Liquid nitrogen pressurizing device, anti-reflection experiment system using same and experiment method

A technology of pressurizing device and liquid nitrogen, which is applied in mining devices, earth-moving drilling, discharging machinery, etc., can solve the problems of slow liquid nitrogen pressurization and increase technical cost, and achieves shortened time, simple and efficient arrangement of steps, and good The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

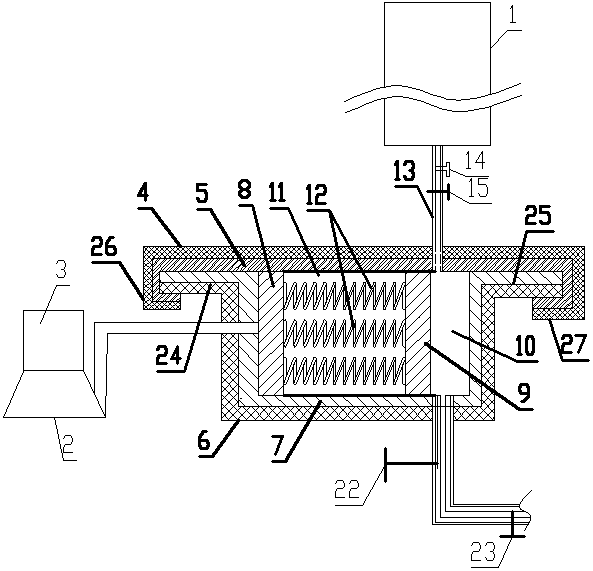

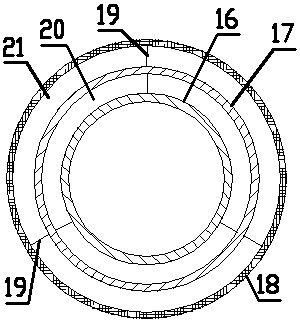

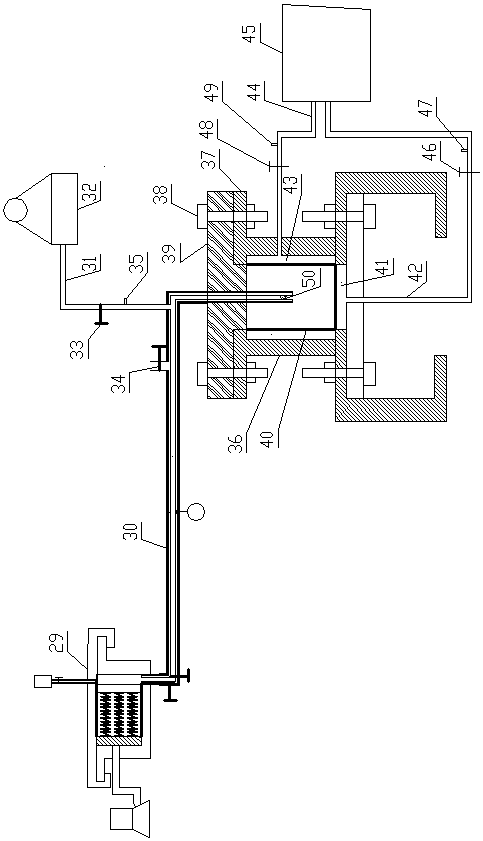

[0053] Such as Figure 1 to Figure 4 As shown, the liquid nitrogen supercharging device 29 in the present invention includes a liquid nitrogen container 1, an electric control device 2, a top cover and a liquid nitrogen tank for liquid nitrogen supercharging, and the electric control device 2 is connected with a display screen 3; The top cover includes a top cover insulation layer 4 on the outer layer and a sliding connection layer 5 on the inner layer, and the sliding connection layer 5 is made of a rigid material; the tank wall of the liquid nitrogen tank includes a tank body insulation layer 6 on the outer layer and an inner layer of rigid material 7,

[0054] The notch of the liquid nitrogen tank faces upward, the top cover is fastened on the liquid nitrogen tank, and the left inner wall of the liquid nitrogen tank (that is, the rigid material layer 7) is connected to the electromagnet 8, and the connection line of the electromagnet 8 is sealed through the liquid nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com