Piston type hydropneumatic buffer

A liquid-gas buffer, piston-type technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of reduced sealing difficulty, great sealing difficulty, and reduced buffer performance, and achieves a reduction in oil Possibility of vaporization, favorable for sealing, and improving the effect of dynamic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

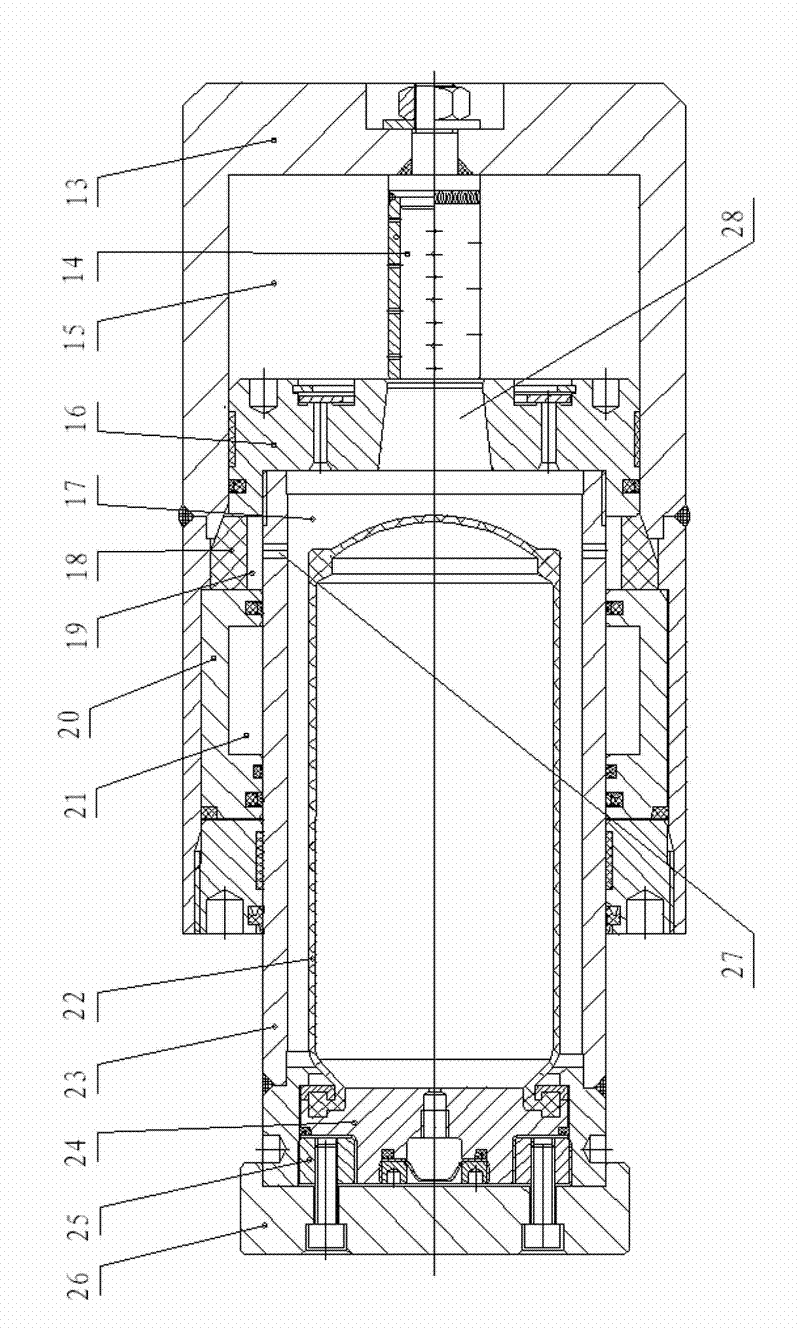

[0026] Such as image 3 As shown, the present invention is further described as follows:

[0027] A piston-type liquid-gas buffer, comprising a cylinder 13, a hollow piston rod 23, and a piston 16, the inner end of the hollow piston rod 23 is fixedly connected to the piston 16, and a second end surface is formed between the inner end surface of the piston and the bottom of the cylinder body. An oil chamber 15, the air bag 22 is housed in the hollow piston rod, the air bag 22 is limited in the piston rod 23 by the plug 24 of its mouth, an airtight device is arranged outside the plug 24, the bottom of the air bag 22 and the piston There is a certain distance between the inner end surfaces of the rod 23, the second oil chamber 17 is formed between the air bag and the piston, and the first throttle passage is provided between the first oil chamber and the second oil chamber;

[0028] The cylinder body extends axially toward the head of the piston rod 23, forming a cavity between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com