Sealed heating system and heating method

A heating system and heating method technology, applied in the field of heating devices, can solve the problems of long start-up time, insufficient installed power, high operating cost, etc., and achieve the effects of ensuring restart, short start-up time and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

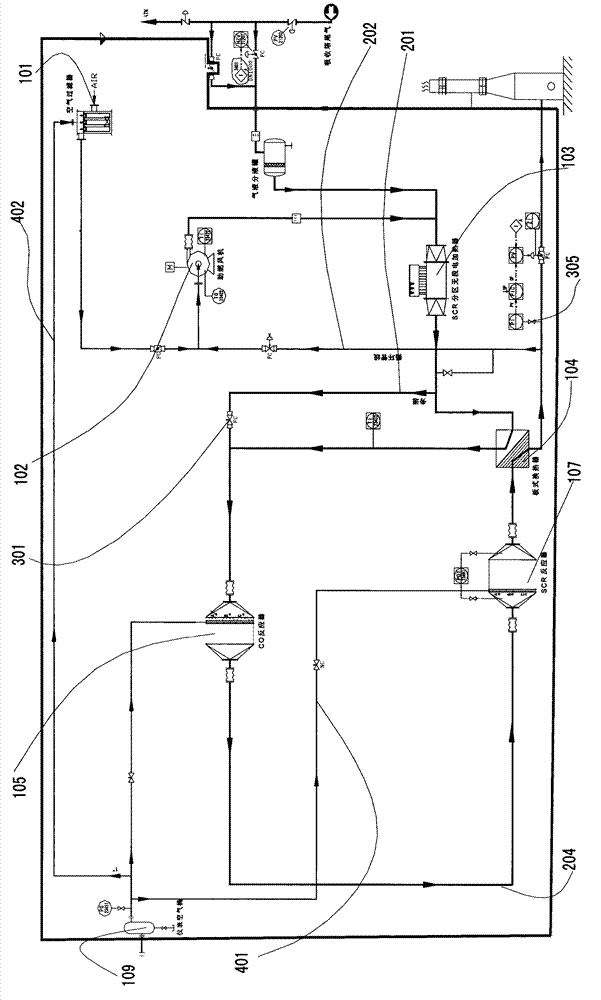

[0029] The present invention is applied in the field of petrochemical industry, especially a closed heating system mainly used in the catalytic oxidation system of chemical products such as acrylonitrile tail gas treatment device, which is a major improvement made on the basis of the existing heating system Improvement has very important practical significance.

[0030] Such as figure 1 As shown, the technology of the present invention mainly adopts a closed-cycle heating method to solve the problems of high installation power, large energy consumption and high operating cost of electric heating. The electric heater is mainly used for the start-up of the system. When the system starts, the electric heater needs to be used to preheat the system to the temperature required for start-up (250-400°C). The closed heating system in the present invention adopts circulating heating, that is, the circulating air first passes through the electric heater 103 to heat the circulating air, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com