A metal surface heat treatment device and treatment method with self-diagnosis function

A heat treatment device and metal surface technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as the decline in the adhesion performance of paint particles, the isolation butterfly valve is not tightly closed, the type does not meet the requirements, etc., to reduce the one-time investment. cost, energy consumption and scrap rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

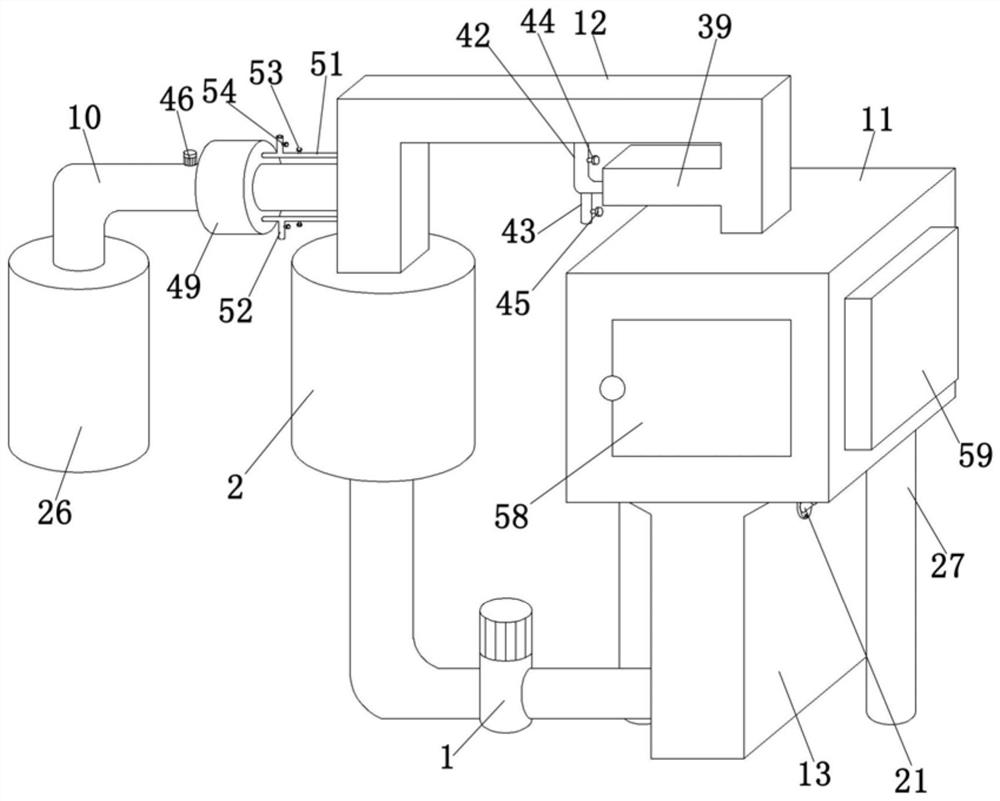

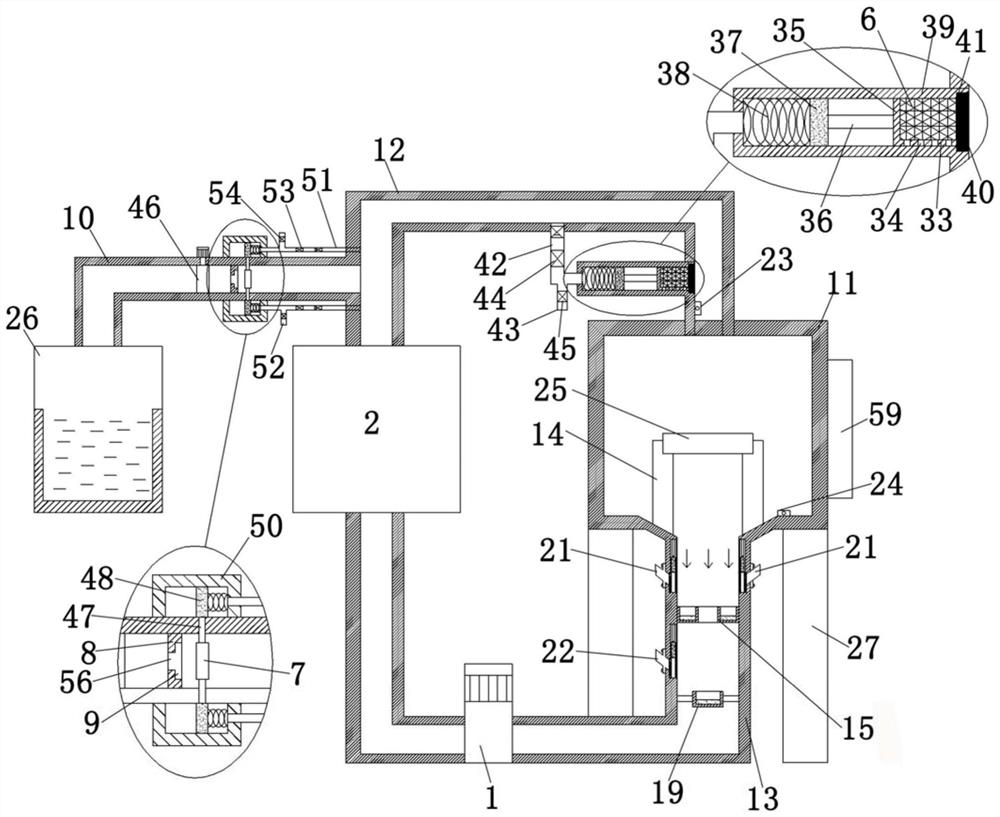

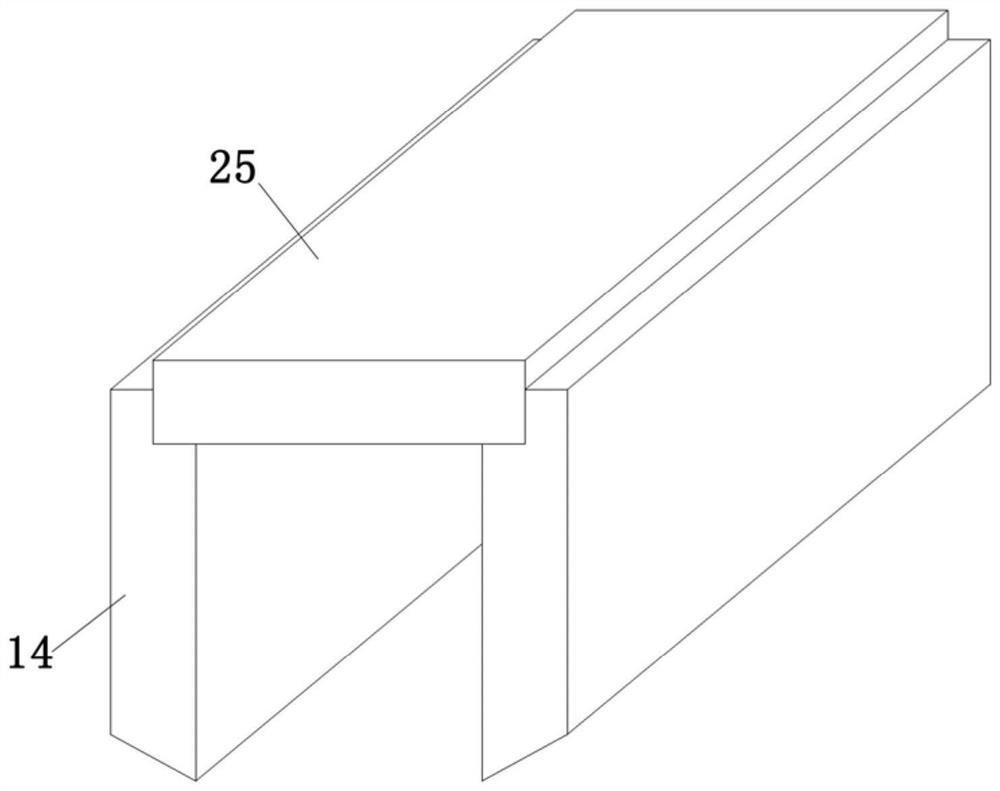

[0031] See eg Figure 1-12 The shown metal surface heat treatment device with self-diagnosis function includes:

[0032] The frequency conversion fan 1 is used to provide air circulation power and maintain a constant wind pressure received by the metal through frequency conversion;

[0033] Air heater 2 for changing the circulating air temperature;

[0034] The indirect image detection component uses glass fiber cotton 3 to capture the paint particles carried in the air after heat exchange with the metal surface, and performs image recognition on the paint on the glass fiber cotton 3 to determine whether the paint falls off on the metal surface. Split structure of air resistance;

[0035] The camera standard verification component, when the indirect image detection component determines that the paint falls off, covers the standard plate 5 coated with the standard pattern 4 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com