Dustless cutting device for PVC (polyvinyl chloride) plates

A cutting device and plate technology, applied in the direction of metal processing, etc., can solve the problems of dust cannot be discharged, loud noise, hidden safety hazards, etc., and achieve the effect of convenient use, simple structure, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

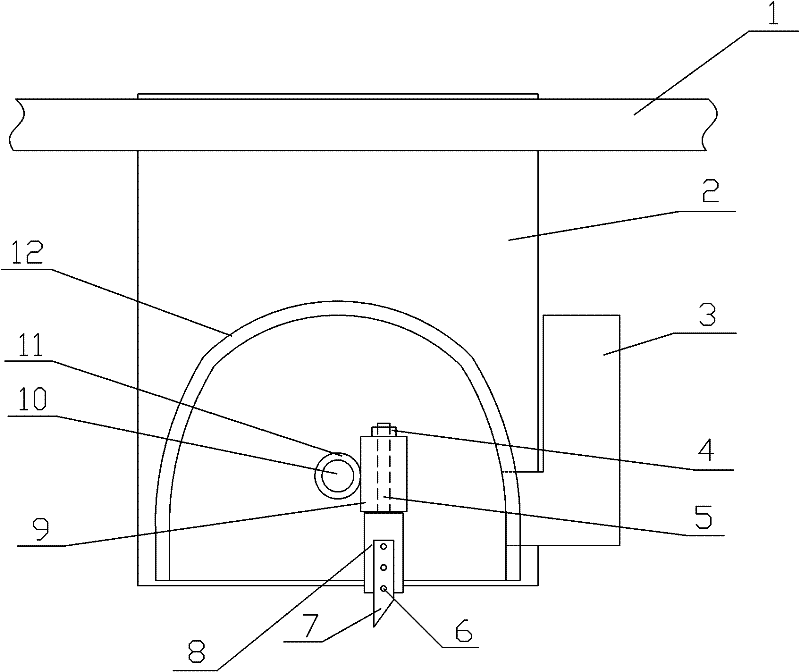

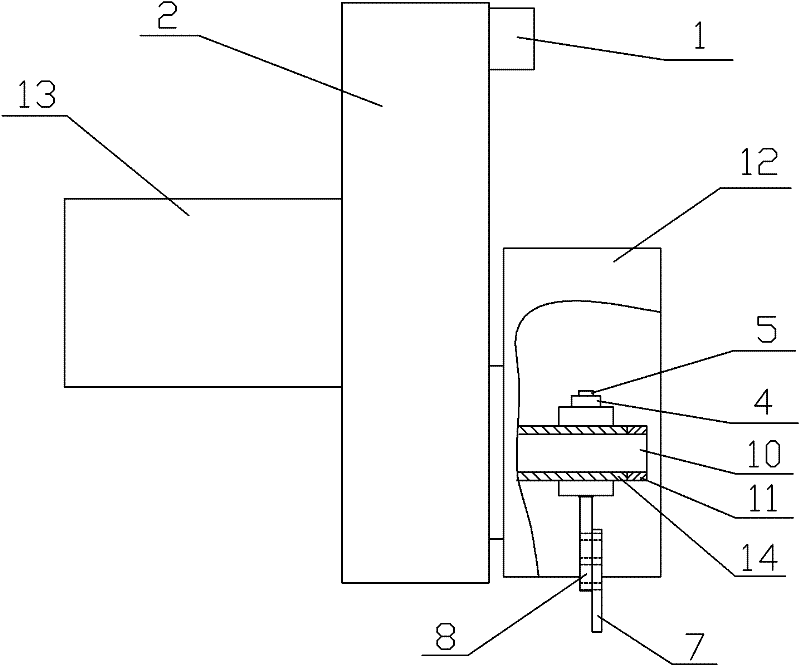

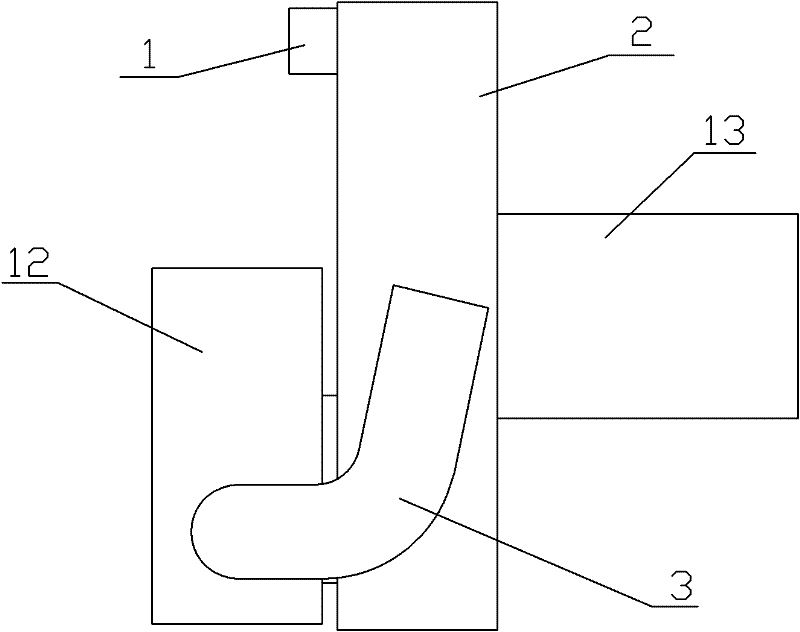

[0011] Refer to the attached figure 1 , attached figure 2 And attached figure 2 The PVC plate dust-free cutting device of the present invention will be described in detail below.

[0012] The PVC sheet dust-free cutting device of the present invention has a structure comprising a motor 13, a transmission device 2 and a rotating shaft 10, the motor 13 and the rotating shaft 10 are connected through the transmission device 2, and the rotating shaft 10 is provided with a rotating shaft locking Nut 11, the transmission device 2 is arranged on the slide rail 1, a sleeve 14 is arranged on the rotating shaft 10, a protective cover 12 is fixed on the outside of the sleeve 14, and a protective cover 12 of the described protective cover 12 A dust removal cylinder 3 is arranged on the side, and the dust removal cylinder 3 communicates with the inner cavity of the protective cover 12, and the sleeve 14 in the protective cover 12 is connected with a blade 7 through a connecting device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com