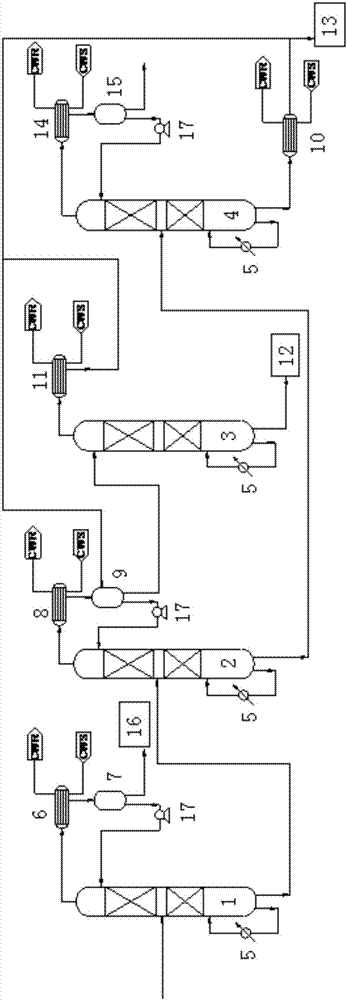

Method and device for refining 2,2-methoxy propane

ActiveCN107382682AWill not affect product qualityReduce gasificationOrganic chemistryOrganic compound preparationAlcoholOil phase

The invention provides a method and device for refining 2,2-methoxy propane. The method includes the steps of S1, primarily separating a feed solution containing 2,2-dimethoxy propane, methyl alcohol, acetone and water via a azeotrope tower, and allowing part of azeotrope of acetone and methyl alcohol which are extracted from the top of the tower to the azeotrope tower; S2, leading materials extracted from the bottom of the azeotrope tower to an extractive rectification tower for rectification, leading the materials extracted from the top of the extractive rectification tower to a stratified tank, and leading the material extracted from the bottom of the extractive rectification tower to a methanol tower; S3, leading part of water from the bottom of the methanol tower to the stratified tank to serve as an extraction agent for recycling use, leading water phase in the stratified tank into the extractive rectification tower as backflow, and leading oil phase into a product tower; S4, obtaining the 2,2-dimethoxy propane from the bottom of the product tower. The method is low in energy consumption, and 2,2-dimethoxy propane products with mass fraction of more than 99.5% can be obtained.

Owner:TIANJIN TIANDA TIANJIU TECH CO LTD

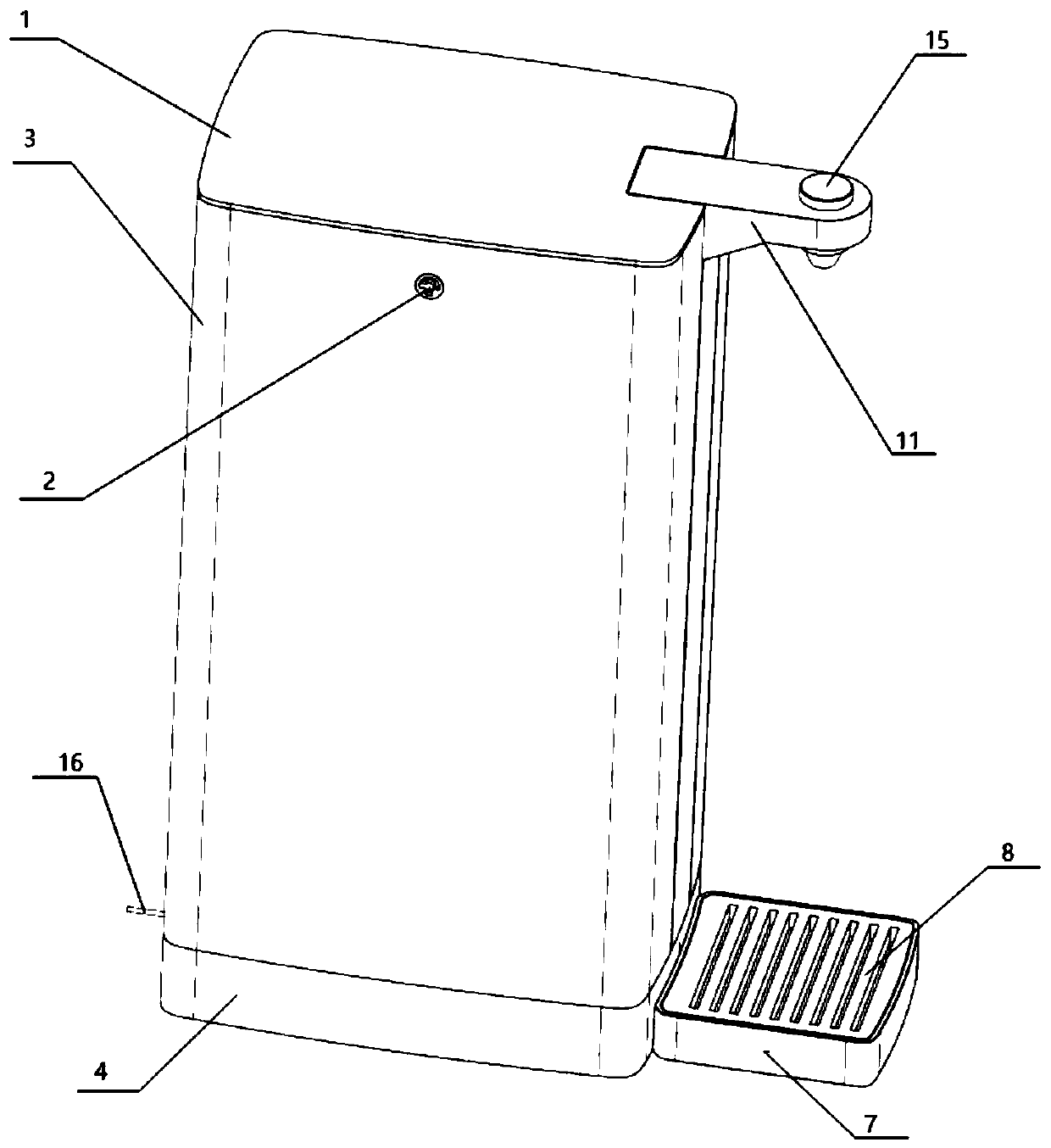

Instant heating type water dispenser

PendingCN111166183AExtend the contact heating film timeEnsure adequate heatingBeverage vesselsWater flowEngineering

The invention discloses an instant heating type water dispenser, and particularly relates to the technical field of water dispensers. The instant heating type water dispenser comprises a water tank, awater tank base is arranged at the bottom of the water tank; a water nozzle shell is arranged at the top of the water tank base, a water outlet nozzle is arranged at the tail end of the water nozzleshell, a water pan is arranged under the water outlet nozzle, a heating mechanism is arranged in the water tank base and comprises a heating assembly, the water outlet end of the heating assembly is connected with a water-gas separation device assembly through a hot water pipe, and the water outlet end of the water-gas separation device assembly is connected with the water nozzle shell. The heating assembly comprises a heating bottom plate, a heating film is attached to the heating bottom plate, a flow guide groove is formed in the heating film, and water flows along a flow guide groove and isheated through the heating film. A first-class baffle and a second-class baffle are arranged in the groove, a gap is formed between the side walls of the flow guide groove of the first-class baffle,the two ends of the second-class baffle are connected with the side walls of the flow guide groove, a gap is formed in the middle of the second-class baffle, and the first-class baffle and the second-class baffle are distributed on the heating film at intervals.

Owner:QINGDAO AUCMA DOMESTIC ELECTRICAL APPLIANCE +1

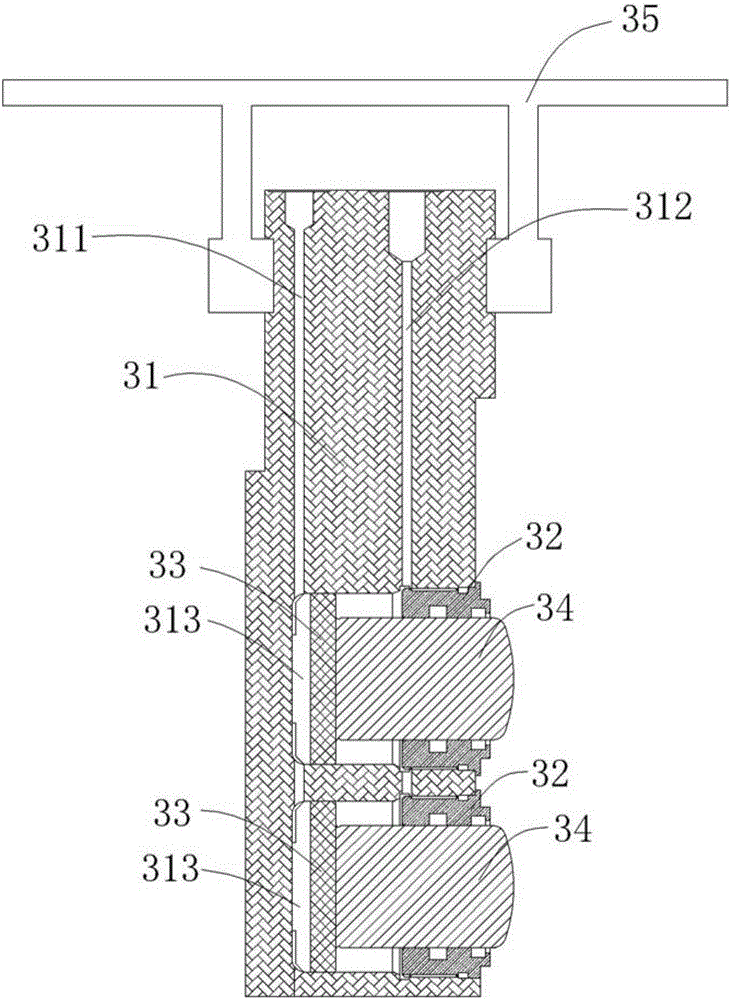

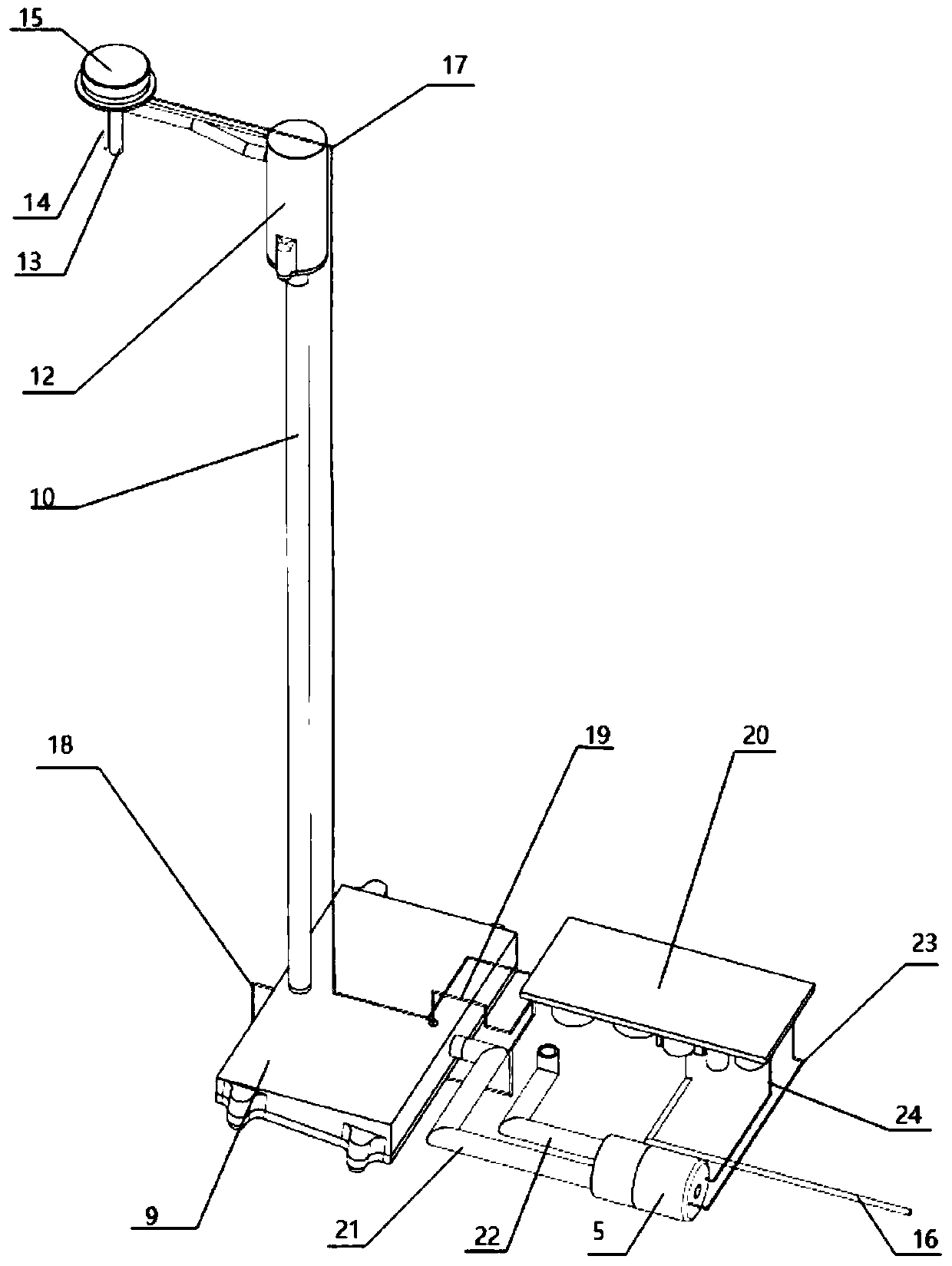

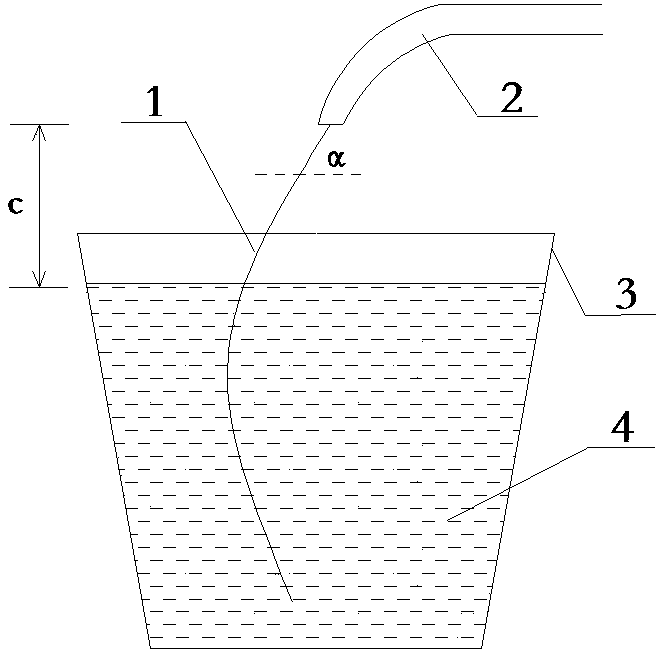

Method and device for improving magnesium absorption rate in nodular cast iron spheroidizing process

The invention provides a method and device for improving the magnesium absorption rate in a nodular cast iron spheroidizing process, and belongs to the technical field of nodular cast iron spheroidizing processes. The method includes the following steps that a, the temperature of molten iron is controlled; b, the molten iron is injected into a spheroidizing ladle; c, a spray gun is inserted into the spheroidizing ladle, and the insertion depth of the spray gun is adjusted; d, a ladle barrel and a ladle cover of the spheroidizing ladle are locked; and e, a spheroidizing agent is sprayed into the molten iron, and the spray pressure and the spray speed of the spray gun are adjusted. By means of the method for improving the magnesium absorption rate in the nodular cast iron spheroidizing process, in the spheroidizing reacting process, escape of magnesium bubbles in the molten iron is reduced, the magnesium absorption rate is increased, the magnesium waste is reduced, and the production cost is saved. The invention also provides a device for improving the magnesium absorption rate in the nodular cast iron spheroidizing process.

Owner:XINXING DUCTILE IRON PIPES CO LTD

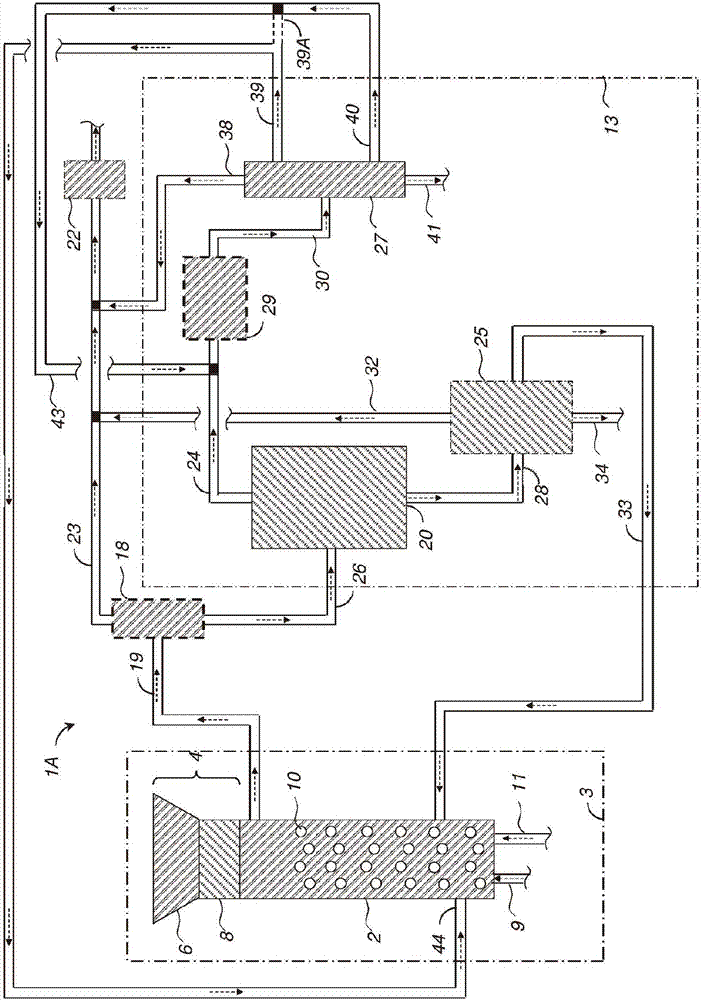

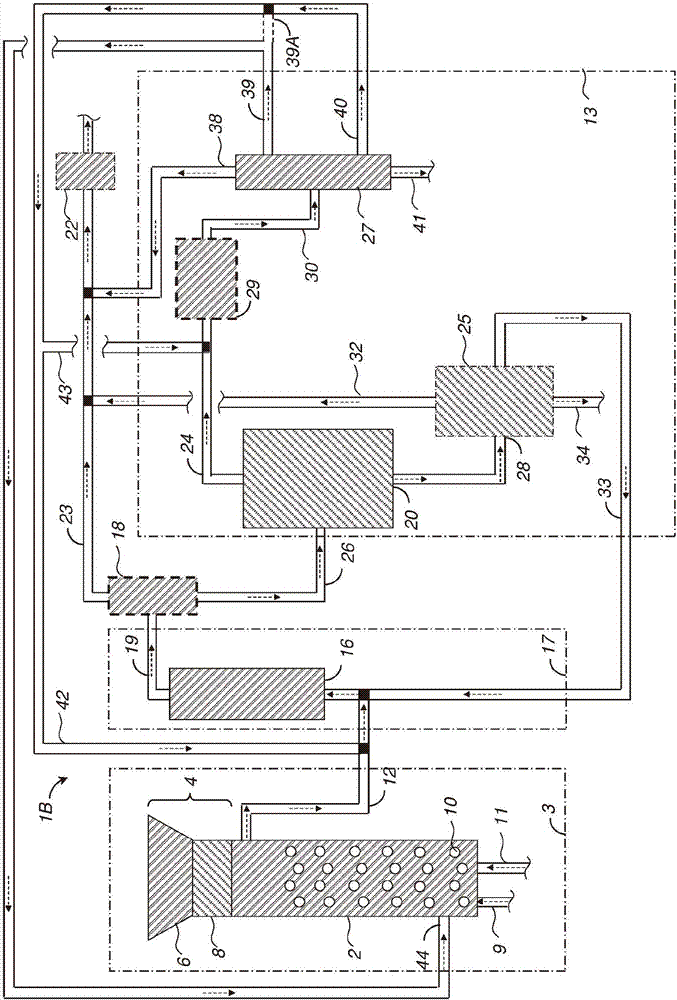

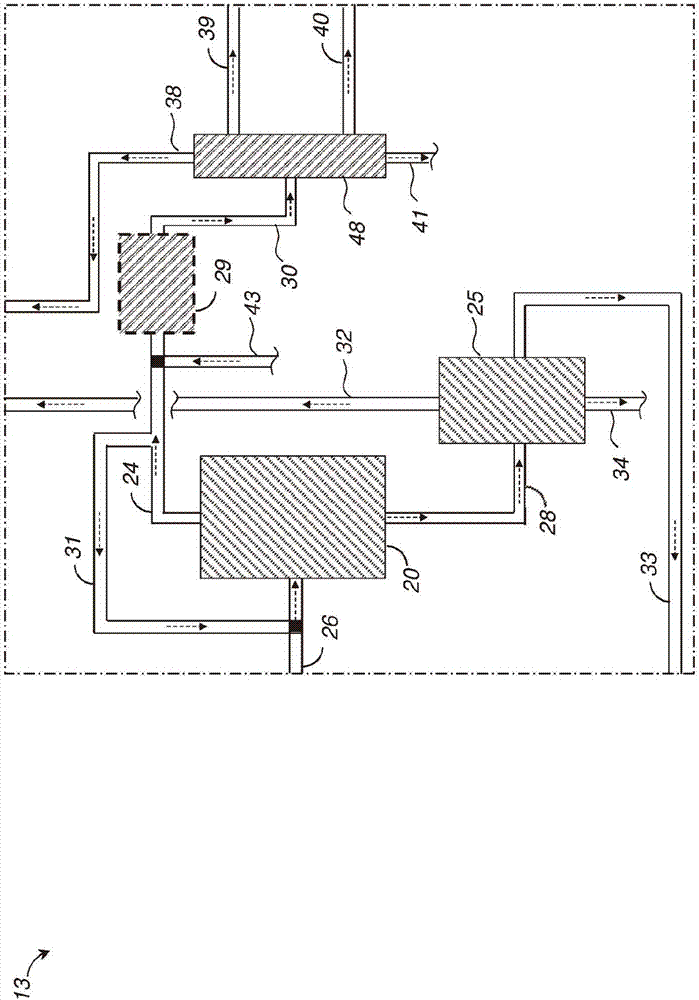

Methods and systems for processing cellulosic biomass

InactiveCN107106924AReduce gasificationLiquid hydrocarbon mixture productionPulp by-products recoveryCelluloseDigestion

Separation of a product of digestion of cellulosic biomass solids may be challenging due to the various components contained therein. Methods and systems for processing cellulosic biomass, particularly a reaction product of a hydrothermal reaction containing lignin-derived products, such as phenolics, comprise providing the reaction product to a separation zone comprising a liquid-liquid phase separation unit. The liquid- liquid phase separation unit can provide an aqueous portion and a non-aqueous portion, where these portions can be separated into various fractions individually. For example, desirable compounds in the aqueous portion and non-aqueous portion can be recovered from the portions individually and optionally combined to be further processed into a fuels product. Heavier components in the aqueous portion and non-aqueous portion can be recovered from the portions individually and used in the process, such as phenolics that can be used as a digestion solvent.

Owner:SHELL INT RES MAATSCHAPPIJ BV

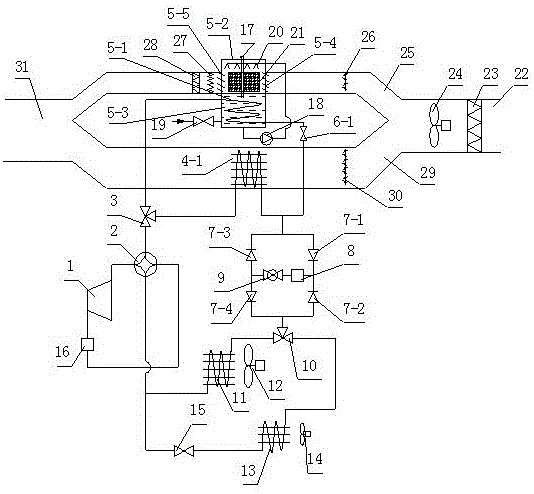

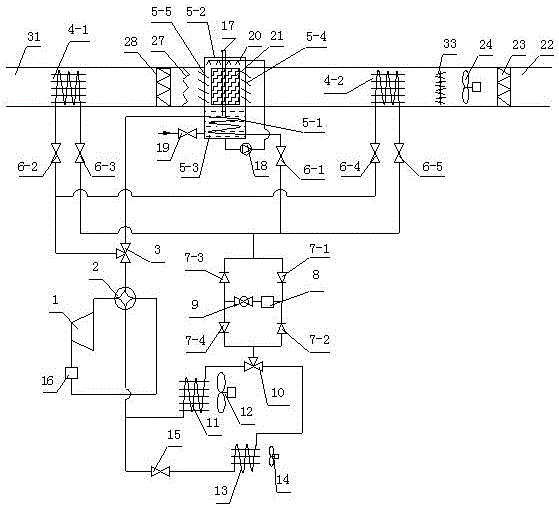

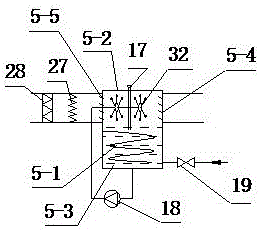

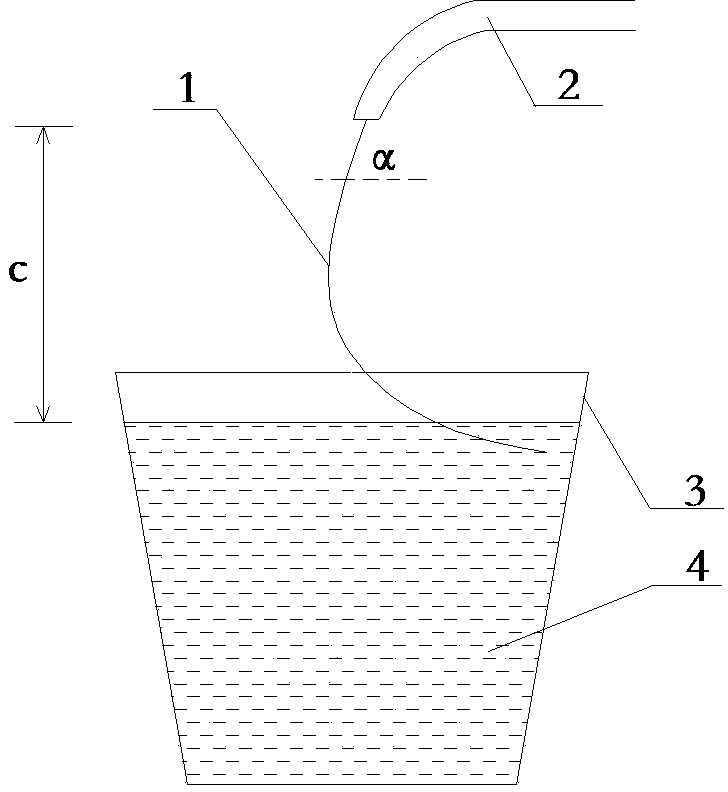

An integrated heat pump device for heating, humidification and cooling

ActiveCN104406321BPlenty of spaceReduce gasificationCompression machines with reversible cycleHeating and refrigeration combinationsFour-way valveActivated carbon filtration

The invention discloses a novel heating, humidifying and cooling integrated heat pump device. The device is characterized by comprising three parts, namely, a heat pump system, a water circuit and an air circuit; the heat pump system comprises a compressor, a four-way valve, an indoor heat exchanger, a secondary indoor heat exchanger, an one-way valve, a three-way valve, a throttling valve, an outdoor unit, an outdoor assisting heat exchanger, a liquid storing device, an air-liquid separator and an air blower; the water circuit comprises a dispenser, a water pump, a water distributor, a transfer packing layer, a water tank, a water supplementing valve, etc.; the air circuit comprises a main air returning pipeline, a branch pipeline, a primary filter, a water baffle, an activated carbon filter screen, a main air supplying pipeline, an air regulation valve, an air blower, etc. The heat pump system can be operated to heat and humidity indoor air at the same time in winter, and cool and dehumidify indoor air by evaporating a refrigerant to absorb heat and evaporating water in summer; therefore, the functions of heating, humidifying, cooling, sterilizing and the like are realized through one unit; the comfort is improved, and the energy consumption in heating and cooling is decreased.

Owner:YANTAI UNIV

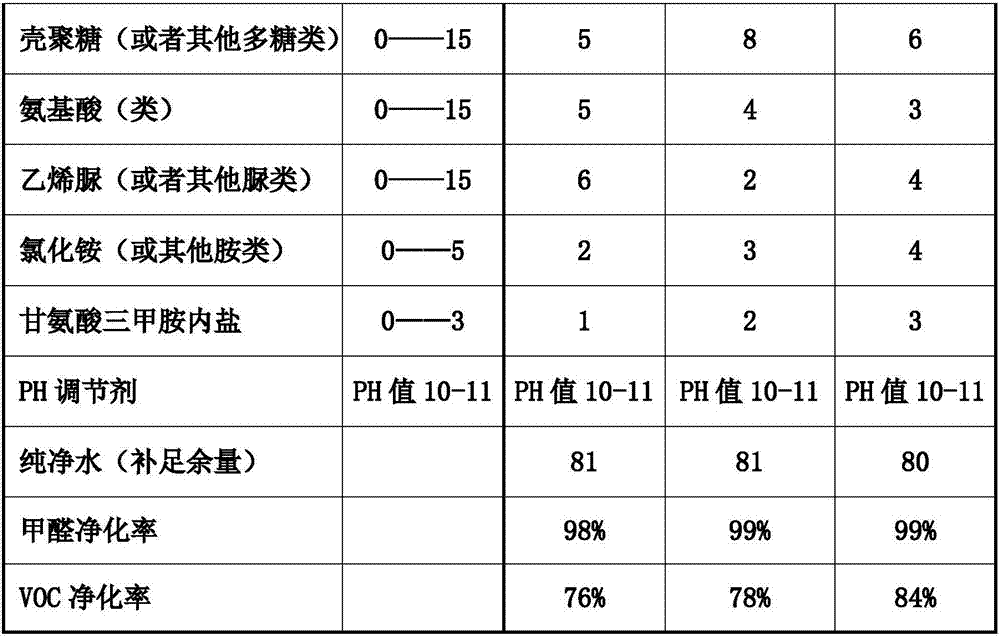

High-efficiency wide-spectrum long-acting cleaning agent for formaldehyde and other VOCs

ActiveCN107126827ADelay gasification processImprove purification effectBiocideGas treatmentLong actingChemistry

The invention discloses a high-efficiency wide-spectrum long-acting cleaning agent for formaldehyde and other VOCs. The cleaning agent mainly comprises the following raw materials by weight: 15 to 30 parts of a stable chlorine dioxide solution with a concentration in a range of 0.0001 to 1%, 0 to 15 parts of chitosan, 0 to 15 parts of amino acid, 0 to 15 parts of ethylene urea, 0 to 5 parts of ammonium chloride, 0 to 3 parts of betaine, 1 to 3 parts of a pH value regulating agent and 75 to 85 parts of purified water. The key point of the invention lies in the ratio and the application method and environment of chlorine dioxide and the polymeric high-molecular cleaning agent. The cleaning agent can effectively remove formaldehyde and other VOCs and has wide-spectrum killing effect on bacteria; the oxidizability of chlorine dioxide stably rises under the conditions of a concentration of 0.05% and a pH value of 10 to 11; the ratio and the alkaline environment employed in the invention are beneficial for obvious delaying of the gasification process of chlorine dioxide and improvement of the cleaning effect of chlorine dioxide; and thus the cleaning agent is high-efficiency wide-spectrum cleaning agent for formaldehyde and other VOCs.

Owner:成都森态源环保科技有限公司

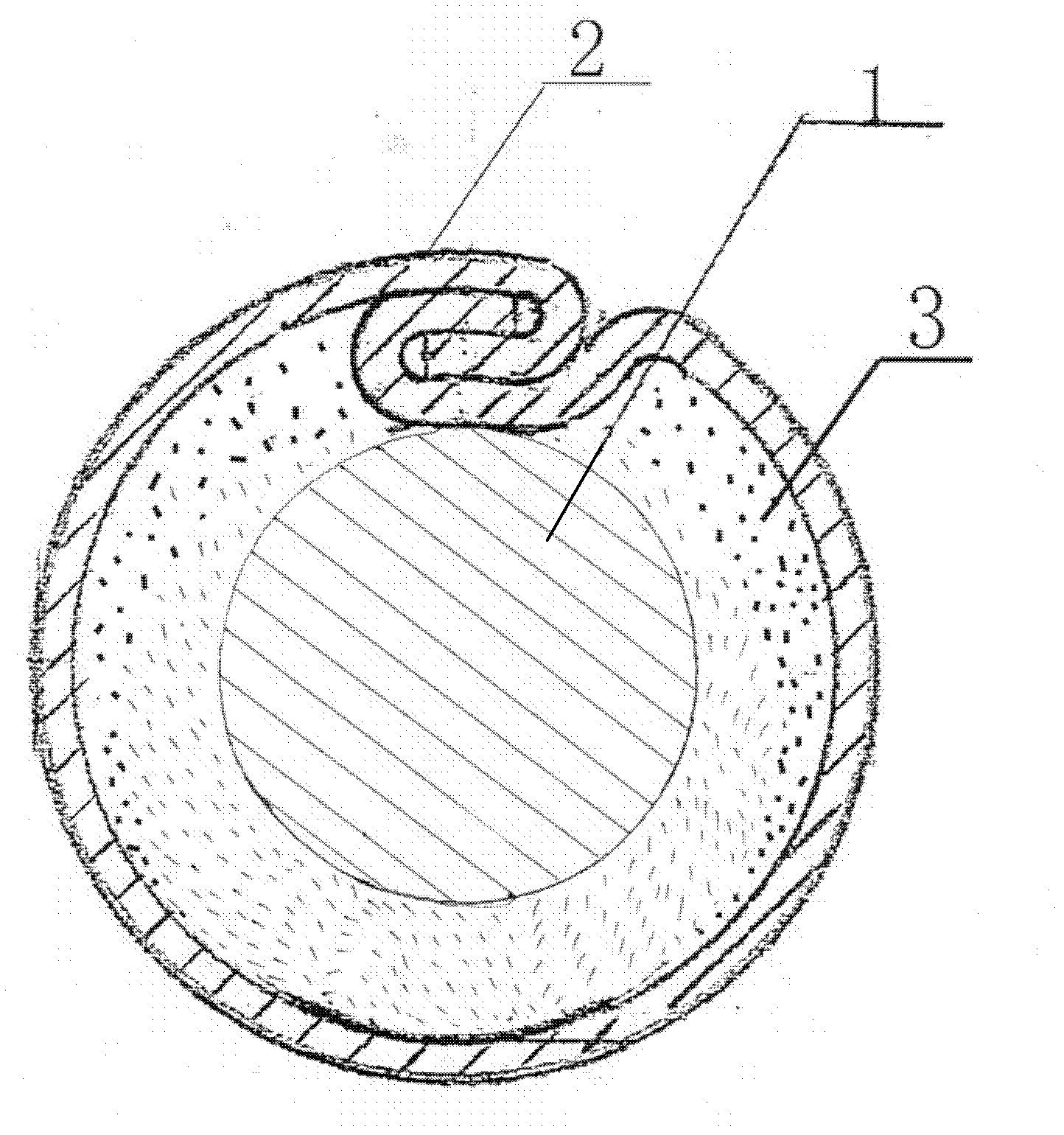

Calcium adding method for deoxidation calcium treatment of liquid steel

The invention belongs to steelmaking external refining technologies and particularly relates to a calcium adding method for deoxidation calcium treatment of liquid steel. The calcium adding method is characterized in that a calcium core wire with a composite structure is adopted and consists of a calcium core, a middle layer and a coating layer, wherein the coating layer wraps the outside surface of the middle layer, the middle layer wraps the outside surface of the calcium core, and the diameter of the calcium core is 6-8mm; the height of incidence of the calcium core wire is that the calcium core wire is just above the liquid surface of the liquid steel in a ladle by 38-42cm, and the angle of incidence of the calcium core wire is that the calcium core wire and the liquid surface of the liquid steel in the ladle form an included angle of 53-57 degrees. The calcium adding method has the advantages that the problem of splashing during the calcium treatment of the liquid steel can be effectively solved due to the adoption of the calcium core wire with the composite structure; meanwhile, the calcium core wire feeding success rate is increased through adopting the best feeding speed, height of incidence and angle of incidence, so that the yield of calcium metal is increased.

Owner:ZHANJIANG SHENGBAO TECH CO LTD

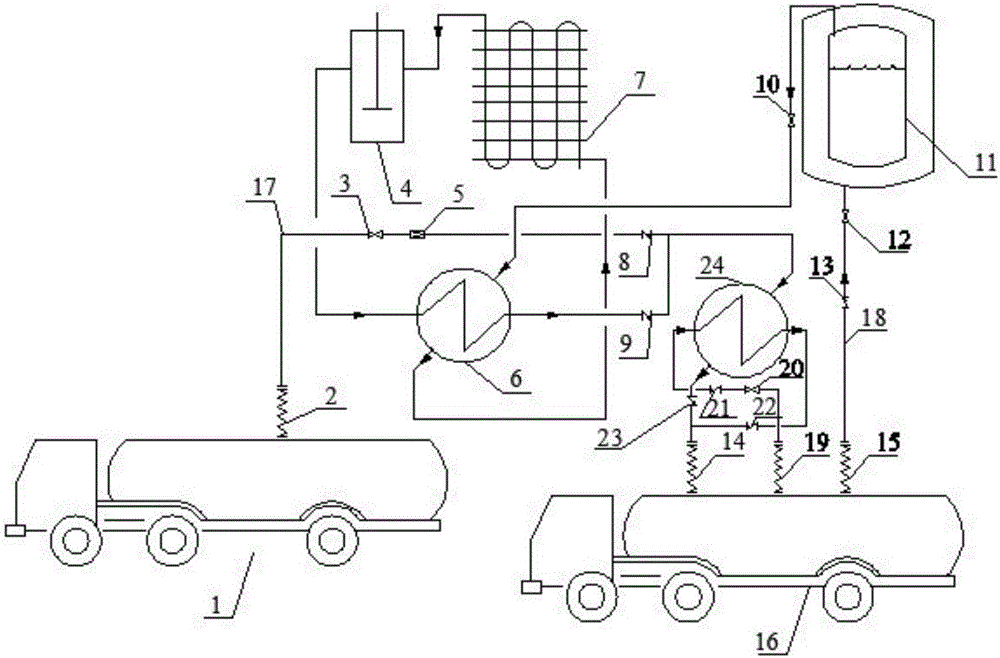

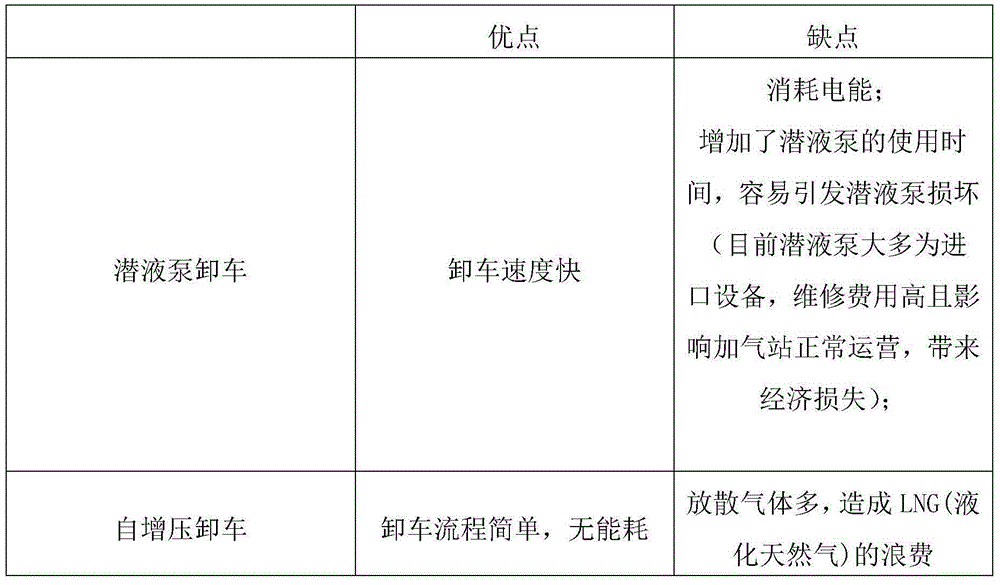

Efficient unloading device for liquefied natural gas tank car and application of efficient unloading device

InactiveCN105090740AReduce gasificationReduce frequent startupContainer filling methodsPressure vesselsProcess engineeringLiquefied natural gas

The invention provides an efficient unloading device for a liquefied natural gas (LNG) tank car. The efficient unloading device has the advantages that the LNG gasification rate can be lowered, waste is avoided and the LNG tank car is convenient in unloading.

Owner:SEDIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com