Electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of being limited to below 60°C, the impact of lithium battery performance, battery leakage and fire, etc., to reduce viscosity, reduce gasification, and prevent redox reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

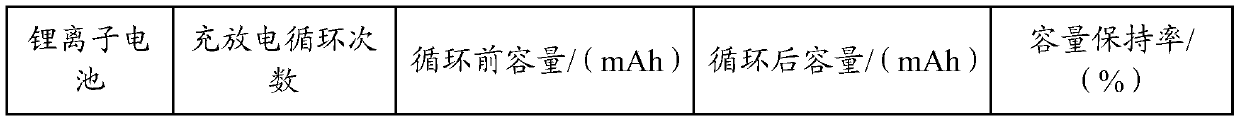

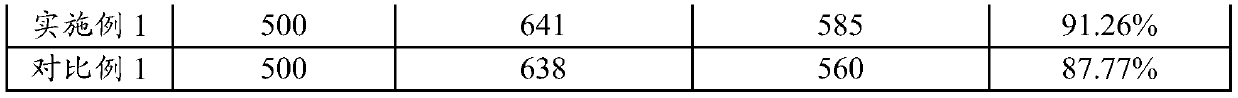

Examples

Embodiment approach

[0022] In one embodiment, an electrolyte solution includes a high-temperature organic solvent, positive and negative electrode protection additives, and an electrolyte lithium salt. Wherein, the high-temperature organic solvent includes the following components in parts by weight: 5-30 parts of ethylene carbonate, 5-30 parts of propylene carbonate, 5-30 parts of diethyl carbonate, 5-50 parts of propyl propionate parts and 1 to 10 parts of fluorobenzene. Wherein, the positive and negative protection additives include the following components in parts by weight: 0.2-5 parts of vinyl sulfate, 0.2-5 parts of fluoroethylene carbonate, 0.2-5 parts of difluoroethylene carbonate, dinitriles 0.2-5 parts of organic matter, 0.2-3 parts of lithium difluorophosphate, 0.2-5 parts of diethylene glycol bispropionitrile ether, 0.2-3 parts of lithium fluorosulfonimide, 0.1-2 parts of 1-propyl phosphoric anhydride, 0.5-20 parts of 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether, 0.1-2 ...

Embodiment 1

[0039] A lithium ion battery comprises a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, and the separator and the electrolyte are spaced between the positive electrode sheet and the negative electrode sheet. The charge and discharge voltage range is 3V ~ 4.45V.

[0040] The positive electrode sheet includes a positive electrode current collector and a positive electrode active material layer coated on the surface of the positive electrode current collector. The positive electrode active material layer includes lithium cobalt oxide, positive electrode conductive carbon and positive electrode binder, lithium cobalt oxide, positive electrode conductive carbon and positive electrode binder. The mass ratio is 98.5:0.5:1.0.

[0041] The negative electrode sheet includes a negative electrode current collector and a negative electrode active material layer coated on the surface of the negative electrode current collector. The negative electrode a...

Embodiment 2

[0045] A lithium ion battery comprises a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, and the separator and the electrolyte are spaced between the positive electrode sheet and the negative electrode sheet.

[0046] The positive electrode sheet includes a positive electrode current collector and a positive electrode active material layer coated on the surface of the positive electrode current collector. The positive electrode active material layer includes lithium cobalt oxide, positive electrode conductive carbon and positive electrode binder, lithium cobaltate, positive electrode conductive carbon and PVDF binder The mass ratio is 97.0:0.03:0.8.

[0047]The negative electrode sheet includes a negative electrode current collector and a negative electrode active material layer coated on the surface of the negative electrode current collector. The negative electrode active material layer includes graphite, PAA binder, CMC binder and negati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com