Particulate diffusion charge thickening method

A particle and charging technology, applied in the field of plasma technology and environmental engineering, can solve the problem of thickening of diffusion charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Describe the embodiment of the present invention in detail below in conjunction with technical scheme and accompanying drawing:

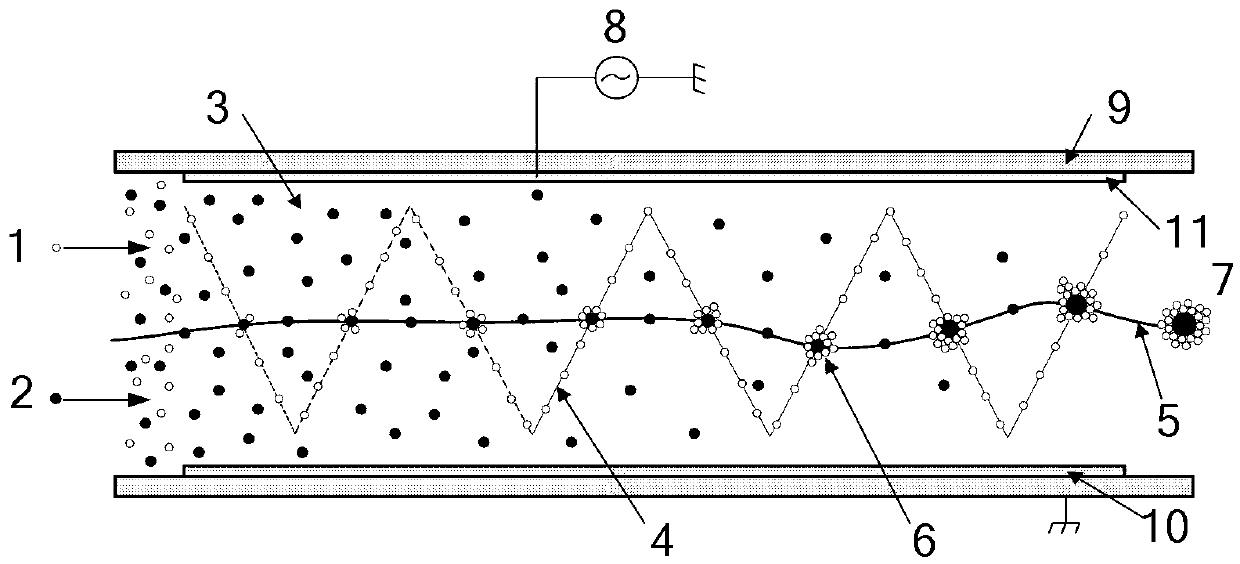

[0037] The principle of the charging and thickening method of PM0.1 primary particulate matter of the present invention is shown as follows figure 1 shown. The output voltage of the high-frequency high-voltage alternating power supply 8 is applied to the high-voltage electrode 11, and a high-frequency high-voltage charging and thickening alternating electric field 3 is formed between the high-voltage electrode 11 and the ground electrode 10, and the concentration is as high as 10 10 / cm 3 ~10 14 / cm 3 The unipolar ions 1 and the gas containing PM0.1 primary particulate matter 2 are injected into the 0.1m-4m long high-frequency high-voltage charged thickening alternating electric field 3, that is, every 1cm 3Unipolar ions in gas up to 10 10 ~10 14 more than one. The unipolar ion 1 makes a 10-degree gap between the high-voltage electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com