Device and method for fine adjustment of molten steel components and for modification of inclusions in continuous casting tundish

A continuous casting tundish and tundish technology, which is applied in the direction of casting molten material containers, casting equipment, manufacturing tools, etc., can solve the problems of poor cleanliness, poor toughness of steel, uneven composition of molten steel, etc., and reduce gasification , prolong the residence time, improve the yield and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

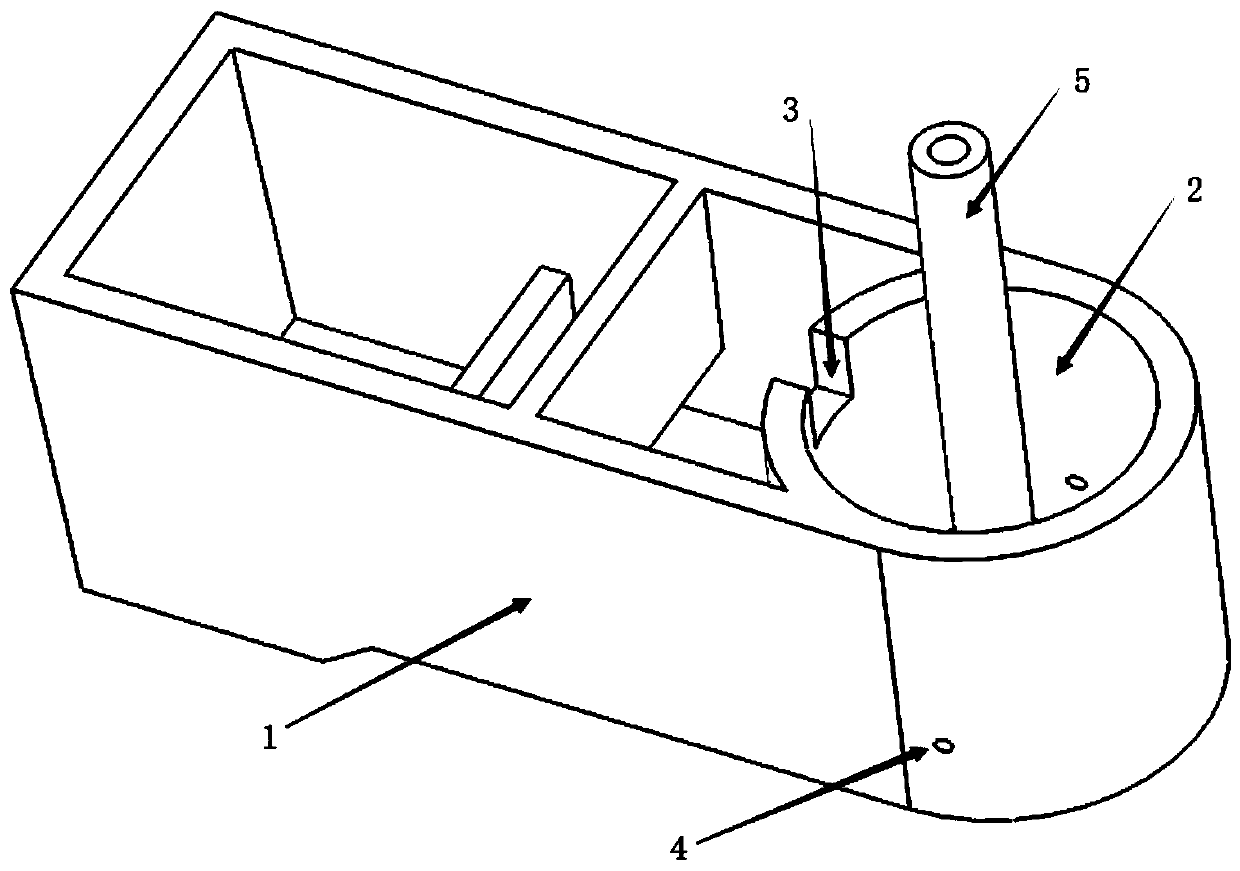

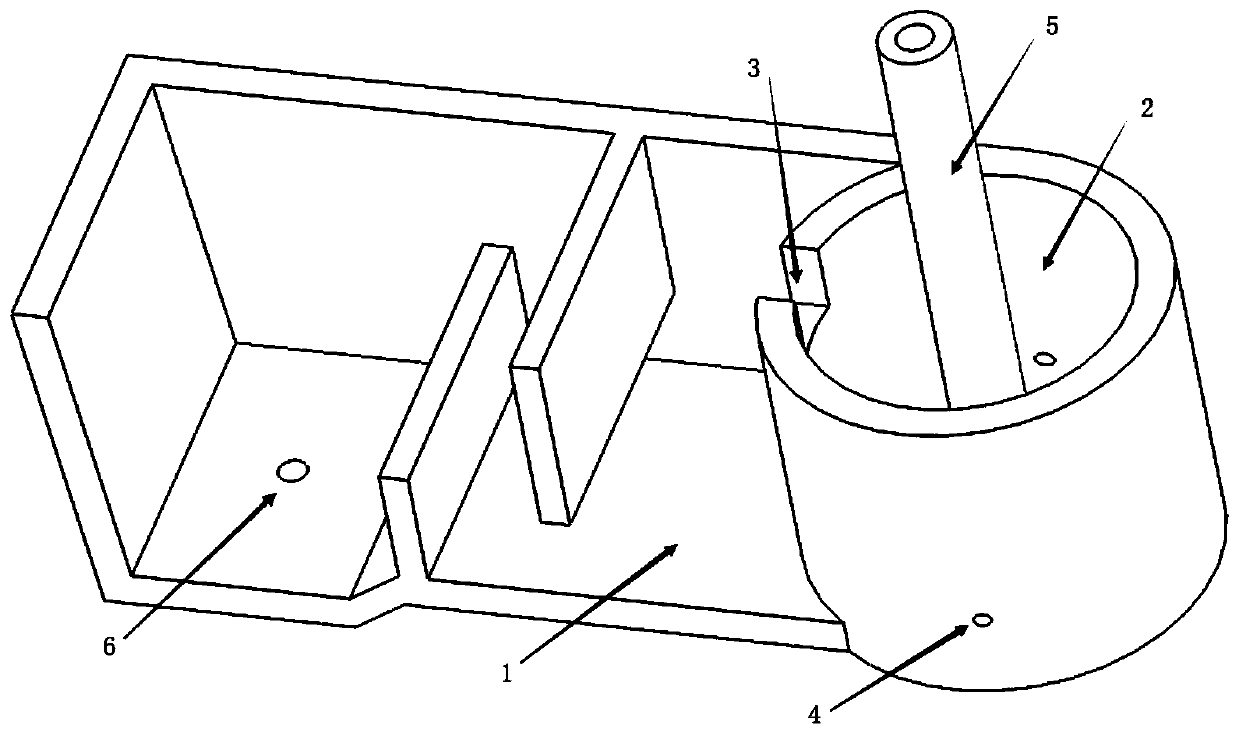

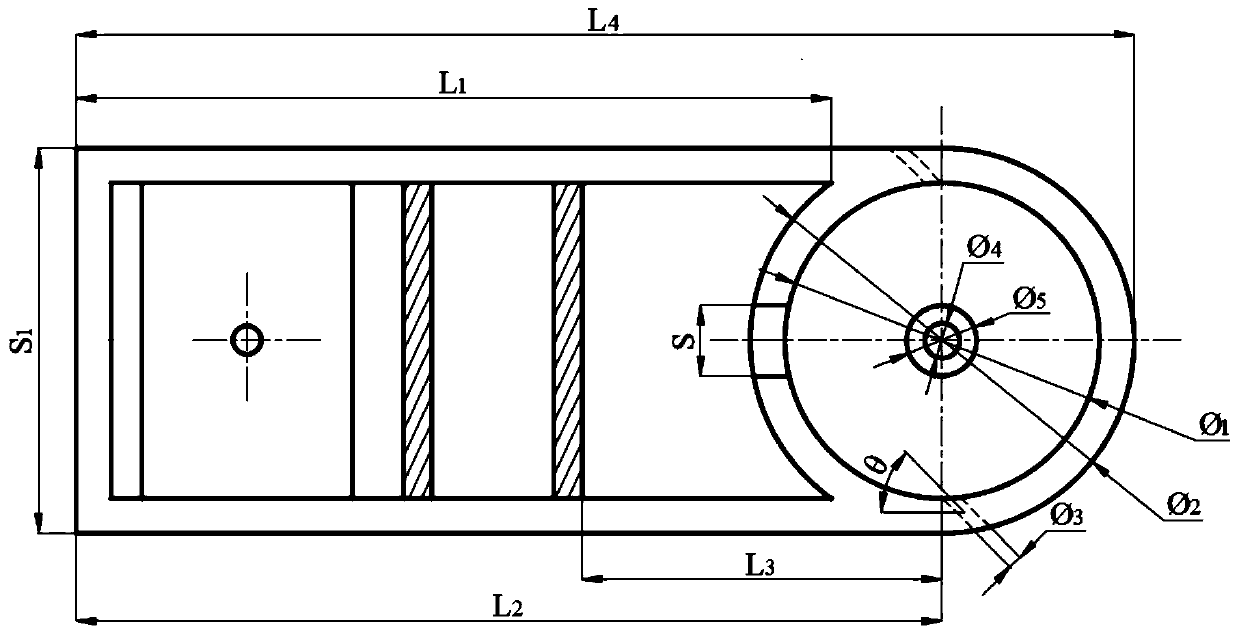

[0051] The invention relates to a device for fine-tuning molten steel composition and modification treatment of inclusions in a tundish. image 3 , Figure 4 The dimension parameters shown are examples.

[0052] The specific method is as follows: molten steel enters the tundish swirl chamber 2 from the ladle shroud 5 located in the center of the tundish swirl chamber 2, and at the same time utilizes the inclined blowing nozzles uniformly arranged along the circumference on the side wall of the tundish swirl chamber 2 Argon gas is blown in the air hole 4, and the alloy powder is blown into the tundish swirl chamber 2 by using argon as the carrier. The molten steel and the alloy powder are fully mixed in the tundish swirl chamber 2, and the fine-tuning of the composition of the molten steel and the improvement of inclusions are preliminarily completed. Then it flows into the rectangular chamber 1 of the tundish from the outlet 3 of the molten steel, and finally flows into the c...

Embodiment 2

[0058] The geometry and size parameters of the tundish rectangular chamber 1 and the tundish swirl chamber 2 involved in this embodiment are the same as those in Embodiment 1, except for the type of alloy powder to be injected and the injection parameters.

[0059] The alloy powder is calcium alloy powder, which is used for modification treatment of inclusions in the tundish. The particle size of the alloy powder is less than 50 μm. The amount of steel added per ton is 90kg. The inclusion content decreases and the inclusion removal rate increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com