Device and method for heat recovery and utilization of waste incinerator fly ash treated by high-temperature melting method

A technology of waste incineration fly ash, high temperature melting, applied in the combustion method, incinerator, combustion type and other directions, can solve the problems of difficult engineering application and large-scale promotion, high equipment cost and operating cost, and high energy consumption of fly ash. , to achieve good economic value, reduce comprehensive energy consumption, and reduce energy consumption costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

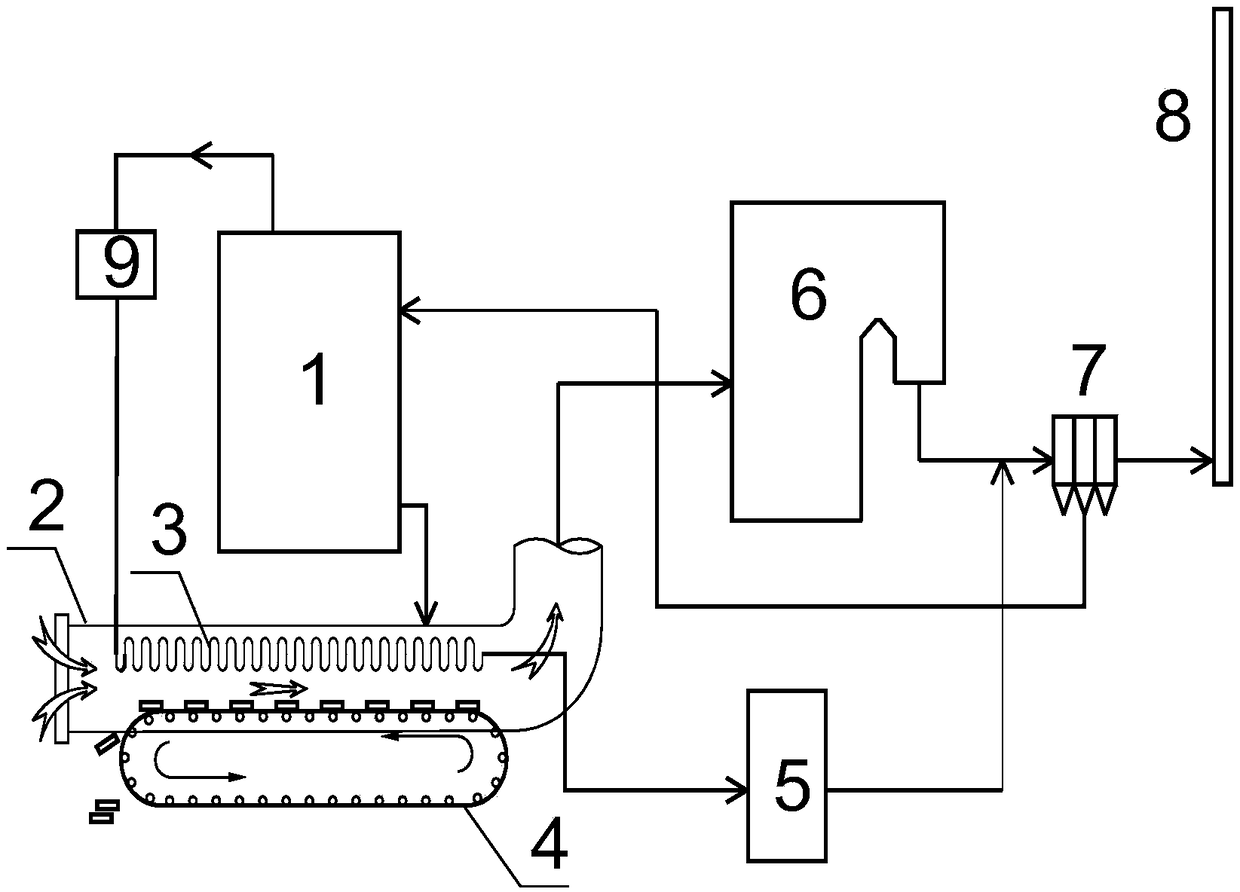

[0038] Device structure:

[0039] Such as figure 1 As shown, the heat energy recovery and utilization device for waste incineration fly ash treated by high-temperature melting method includes a high-temperature melting furnace 1, and the slag discharge port of the high-temperature melting furnace 1 is connected with the slag inlet port of IHE2. IHE2 is equipped with a high-temperature tail gas radiator 3 and melting The slag cooling conveying device 4, the inlet of the high-temperature tail gas radiator 3 is connected to the exhaust port of the high-temperature melting furnace 1, the outlet of the high-temperature tail gas radiator 3 is connected to the inlet of the flue gas heavy metal removal treatment equipment 5, and the high-temperature melting furnace 1 is connected to the IHE 2 is provided with denitrification equipment 9, the hot air outlet of IHE2 is connected with the combustion air supply inlet of waste incineration boiler 6, and the flue gas outlet of waste inciner...

Embodiment 2

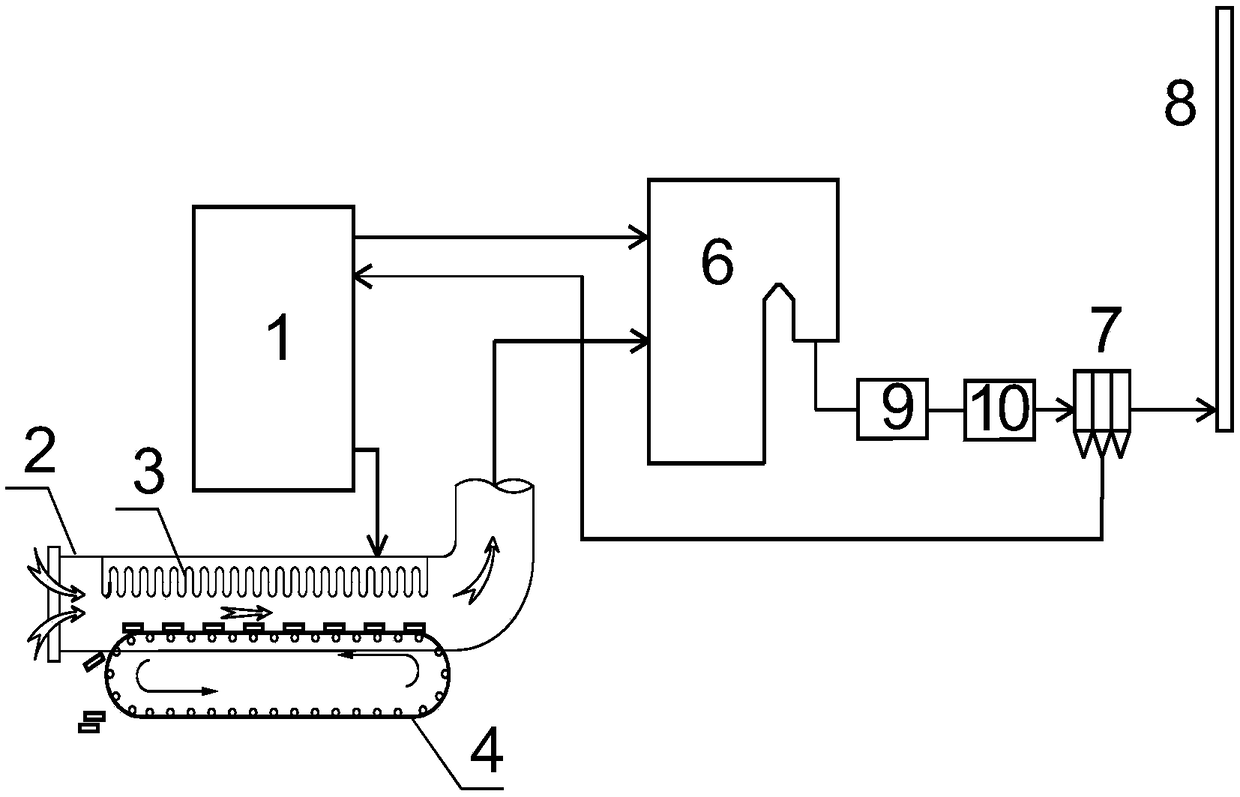

[0047] Device structure:

[0048] Such as figure 2 As shown, the heat energy recovery and utilization device for waste incineration fly ash treated by high-temperature melting method includes a high-temperature melting furnace 1, the slag discharge port of the high-temperature melting furnace 1 is connected with the slag inlet port of IHE 2, and a high-temperature tail gas radiator 3 is installed in IHE 2 and the slag cooling conveying device 4, the hot air outlets of the high-temperature melting furnace 1 and the IHE 2 are respectively connected with the combustion air supply inlet of the waste incineration boiler 6, and the flue gas outlet of the waste incineration boiler 6 is connected with the flue gas inlet of the dust collector 7, The fly ash collected by the dust collector 7 is connected to the high-temperature melting furnace 1 through a conveying device. The front end of the flue gas inlet of the dust collector 7 is provided with a denitrification device 9 and a deac...

Embodiment 3

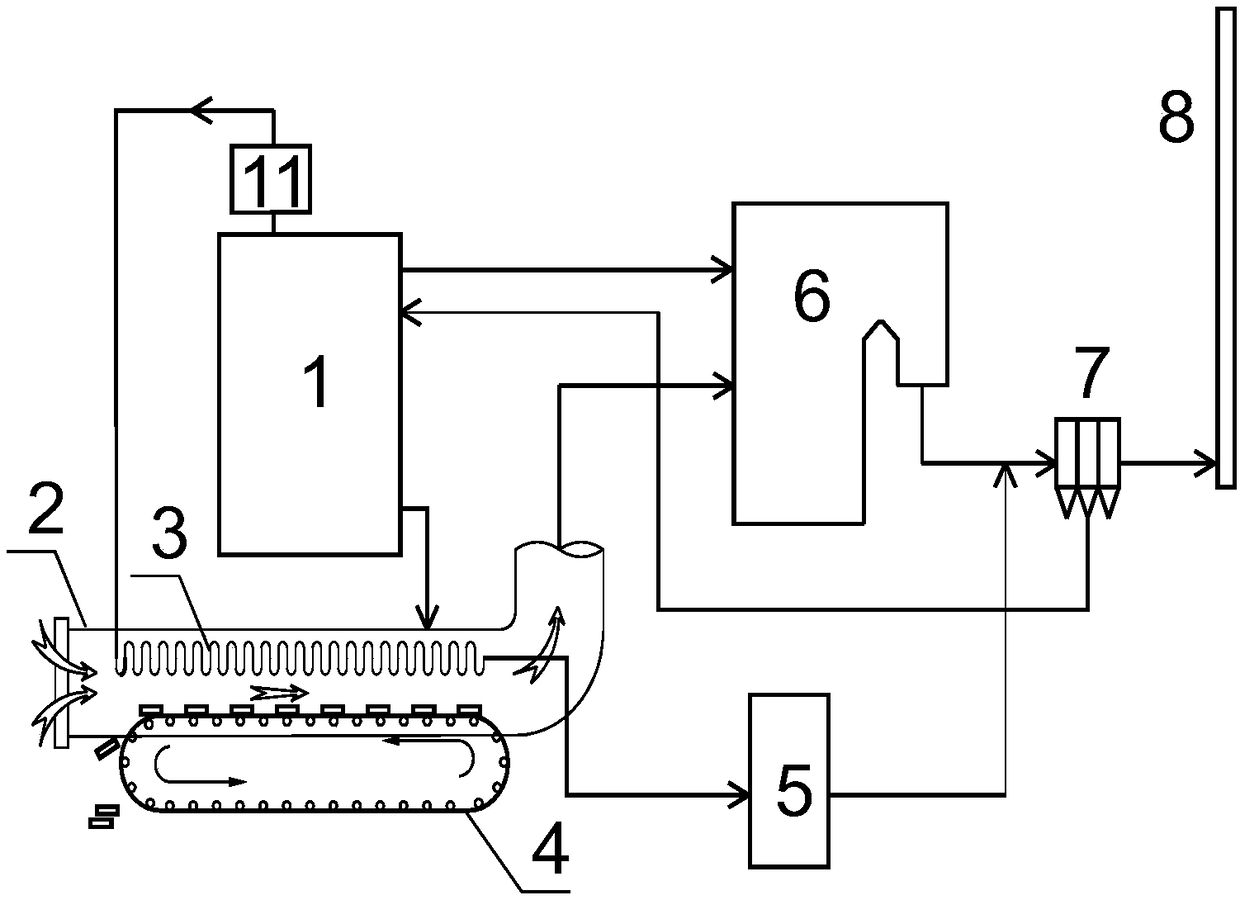

[0056] Device structure:

[0057] Such as image 3 As shown, the heat energy recovery and utilization device for waste incineration fly ash treated by high-temperature melting method includes a high-temperature melting furnace 1, the slag discharge port of the high-temperature melting furnace 1 is connected with the slag inlet port of IHE 2, and a high-temperature tail gas radiator 3 is installed in IHE 2 and the slag cooling transfer device 4, the exhaust port of the high temperature melting furnace 1 is provided with a tail gas component detection device 11, the inlet of the high temperature tail gas radiator 3 is connected with the exhaust port of the high temperature melting furnace 1, and the outlet of the high temperature tail gas radiator 3 is connected with the exhaust port of the high temperature melting furnace 1. The inlet of flue gas heavy metal removal treatment equipment 5 is connected, the hot air outlets of high temperature melting furnace 1 and IHE 2 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com