System and method for efficiently utilizing desulfurization by-products

A desulfurization by-product, high-efficiency technology, applied in the direction of separation methods, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of forest tree damage, sharp decline in volume, forest tree death, etc., and achieve high economic benefit utilization , realize efficient utilization and avoid the effect of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

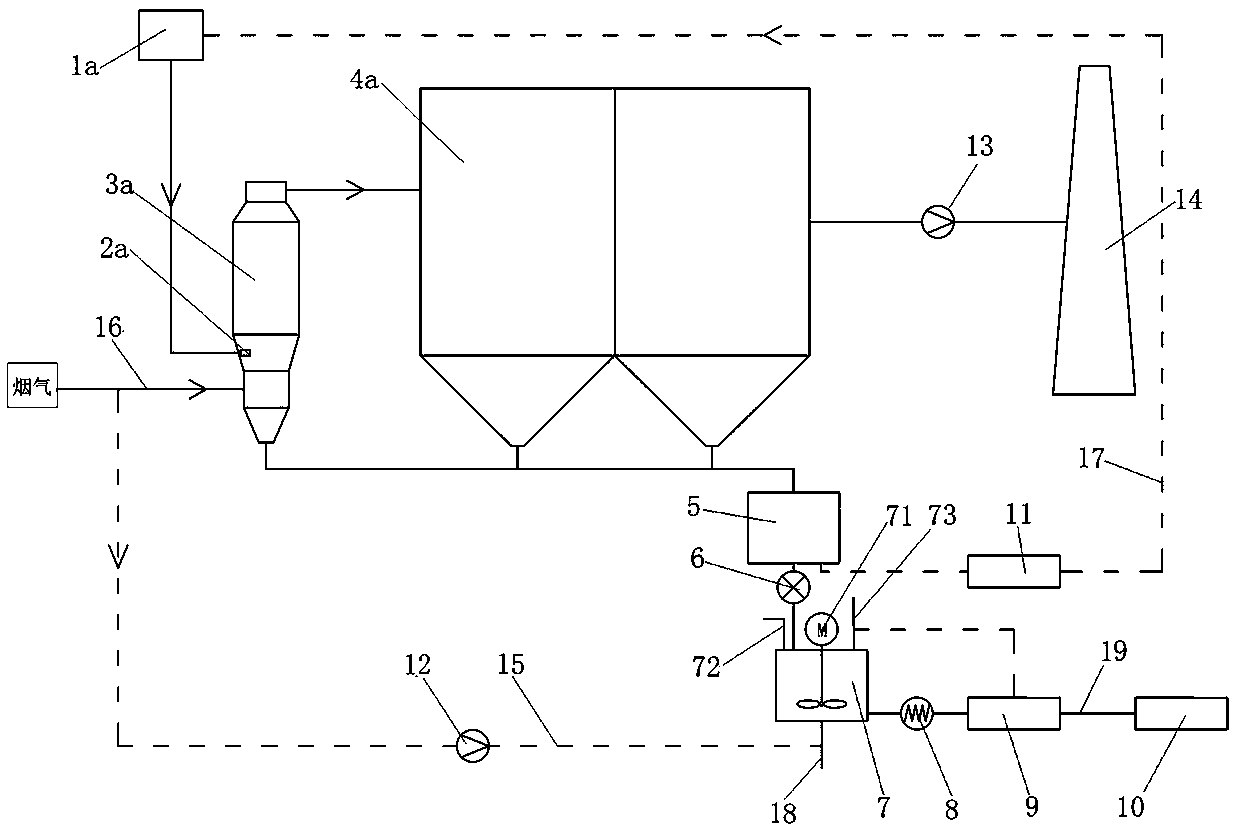

[0032] like figure 1 Shown: the present embodiment is a high-efficiency utilization system of desulfurization by-products, including a desulfurization and dust removal device, a waste ash storage tank 5, a gypsum preparation tank 7 and a gypsum finished product storage device 10, and the flue gas enters the desulfurization and dust removal device through the main flue 16, The tail gas generated by the desulfurization and dust removal device is sucked by the second fan 13 and finally discharged from the chimney 14, and the waste ash generated by the desulfurization and dust removal device is transported to the waste ash storage tank 5 through the pipeline, and the waste ash storage tank 5 is connected with the top of the gypsum preparation tank 7 through the pipeline, An air conveying pipe 18 is connected to the bottom of the gypsum preparation tank 7, the main flue 16 is communicated with the air conveying pipe 18 through the bypass flue 15, a stirring device 71 is arranged ins...

Embodiment 2

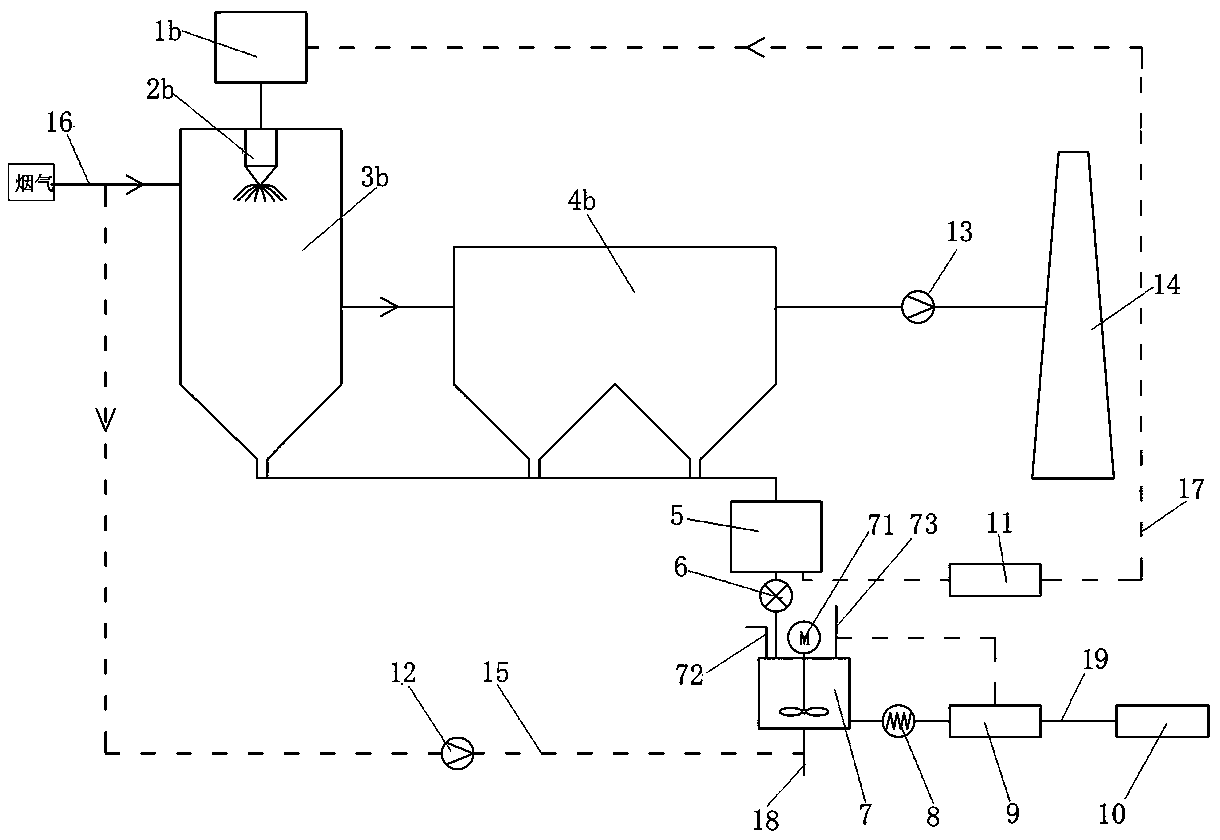

[0040] like figure 2 As shown: this embodiment is similar in structure to the first embodiment, the only difference is that the desulfurization and dust removal device in this embodiment is a semi-dry desulfurization and dust removal device, and the semi-dry desulfurization and dust removal device includes a pulping system 1b, a rotary atomizer 2b, the semi-dry desulfurization tower 3b and the bag filter 4b, the flue gas enters the semi-dry desulfurization tower 3b through the main flue 16, the rotary atomizer 2b is installed on the top of the semi-dry desulfurization tower 3b, and the pulping system 1b prepares The lime desulfurizer slurry is centrifugally atomized by the rotary atomizer 2b and sprayed into the semi-dry desulfurization tower 3b to fully contact and react with the flue gas; the flue gas desulfurized by the semi-dry desulfurization tower 3b enters the bag filter 4b for dust removal Filtration, the tail gas generated by the bag filter 4b is sucked by the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com