Method and device for refining 2,2-methoxy propane

A technology of methoxypropane and dimethoxypropane, which is applied in the refining field of 2,2-methoxypropane and can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

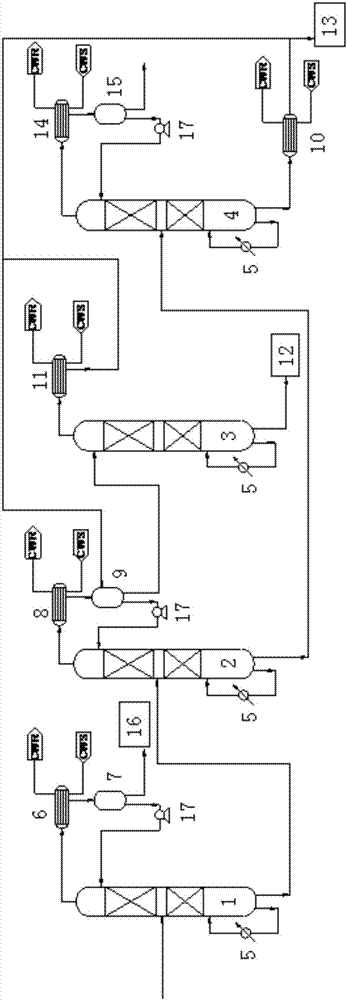

[0034] like figure 1 As shown, a refining device for 2,2-methoxypropane comprises an azeotrope tower 1, an extractive distillation tower 2, a product tower 3 and a methanol tower 4, and a reboiler 5 is provided at the lower end of each tower;

[0035] A raw material liquid inlet is arranged in the middle of the azeotrope tower 1, and the material outlet at the top of the azeotrope tower 1 is connected to the first condenser 6, the first reflux tank 7 and the upper end feed port of the azeotrope tower 1 in turn; the material outlet at the bottom of the azeotrope tower 1 Connected to the middle feed port of the extractive distillation column 2;

[0036] The discharge port at the top of the extractive distillation tower 2 is connected to the second condenser 8, the stratified tank 9 and the upper end feed port of the extractive distillation tower 2 in turn; the bottom discharge port of the stratified tank 9 is connected with the product tower 3; the product tower 3. The discharg...

Embodiment 2

[0045] This example is basically the same as Example 1, except that in the method of refining 2,2-dimethoxypropane: the operating reflux ratio of the azeotropic column is 7:1, the top temperature is 55°C, and the bottom temperature The operating reflux ratio of the extractive distillation column is 2:1, the tower top temperature is 65°C, and the tower bottom temperature is 79°C; the operating reflux ratio of the product tower is 3:1, and the tower top temperature is 70°C. The bottom temperature is 81°C; the operating reflux ratio of the methanol column is 1.5:1, the tower top temperature is 63°C, and the tower bottom temperature is 102°C.

[0046] The operating pressures of the azeotropic column 1, the extractive distillation column 2, the product column 3 and the methanol column 4 are all normal pressures.

[0047] In this example, 2,2-dimethoxypropane with a mass fraction of 99.9% was extracted from the bottom of the product tower 3, and the yield was 98.6%.

Embodiment 3

[0049] This example is basically the same as Example 1, except that in the method of refining 2,2-dimethoxypropane: the operating reflux ratio of the azeotropic column is 14.5:1, the tower top temperature is 56°C, and the tower bottom temperature The operating reflux ratio of the extractive distillation tower is 3.7:1, the tower top temperature is 66°C, and the tower bottom temperature is 81°C; the operating reflux ratio of the product tower is 4:1, and the tower top temperature is 71°C. The bottom temperature is 83°C; the operating reflux ratio of the methanol column is 2.4:1, the tower top temperature is 65°C, and the tower bottom temperature is 101°C.

[0050] The operating pressures of the azeotropic column 1, the extractive distillation column 2, the product column 3 and the methanol column 4 are all normal pressures.

[0051] In this example, 2,2-dimethoxypropane with a mass fraction of 99.86% was extracted from the bottom of product tower 3, and the yield was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com