Gallium purification device and method

A purification method and crystallization tank technology, applied in the field of gallium purification devices, can solve the problems of difficult to control the crystal growth direction, high-purity gallium pollution, difficult solid-liquid separation, etc., and achieve the effect of facilitating automatic control, changing the separation method, and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

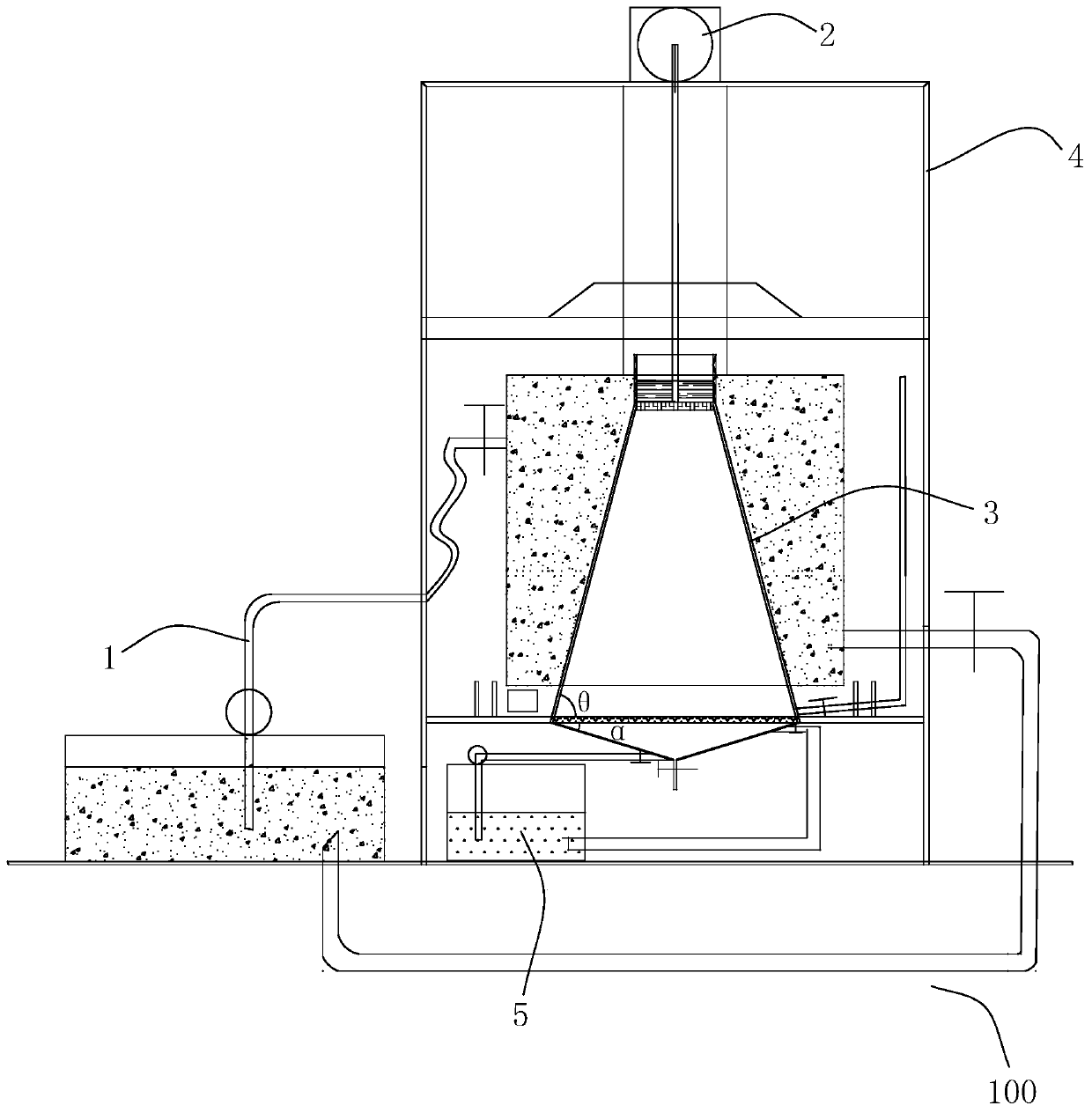

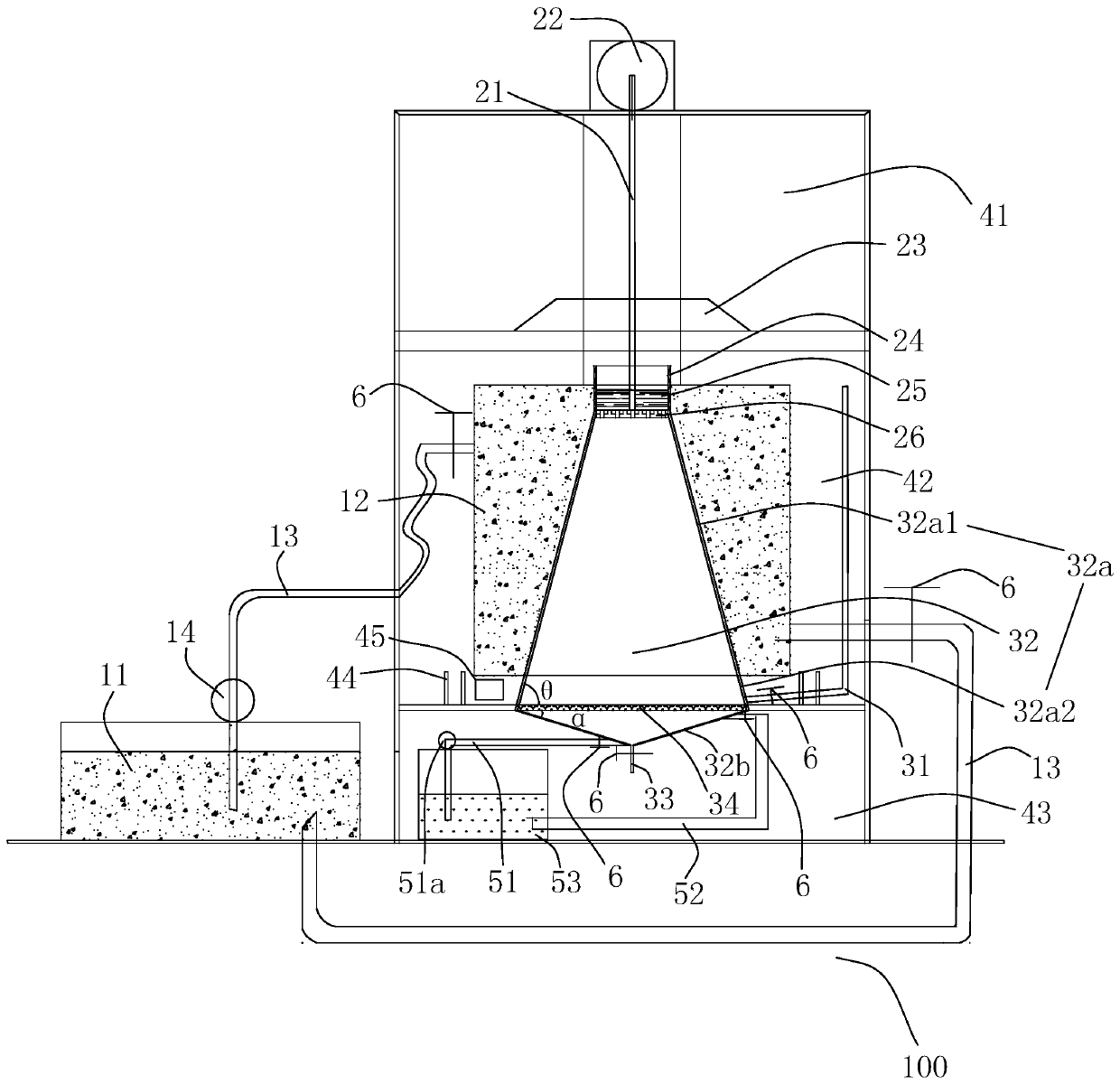

[0045] After the gallium purification device is installed, 4N gallium is melted at 45°C to form crystallization mother liquor, and the crystallization mother liquor is fed into the crystallization tank through the feeding pipe. The angle θ formed between the upper part of the crystallization tank and the horizontal direction is 75 degrees, and the lower part of the crystallization tank The angle α formed with the horizontal direction is 30 degrees; the distance between the upper liquid level of the crystallization mother liquid in the crystallization tank and the crystallization slot is 18cm measured by the tray rod with scale; the temperature of the closed space in the upper part of the cover is controlled by the temperature controller The temperature is 50°C; start the rotating device to rotate the tray rod, so that the seed crystal plate slowly moves down 18cm so that the lower surface of the seed crystal touches the upper surface of the crystallization mother liquor; start t...

Embodiment 2

[0047] After the gallium purification device is installed, 4N gallium is melted at 70°C to form crystallization mother liquor, and the crystallization mother liquor is fed into the crystallization tank through the feeding pipe. The angle θ formed between the upper part of the crystallization tank and the horizontal direction is 30 degrees, and the lower part of the crystallization tank The angle α formed with the horizontal direction is 75 degrees; the distance between the upper liquid level of the crystallization mother liquid in the crystallization tank and the crystallization slot is 18cm measured by the tray rod with scale; the temperature of the closed space in the upper part of the cover is controlled by the temperature controller The temperature is 35°C; start the rotating device to rotate the tray rod, so that the seed crystal plate slowly moves down 18cm so that the lower surface of the seed crystal touches the upper surface of the crystallization mother liquor; start t...

Embodiment 3

[0049] After the gallium purification device is installed, 4N gallium is melted at 30°C to form a crystallization mother liquor, and the crystallization mother liquor is fed into the crystallization tank through the feeding pipe. The angle θ formed between the upper part of the crystallization tank and the horizontal direction is 45 degrees, and the lower part of the crystallization tank The angle α formed with the horizontal direction is 40 degrees; the distance between the upper liquid level of the crystallization mother liquid in the crystallization tank and the crystallization tank opening is 18cm measured by the tray rod with scale; the temperature of the closed space in the upper part of the cover is controlled by the temperature controller The temperature is 29°C; start the rotating device to rotate the tray rod, so that the seed crystal plate slowly moves down 18cm so that the lower surface of the seed crystal touches the upper surface of the crystallization mother liquo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com