Deep overcooling solidification process for preparing superconductive MgB2 material

A superconducting material and deep supercooling technology, applied in the field of superconductivity, can solve the problems of cumbersome operation, high experimental conditions, and MgB2 scale failing to meet the ideal requirements, and achieve the effect of avoiding volatilization and lowering the melting point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

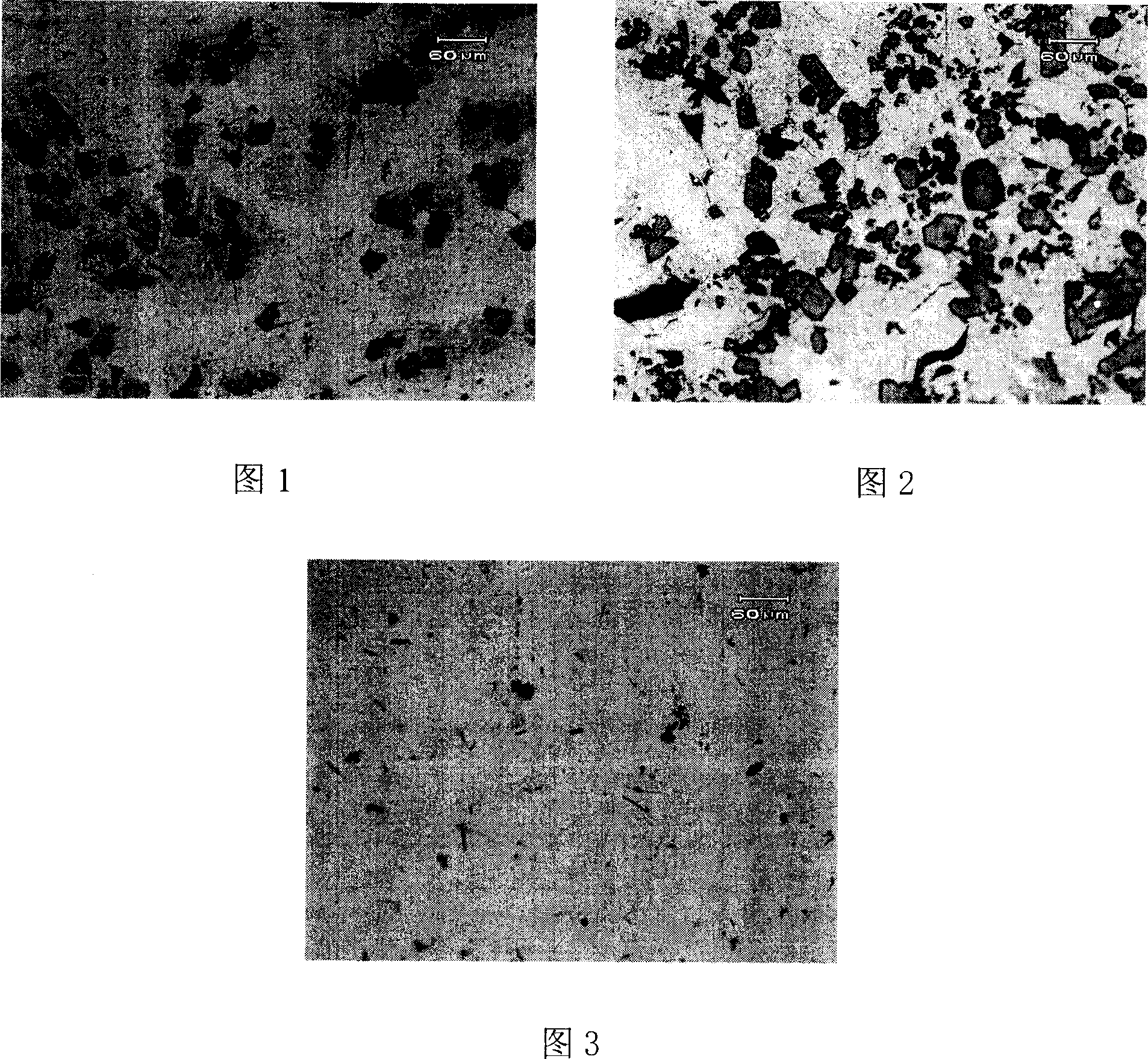

[0031] Mg block (purity of 99.9%) and Cu block (purity of 99.9%), as well as Cu block (purity of 99.9%) and B particles (purity of 97%) were mixed at atomic ratios of 58:42 and 86.7:13.3, respectively. Put the ingredients into the quartz crucible, and then put the quartz crucible into the induction coil in the high-frequency induction melting furnace, so that the ingredients are located in the middle of the induction coil, and then close the furnace body and draw a high vacuum until a certain degree of vacuum is reached ( About 3×10 -3 After Pa), fill the furnace with high-purity argon and make the pressure in the furnace a positive pressure (about 0.2MPa) to limit the volatilization and oxidation of Mg, and then use high-frequency induction smelting at 1100°C and 1200°C respectively Two kinds of alloys were obtained after 5mins of smelting. Subsequently, the binary Mg-Cu and Cu-B alloys are mixed according to a ratio of 0.238:1 (wt.%) and then subjected to induction smelting. Aft...

example 2

[0033] Mg block (purity of 99.9%) and Cu block (purity of 99.9%), as well as Cu block (purity of 99.9%) and B particles (purity of 97%) were mixed at atomic ratios of 58:42 and 86.7:13.3, respectively. Put the ingredients into the quartz crucible, and then put the quartz crucible into the induction coil in the high-frequency induction melting furnace, so that the ingredients are located in the middle of the induction coil, and then close the furnace body and draw a high vacuum until a certain degree of vacuum is reached ( About 3×10 -3 After Pa), fill the furnace with high-purity argon and make the pressure in the furnace a positive pressure (about 0.2MPa) to limit the volatilization and oxidation of Mg, and then use high-frequency induction smelting at 1100°C and 1200°C respectively Two kinds of alloys were obtained after 5mins of smelting. Subsequently, the binary Mg-Cu and Cu-B alloys were mixed according to a ratio of 0.238:1 (wt.%) and then subjected to induction smelting. Af...

example 3

[0035] Mg block (purity of 99.9%) and Cu block (purity of 99.9%), as well as Cu block (purity of 99.9%) and B particles (purity of 97%) were mixed at atomic ratios of 58:42 and 86.7:13.3, respectively. Put the ingredients into the quartz crucible, and then put the quartz crucible into the induction coil in the high-frequency induction melting furnace, so that the ingredients are located in the middle of the induction coil, and then close the furnace body and draw a high vacuum until a certain degree of vacuum is reached ( About 3×10 -3 After Pa), fill the furnace with high-purity argon and make the pressure in the furnace a positive pressure (about 0.2MPa) to limit the volatilization and oxidation of Mg, and then use high-frequency induction smelting at 1100°C and 1200°C respectively Two kinds of alloys were obtained after 5mins of smelting. Subsequently, the binary Mg-Cu and Cu-B alloys were mixed according to a ratio of 0.238:1 (wt.%) and then subjected to induction smelting. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com