Polypropylene production process and production device

A production process and production device technology, applied in the field of polypropylene production process, can solve the problems of large public works consumption, power consumption, large compressor capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

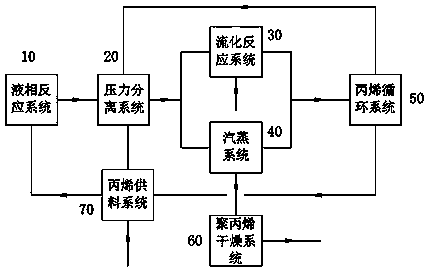

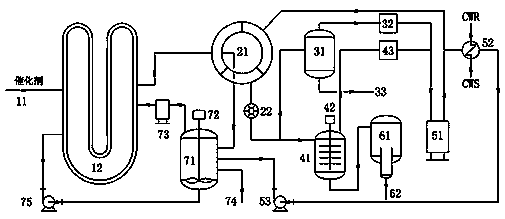

[0080] see figure 1 with figure 2 , this propylene production unit includes:

[0081] A liquid phase reaction system 10 for liquid phase homopolymerization;

[0082] A pressure separation system 20 used for separation, liquid removal, discharge and sealing of polypropylene powder and propylene liquid;

[0083] A fluidized bed reaction system (or called a fluidized reaction system) for producing copolymerized polypropylene by completing the copolymerization reaction between polypropylene copolymer and other monomers30;

[0084] Steaming system 40 for polypropylene pre-drying;

[0085] A propylene recycling system 50 for the recovery and recycling of propylene and other monomers;

[0086] Polypropylene drying system 60;

[0087] Propylene supply system 70.

[0088] The working process is as follows:

[0089] The configured catalyst is injected into the liquid phase reactor (liquid phase bulk reactor) 12 through the catalyst inlet 11 in the liquid phase reaction system 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com