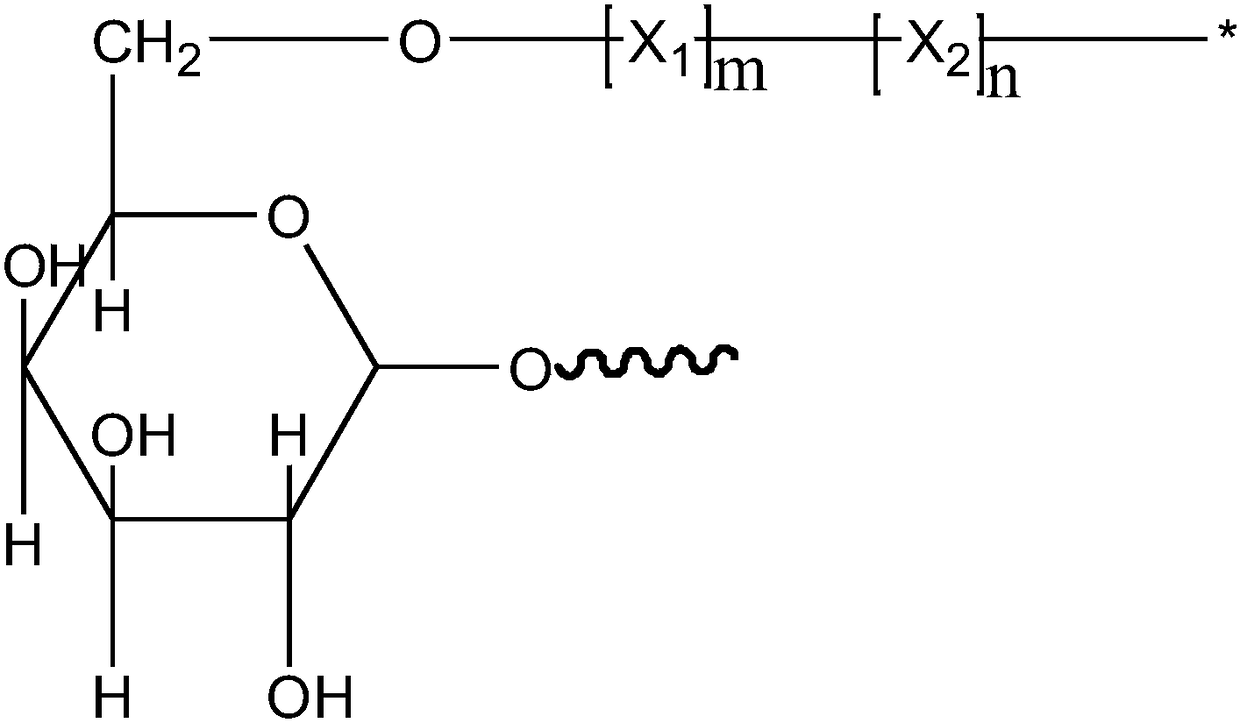

Saponin-grafted copolymer water-coal-slurry dispersing agent and preparation method thereof

A technology of graft copolymer and dispersant, which is applied in the field of saponin graft copolymer coal-water slurry dispersant and its preparation, can solve the problems of pollution, high production cost, poor storage stability, etc., and achieve good development prospects and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

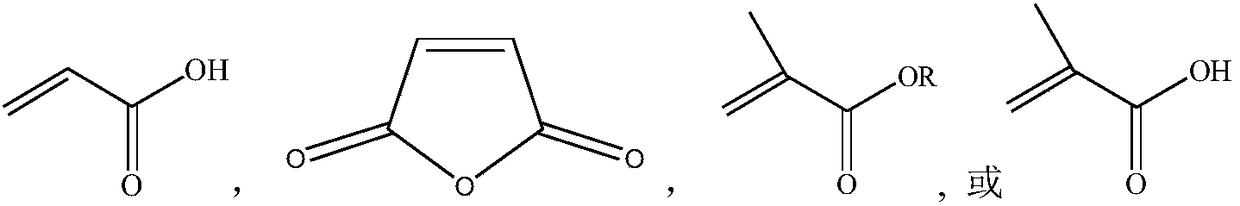

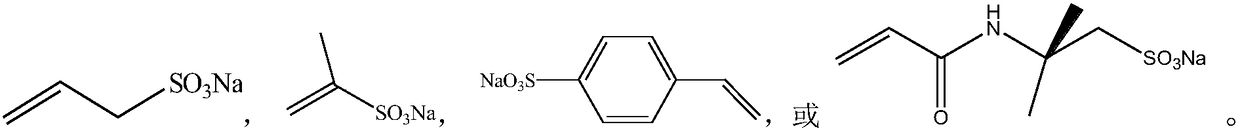

Method used

Image

Examples

Embodiment 1

[0039] First, dissolve deionized water and 3.5g saponin in a three-necked flask to make a saponin deionized aqueous solution with a mass fraction of 7%, then add 0.075g ammonium persulfate, heat and stir at 90°C, and make it react for 30min; cool down to 80°C ℃, adjust the pH to 8, first add a mixed solution of 1.9g sodium allyl sulfonate and 0.093g sodium bisulfite to a three-necked flask, then add a mixed solution of 0.11g ammonium persulfate and 1.3g acrylic acid, and react for 4 hours, Cool the mixed product to room temperature; at room temperature, adjust the pH of the product to 7.0 with a 20% NaOH aqueous solution by mass fraction to obtain a saponin graft copolymer coal water slurry dispersant.

Embodiment 2

[0041] First, dissolve deionized water and 4g saponin in a three-necked flask to make a saponin deionized aqueous solution with a mass fraction of 9%, then add 0.084g potassium permanganate, heat and stir at 88°C, and make it react for 25min; cool down to 78°C ℃, adjust the pH to 8.4, first add a mixed solution of 1.76g sodium substituted methyl ethylene sulfonate and 0.098g citric acid into the three-necked flask, then add a mixed solution of 0.14g potassium permanganate and 1.42g maleic anhydride, and react 4.5 After h, the mixed product was cooled to room temperature; at room temperature, the pH of the product was adjusted to 7.5 with a 30% NaOH aqueous solution by mass fraction to obtain a saponin graft copolymer coal-water slurry dispersant.

Embodiment 3

[0043] First, dissolve deionized water and 3.9g saponin in a three-necked flask to make a saponin deionized aqueous solution with a mass fraction of 8%, then add 0.076g horseradish peroxidase HPR, heat and stir at 85°C, and allow it to react for 25 minutes; Cool down to 83°C, adjust the pH to 8.9, first add a mixed solution of 1.88g sodium p-vinylbenzenesulfonate and 0.095g hydrogen peroxide into a three-necked flask, then add 0.11g horseradish peroxidase HPR and 1.54g formazan After reacting for 4.3 hours, the mixed product was cooled to room temperature; at room temperature, the pH of the product was adjusted to 8.0 with 25% NaOH aqueous solution to obtain a saponin graft copolymer coal-water slurry dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com