Antimony wire for RH refining and adding method thereof

A technology of antimony wire and metal antimony is applied to the antimony wire used in RH refining and the field of adding it, so as to achieve the effects of improving yield, reducing production cost and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The steel type is silicon steel W600, the size of the ladle used is 200t, and the weight of molten steel is 175-185t. Taking the vacuum treatment of the process of the present invention as an example, the present invention is further described.

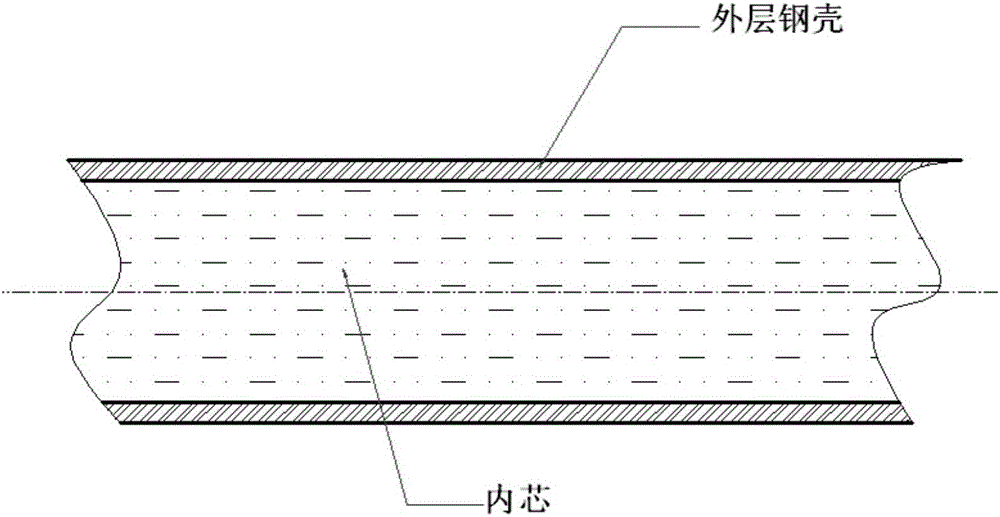

[0021] During RH vacuum refining, antimony wire is fed to the ladle. The antimony wire includes metal antimony as the inner core and the outer steel shell. The inner diameter of the inner core of the antimony wire is 8mm, and the weight of metal antimony contained in the inner core is not less than 326g / m. The inner core metal antimony contains 97% antimony by mass percentage, and the thickness of the outer steel shell of the antimony wire is 4mm. The structure diagram of the antimony wire is as follows figure 1 shown.

[0022] The mass percent of molten steel composition before RH vacuum cycle treatment is: C 0.042%; Si0.0035%; Mn 0.082%; P 0.0103%; S 0.0016%; Al 0.0008; Sb0.0006%; .

[0023] The molten steel was subjected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com