Method for preparing ammonia synthesis gas from iron alloy smoke

An ammonia synthesis gas and ferroalloy technology, which is applied in the field of comprehensive utilization of resources, can solve the problems of large smoke and dust, small capacity of electric furnaces, pollute the environment, etc., and achieve the effects of investment saving, cost reduction, energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

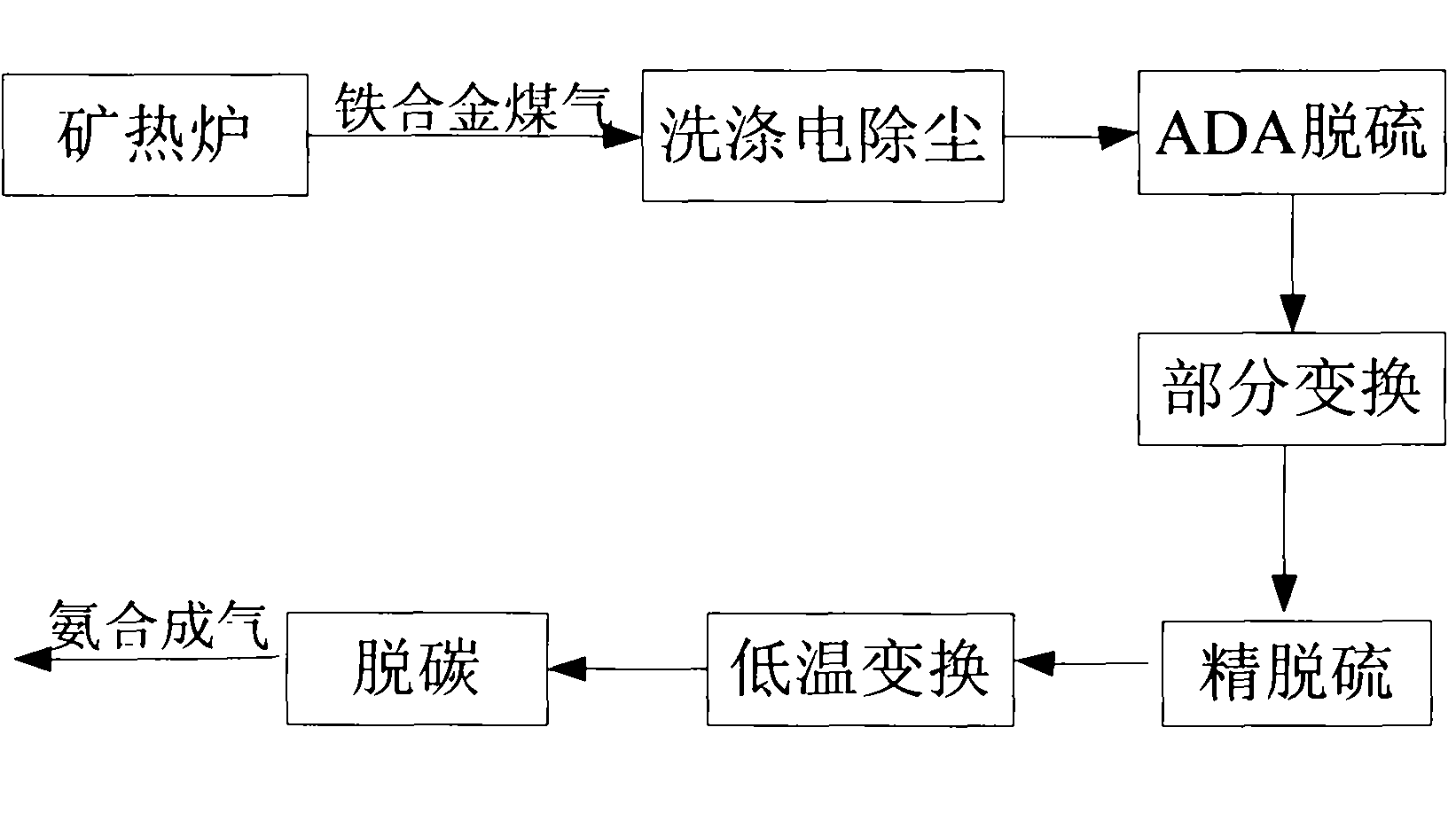

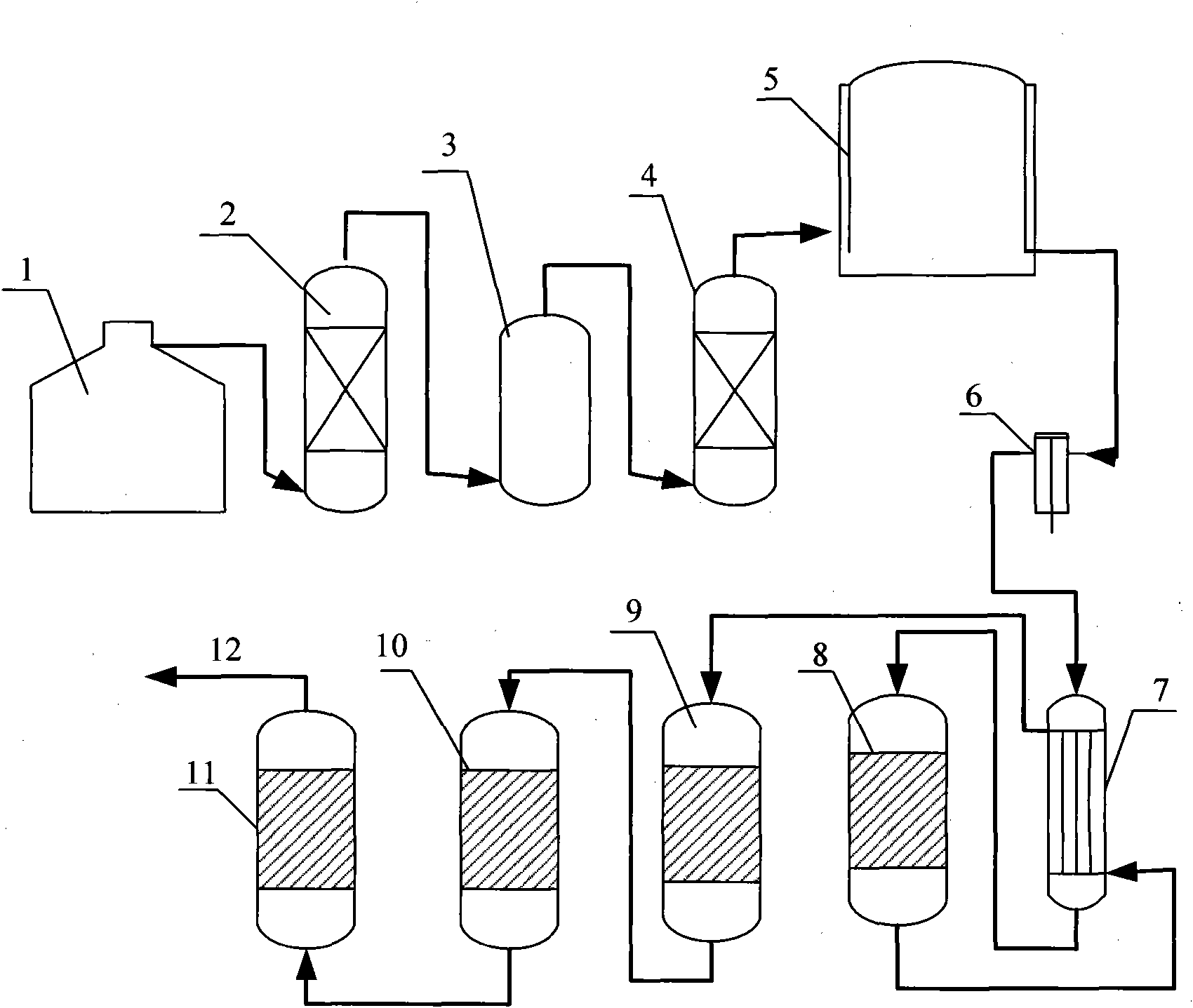

[0045] Embodiment 1: the process of producing ammonia synthesis gas from medium-capacity submerged arc furnace ferrosilicon alloy gas, see figure 2 .

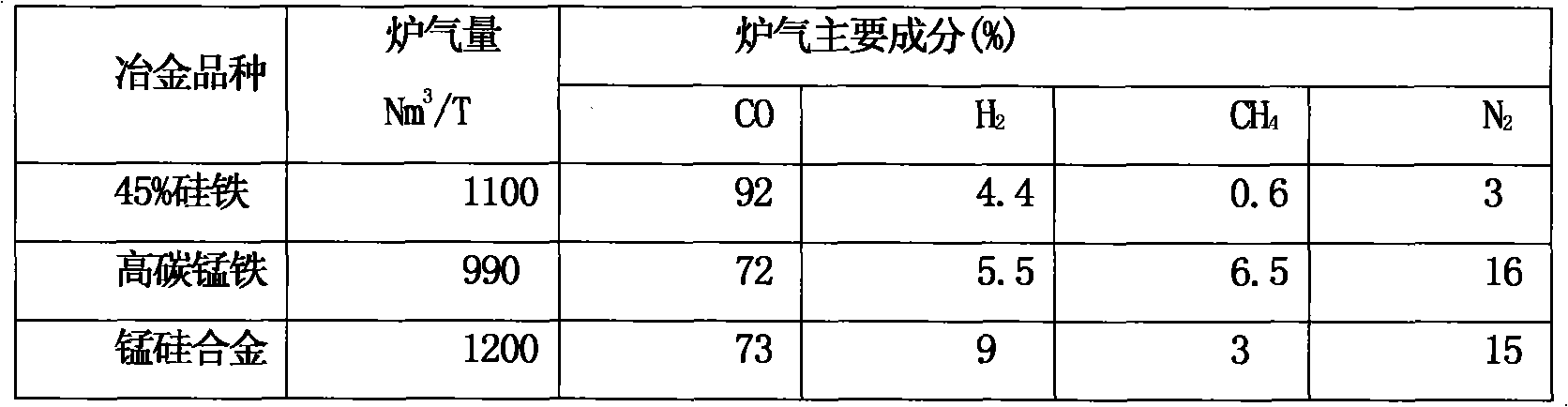

[0046] The 33000KVA submerged arc furnace produces 45% ferrosilicon alloy, with a daily output of 150 tons of ferrosilicon, and extracts 6800m of ferroalloy gas 3 / h, the recovery rate is 90%, and pure nitrogen is added 1790m 3 / h, ammonia production syngas 7730m 3 / h, synthetic ammonia 2.6 tons / h, with an annual output of 21,000 tons of synthetic ammonia.

[0047] The ferroalloy gas is drawn from the top of the submerged arc furnace 1 and enters the washing and dust removal device 2. After dedusting and cooling, it enters the electrostatic precipitator 3 for further dust removal. After desulfurization by the desulfurization device 4, it enters the gas cabinet 5 to store and stabilize the components, and then is compressed by the gas compressor 6. When the temperature reaches 0.8mpa, it enters the shift gas heat exchanger 7...

Embodiment 2

[0048] Embodiment 2: the process of producing ammonia synthesis gas from large-capacity submerged arc furnace ferrosilicon alloy gas, see figure 2 .

[0049] The 105000KVA submerged arc furnace produces 45% ferrosilicon alloy, with a daily output of 500 tons of ferrosilicon, and extracts 30000m of ferroalloy gas 3 / h, the recovery rate is 90%, and pure nitrogen is added at 7900m 3 / h, ammonia production syngas 34900m 3 / h, 12 tons / h of synthetic ammonia, with an annual output of 95,000 tons of synthetic ammonia.

Embodiment 3

[0050] Embodiment 3: High carbon manganese ferroalloy gas produces ammonia synthesis gas flow process, see figure 2 .

[0051] The 33000KVA submerged arc furnace produces high carbon ferromanganese alloy, with a daily output of 150 tons of high carbon ferromanganese, and extracts 6200m of ferroalloy gas 3 / h, recovery rate 90%, add pure nitrogen 550m 3 / h, ammonia production syngas 6080m 3 / h, synthetic ammonia 2.0 tons / h, with an annual output of 16,000 tons of synthetic ammonia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com