An Alternate Fixture Type Metal Surface Treatment System

A metal surface treatment and surface heat treatment technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of decreased adhesion of paint particles, loose isolation butterfly valve closure, unqualified spraying process, etc., to achieve mechanical automation High efficiency, reduced energy consumption, and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the following examples.

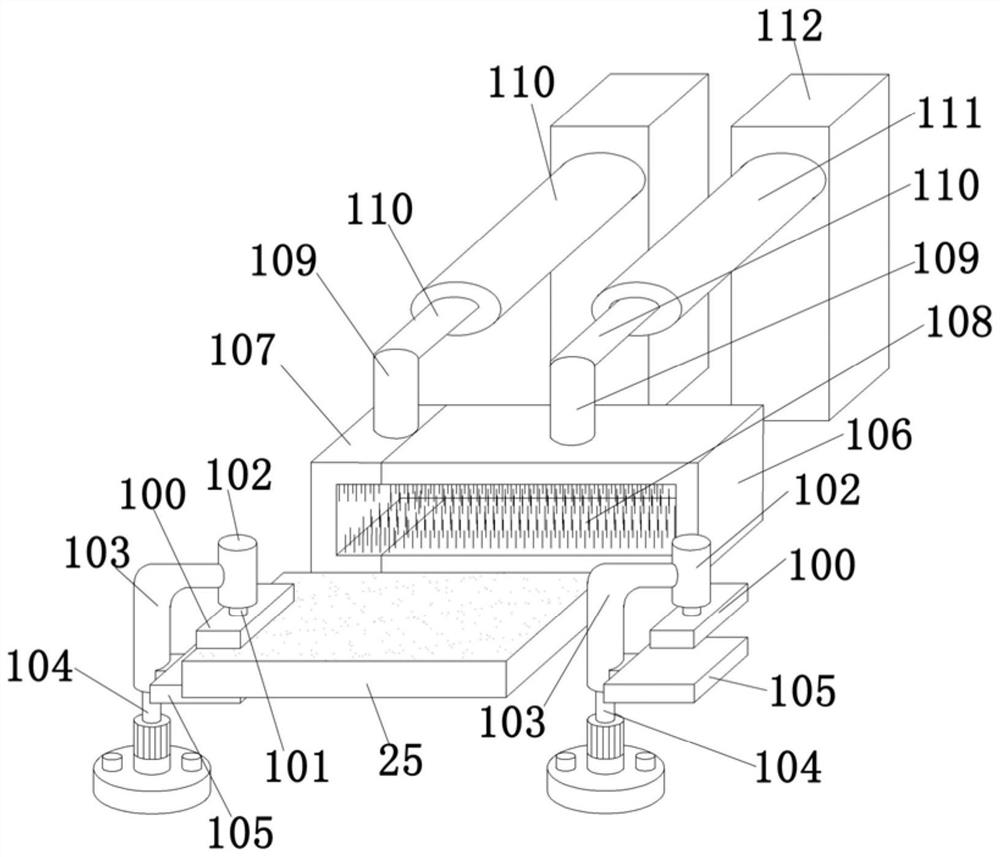

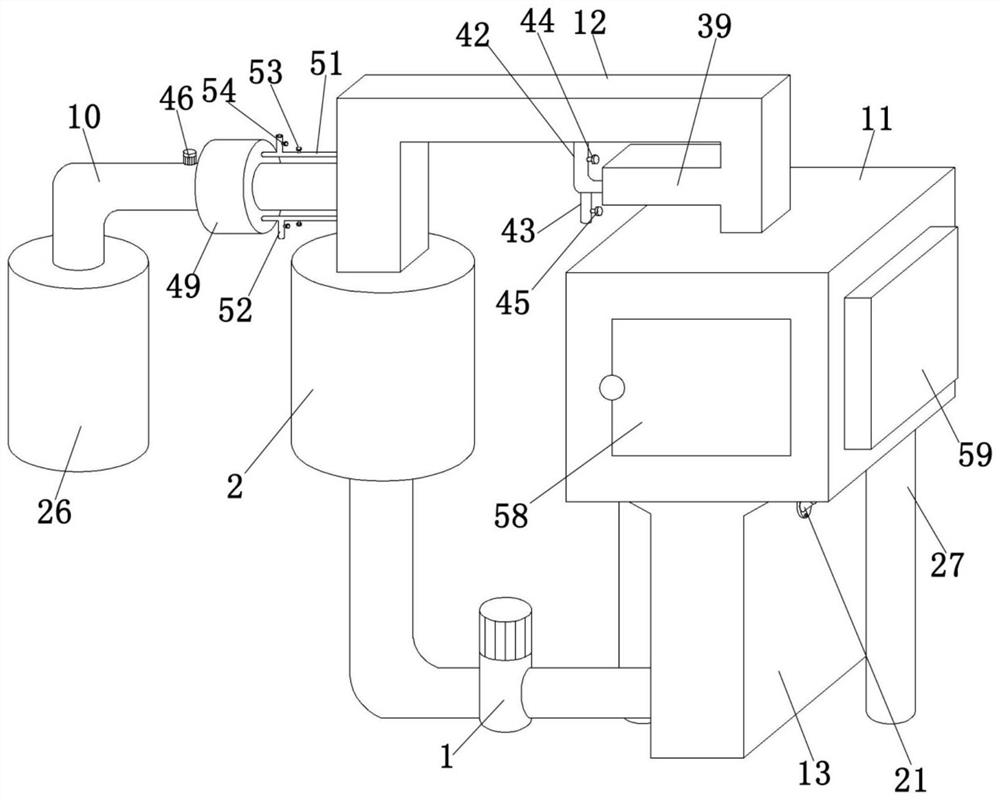

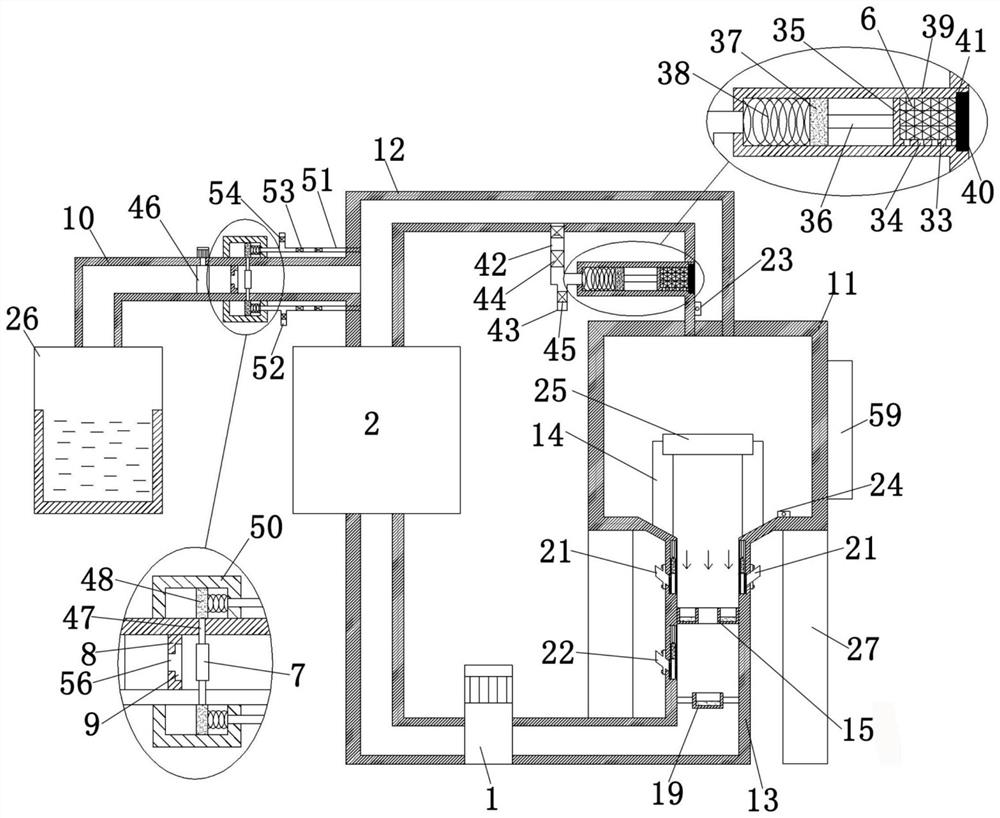

[0035] See eg figure 1 An alternate fixture type metal surface treatment system is shown, including a surface cleaning device and a surface heat treatment device. The metal plate 25 is cleaned by the surface cleaning device for surface dust removal, and then coated with paint, and then sent to the surface heat treatment device by the operator Carrying out surface heat treatment, the surface cleaning device includes splints 100 arranged on both sides of the metal plate 25, each splint 100 is affixed to a hydraulic cylinder output rod 101, and the hydraulic cylinder 102 is affixed to the motor output shaft 104 through an L-shaped rod 103, A pressure plate 105 is fixedly attached to the side wall of the L-shaped bar 103 . It also includes a main brush box 106 and a secondary brush box 107 with front openings. The upper and lower side walls of the main brush box 106 and the secondary b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com