Patents

Literature

32results about How to "Reduce the investment cost once" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

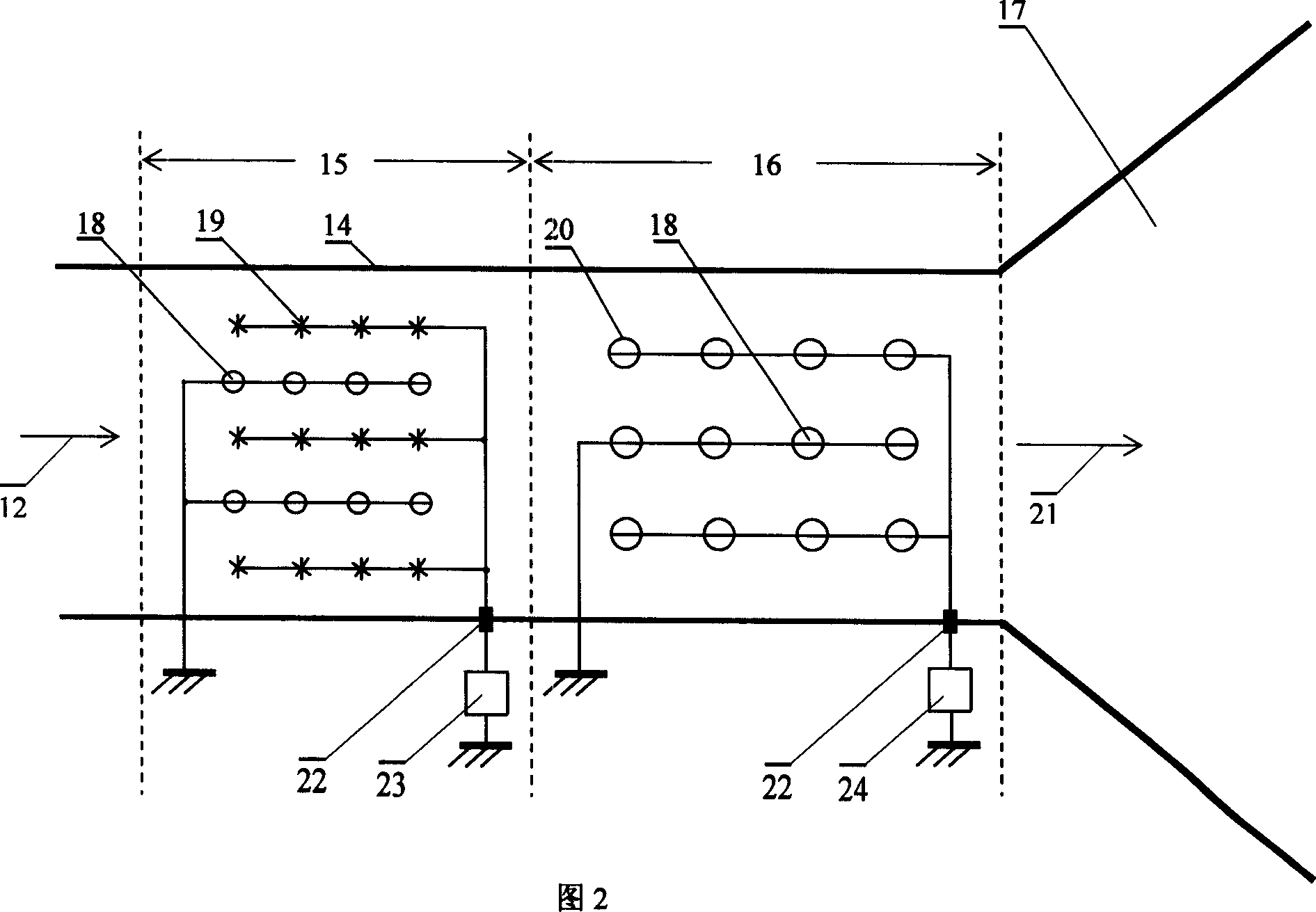

Electrical charging coagulation method for dust in flue gas transfering pipeline

InactiveCN101045220AImprove the efficiency of capturing fine dustImprove purification efficiencyElectric supply techniquesElectrode constructionsElectricityFlue gas

A method for electrically charging and coagulating powder dust in the fume delivering pipeline features that the charging and coagulating reaction of powder dust is performed at the entrance of an electric duster to make the dust particles be electrically saturated and to increase their diameter by 4-400 times, so increasing the dusting efficiency.

Owner:DALIAN MARITIME UNIVERSITY

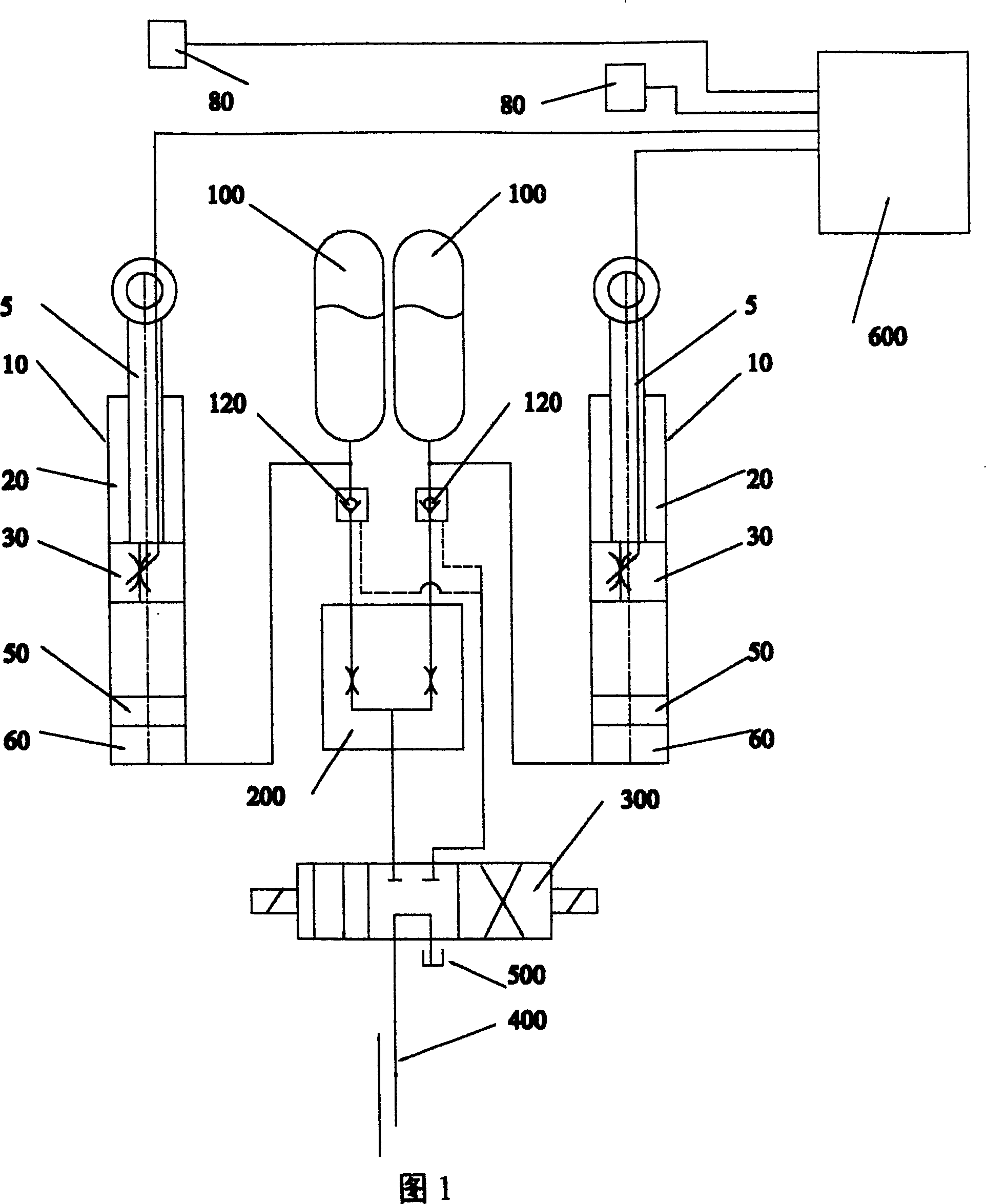

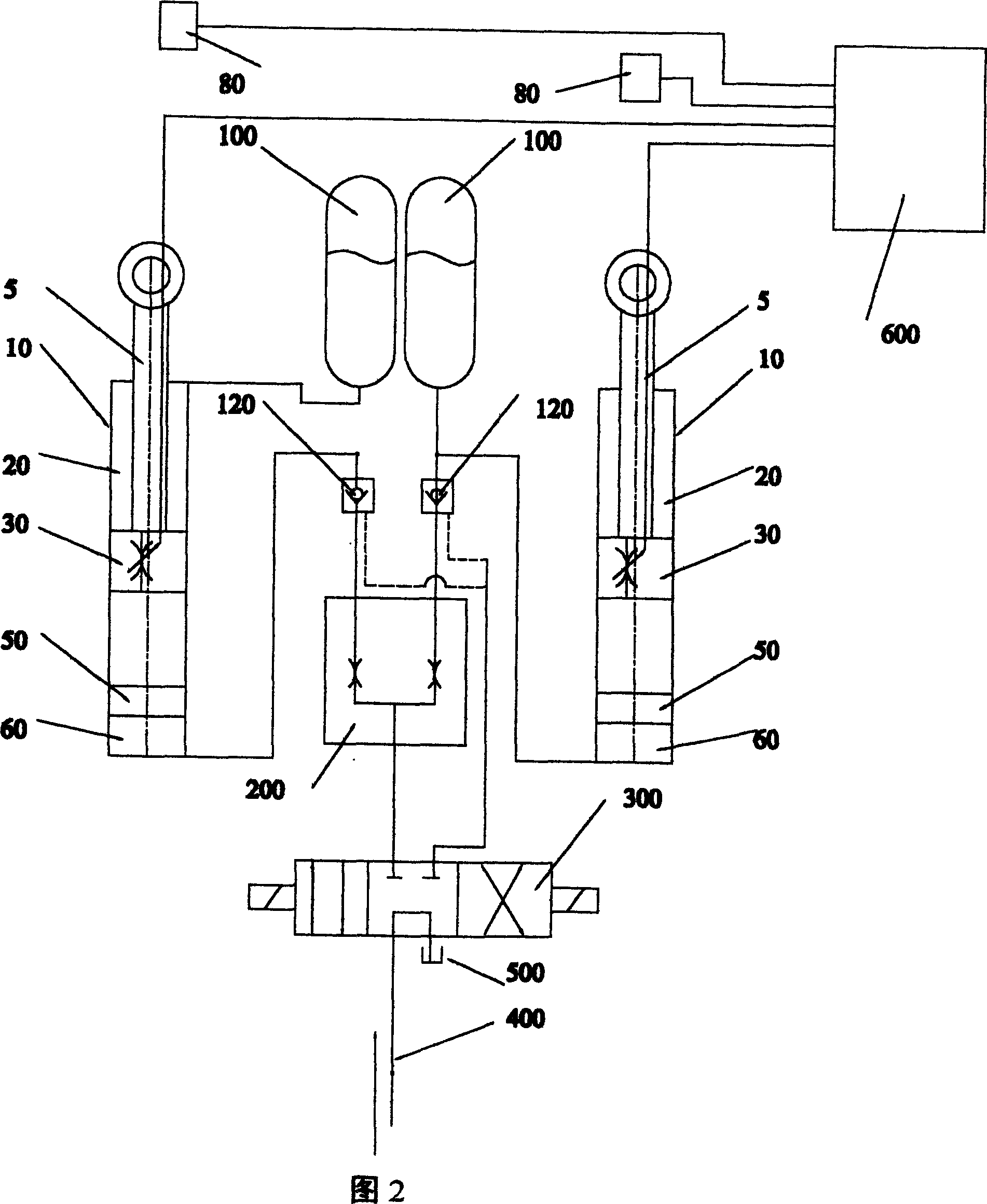

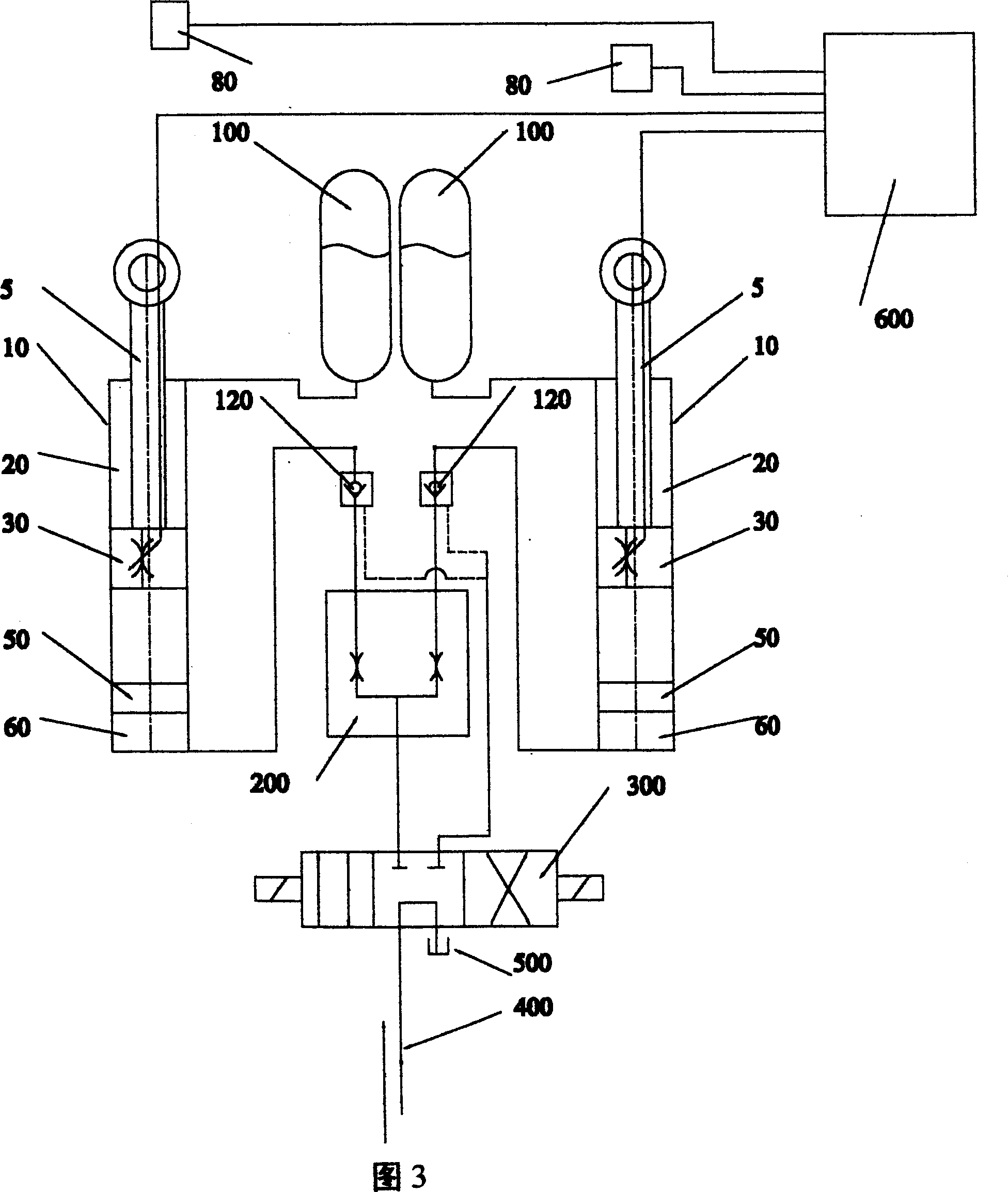

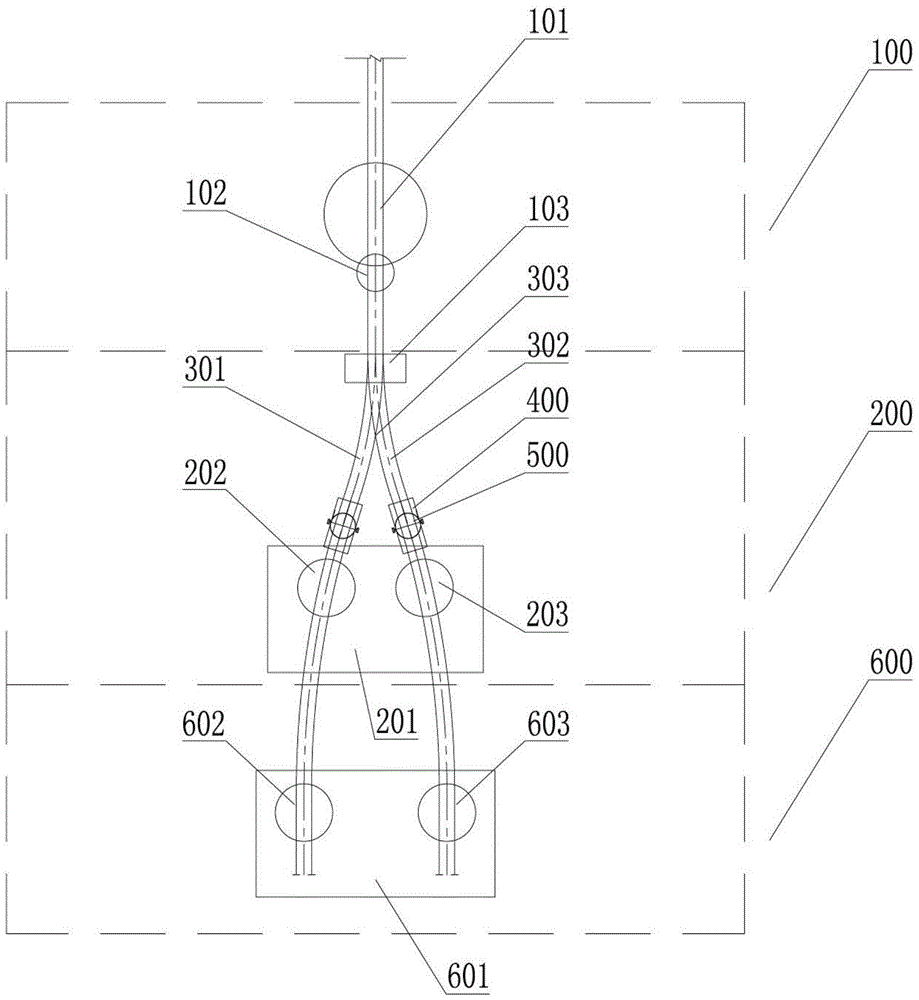

Electromagnetic-rheological fluid hydro-pneumatic hanging system

InactiveCN1971080AImprove reliabilityReduce the investment cost onceNon-rotating vibration suppressionResilient suspensionsVariable stiffnessControl theory

The invention relates to a hydro-pneumatic suspension system with electromagnetic rheological fluid. As the cubage compensation cavity formed by floating piston is connected with bypass oil channel of said dividing-combining valve in the hydro-pneumatic damper, said floating piston makes the electromagnetic rheological fluid in the hydro-pneumatic damping subsystem with electromagnetic rheological fluid and the fluid for conventional hydraulic transmission in assistant hydraulic synchronization subsystem block off and makes said hydro-pneumatic damping subsystem with electromagnetic rheological fluid and said assistant hydraulicsynchronization subsystem couple so that the hydro-pneumatic damper with electromagnetic rheological fluid and two totally different driving mediums of electromagnetic rhelogical fluid and the fluid for convention hydraulic transmission are made full use of, and active variable damper ratio control, active variable stiffness control and active adjusting high synchronization control for said controlled object are realized in the same time or respectively.

Owner:吕崇耀

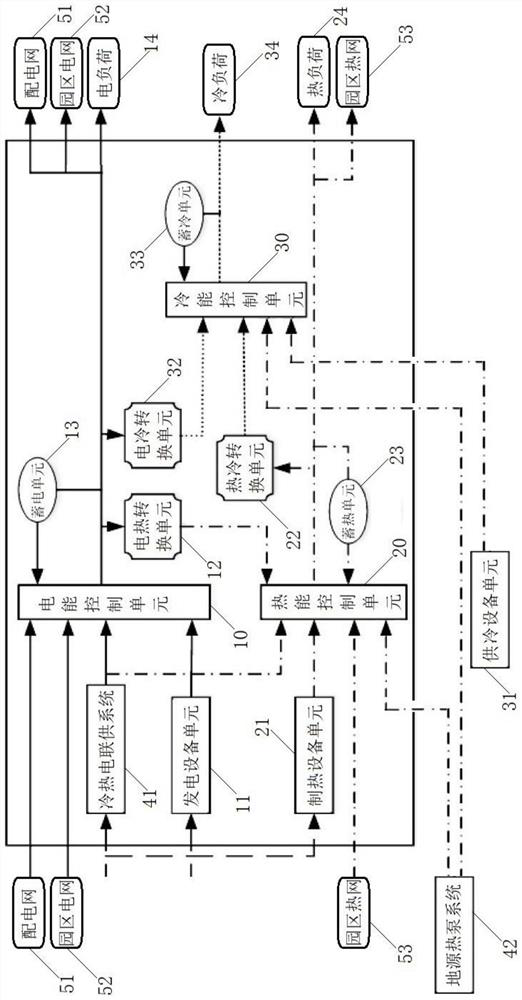

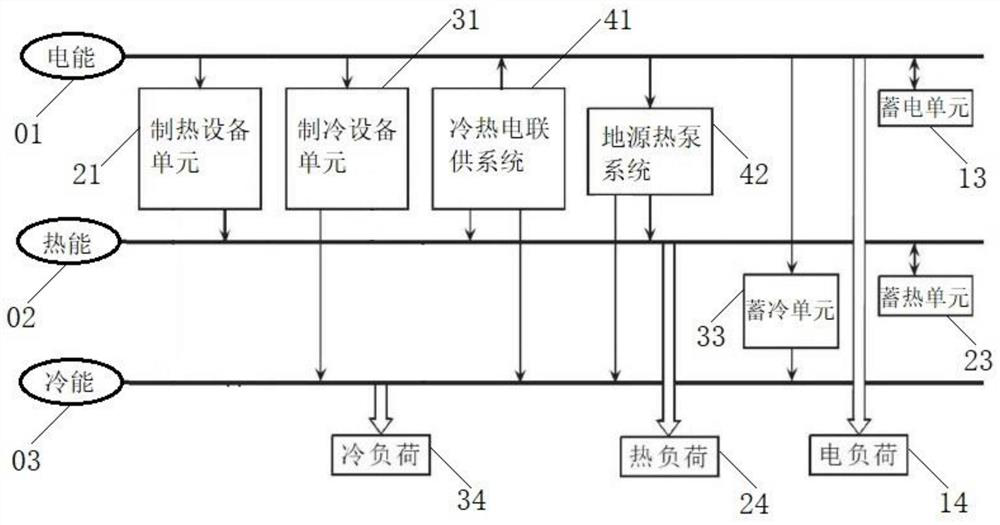

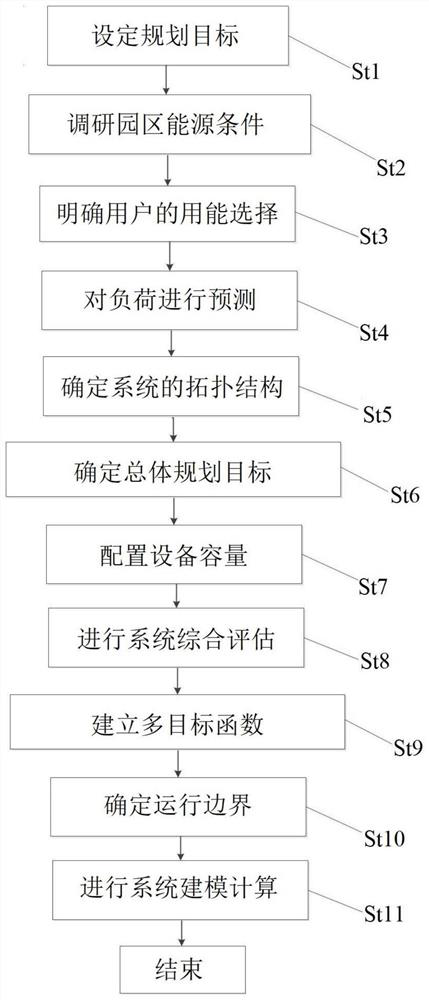

Park-level integrated energy system and control method thereof

PendingCN113344736AFacilitate large-scale accessEfficient use ofResourcesSystems intergating technologiesEnergy controlIntegrated energy system

The invention provides a park-level comprehensive energy system and a control method thereof. The system comprises an electric energy control unit, a heat energy control unit, a cold energy control unit, an electricity-heat conversion unit, an electricity-cold conversion unit and a heat-cold conversion unit. The method comprises the steps of setting a planning target, investigating park energy conditions, determining energy selection of users in a park, predicting loads in the park, determining a topological structure of a system, determining an overall planning target, configuring equipment capacity, performing comprehensive evaluation of the system and the like. The park-level comprehensive energy system and the control method thereof provided by the invention are independent and controllable systems and methods for realizing balance of energy supply and demand, and complementary advantages among the systems can be excavated to a greater extent through coordination of different energy sources in the park-level comprehensive energy system. The energy efficiency is improved, the energy cost is reduced, large-scale access and efficient utilization of renewable energy sources are facilitated, and the renewable resources can be utilized to the maximum extent.

Owner:WENZHOU ELECTRIC POWER DESIGN +1

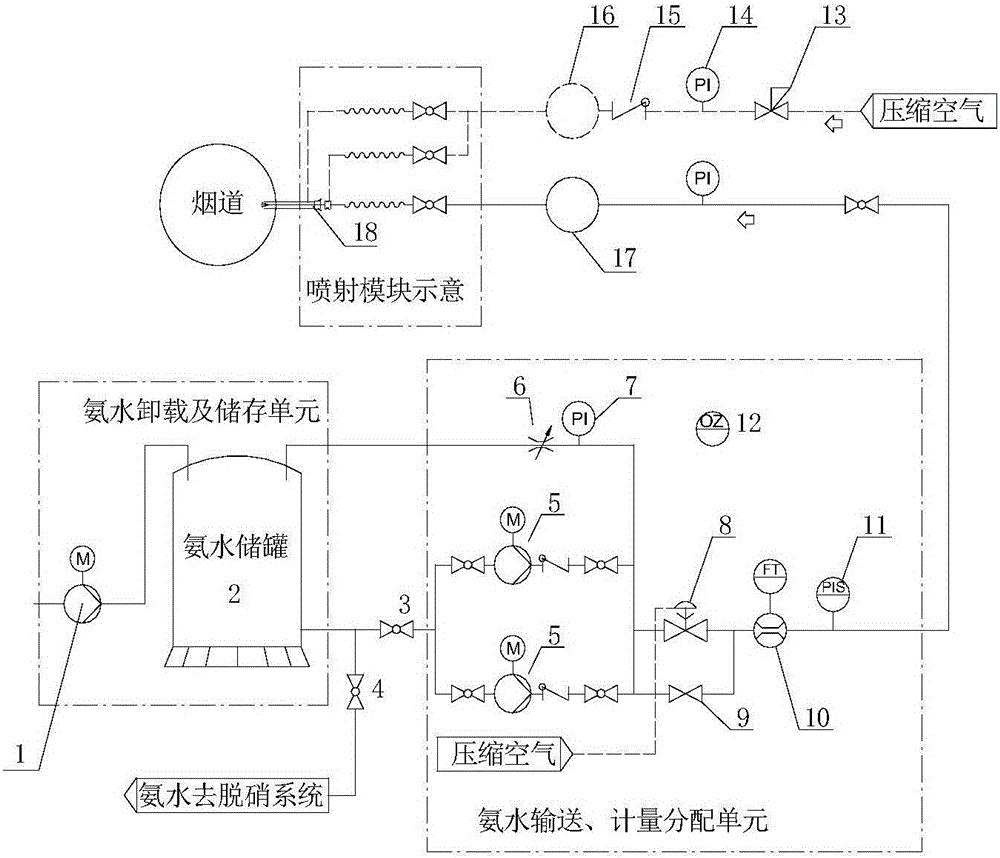

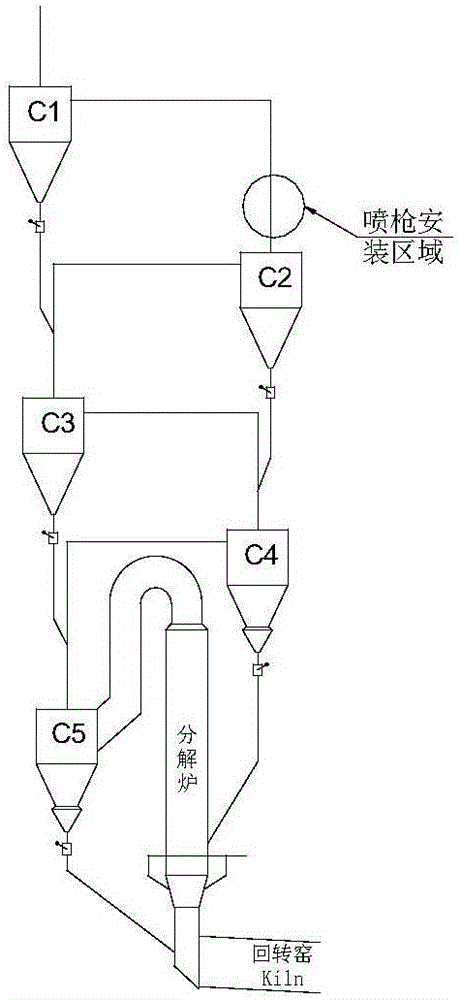

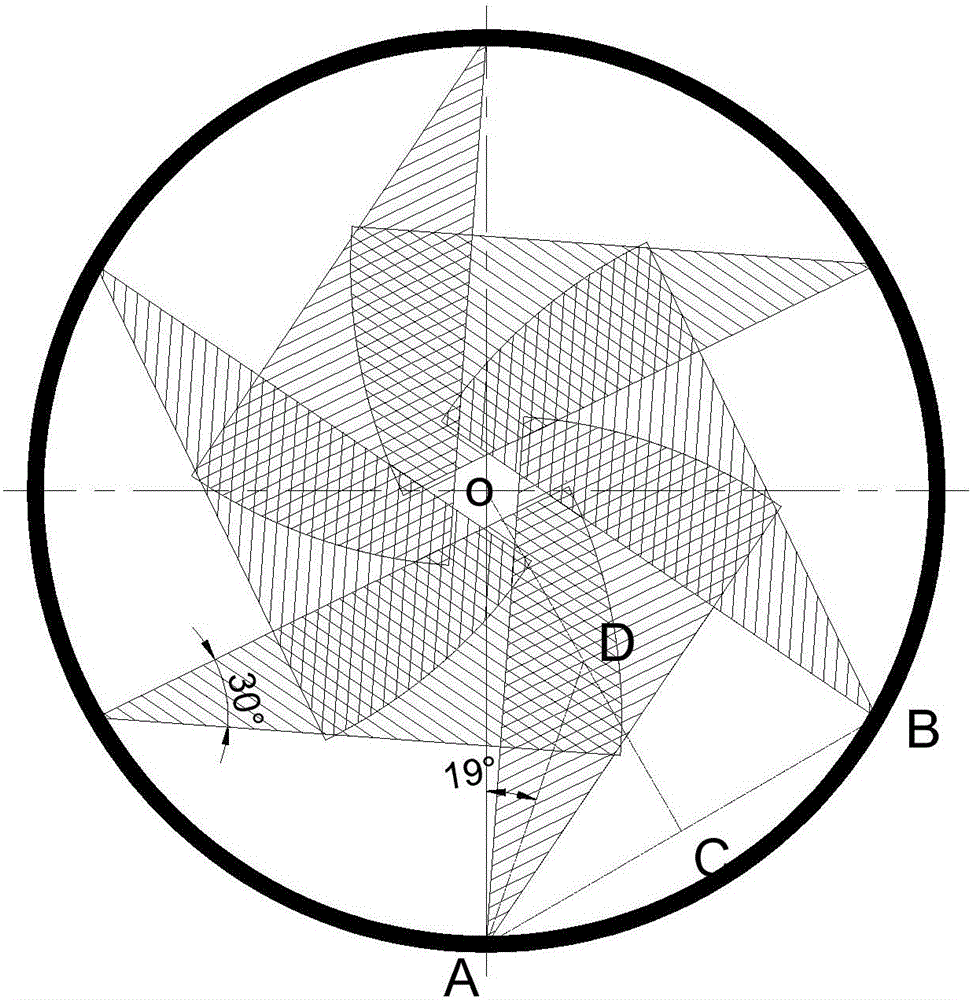

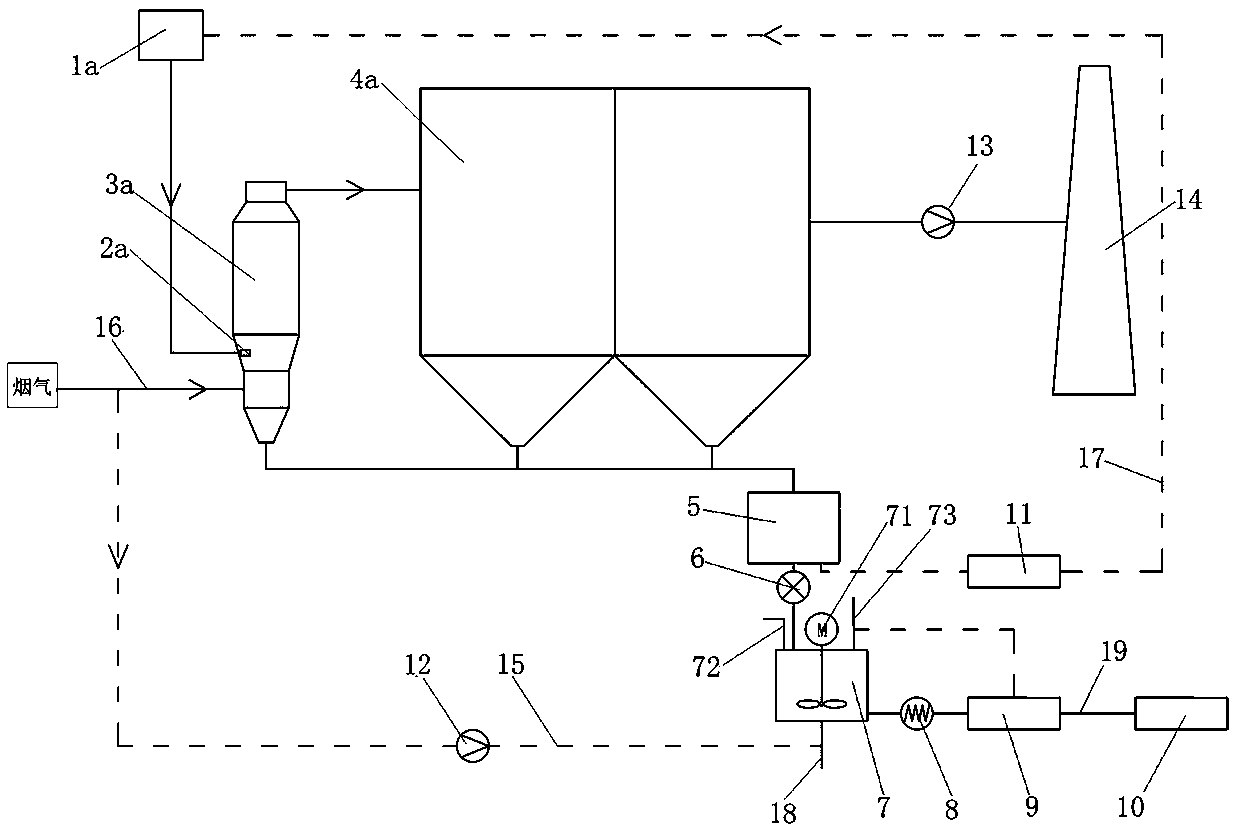

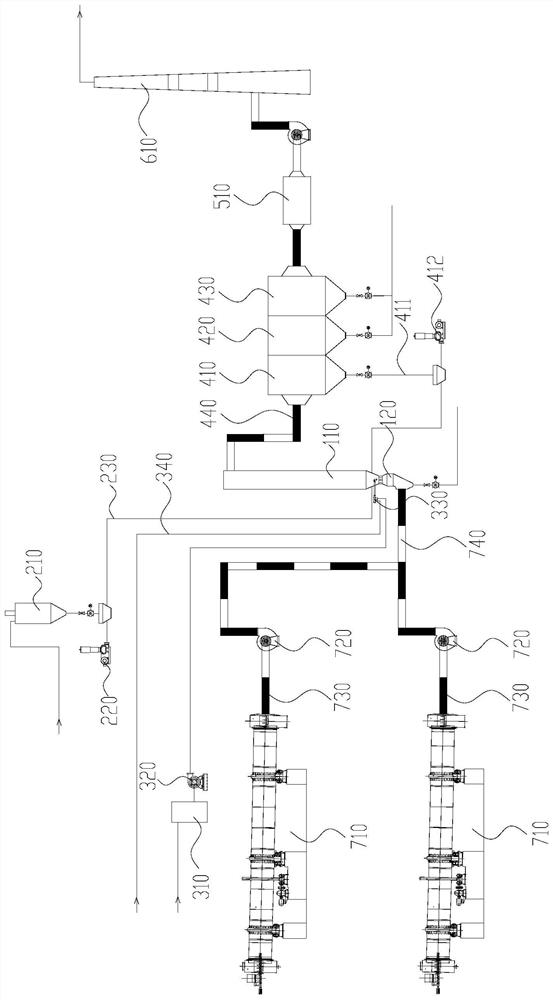

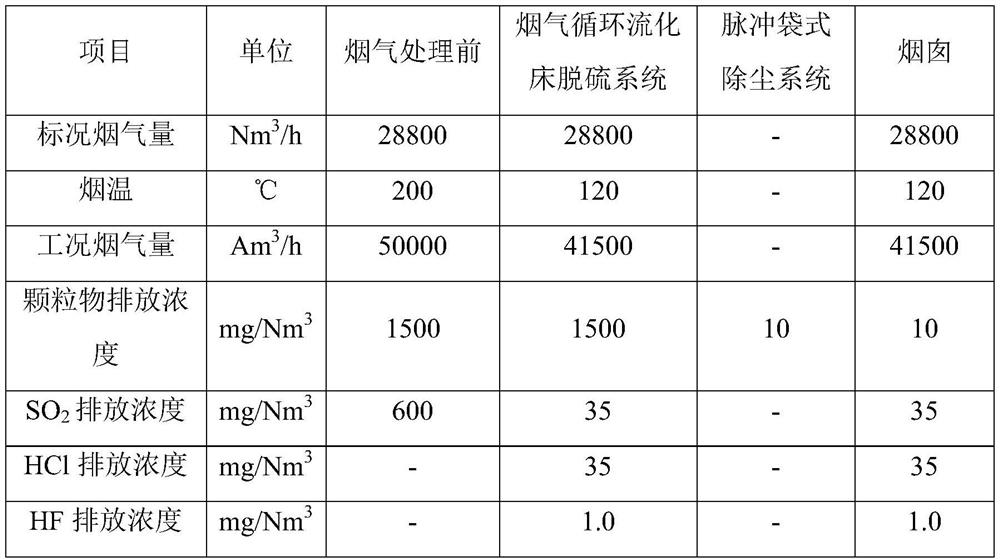

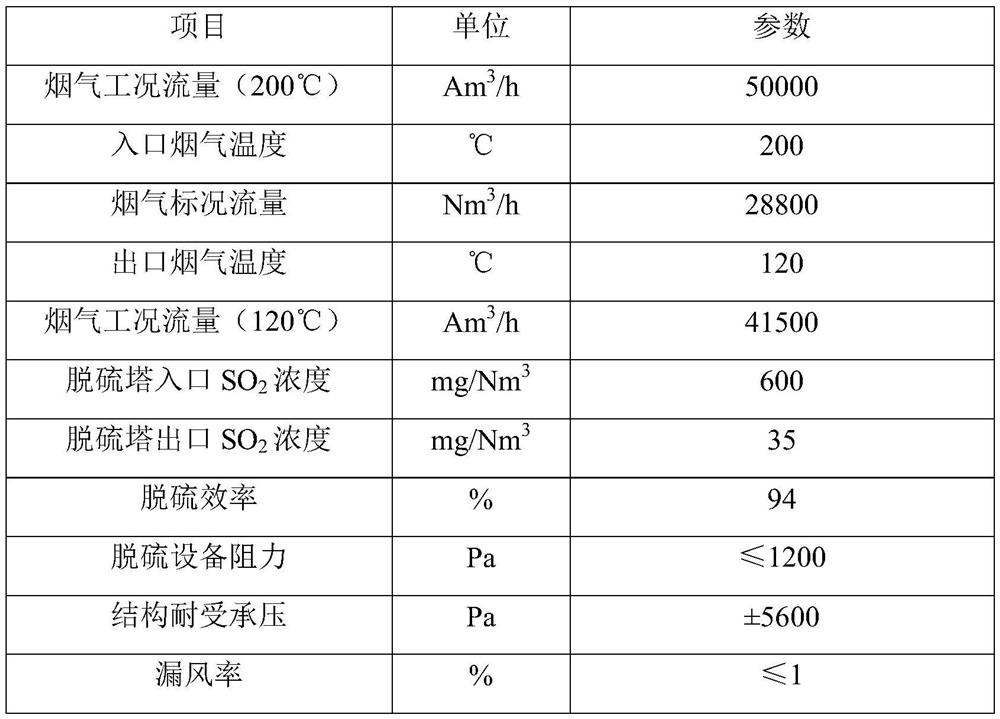

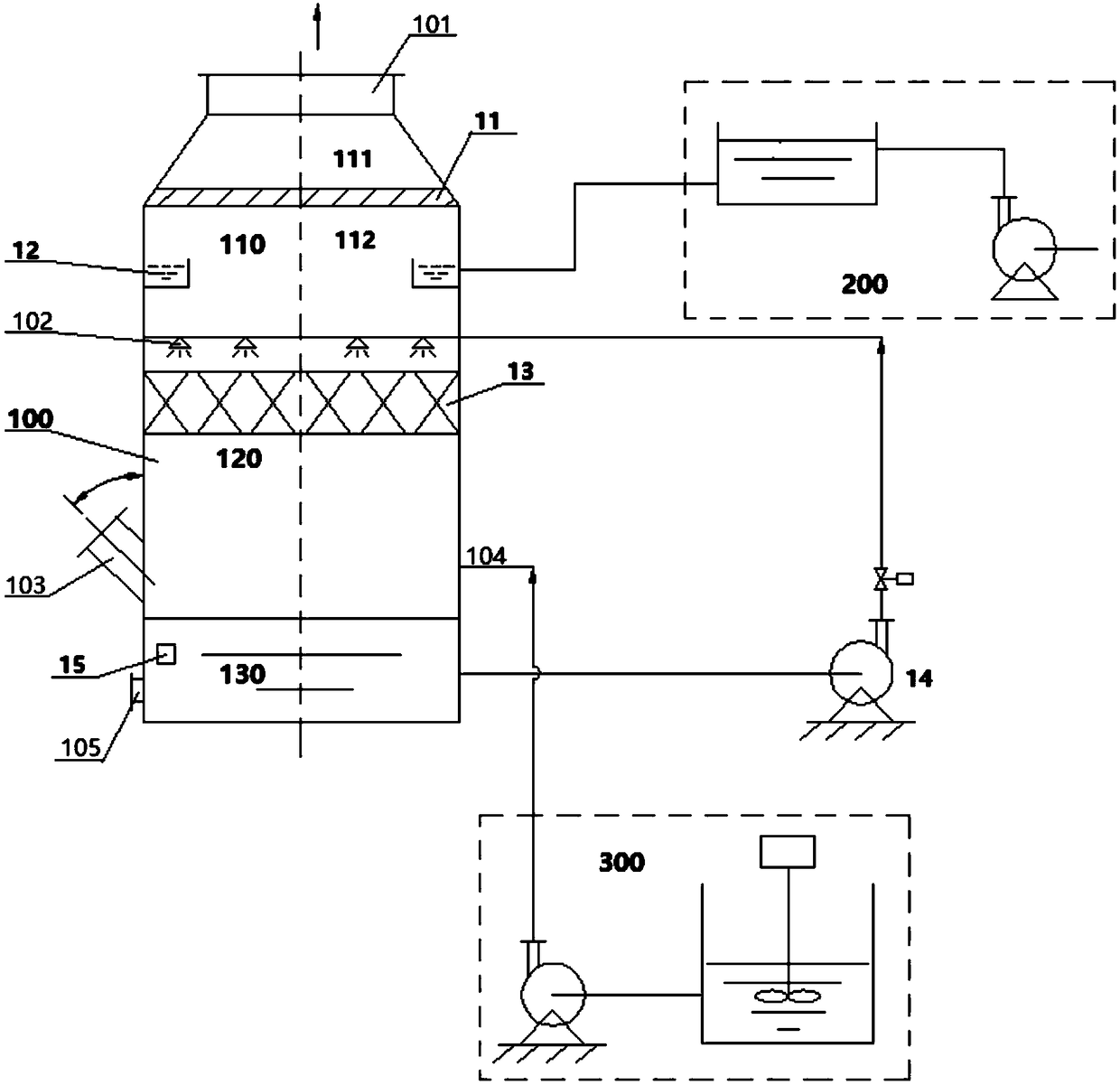

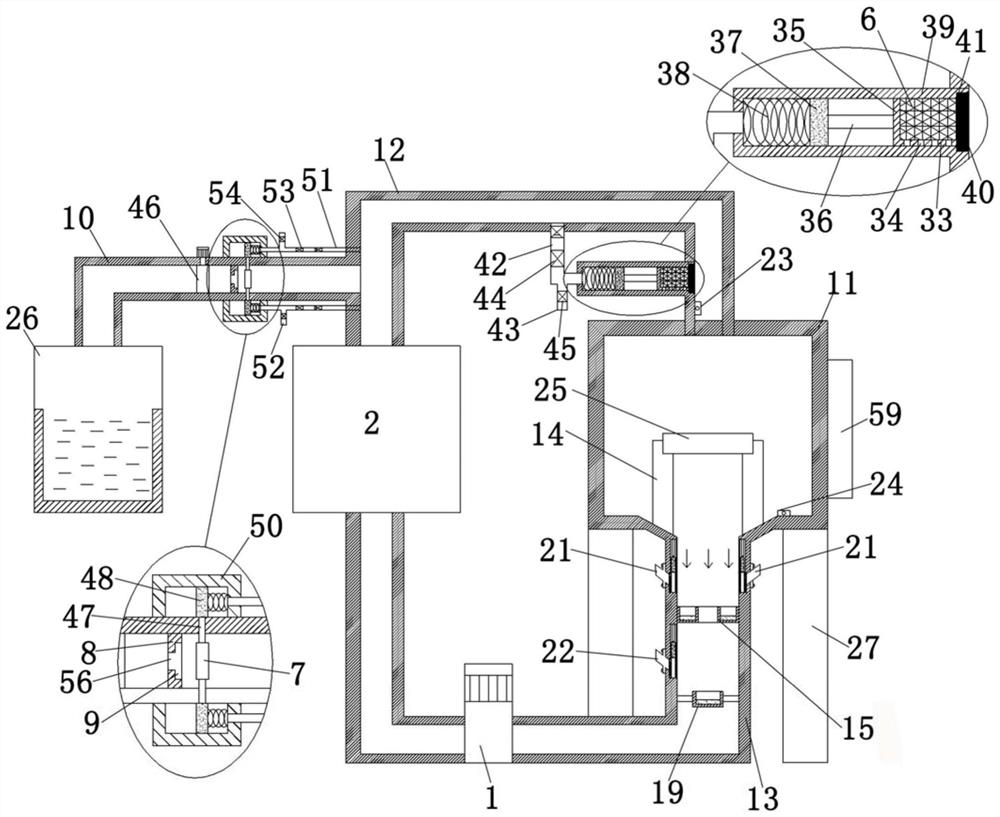

Desulfurization system and method for flue gas of cement kiln furnace

ActiveCN106166437ALess investmentReduce the investment cost onceGas treatmentDispersed particle separationFlue gasSulfur

The invention relates to a desulfurization system and method for flue gas of a cement kiln furnace. The desulfurization system comprises an ammonia water storing tank, conveying pumps, spraying guns, a cement decomposing furnace, a cement kiln pre-decomposing system and an automatic control system, wherein the cement kiln pre-decomposing system comprises a multi-stage pre-heater; the ammonia water storing tank communicates with the spraying guns through the conveying pumps; and spraying points of the spraying guns are located at an outlet of a cyclone barrel of a second-stage pre-heater. The desulfurization method comprises the following steps of I, preparing a 15-25% ammonia water; II, performing real-time detection on the concentration of SO2, and according to the concentration of the SO2 in flue gas, calculating and adjusting the spraying amount of the ammonia water through the automatic control system; and III, according to the spraying amount of the ammonia water, which is obtained through calculation in the step II, injecting the ammonia water which is pressurized through the conveying pumps to the spraying guns, and spraying the ammonia water into the cement kiln pre-decomposing system, wherein the spraying points of the spraying guns are located at the outlet of the cyclone barrel of the second-stage pre-heater. According to the desulfurization system and method disclosed by the invention, the desulfurization efficiency can reach 95% or above, the desulfurization efficiency is high, the ammonia-sulfur ratio is 2-2.5, and the operating cost is low.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

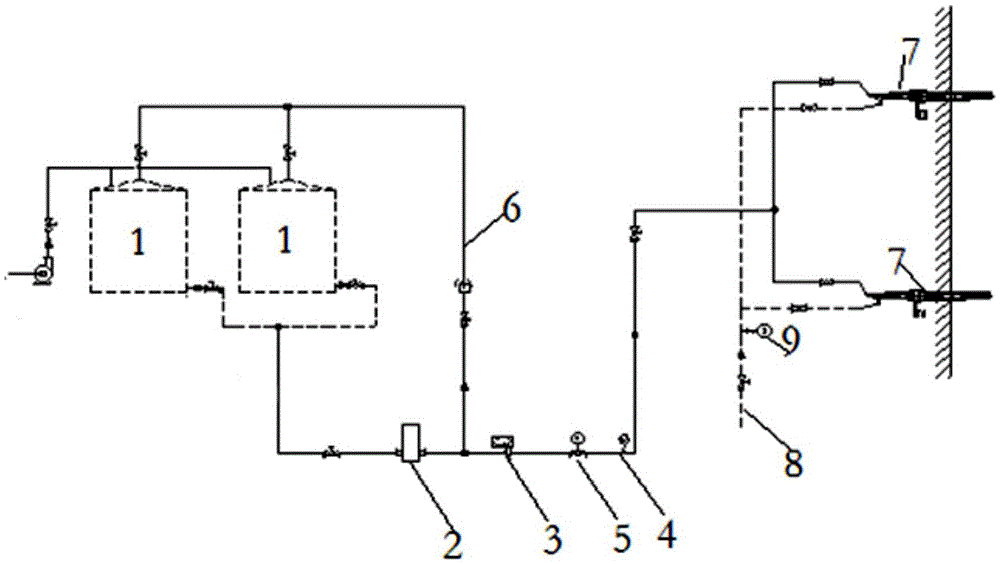

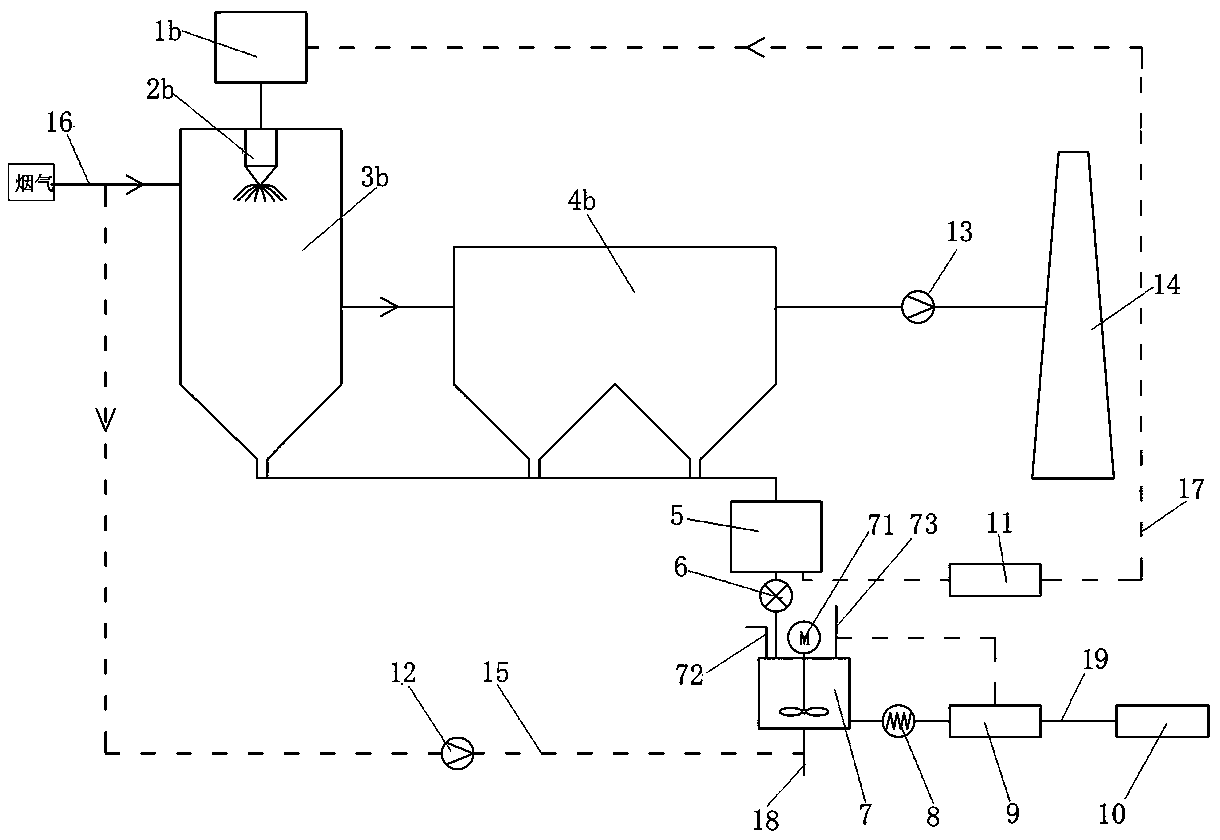

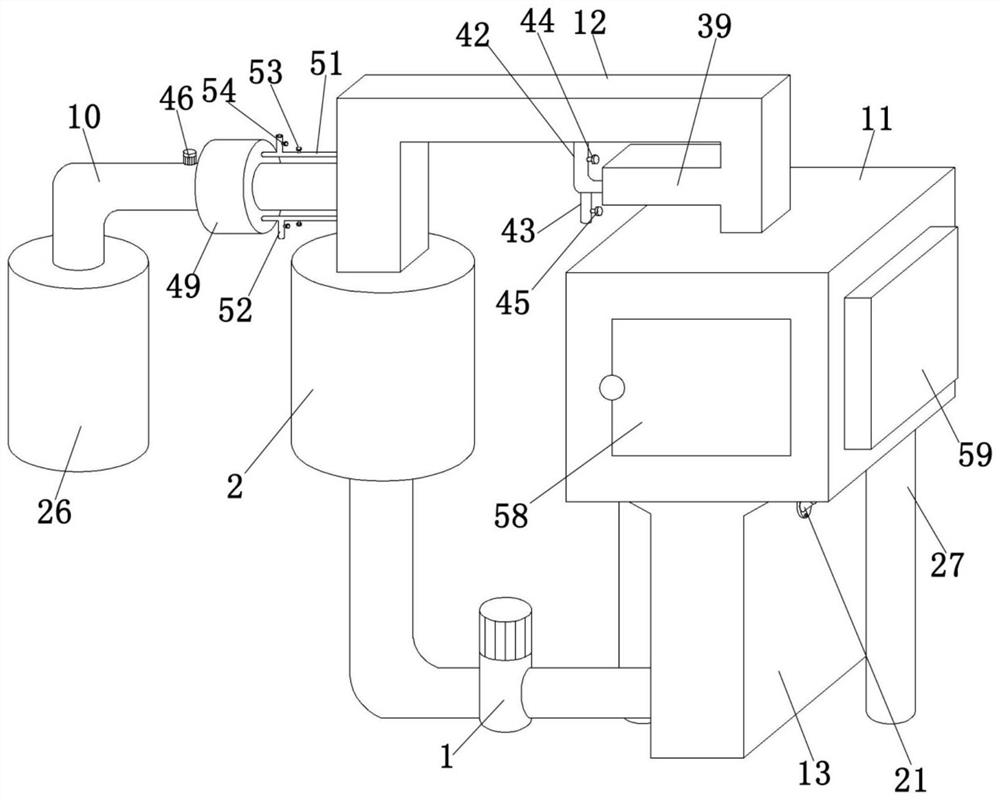

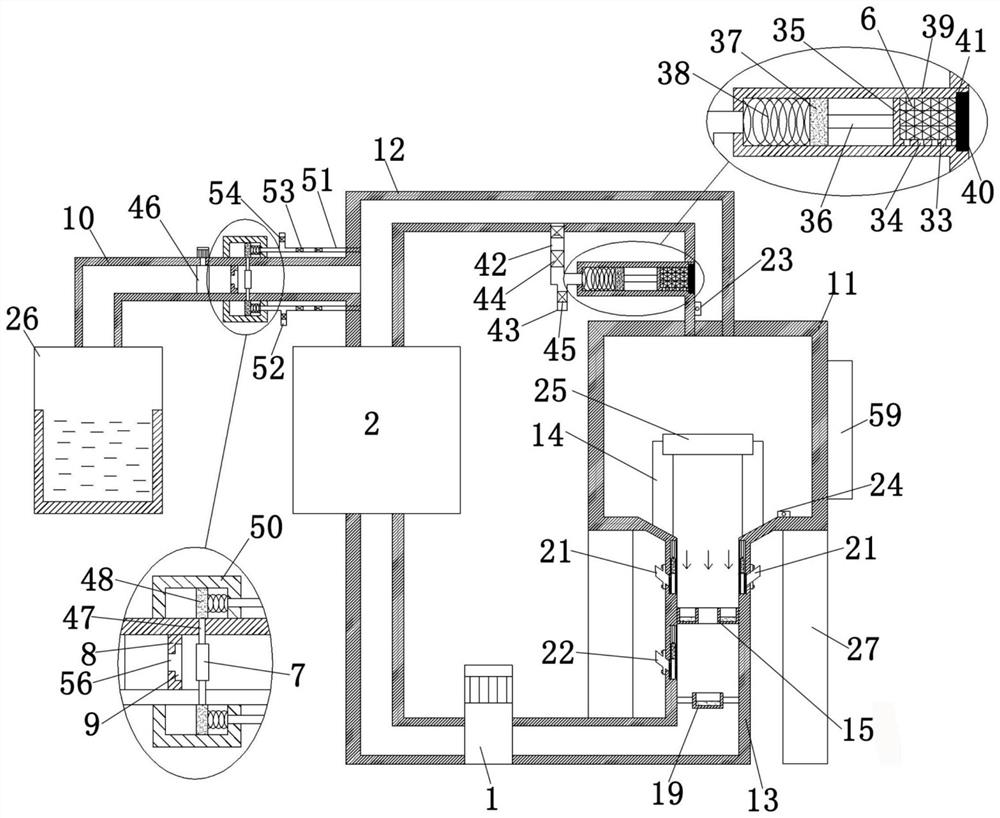

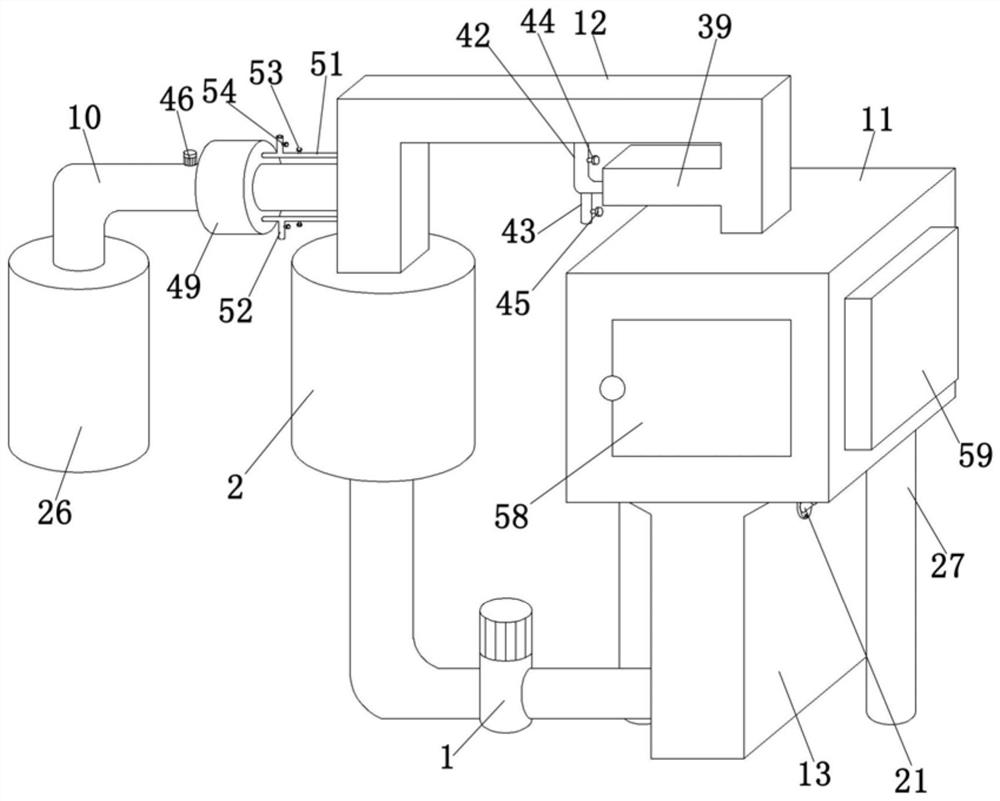

Cement kiln smoke ammonia desulfurization system and method

InactiveCN105457478ASimple structureLow running costGas treatmentDispersed particle separationCement kilnWater storage tank

The invention provides a cement kiln smoke ammonia desulfurization system and method. The system is simple in structure and low in operation cost and one-time investment cost. The system comprises an ammonia water storage system and an ejection unit connected with the ammonia water storage system; the ammonia water storage system comprises two ammonia water storage tanks, the bottoms of the ammonia water storage tanks are connected with a high-pressure pump through valves, and the high-pressure pump is connected with the ejection unit through a flow meter and a pressure transmitter; the high-pressure pump and the flow meter are connected, and the middle between the high-pressure pump and the flow meter is connected to the tops of the ammonia water storage tanks through return pipes. According to the cement kiln smoke ammonia desulfurization system and method, the desulphurization efficiency in the desulfurization process can reach 80% or more; when a proper ratio of ammonia to sulphur is selected, additional pollution caused by ammonia escape does not exist, and no other pollution is produced; the operation cost is mainly expenses of ammonia water, and one-time investment cost and operation cost for a traditional desulfurization process are reduced.

Owner:中材国际环境工程(北京)有限公司

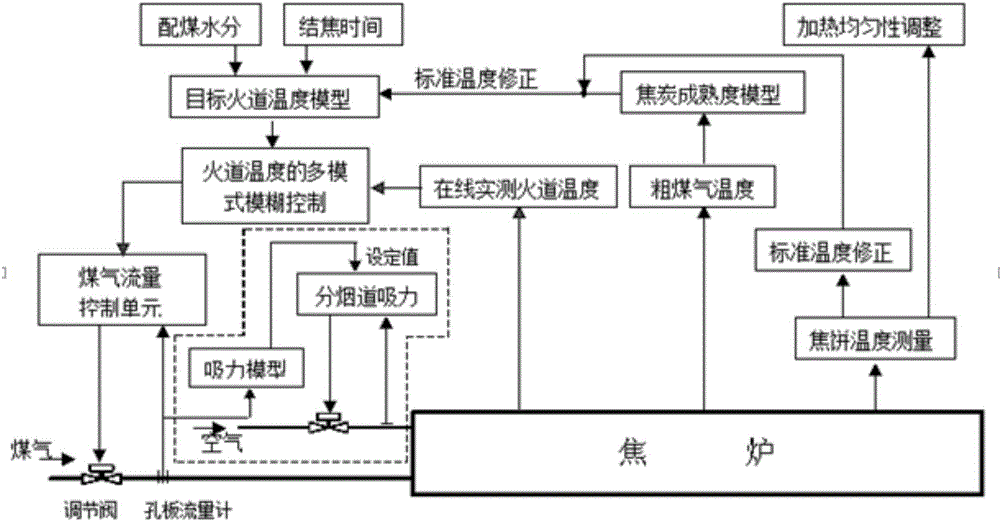

Control system and method for reducing oxynitride in coke oven waste gas

InactiveCN104830351AEmission reductionReduce the investment cost onceCombustible gas coke oven heatingAutomatic controlControl system

A control system and method for reducing oxynitride in coke oven waste gas are disclosed. The control system comprises a coke oven, a temperature detection system, a heating automatic control system, a coking end time automatic judging model, a coking coal maturity model, a target coke oven flue temperature model, a gas flow control unit, and a sub-flue suction control system. The control method comprises the following steps: detecting the temperature of raw gas in a coke oven, the online flue temperature, and coke cake temperature by a temperature sensing probe, sending the raw gas temperature to the coking end time automatic judging model and coking coal maturity model; sending the CI and K values to the target coke oven flue temperature model by the coking end time automatic judging model and coking coal maturity model, sending the target coke oven flue temperature (Ts) to the heating automatic control system by the target coke oven flue temperature model; and controlling the heating automatic control system to control the gas flow control unit and the sub-flue suction control system to feed gas and sub-flue waste gas into the coke oven. The provided control system and method can prominently reduce the oxynitride discharge, and have the advantages of easy promotion and application, and low investment and operation cost.

Owner:MAANSHAN JIANGHAI ENERGY SAVING TECH CO LTD

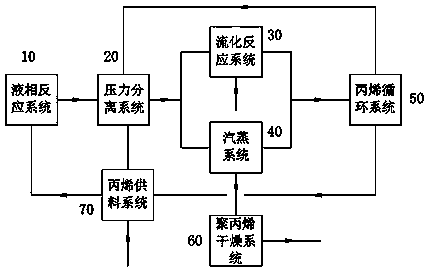

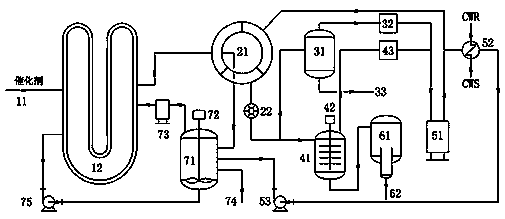

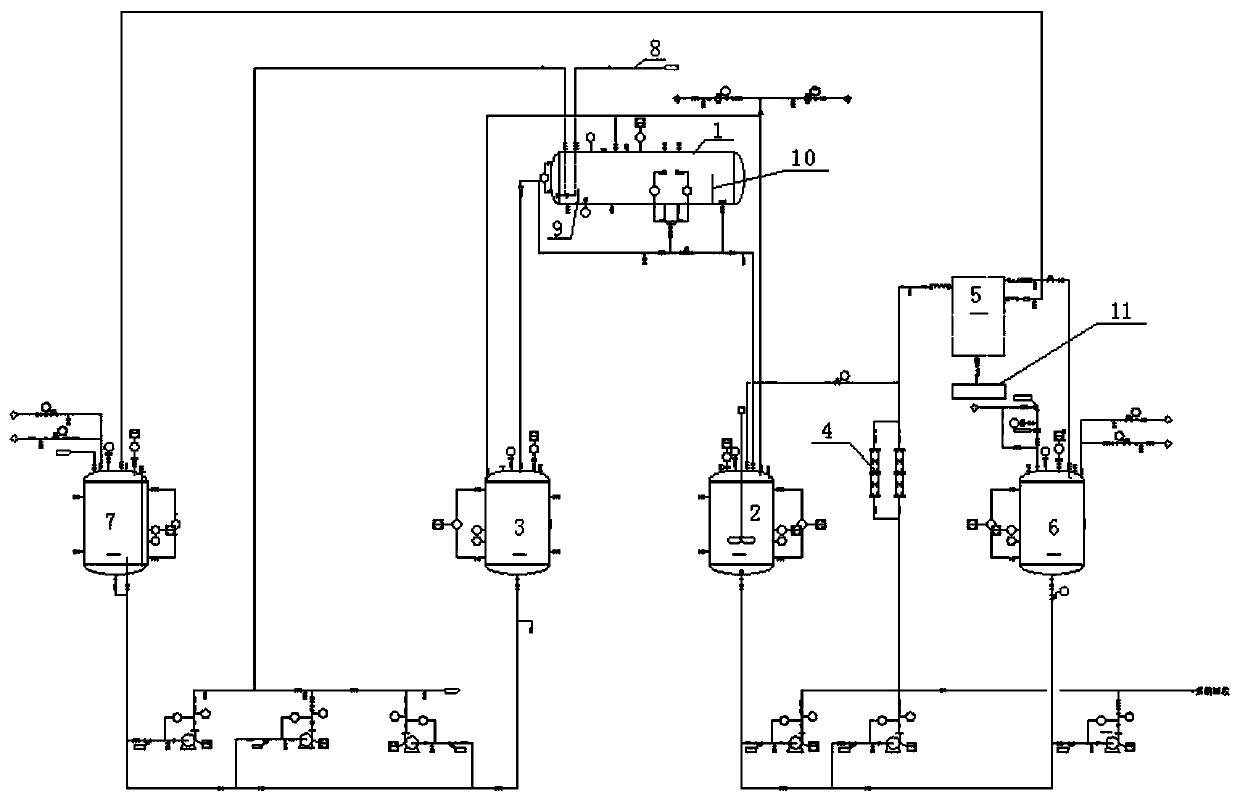

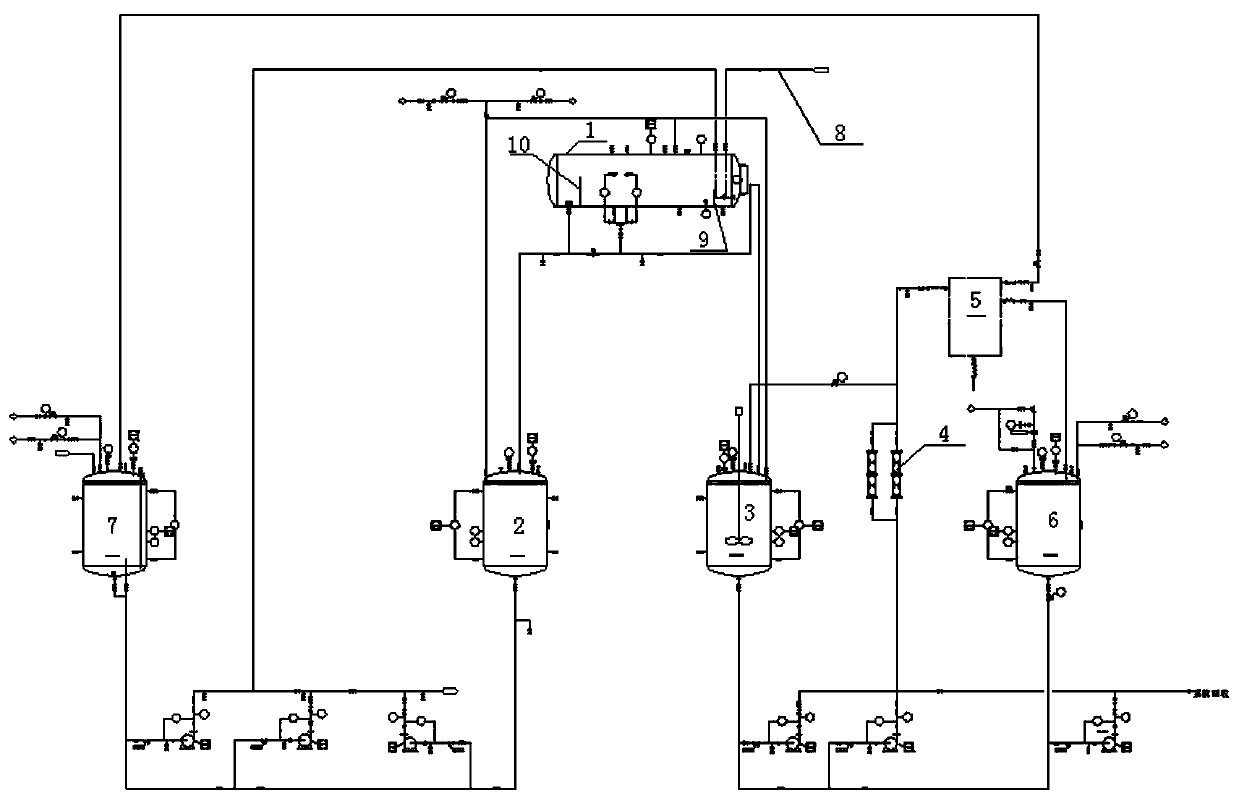

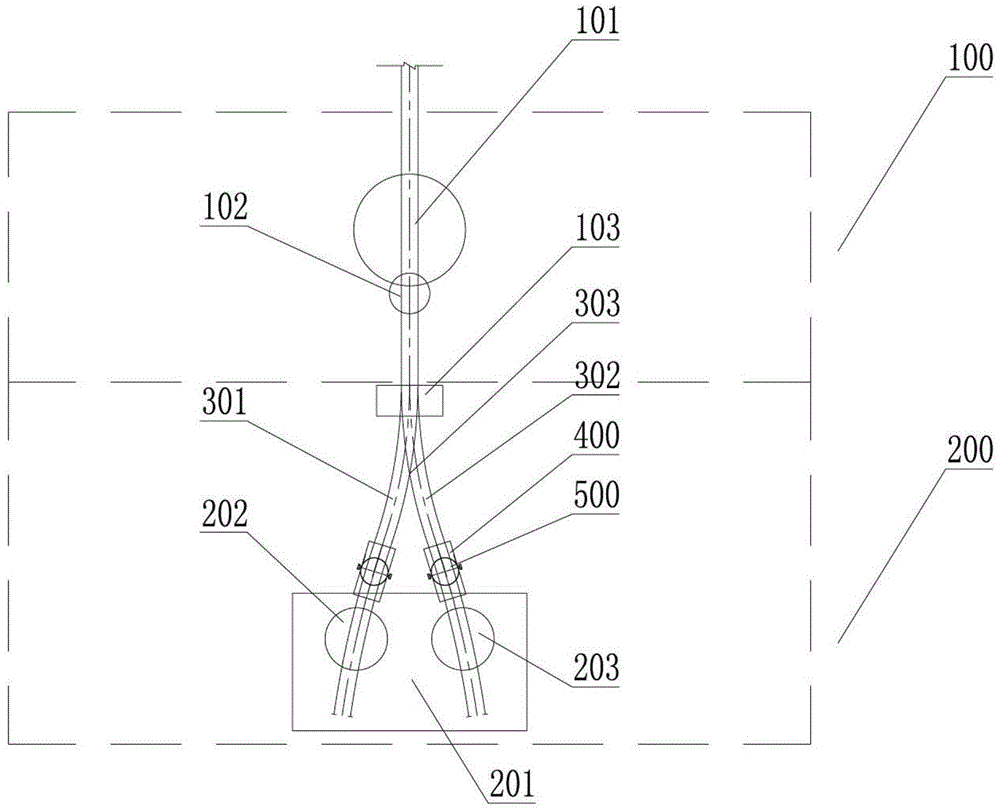

Polypropylene production process and production device

InactiveCN110606905AChange separation methodImprove separation efficiencyMoving filtering element filtersPolypropyleneChemistry

The invention relates to a polypropylene production process and a polypropylene production device. The production process comprises the following steps: polymerizing liquid-phase propylene in a liquid-phase reaction system under the action of a catalyst; introducing a solid-liquid mixture generated by the polymerization reaction into a pressure separation system for solid-liquid separation under the condition of not carrying out other solid-liquid separation; feeding filtrate obtained by solid-liquid separation into a liquid-phase reaction system to be used as a propylene raw material; feedinga solid separated material obtained by the solid-liquid separation into a steaming system and a drying system for steaming liquid removal and drying to form homo-polypropylene powder. The productiondevice comprises the corresponding liquid phase reaction system, the pressure separation system, a propylene feeding system, the steaming system, the drying system and the like. The process and the production device have the advantages of being small in equipment number, short in flow and high in process operability, one-time investment of project construction is reduced, and meanwhile the problemof huge energy consumption caused by liquid phase reactor discharging gasification, flash evaporation, propylene recompression and condensation liquefaction in a traditional process is solved.

Owner:北京泽阳天成化工技术有限公司

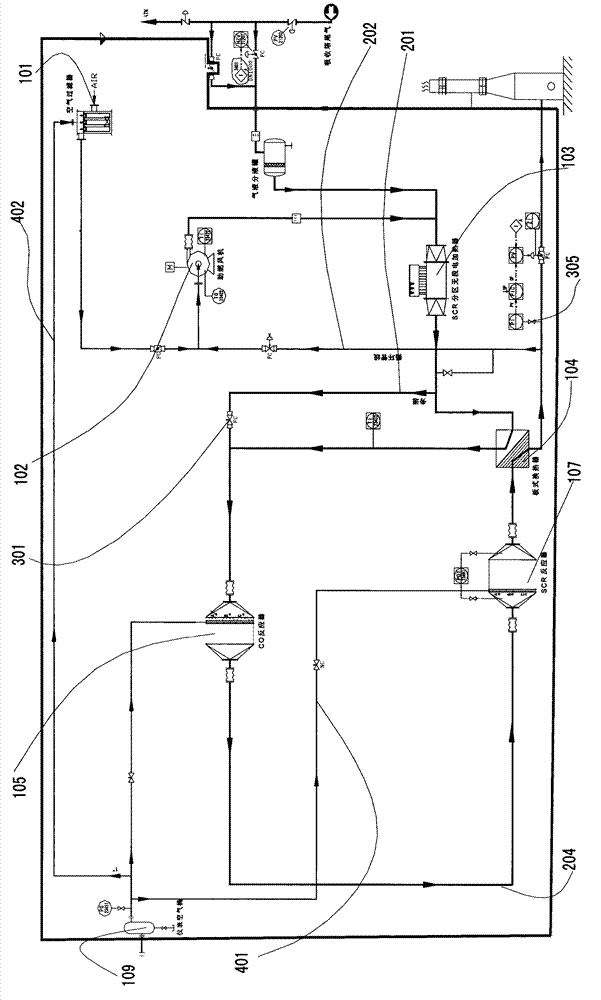

System and method for efficiently utilizing desulfurization by-products

PendingCN110104670AHigh economic benefit utilizationEfficient use ofCalcium/strontium/barium sulfatesDispersed particle separationFlue gasEconomic benefits

The invention discloses a system for efficiently utilizing desulfurization by-products. The system comprises a desulfurization and dust removal device, a waste ash storage tank, a gypsum preparation tank and a finished gypsum product storage device; flue gas enters the desulfurization and dust removal device through a main flue, tail gas generated by the desulfurization and dust removal device issucked by a second fan and finally discharged by a chimney, waste ash generated by the desulfurization and dust removal device is conveyed to the waste ash storage tank through a pipeline, the waste ash storage tank is communicated with the top of the gypsum preparation tank through a pipeline, the bottom of the gypsum preparation tank is communicated with an air conveying pipeline, and the main flue is communicated with the air conveying pipeline through a bypass flue; the gypsum preparation tank is internally provided with a stirring device, the top of the gypsum preparation tank is providedwith a gas outlet and a water adding pipe, the gypsum preparation tank is communicated with the finished gypsum product storage device through a discharging pipe, and the discharging pipe is providedwith a slurry conveying pump and a dewatering device. The system truly achieves the efficient utilization of the desulfurization by-products, can effectively solve the problem of large treatment difficulty of the desulfurization by-products, increases the economic benefits, saves energy and protects the environment.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST

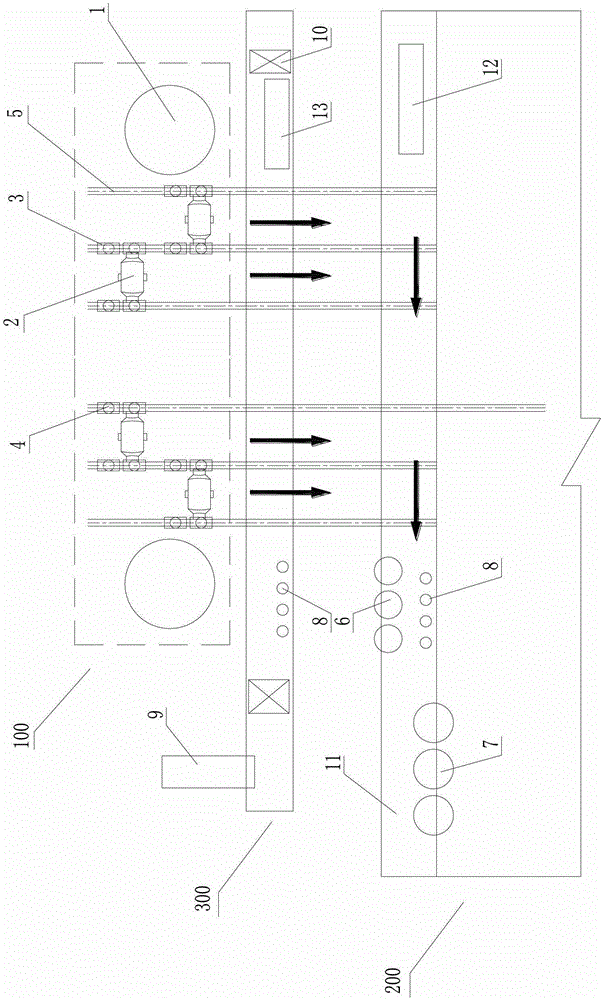

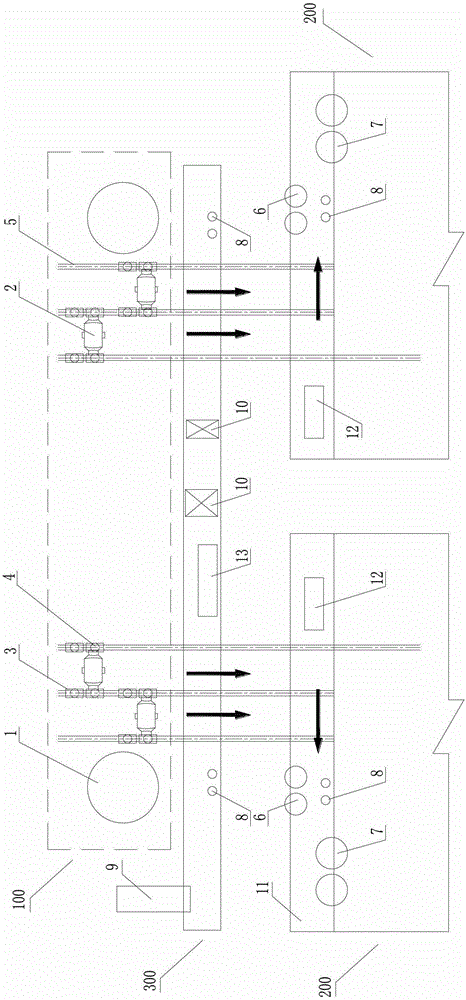

Compact hot metal transport system

ActiveCN103343632BSmall footprintReduce investmentBlast furnace detailsIndustrial buildingsSteelmakingIron transport

Owner:BERIS ENG & RES CORP

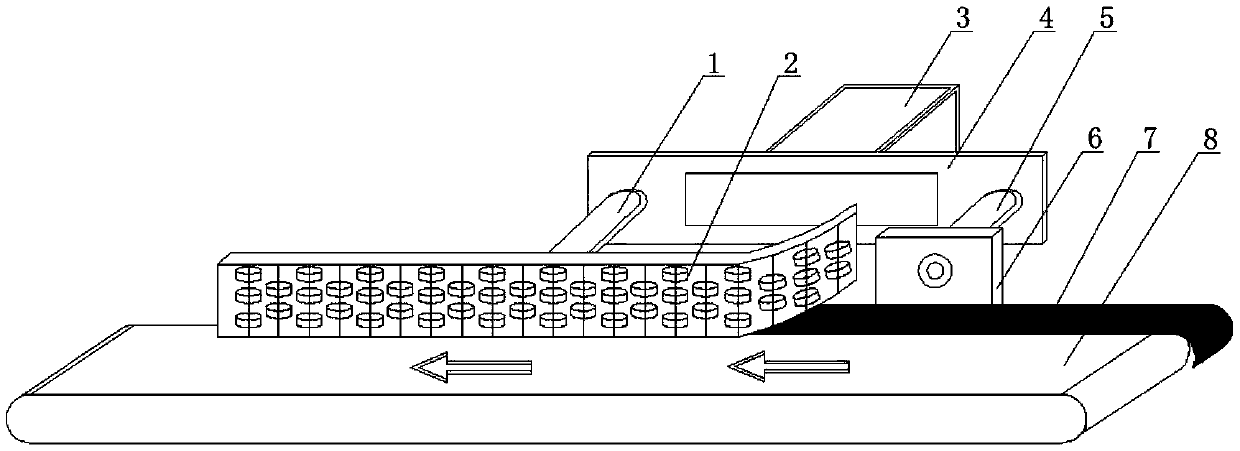

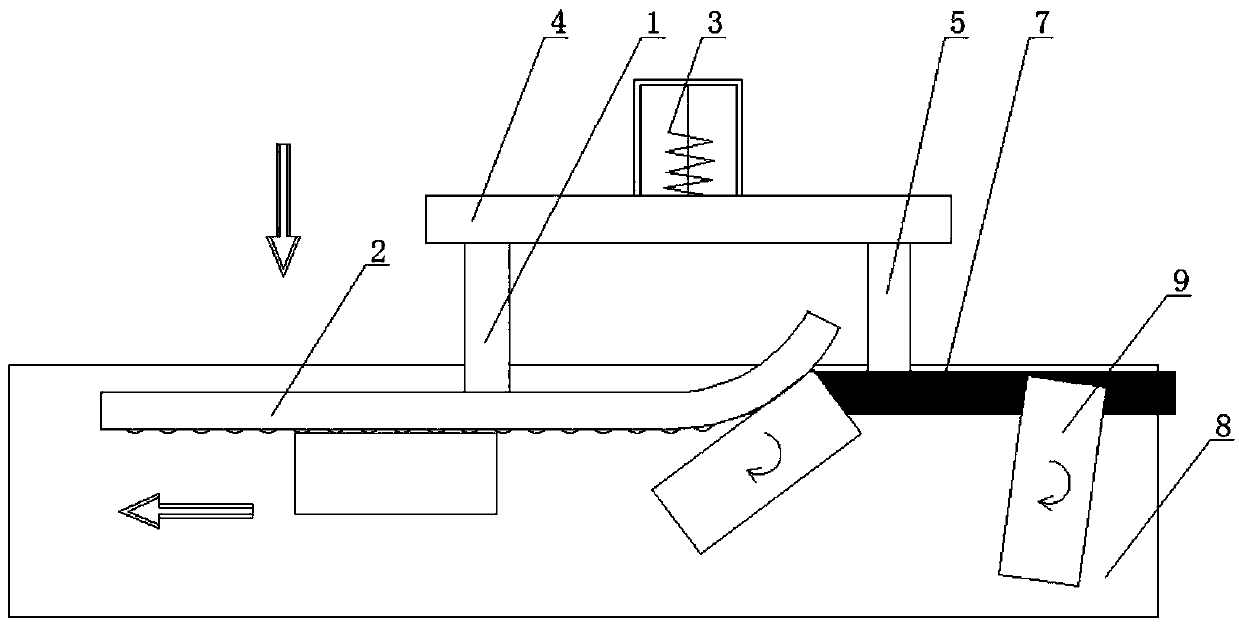

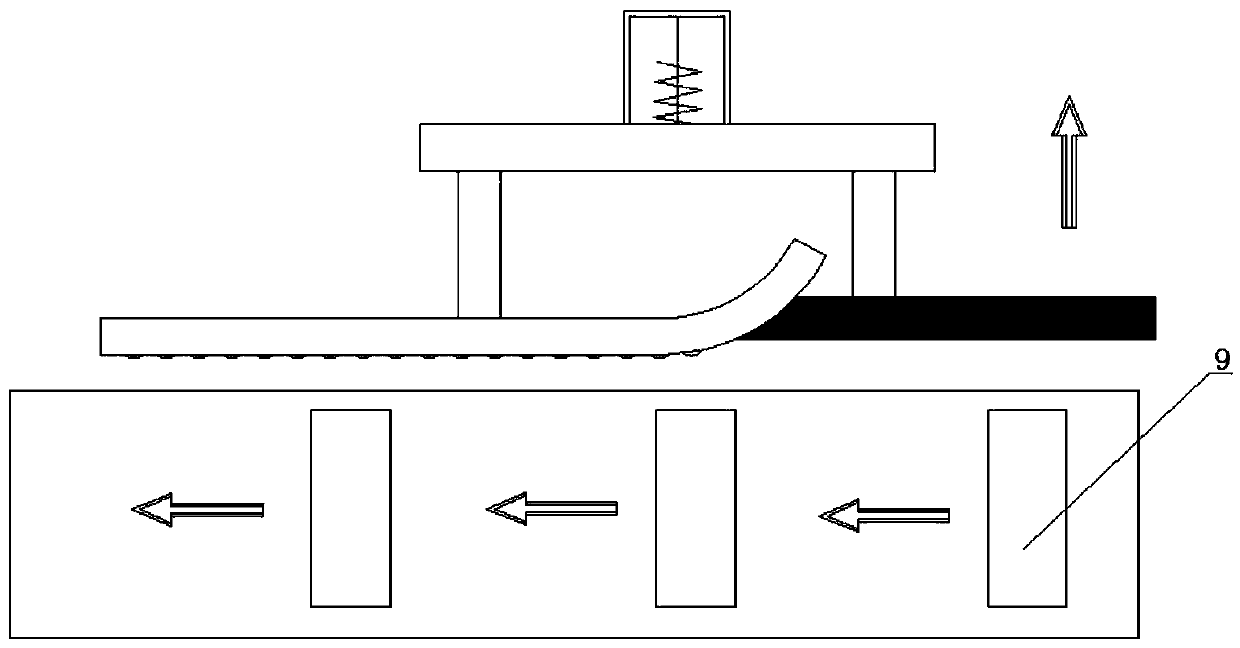

Perpendicular steering device for packaging box

InactiveCN110893993ASteering precisionEasy to operateConveyorsConveyor partsRubber sheetControl theory

The invention relates to a perpendicular steering device for a packaging box. The perpendicular steering device comprises a driving mechanism, a supporting plate, a rubber plate and a ball baffle. Theoutput end of the driving mechanism and the back face of the supporting plate are fixedly mounted, and one ends of two cantilevers are symmetrically and fixedly mounted at the two ends of the front face of the supporting plate. The ball baffle is fixedly mounted at the other end of the left cantilever. The ball baffle is located above a conveying belt and is vertically mounted, and a fixed frameis fixedly mounted at the other end of the right cantilever. The rubber plate is fixedly mounted on the fixed frame. The rubber plate is located on one side of the conveying belt, and the bottom faceof the rubber plate is slightly higher than the top face of the conveying belt. According to the perpendicular steering device, a box steering action is completed through dual control of the frictionrubber plate and the ball baffle. The packaging box steers by 45 degrees or above when reaching the ball baffle and continues to steer to reach 90 degrees along the baffle, and the precise steering of90 degrees of the packaging box is guaranteed. Operation is convenient, the labor cost and operation cost are reduced, and the one-time investment cost is reduced.

Owner:中粮可口可乐饮料(天津)有限公司

Sealed heating system and heating method

InactiveCN102865585ALow running costSave electricityIncinerator apparatusHeating systemElectric energy

The invention provides a sealed heating system which comprises a circulation sealed structure which is composed of a combustion fan, a heater, a heat exchanger, a reactor and pipelines for mutually connecting the combustion fan, the heater, the heat exchanger and the reactor. The sealed heating system has the beneficial effects that compared with an opened type heating system, with same devices, the sealed heating system is relatively small in installation power, low in once investment cost and operation cost, short in starting time, convenient to operate and capable of ensuring that the system can be restarted within a short time, and a great deal of electric energy can be saved.

Owner:上海凯鸿环保工程有限公司

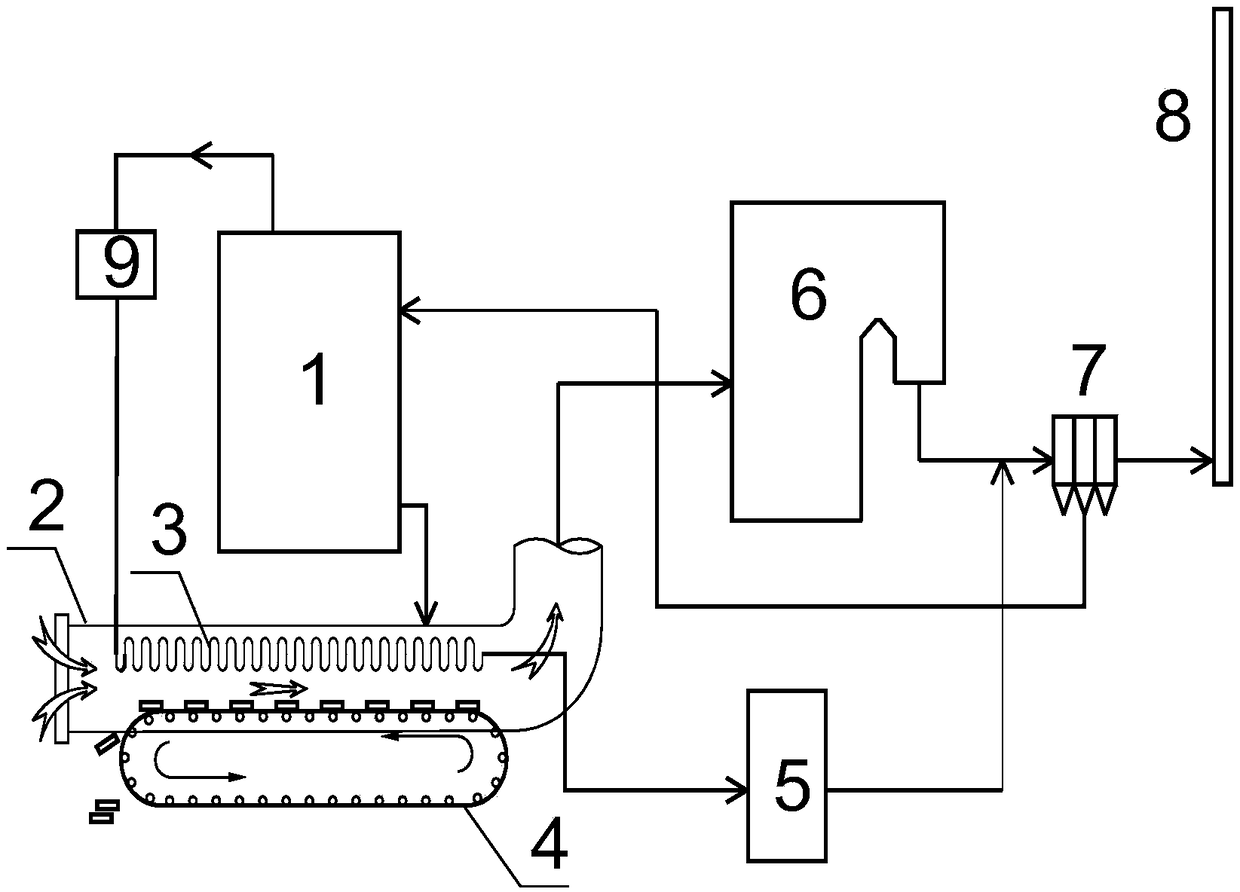

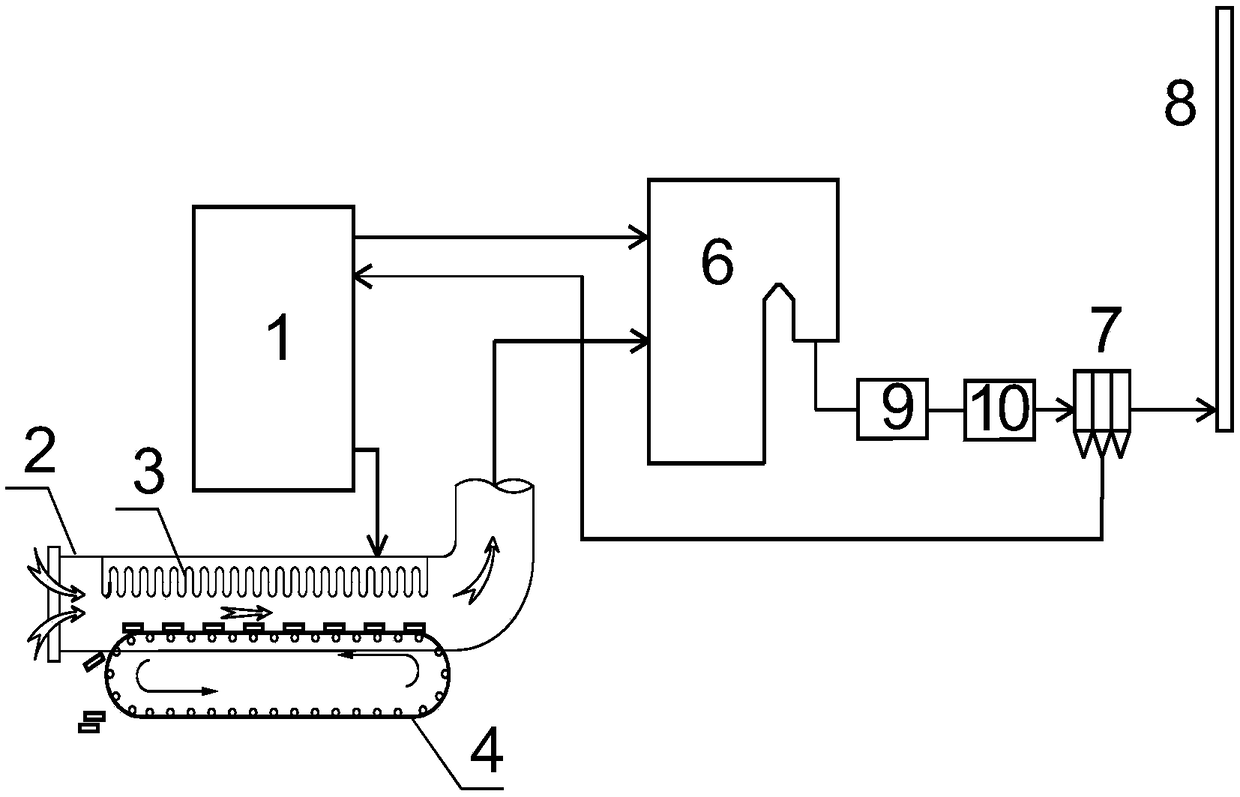

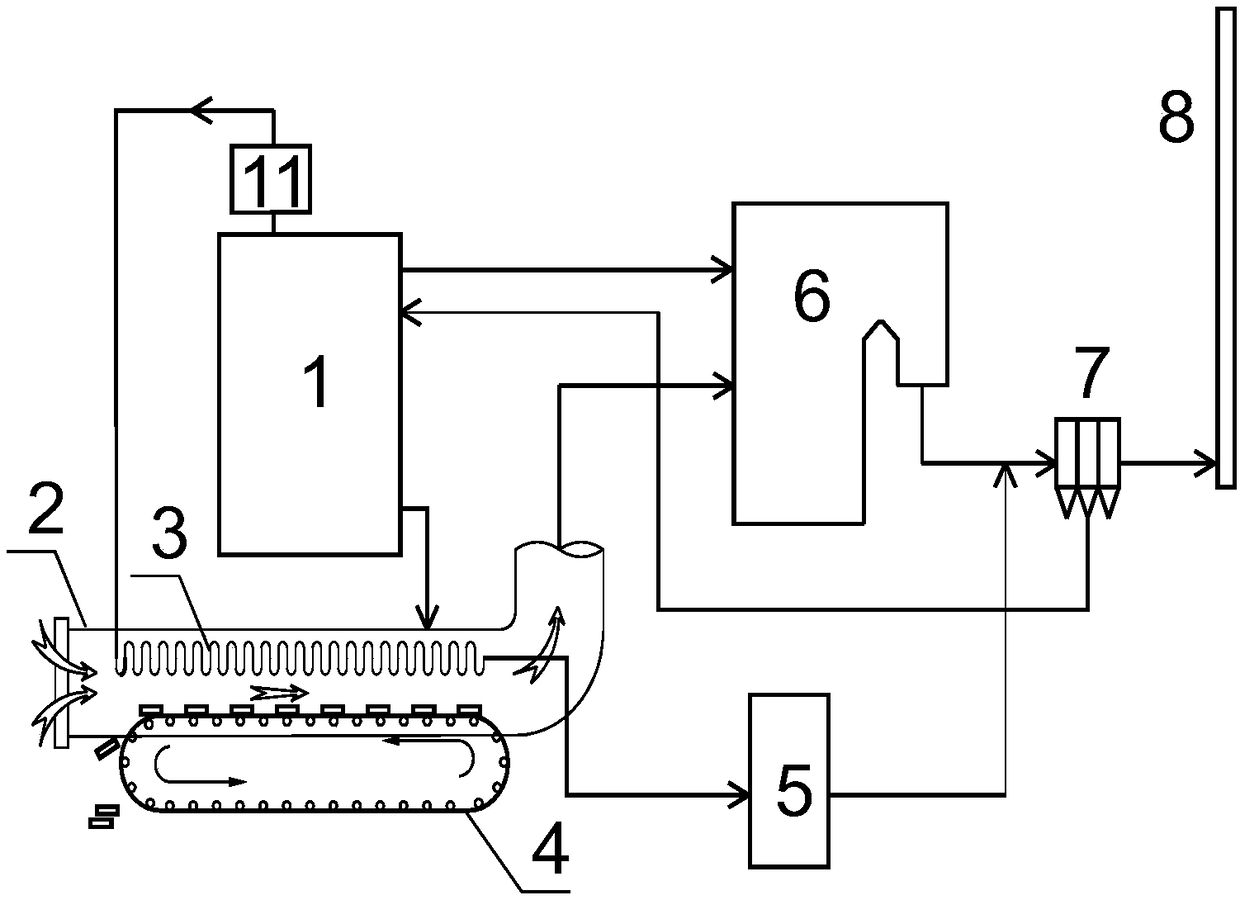

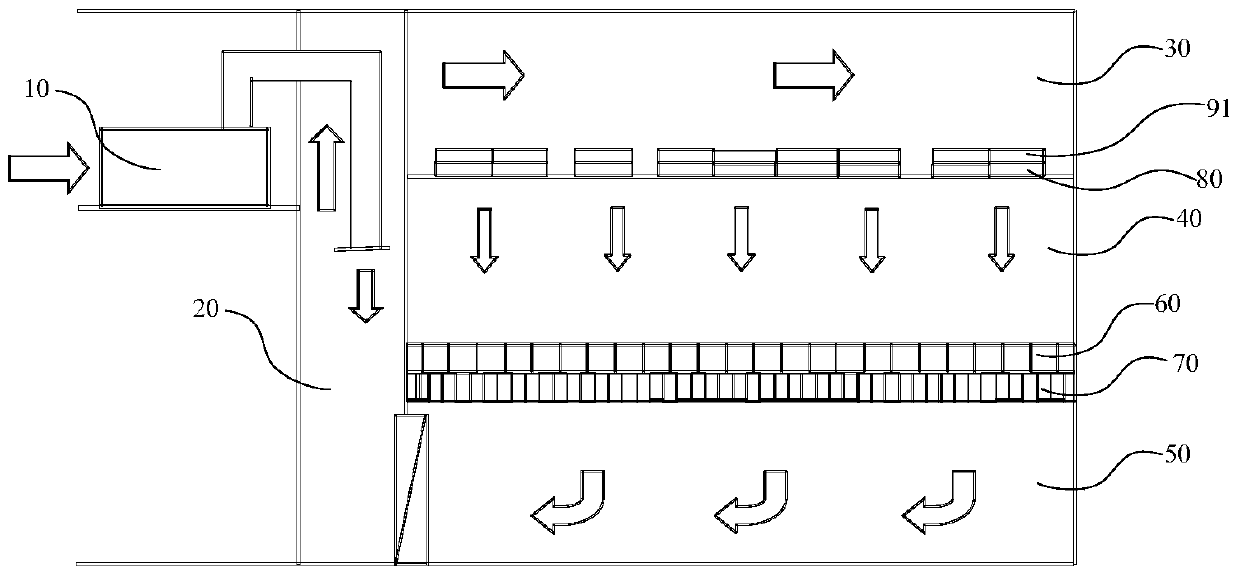

Device and method for heat recovery and utilization of waste incinerator fly ash treated by high-temperature melting method

The invention belongs to the technical field of manufacture of environmental protection equipment, and relates to a thermal energy recycling device and method for treating flying ash of a garbage incinerator by a high-temperature melting method. The device comprises a high-temperature melting furnace, an IHE, a high-temperature tail gas heat sink, a molten slag cooling and conveying device, flue gas heavy metal desorption treatment equipment, a garbage incineration boiler, a dust remover and a chimney, wherein high-temperature tail gas of the high-temperature melting furnace is delivered to the flue gas heavy metal desorption treatment equipment and is treated after being cooled; molten slag in the high-temperature melting furnace becomes glass bodies after being cooled; the glass bodies are discharged along with a conveying chain of the molten slag cooling and conveying device; and thermal energy of the high-temperature tail gas and thermal energy in the molten slag are recycled in the garbage incineration boiler and is utilized. Garbage flying ash treated by the high-temperature melting method is directly applied to the garbage incineration boiler, energy consumption cost is greatly reduced, furthermore, the tail gas treatment mode is simplified, a system is also simplified greatly, primary investment costs are reduced, and by application of the high-temperature melting method on the garbage incineration boiler, harmless treatment of the flying ash can be realized, and furthermore, the economic value is high.

Owner:ANHUI TENGLONG ELECTRIC

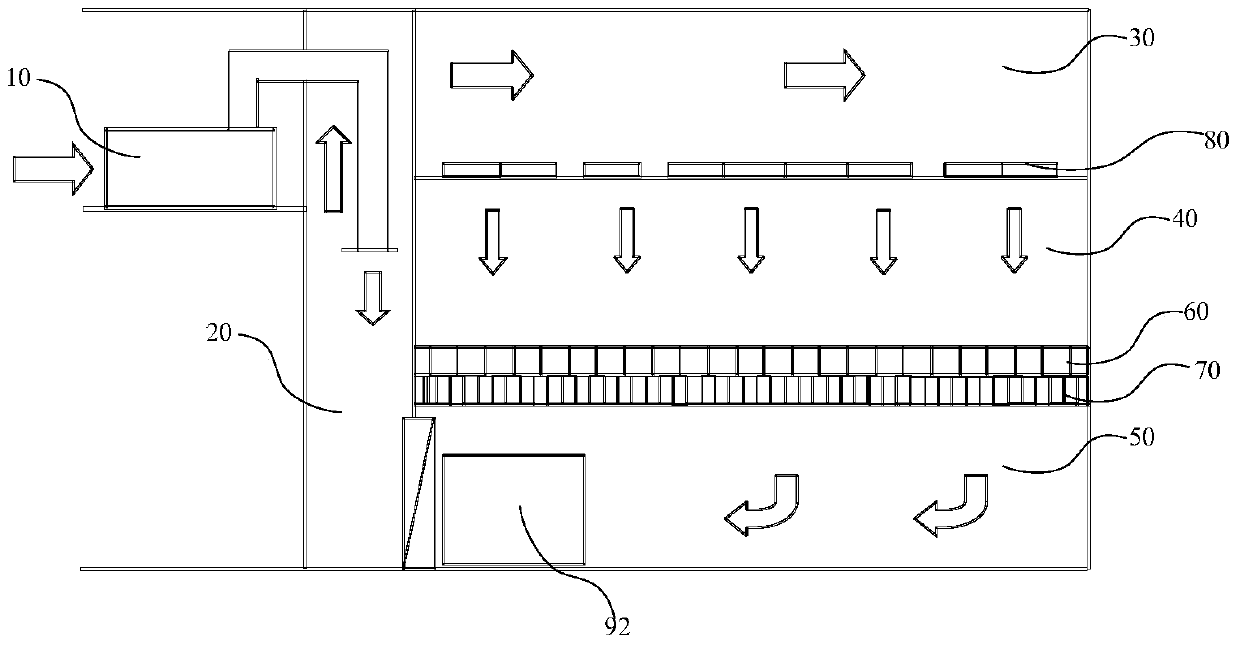

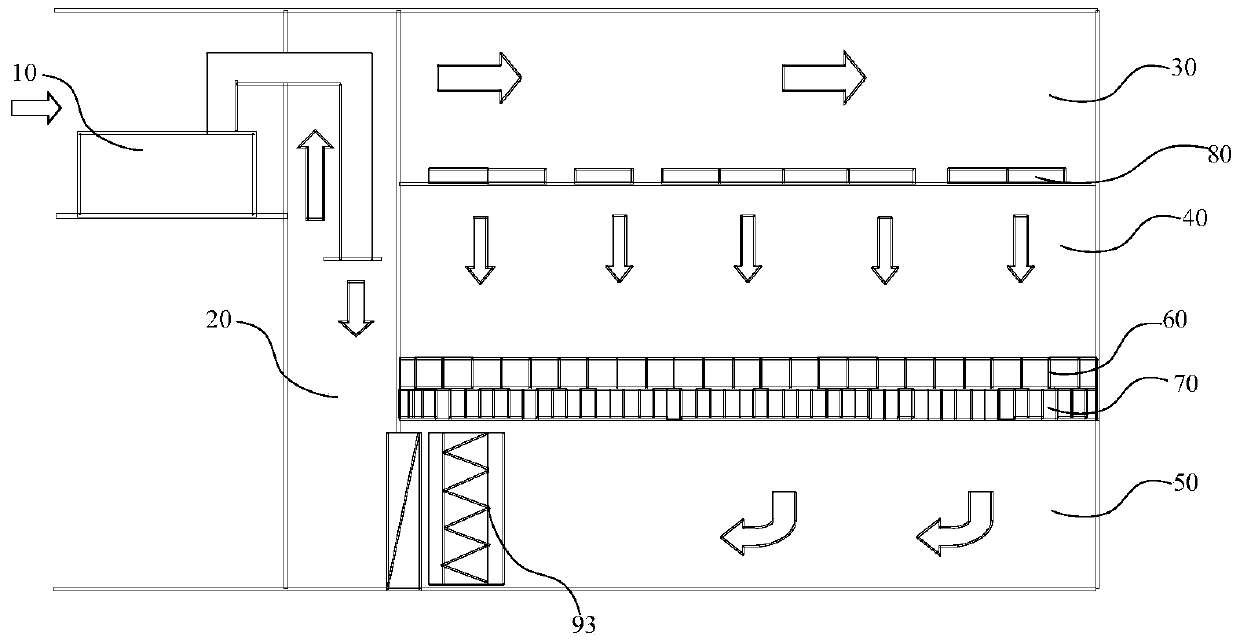

air handling system

ActiveCN105987433BImprove processing efficiencyReduce complexityLighting and heating apparatusSpace heating and ventilation detailsAir treatmentHandling system

The invention discloses an air treatment system. The air treatment system comprises a clean room, an upper interlayer, a lower interlayer and an air-returning shaft, wherein the upper interlayer is located on the clean room, and the lower interlayer is located under the clean room; equipment fences are arranged inside the clean room, and space defined by the equipment fences is used for containing equipment generating chemical substance pollutants in the work process; the lower interlayer and the clean room are separated by a separation plate system with an air return port; lower-layer fences extending to the bottom from the top of the lower interlayer are arranged inside the lower interlayer, and air inside the equipment fences can enter the lower-layer fences from the air return port of the separation plate system; a chemical substance pollutant treatment device located inside the lower interlayer communicates with the space defined by the lower-layer fences through a pipeline; air treated by the chemical substance pollutant treatment device can enter the upper interlayer through the air-returning shaft. According to the air treatment system, the technical problems that because circulating air inside the clean room needs to be completely treated by the chemical substance pollutant treatment device, the amount of the air to be treated is huge and the treatment efficiency is low are solved.

Owner:S Y TECH ENG & CONSTR CO LTD +1

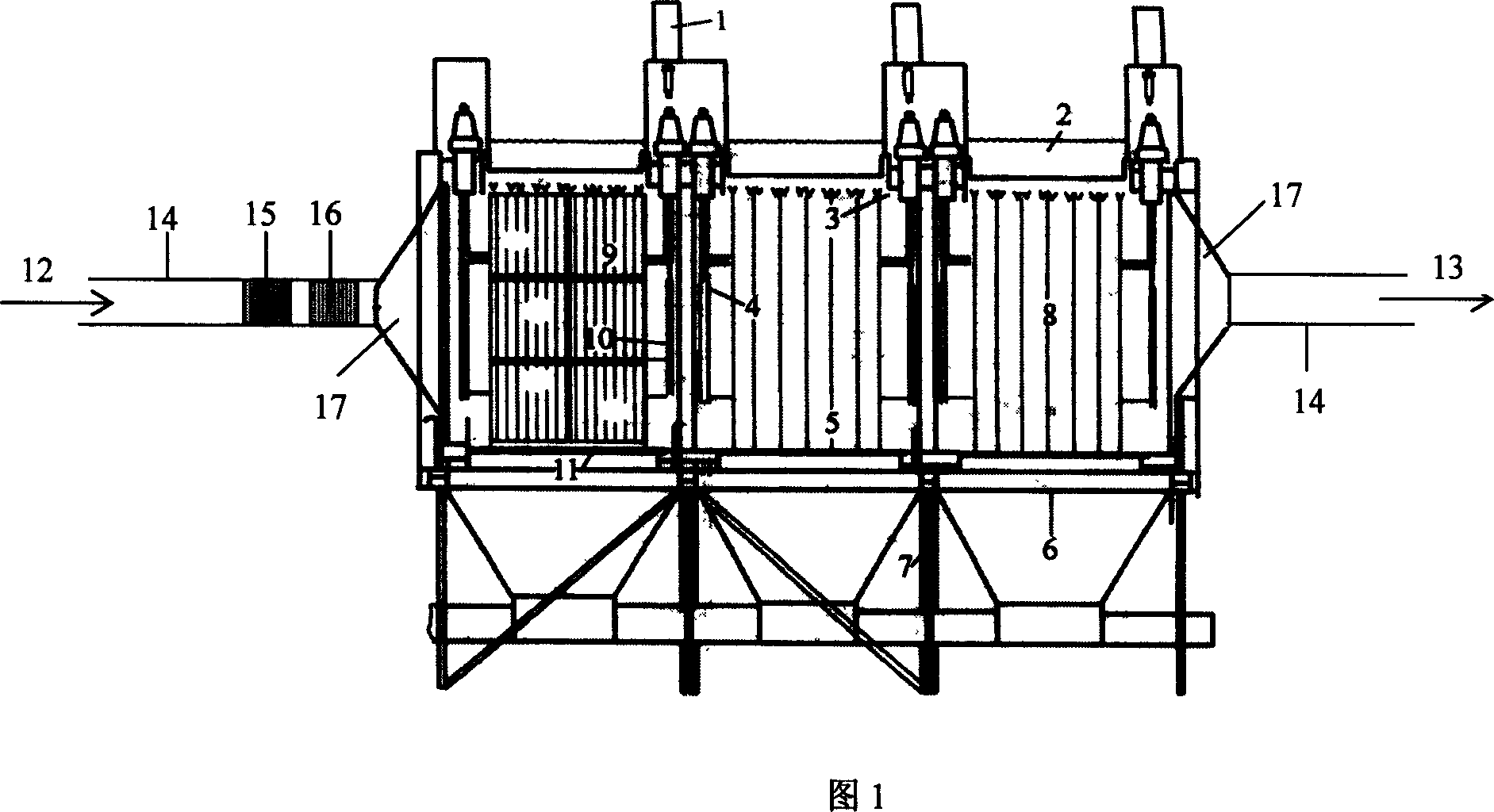

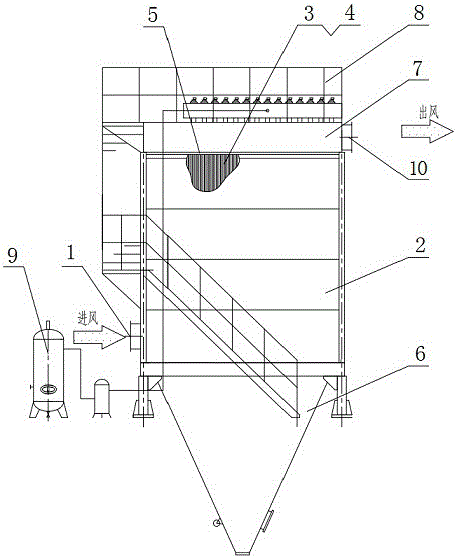

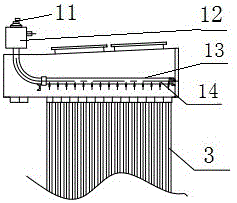

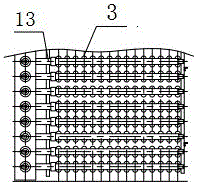

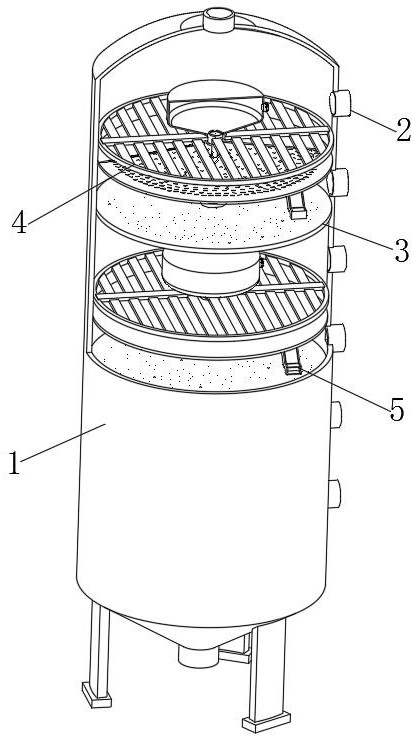

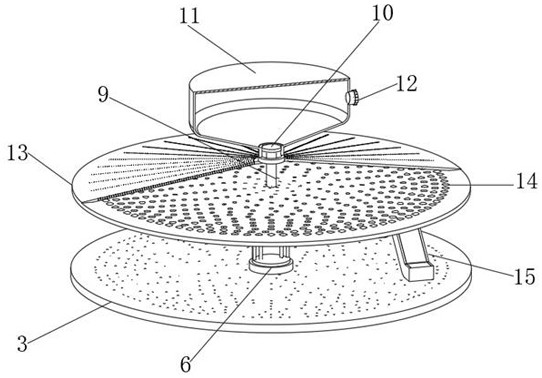

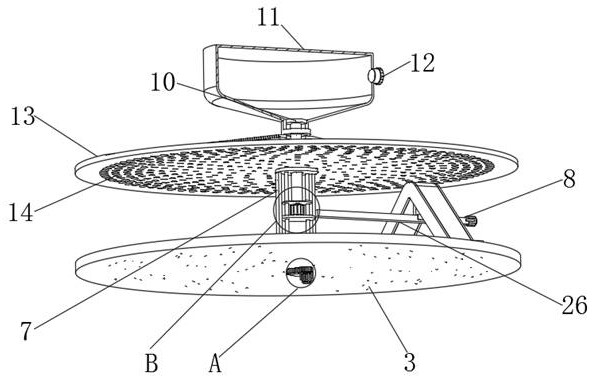

Oblate bag type dust collector

InactiveCN105879515ASolve the large consumption of steelSolve the disadvantages of poor cleaning effect of rotary blowback flat bagHuman health protectionDispersed particle filtrationEngineeringSmall footprint

The invention relates to an oblate bag type dust collector. The oblate bag type dust collector comprises an inlet air channel 1, an outlet air channel 10, an upper box 7, a middle box 2, a patterned plate 5, a blowing device 8, an ash bucket 6, a filter bag frame 4 and oblate filter bags 3 supported by the filter bag frame 4, wherein the blowing device 8 comprises an air bag 12, a pulse valve 11 and blowing pipes 3, the blowing pipes are provided with blowing holes 14, a compressed air system 9 is connected with the air bag 12, the oblate filter bags 3 and the blowing pipes 13 are in fixed row arrangement, the blowing pipes 13 are fixed on the air purifying chamber of the upper box 7, the blowing pipes 13 and the oblate filter bags are in row correspondence, and the blowing hole 14 of each blowing pipe 13 and the oblate filter bag 3 in the same row are in one-to-one correspondence. The oblate bag type dust collector has the advantages that investment cost can be lowered while the dust collecting effect is guaranteed; fine dust generated by various process suitable for a bag type dust collector can be collected effectively, the requirements of environment protection and industrial sanitation can be satisfied, and the oblate bag type dust collector is small in floor space, low in steel consumption, reliable in operation and high in collecting efficiency.

Owner:中钢集团天澄环保科技股份有限公司

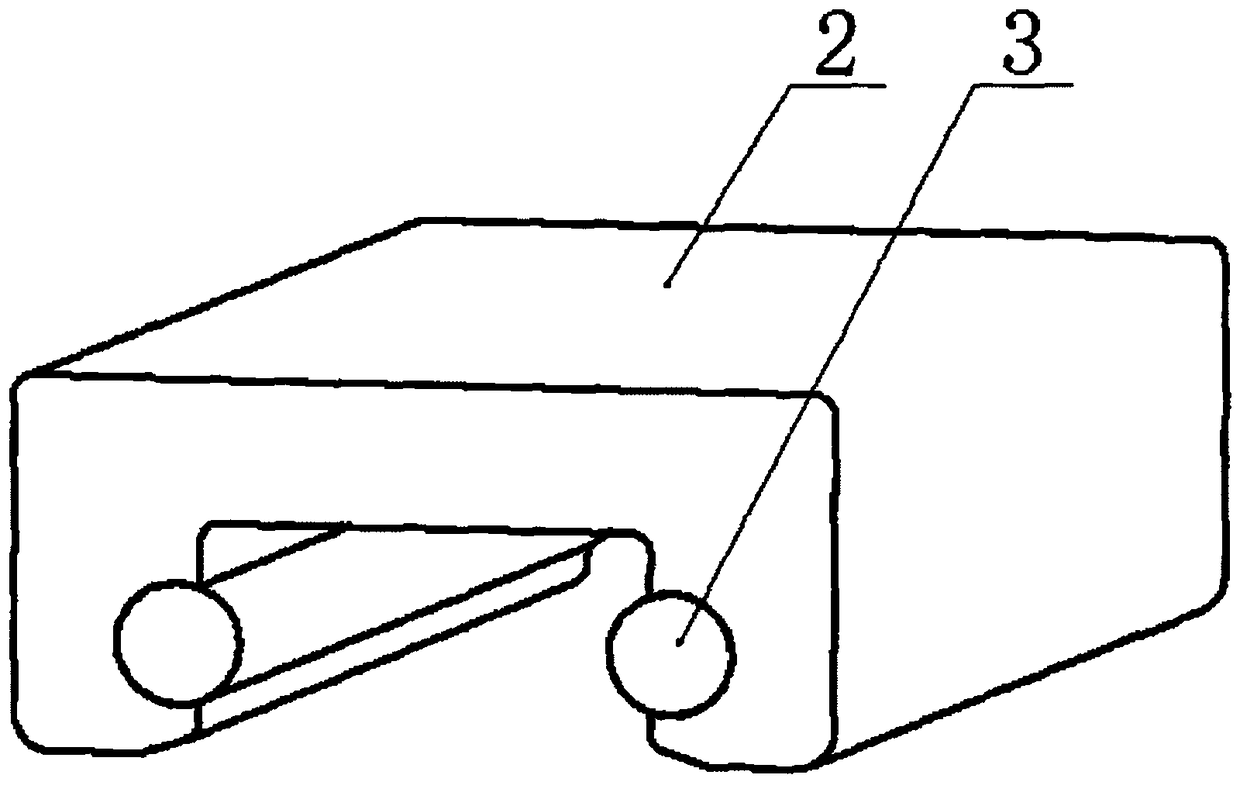

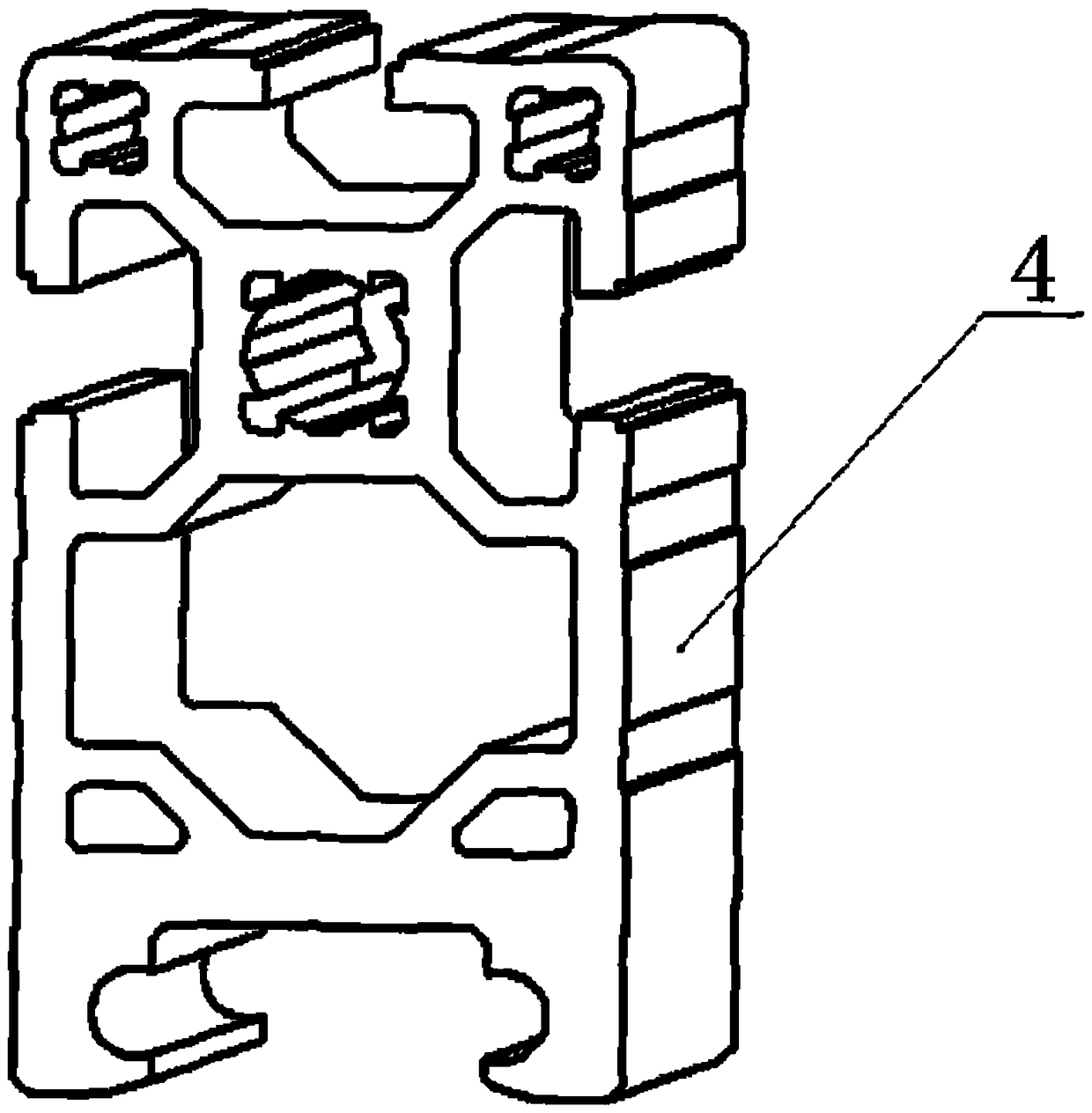

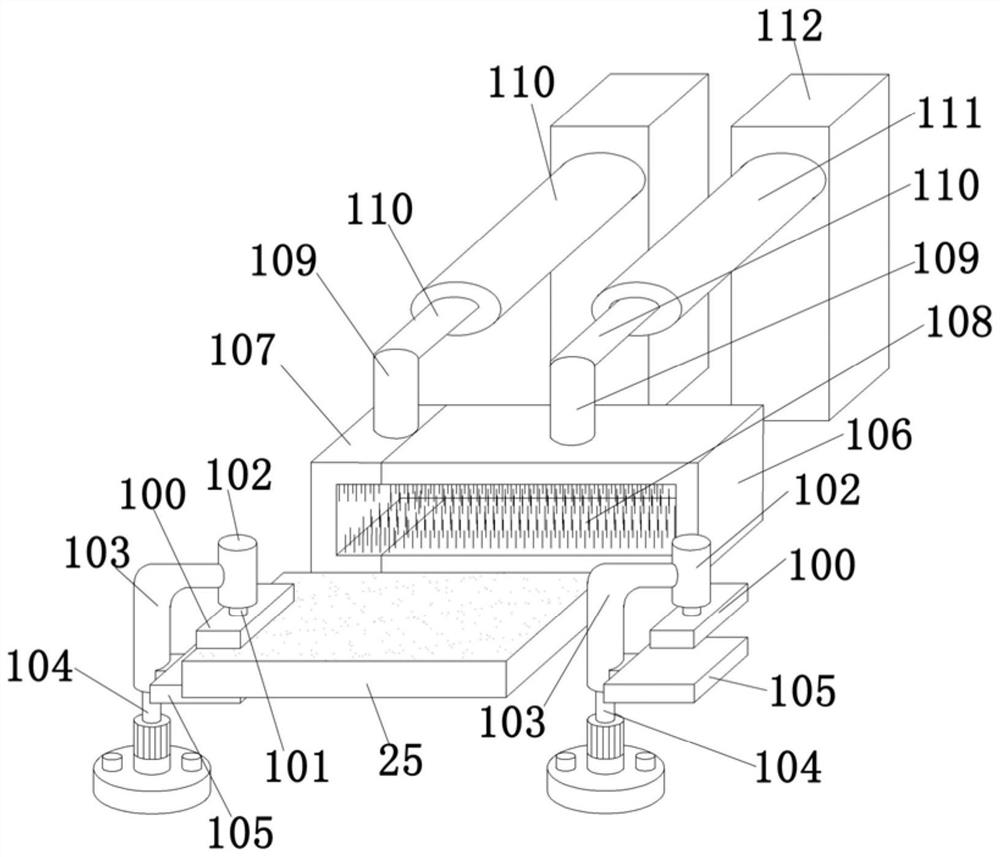

An aluminum alloy section bar provided with a double-shaft linear guide rail and specially used for a setting machine

An aluminum alloy section bar provided with a double-shaft linear guide rail and specially used for a setting machine is provided. An aluminum alloy section bar and a double-shaft linear guide rail are directly integrated, installation of components essential for linear motion and twisting force resisting on the aluminum alloy is omitted, labor hours and a high number of bolts for installation aresaved, and the precision is improved. The double-shaft linear guide rail is a novel product popular in recent years, has higher positioning precision and flexibility than conventional products, has asimple structure and long service lifetime and is convenient to adjust and maintain.

Owner:郝金芳

Method for cooling hydrogen in front of hydrogenation machine

The invention discloses a method for cooling hydrogen in front of a hydrogenation machine. The method comprises the following steps that (1), a coolant is introduced into a cooler; and (2), hydrogen is introduced into the cooler and filling is carried out. The coolant is liquid nitrogen. The method for cooling the hydrogen in front of the hydrogenation machine has the following beneficial effects that (1), a coolant circulating cooling system is cancelled, so that the one-time investment cost and the operation and maintenance cost of the system are reduced; (2), liquid nitrogen is adopted as the coolant, so that corrosion of the coolant to equipment is avoided, the safety of the system is improved, the heat exchange efficiency is high, and the requirement of the hydrogenation machine for quickly hydrogenating an automobile can be met; and (3), the liquid nitrogen is adopted as the coolant, after the hydrogen is cooled, the liquid nitrogen is slightly treated and emptied, and no pollutant is discharged.

Owner:CHINA PETROLEUM & CHEM CORP +2

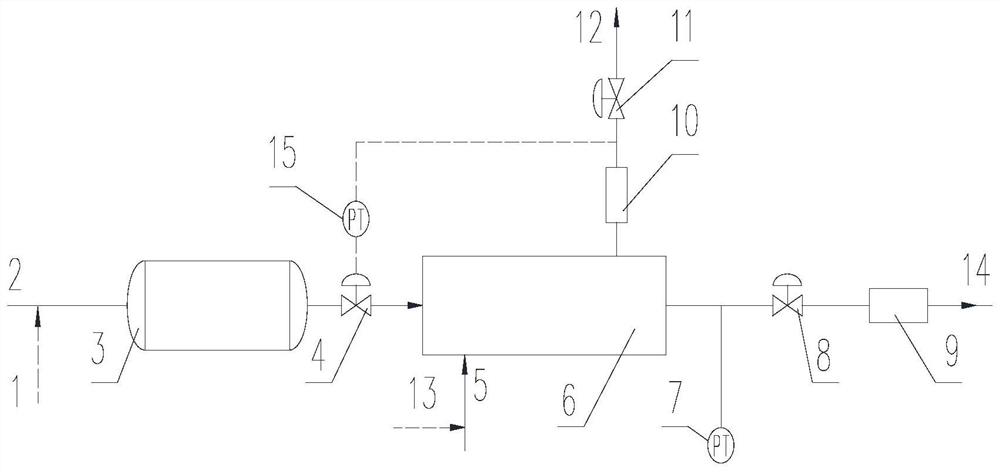

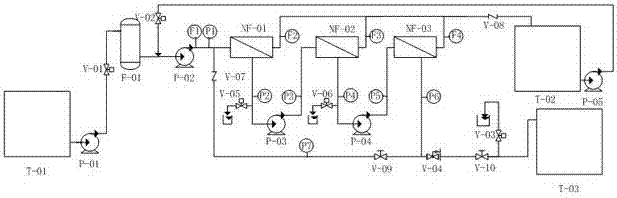

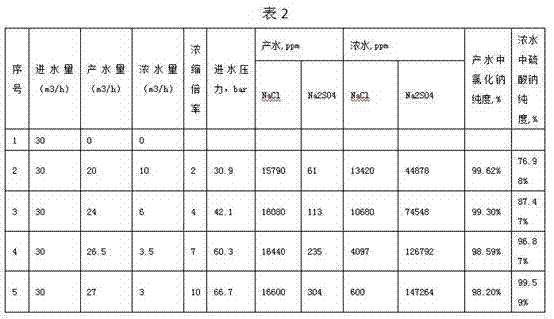

High-concentration salt water nano-filtration membrane bidirectional separating device and method

PendingCN107497300ARealize resourcesEmission reductionWater/sewage treatment bu osmosis/dialysisReverse osmosisHigh concentrationInorganic salts

The invention discloses a high-concentration salt water nano-filtration membrane bidirectional separating device and a high-concentration salt water nano-filtration membrane bidirectional separating method. Univalent salt is separated from bivalent salt through a nano-filtration device by intruding high-concentration salt water to be treated into a primary liquid trough; bidirectional separating is realized and required purity is achieved by performing nano-filtration treatment on a two-component inorganic salt solution; the nano-filtration in specific application ensures the purity of sodium chloride, simultaneously takes the purification of sodium sulphate into consideration, and has the advantages of helping to realize resource of salt to the greatest extent and the like. The process of performing nano-filtration and evaporating can be greatly simplified and the one-time investment and the operating cost of a salt separating device are reduced when the device and the method are applied to engineering.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

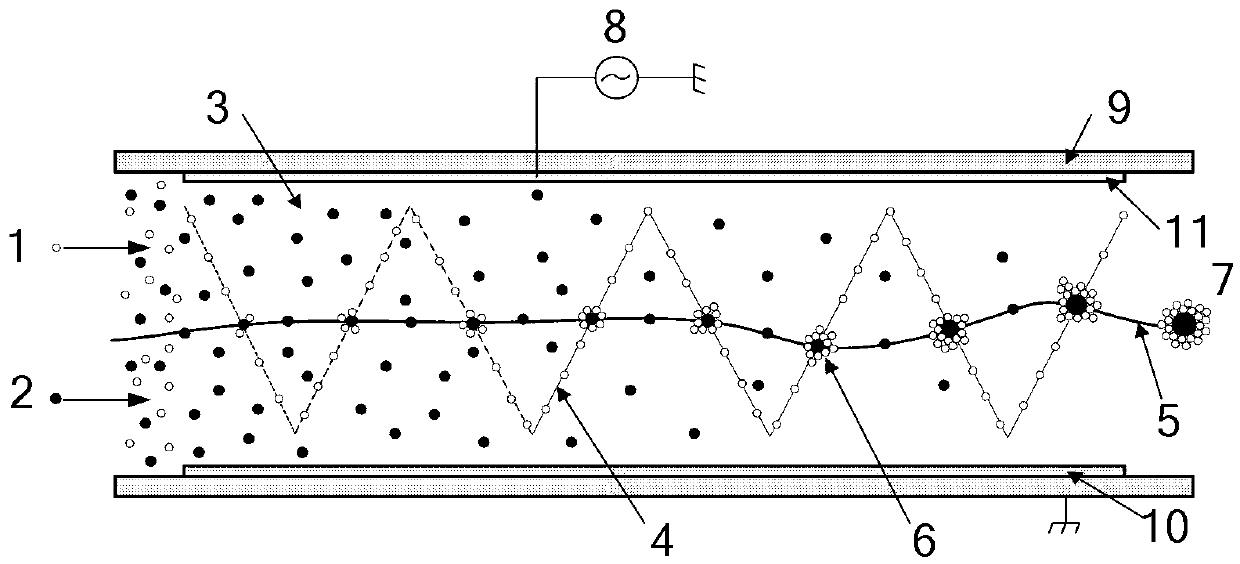

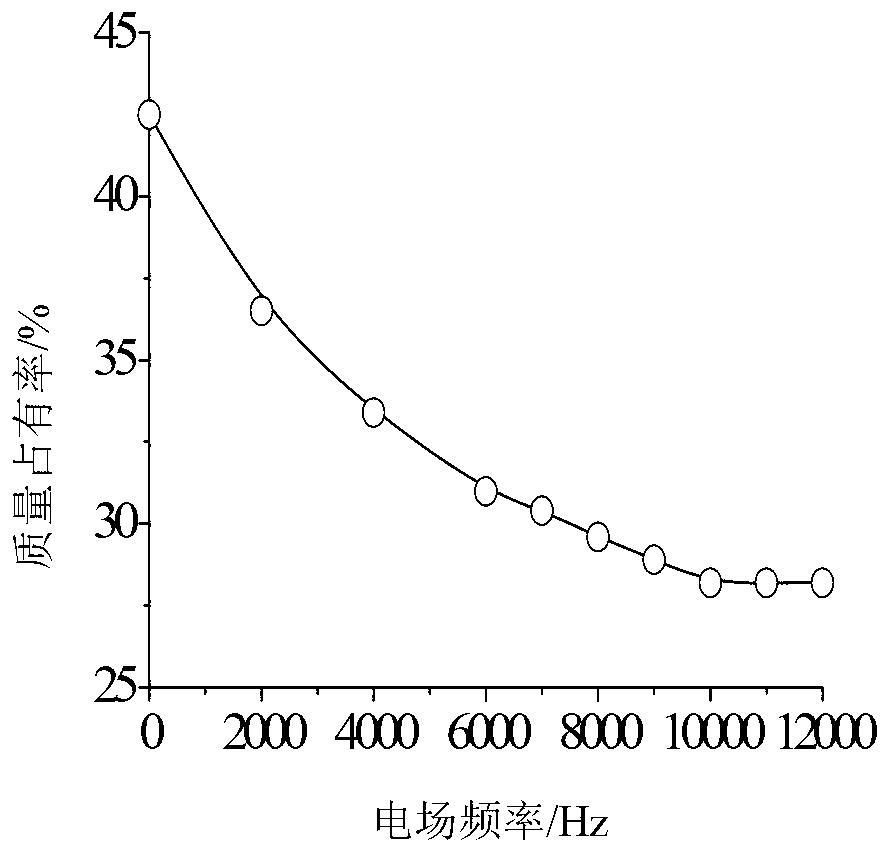

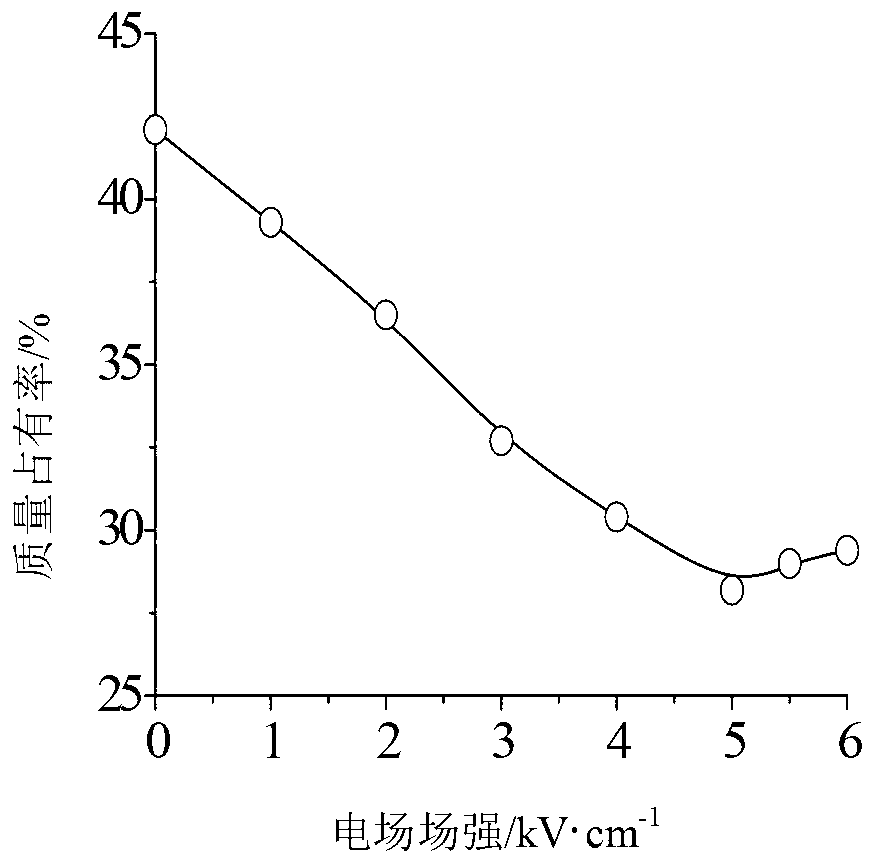

Particulate diffusion charge thickening method

InactiveCN103272696ASolve the problem of capture and purificationImprove purification efficiencyElectric supply techniquesParticulatesHigh pressure

A particulate diffusion charge thickening method belongs to the technical field of environmental engineering and the like. The method provided by the invention is characterized in that primary particulates of PM0.1 and unipolar ions are injected together in a high-frequency high-voltage alternating electric field; the unipolar ions perform reciprocating motions up and down in the high-frequency high-voltage alternating electric field for 103-104 times; and each particulate of PM0.1 and the unipolar ions undergo collision charge thickening for tens of thousands even hundreds of thousands so as to further increase the particle size by 10-103 times and agglomerate to form primary particulates with the particle size being greater than 2 microns. Effects and advantages of the method provided by the invention are as follows: an effective method is provided to remove the atmospheric pollutant primary particulates of PM0.1; the method also can be used in ultramicro-sized coal dust dispersion charge electrocoagulation pretreatment by a dust remover; and one-time investment and operation costs and energy consumption are all reduced significantly.

Owner:DALIAN MARITIME UNIVERSITY

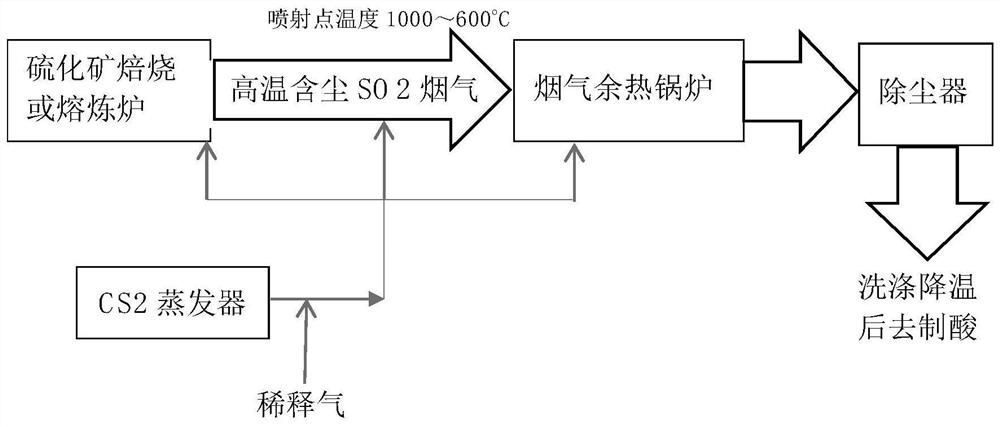

A method for suppressing the production of sulfur trioxide in flue gas from heavy non-ferrous metal smelting acid production

The invention relates to a method for suppressing the generation of sulfur trioxide in the flue gas of acid-making smelting of heavy nonferrous metals. Carbon disulfide is used as a reducing agent to suppress the generation of sulfur trioxide. Add a certain concentration of CS 2 gas for this purpose. Its principle of action is to use the injected CS 2 Gas pairs with catalytic SO 2 form SO 3 The effect of the dust surface to compete with the reaction, thereby inhibiting the SO 2 Catalytic oxidation to produce SO 3 ; additional CS 2 It is also possible to directly put the SO 3 Revert to SO 2 . Eliminate SO through the above effects 3 the goal of. Compared with the prior art, the present invention has the advantages of simple operation, low cost and high efficiency, and does not consume SO in the flue gas during the elimination process 2 The production of sulfuric acid is reduced, and there will be no secondary pollution such as waste water and residue.

Owner:SHANGHAI JIAO TONG UNIV

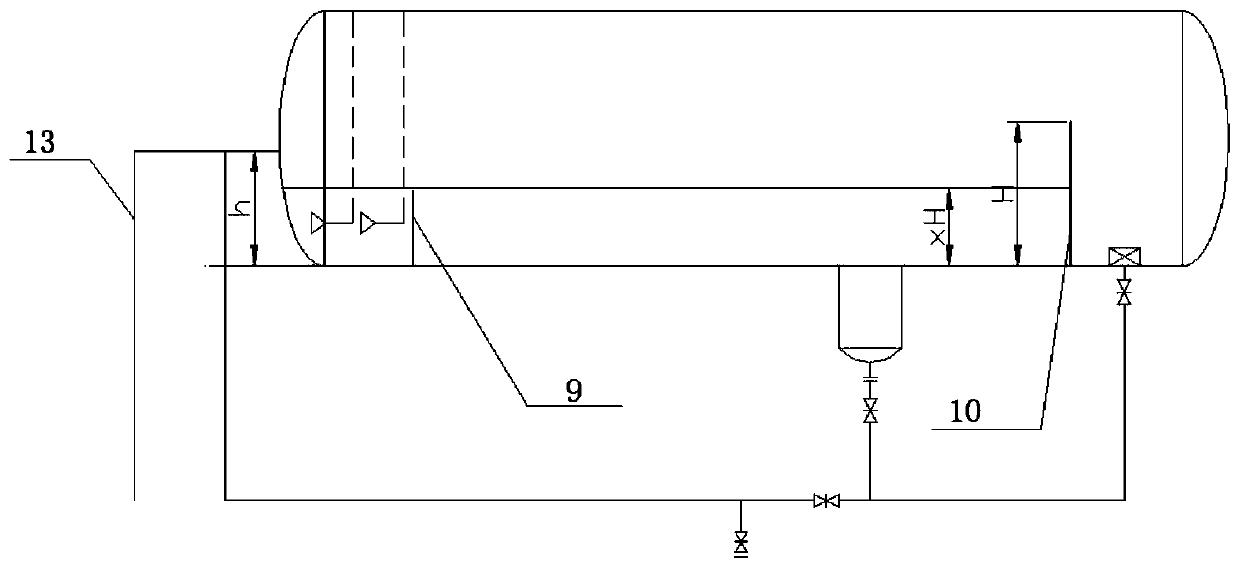

Liquid-liquid two-phase separation system for unsteady state feeding partial emulsification and application

PendingCN111437629AIncrease productivityImprove separation thoroughnessWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesProcess engineeringMechanical engineering

The invention relates to a liquid-liquid two-phase separation system for unsteady state feeding partial emulsification and application. The liquid-liquid two-phase separation system comprises a pre-separation tank, a collection tank, an extrusion demulsification device, a centrifuge and a recovery tank, the centrifuge is also communicated with a circulation tank, and the circulation tank is communicated with the pre-separation tank; the pre-separation tank is communicated with a separation liquid inlet pipe, and the separation liquid inlet pipe and the circulation tank respectively extend intothe bottom of the pre-separation tank through corresponding insertion pipes; a first baffle and a second baffle are arranged in the pre-separation tank, the first baffle is close to the insertion pipe, and the second baffle is close to one side of a heavy component assembly bag; and the pre-separation tank is communicated with a heavy component collection tank through a siphon. According to the invention, the production efficiency can be greatly improved, the separation thoroughness is improved, and the equipment size is reduced; meanwhile, only the separation degree of an outlet in one sideof the centrifugal machine needs to be improved to guarantee the separation precision, the operation condition of the other side does not need to be considered, the system operation stability and thefeeding adaptive capacity are greatly improved, and the working condition of large-range fluctuation can be met.

Owner:ZHEJIANG ZHONGLI SYNTHETIC MATERIAL TECH CO LTD

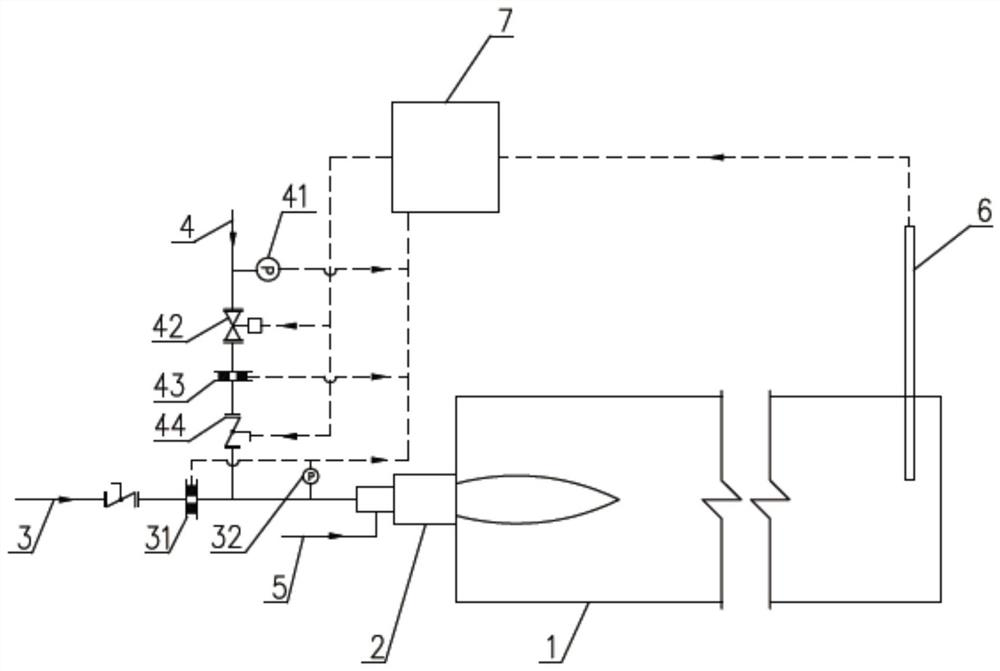

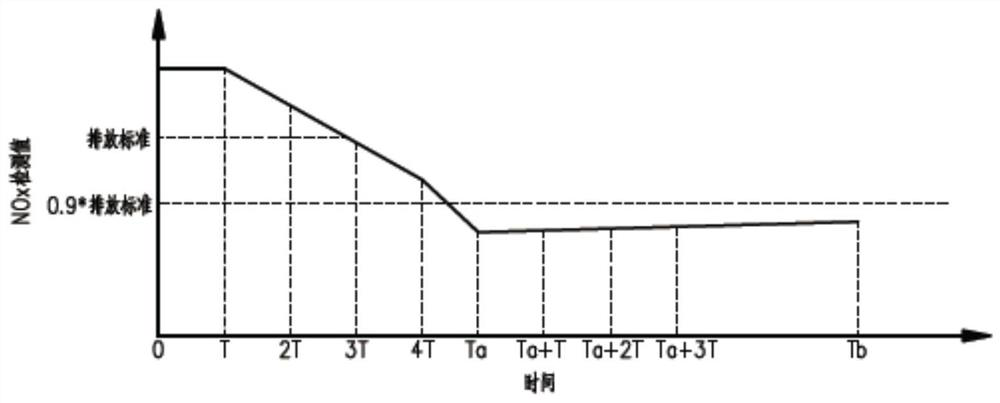

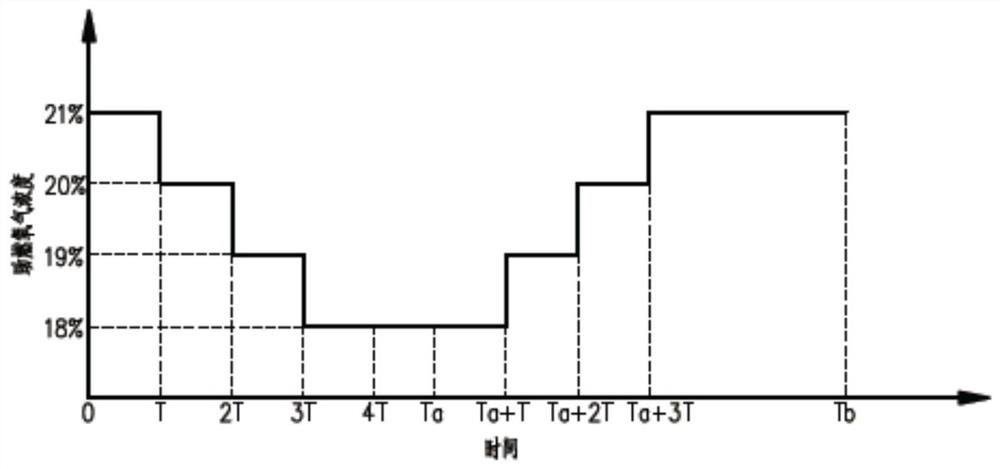

Ultralow NOx emission system and method for heating furnace

PendingCN113606948AEmission reductionReduce the investment cost onceMaintainance of heating chambersControl devices for furnacesEmission standardNitrogen gas

The invention belongs to the field of metallurgical industry furnaces and kilns, and relates to an ultralow NOx emission system and method for a heating furnace. The ultralow NOx emission system is composed of the heating furnace, a burner, a nitrogen pipeline, an air pipeline, a fuel gas pipeline, a flue gas NOx detection device and a control system, a nitrogen cut-off valve and a regulating valve are controlled by NOx detection values in an interlocking mode, and the control system controls opening and closing of the nitrogen pipeline and nitrogen flow according to the NOx detection values; and when NOx exceeds the emission standard, the nitrogen flow is intermittently regulated upwards, when the NOx is lower than the emission standard and higher than 0.9 time of the emission standard, the nitrogen flow is kept unchanged, and when the NOx is lower than the 0.9 time of the emission standard, the nitrogen flow is intermittently regulated downwards. The ultralow NOx emission system and method for the heating furnace can effectively solve the problem that the NOx of the existing heating furnace intermittently exceeds the standard, the system and the method are simple and efficient, and a small amount of nitrogen is used in the production process, so that the one-time investment cost and the operation cost are low; and the system and the method can be used for upgrading and reconstruction of an existing system, secondary pollution is avoided, NOx emission of the heating furnace is flexibly and effectively reduced, and good economic and social benefits are achieved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Semi-dry desulfurization and dust removal method for sludge sintering ceramic ceramsite waste gas

PendingCN113144877AMeet governance standardsMeet emission standardsCombination devicesGas treatmentTemperature controlSludge

The invention provides a semi-dry desulfurization and dust removal method for sludge sintering ceramic ceramsite waste gas, and relates to the technical field of environmental protection. A semi-dry desulfurization and dust removal system is adopted for waste gas treatment and comprises a desulfurization system, a lime system, a temperature control and humidification system, a dust removal system, an adsorption system and a discharge system. The waste gas treatment process comprises the following steps: desulfurization: introducing the sludge sintering ceramic ceramsite waste gas into a desulfurization tower, and reacting the waste gas with a desulfurization material in the desulfurization tower for desulfurization; dust removal: introducing the desulfurized waste gas into the dust removal system for dust removal; adsorption: introducing the waste gas into the adsorption system to adsorb volatile organic compounds; and discharging: introducing the desulfurized and dedusted waste gas into the discharge system, and discharging the qualified waste gas after detection. The method not only can meet the up-to-standard discharge requirement, but also can simplify the process route, reduce one-time investment and operation cost, reduce the occupied area, and can greatly reduce the generation of wastewater and wet smoke plume.

Owner:JIANGMEN TONGLI ENVIRONMENTAL PROTECTION TECH

High-temperature washing and deacidifying system

PendingCN109045978AEnsure high temperature strengthEnsure corrosionGas treatmentUsing liquid separation agentGlass fiberFlue gas

The invention discloses a high-temperature washing and deacidifying system which comprises a glass fiber reinforced plastic washing tower, a water supplementary device and an automatic alkaline solution supplementary device. A defogging area, a spraying area and a reaction area are defined in the glass fiber reinforced plastic washing tower from top to bottom; the defogging area is provided with aclean gas outlet; a defogging device is arranged in the defogging area and located under the clean gas outlet; a high-temperature overflow water film protection device is arranged on the inner wall of the defogging area and located under the defogging device; the spraying area is provided with a recycled alkaline solution spraying port; the recycled alkaline solution spraying port is connected with the lower part of the reaction area through a circulating pump; a filler layer is arranged on the spraying area and located under the alkaline solution spraying port; the reaction area is providedwith a high-temperature flue gas inlet, an alkaline solution supplementary inlet, a pH detector and a drain outlet; the water supplementary device is connected with the high-temperature overflow waterfilm protection device; the automatic alkaline solution supplementary device is connected with the alkaline solution inlet.

Owner:CHINA ENFI ENGINEERING CORPORATION

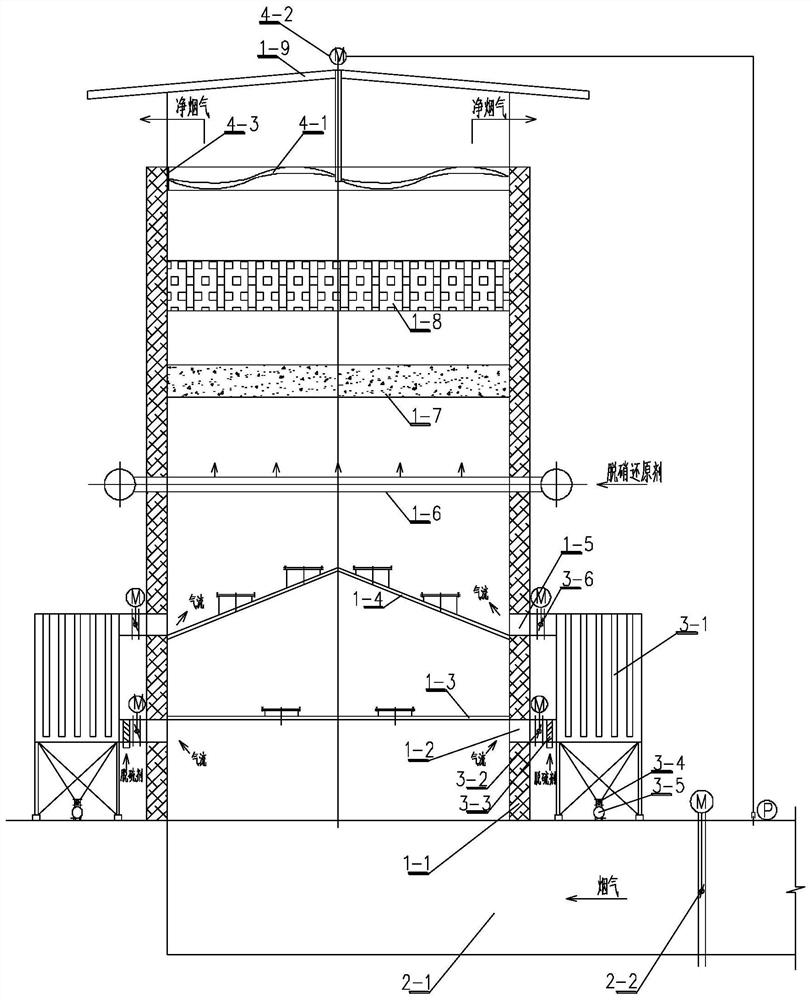

Chimney type desulfurization, denitrification and dust removal integrated device and working method thereof

PendingCN113350992ACompact structureSmall footprintGas treatmentDispersed particle filtrationPtru catalystFlue gas

The invention relates to a chimney type desulfurization, denitrification and dust removal integrated device and a working method thereof. The device comprises a main treatment tower and a desulfurization and dust removal reactor, wherein the bottom of the main treatment tower is directly communicated with a coke oven main flue channel, a rainproof top cover is arranged above a top opening, the desulfurization and dust removal reactor is arranged on the outer side of the lower portion of the main treatment tower, a bottom interlayer plate, a lower interlayer plate, a denitration reducing agent spraying pipe, a foam metal uniform distribution layer, a denitration catalyst layer and a fan are sequentially arranged in the main treatment tower from bottom to top, a desulfurization and dust removal inlet is formed in the main treatment tower body below the bottom interlayer plate and is communicated with the desulfurization and dust removal reactor, a desulfurization and dust removal outlet is formed in the main treatment tower body above the lower interlayer plate and is communicated with the desulfurization and dust removal reacto, and the fan is arranged at the top opening of the main treatment tower. According to the invention, on the premise of meeting the flue gas treatment requirement, the process design is further optimized, the device is compact in structure, reliable in operation and small in occupied area, and the investment and operation cost of a coke oven flue gas purification treatment system can be effectively reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

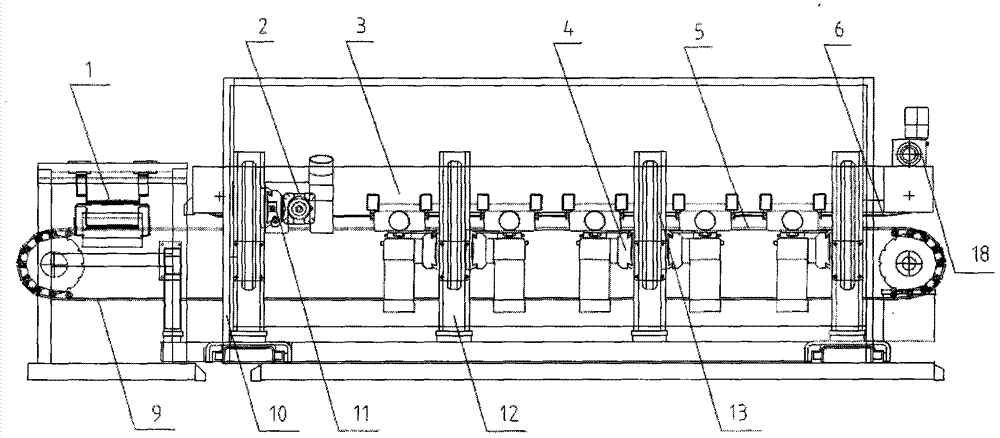

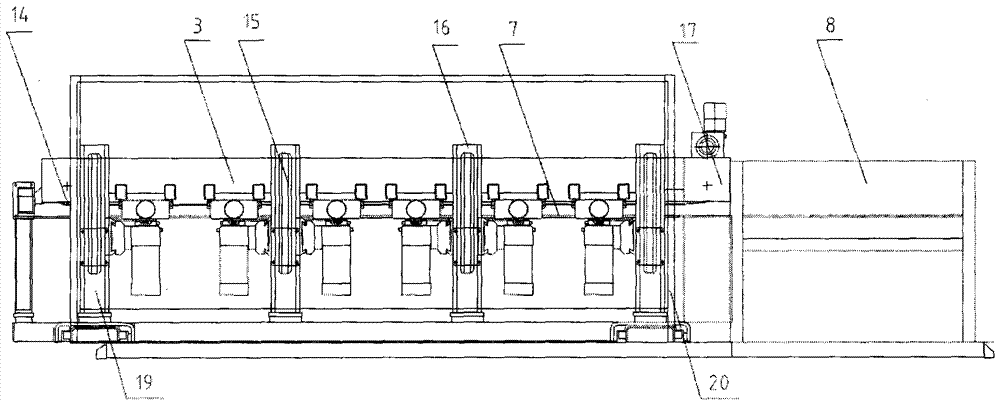

A kind of wooden window processing equipment and technology

ActiveCN104842427BReduce use costReduce the investment cost onceWood working apparatusMolding machineMachined surface

The invention discloses wood window machining equipment and process. The wood window machining equipment comprises an end part molding machine and a vertical molding machine, and particularly comprises a feeding device, a horizontal cutter shaft, a vertical cutter shaft, a hoisting moving device, a conveyor belt, a first upper material pressing conveyor belt, a second upper material pressing conveyor belt, a worktable, a discharging device, a feeding chain belt, a first rack, a second rack, a first precision slide rail, a second precision slide rail, a third precision slide rail, a first stand column, a second stand column, a third stand column, a first motor and a second motor. In the set of equipment, the machining of 30 window materials can be finished at maximum in each minute and a machined surface has a polishing-free effect. The service life of a tool is 30-45 times as much as the service life of an existing imported molded line tool under the same cutting condition; the comprehensive use cost of the tool is reduced by 60% and the production efficiency is greatly improved.

Owner:吉林市泗洋超硬工具有限公司

A gas phase aldehyde hydrogenation reactor

ActiveCN111921460BEvenly distributedUnloading in timeChemical/physical processesPtru catalystHydrogenation reaction

The invention discloses a gas-phase aldehyde hydrogenation reactor, which comprises a reactor body, a manhole arranged on the reactor body, a catalyst bed body arranged inside the reactor body, and a distributor distributed on the catalyst bed body. The catalyst bed is provided with a driving loading device that is convenient for catalyst replacement and loading. This gas-phase aldehyde hydrogenation reactor is provided with a catalyst loading device on the corresponding catalyst body inside the reactor body. The catalyst loading device can make The catalyst is evenly distributed on the catalyst bed, and the loaded catalyst can be evenly paved and compacted. At the same time, after the catalyst has reacted many times, the reacted catalyst can be unloaded in time. It can not only ensure the complete unloading, but also save the amount of catalyst loading as much as possible, reduce the primary investment cost, and thus effectively improve the reaction rate of gas phase aldehydes.

Owner:NINGBO JUHUA CHEM TECH CO LTD

Online molten steel refining process

Owner:BERIS ENG & RES CORP

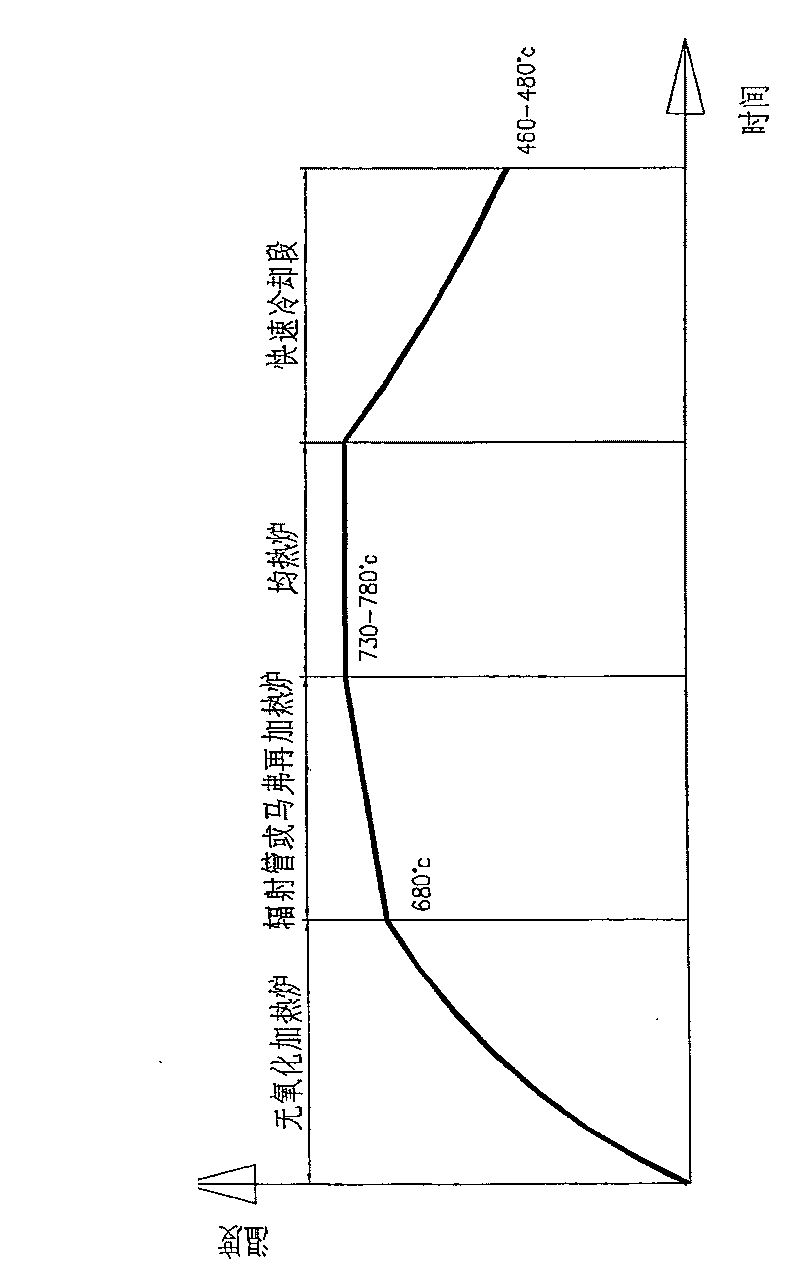

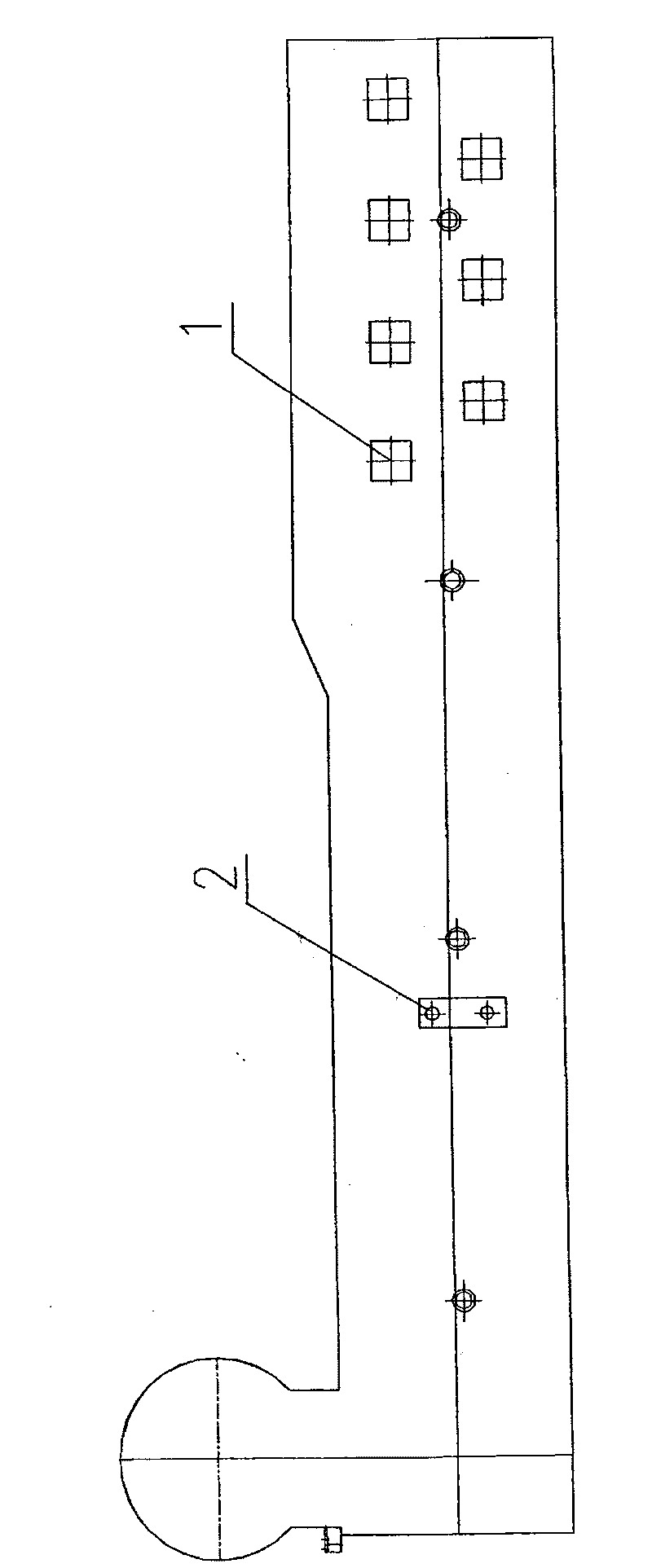

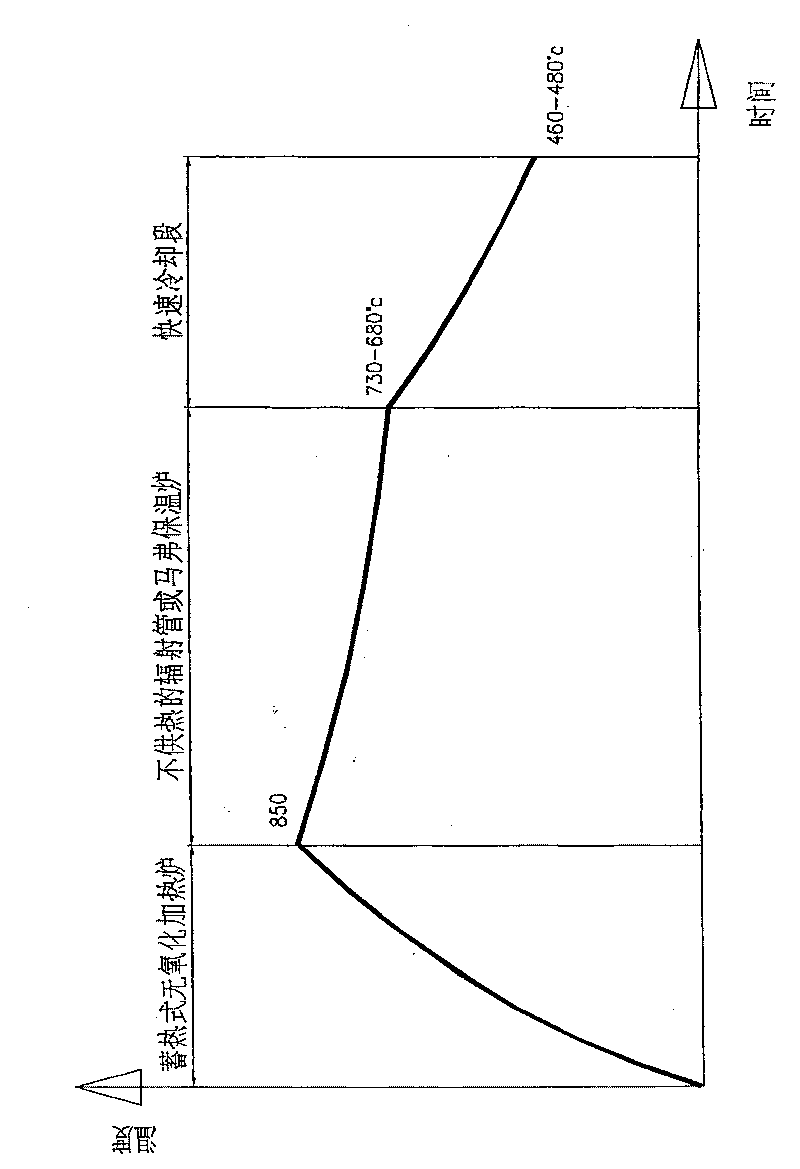

Hot dip galvanizing annealing process and high temperature annealing furnace

InactiveCN101435018BReduce the investment cost onceHot-dipping/immersion processesFurnace typesStrip steelHeating furnace

The invention belongs to the technical field of metallurgy, and discloses a method for heat treatment, in particular a hot galvanizing annealing technique and a high temperature annealing furnace, which are adopted by galvanized wires. The method comprises the following steps: strip steel is heated in a non-oxidation regenerative heating furnace; the heated strip steel enters a heat holding furnace without supplying heat so as to lead the strip steel to complete reduction and recrystallization annealing; after the recrystallization annealing is completed, the strip steel enters a fast coolingsection and then enters a zinc pot by a steering roll chamber after being cooled. The high temperature annealing furnace used by the annealing technique comprises the non-oxidation regenerative heating furnace, the heat holding furnace without supplying heat and the fast cooling section. The invention can reduce the cost of one-time investment by more than 30 percent, simultaneously save the energy by more than 30 percent and can be widely applied to the hot galvanizing annealing technique of the galvanized wires.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

An Alternate Fixture Type Metal Surface Treatment System

ActiveCN111139344BEasy to cleanIncrease the areaFurnace typesHeat treatment process controlHydraulic cylinderSurface cleaning

The invention discloses an alternating clamp type metal surface treatment system. The alternating clamp type metal surface treatment system comprises a surface cleaning device and a surface heat treatment device; a metal plate is subjected to surface dust removing cleaning through the surface cleaning device, and then paint coating is performed; later, the metal plate is conveyed by an operator into the surface heat treatment device for surface heat treatment; the surface cleaning device comprises clamping plates correspondingly arranged on the two sides of the metal plate; each clamping plateis fixedly connected with one hydraulic cylinder output rod; a hydraulic cylinder is fixedly connected with a motor output shaft through an L-shaped rod; the side wall of the L-shaped rod is fixedlyconnected with an abutting pressing plate; a main brush box with an opening in the front end and an auxiliary brush box are further included; the upper and lower side walls of the main brush box and the auxiliary brush box are each fixedly connected with a plurality of flexible brush wires; the upper walls of the main brush box and the auxiliary brush box are fixedly connected with pneumatic cylinder output rods through connection columns; and pneumatic cylinders are fixedly connected to vertical plates.

Owner:苏州天金刚金属制品有限公司

A metal surface heat treatment device and treatment method with self-diagnosis function

ActiveCN111286590BReduce scrap rateEnsure comprehensivenessHeat treatment process controlEngineeringMaterials science

The invention discloses a metal surface heat treatment device with a self-diagnostic function, which includes a frequency conversion fan, an air heater, an indirect image detection component, a camera standard calibration component, an activated carbon propulsion component, and a steam pipe isolation component, which can monitor the metal surface. Self-diagnosis of paint falling off has good promotion value.

Owner:翰贝摩尔表面技术(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com