Yttria-stabilized zirconia doped lanthanum-cerium oxide material powder for plasma physical vapor deposition and preparation method thereof and application

A technology of physical vapor deposition and stabilization of zirconia, which is applied in metal material coating process, coating, melt spraying and other directions, can solve the problem of high powder tap density and the inability to successfully prepare quasi-columnar crystal structure thermal barrier coatings and other problems, to achieve the effect of avoiding thermal cycle performance, avoiding the reduction of gasification capacity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

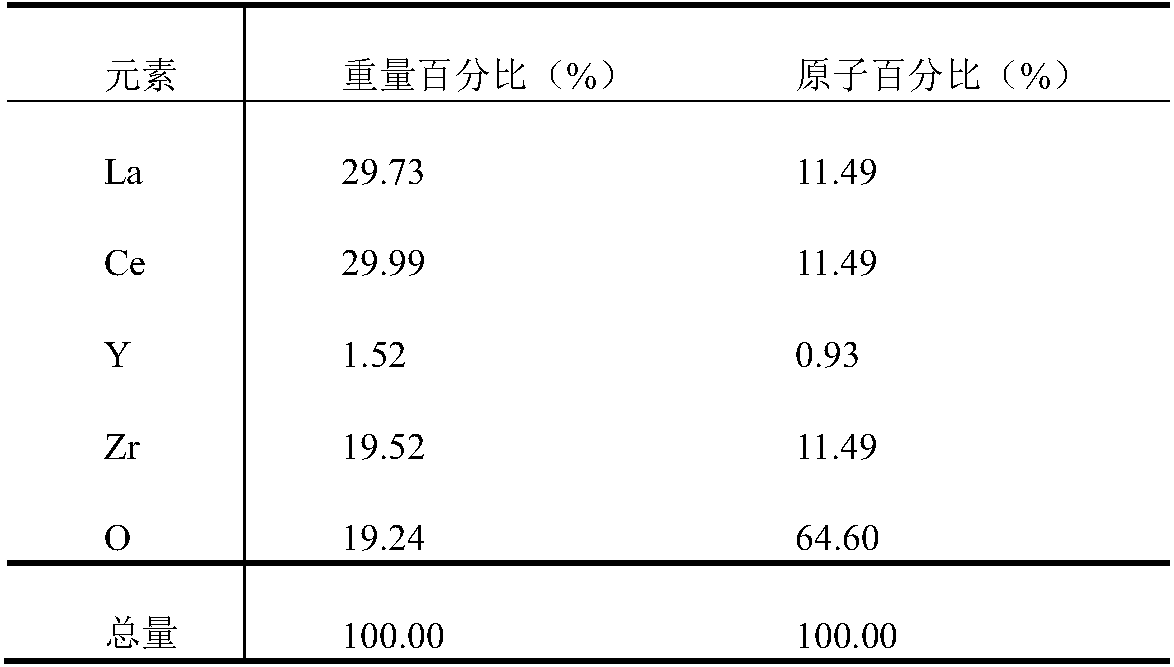

[0042] This embodiment provides a method for preparing yttria-stabilized zirconia-doped lanthanum cerate material powder for plasma physical vapor deposition, which includes the following steps:

[0043] Step 1. Four raw material powders of lanthanum oxide, cerium oxide, yttrium oxide and zirconium oxide are mixed according to the molar ratio of La:Ce:Y:Zr=0.8:1:0.08:1 and ball milled to obtain a ball milled product.

[0044] The ball milling process is as follows: first mix alcohol, zirconia balls and raw material powder according to the mass ratio of 1:1:1, the particle size of the balls is 3 μm, the speed of the ball mill is 500 r / min, wet ball milling for 20 hours, and then dry to obtain a solid product ; Then mix the dried solid product with zirconia balls in a mass ratio of 2:1, the zirconia balls have a particle size of 3 μm, and the ball mill speed is 500r / min, and carry out dry ball milling for 10 hours; after ball milling, the particle size distribution of the ball mi...

Embodiment 2

[0060] The preparation method of yttria-stabilized zirconia-doped lanthanum cerate material powder for plasma physical vapor deposition in this embodiment includes the following steps:

[0061] Step 1. Mix lanthanum oxide, cerium oxide, yttrium oxide and zirconia powder according to the molar ratio of La: Ce: Y: Zr = 1.3: 1: 0.08: 1 for ball milling: first mix alcohol, zirconia balls and raw materials Mix according to the mass ratio of 1:1:1, the particle size of the ball is 3μm, the speed of the ball mill is 500r / min, wet ball mill for 40h and dry, and then the product and the zirconia ball are mixed according to the mass ratio of 2:1, and the particle size of the ball is 3μm , the speed of the ball mill is 500r / min, and dry ball milling is carried out for 20h; after the ball milling, the particle size distribution is 1-35μm;

[0062] Step 2. Filter the ball milling product described in step 1 to get the retentate, wash the retentate with alcohol until it is neutral and dry i...

Embodiment 3

[0077] In this embodiment, the yttria-stabilized zirconia-doped lanthanum cerate material and its coating preparation method for plasma physical vapor deposition include the following steps:

[0078] Step 1. Mix lanthanum oxide, cerium oxide, yttrium oxide and zirconia powder according to the molar ratio of La: Ce: Y: Zr = 1.1: 1: 0.08: 1 for ball milling. First, alcohol, zirconia balls and raw materials Mix according to the mass ratio of 1:1:1, the particle size of the ball is 3μm, the speed of the ball mill is 500r / min, wet the ball mill for 30h and dry it, then mix the product with the zirconia ball at a mass ratio of 2:1, and the particle size of the ball is 3μm , the speed of the ball mill is 500r / min, and dry ball milling is carried out for 15 hours; after the ball milling, the particle size distribution is 1-40 μm;

[0079] Step 2. Filter the ball milling product described in step 1 to get the retentate, wash the retentate with alcohol until neutral and dry it at 100°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com