Automatic start-stop control device for internal combustion engine

A starting control device and automatic stop technology, which are applied in the directions of motor starting, engine control, and engine starting, etc., can solve the problems of increasing the number of starts, reducing the speed range, and taking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

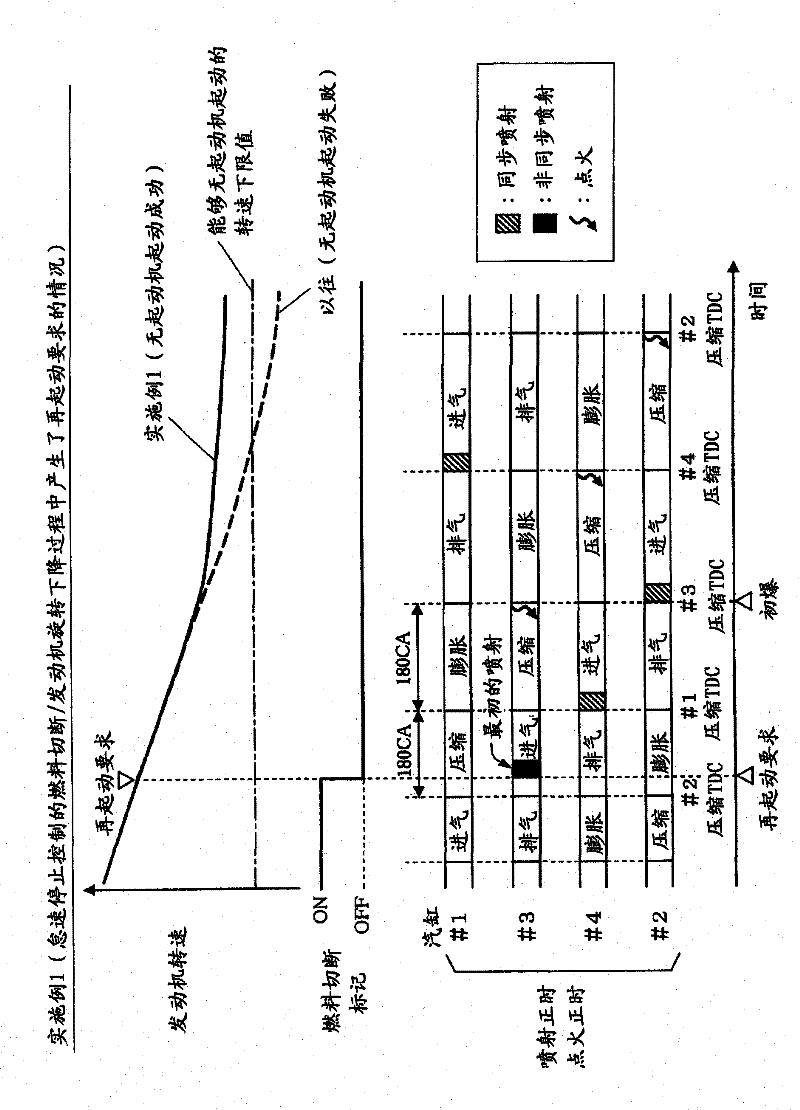

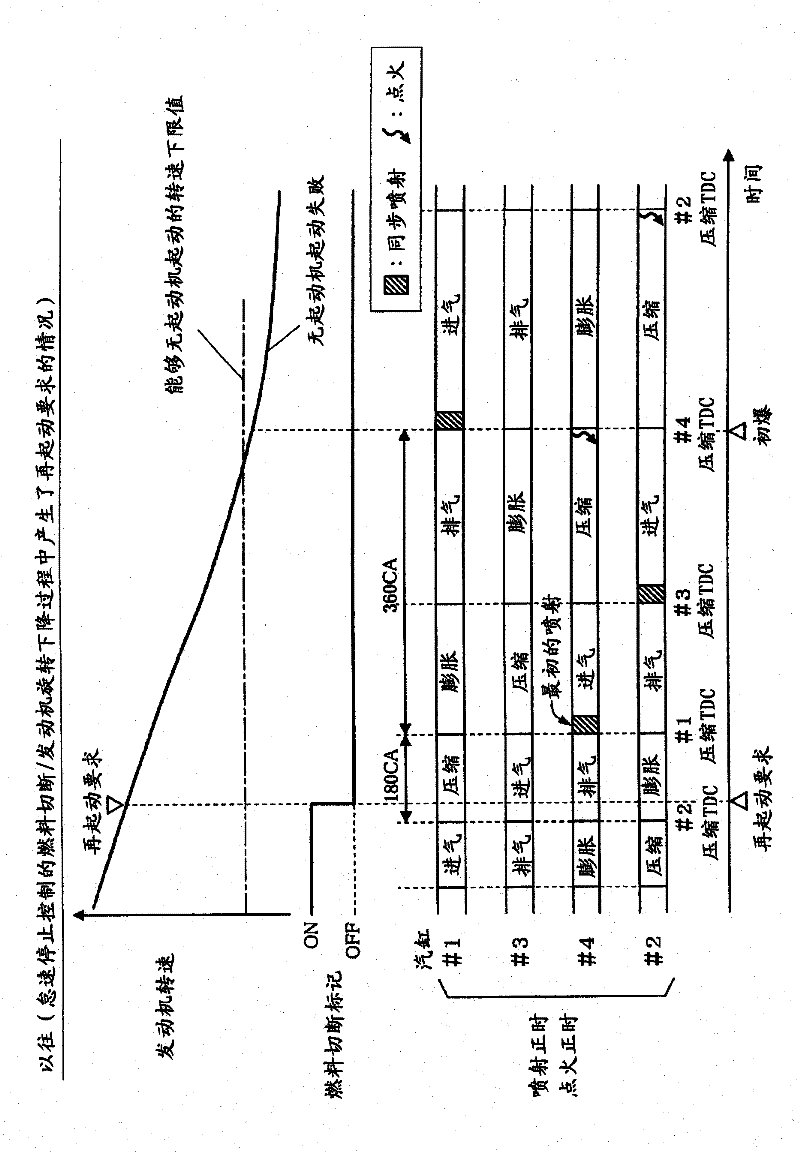

Embodiment 1

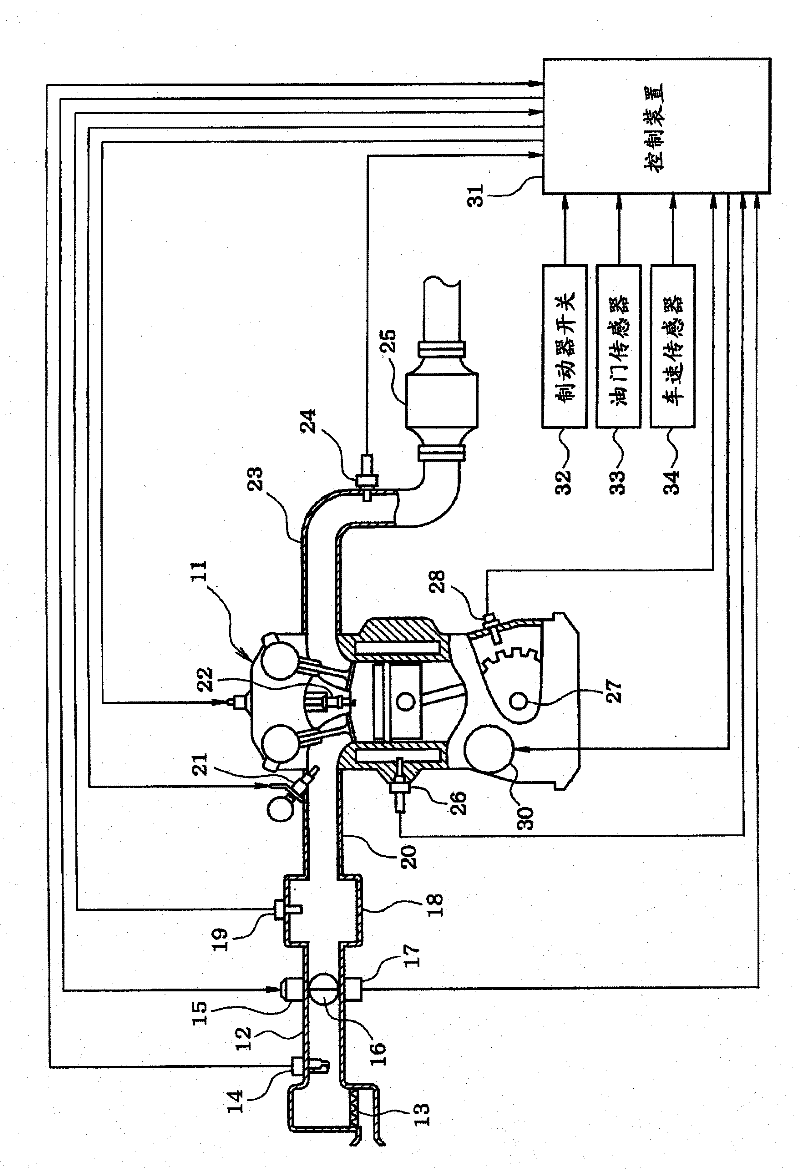

[0032] based on Figure 1 to Figure 5 Example 1 of the present invention will be described.

[0033] First, based on figure 1 The schematic configuration of the entire engine control system will be described.

[0034] An air cleaner 13 is provided at the most upstream portion of the intake pipe 12 of the port injection engine 11, which is a port injection internal combustion engine, and an air cleaner 13 for detecting the amount of intake air is provided on the downstream side of the air cleaner 13. flowmeter14. A throttle valve 16 whose opening is adjusted by a motor 15 and a throttle opening sensor 17 which detects the opening of the throttle valve 16 (throttle opening) are provided on the downstream side of the air flow meter 14 .

[0035] Further, on the downstream side of the throttle valve 16 , a surge tank 18 is provided, and an intake pipe pressure sensor 19 for detecting the intake pipe pressure is provided in the surge tank 18 . In addition, the surge tank 18 is...

Embodiment 2

[0066] The first embodiment described above is configured to execute the first fuel injection by asynchronous injection only to the cylinder in the intake stroke when the restart request is generated. When a restart request is generated while the rotation speed falls below the rotation speed range in which starterless start is possible (restart is possible only by fuel injection), the following starterless start is performed: Immediately execute non-startup for all cylinders simultaneously. The synchronous injection executes the first fuel injection and then returns to the independent recovery control of the synchronous injection, and restarts the engine 11 only by fuel injection without using the starter 30 . Other matters are the same as in the first embodiment.

[0067] For example, when the driver suddenly depresses the accelerator pedal to request rapid acceleration, if asynchronous injection is performed on all cylinders at the same time, it can be expected that the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com