Full-automatic stone cracking machine

A rock splitter, fully automatic technology, applied in the direction of discharge machinery, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of inability to automatically control, prolong oil drainage time, and difficult to automate, and achieve simple and reliable structure and sealing. The effect of convenient construction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

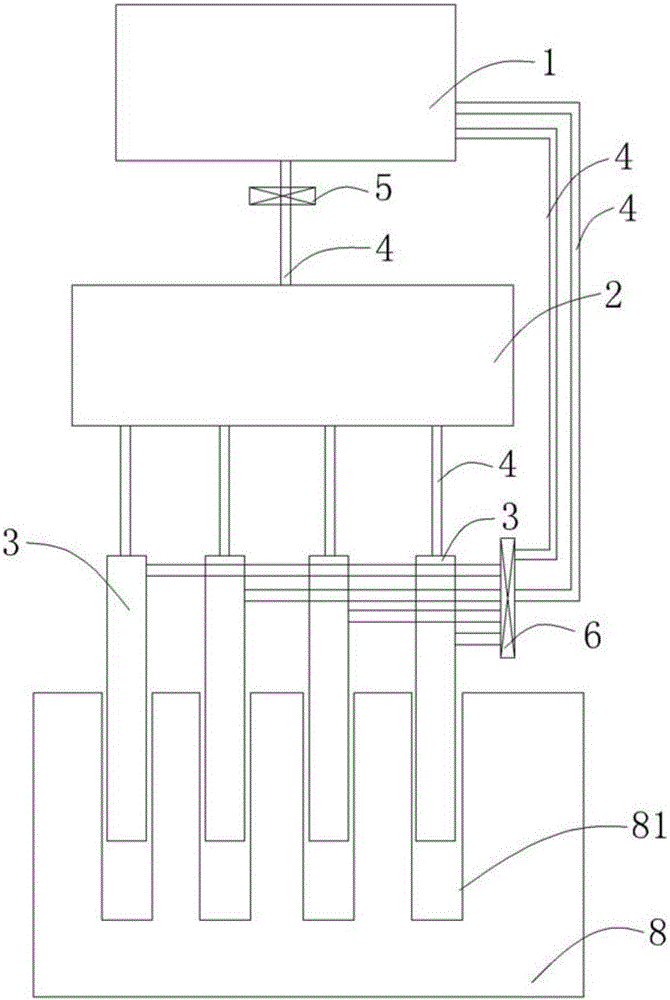

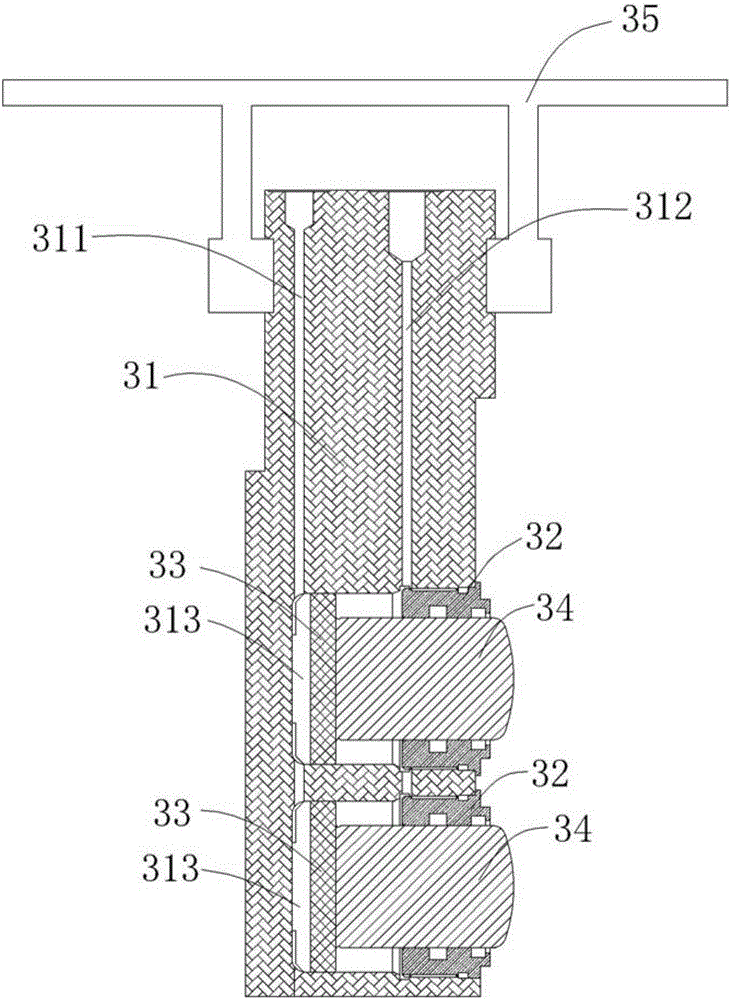

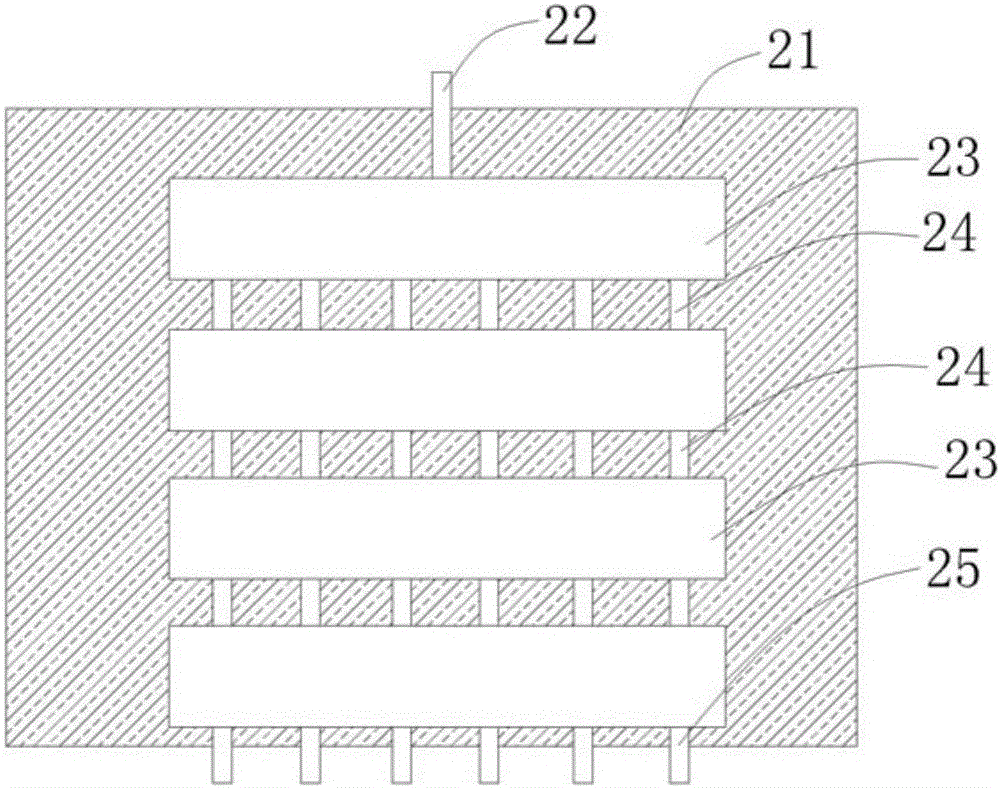

[0028] Such as figure 1 with 2 As shown, the fully automatic rock splitter of the present invention includes a hydraulic station 1, a distributor 2, four rock splitter rods 3, a hydraulic pipe 4, a one-way valve 5 and a pressure relief valve 6, and one of the branches of the hydraulic station 1 outputs high-pressure oil , the high-pressure oil flows into the distributor 2 in one direction through the one-way valve 5, and the distributor 2 injects the oil into the four cracking rods 3 (rodless cavity) at equal pressure, so as to realize the ejection of the four cracking rods 3 action to achieve the purpose of cracking rocks; another output branch of the hydraulic station 1 is high-pressure oil, and the high-pressure oil is injected into the pressure relief valve 6, so as to realize the opening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com