Liquid-liquid two-phase separation system for unsteady state feeding partial emulsification and application

A non-steady state, phase separation technology, applied in the field of chemical production, can solve the problems of the centrifuge system not running normally, not having industrial application value, extremely unstable feeding state, etc., to improve the completeness of separation and the economic benefits of operation. Significant, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

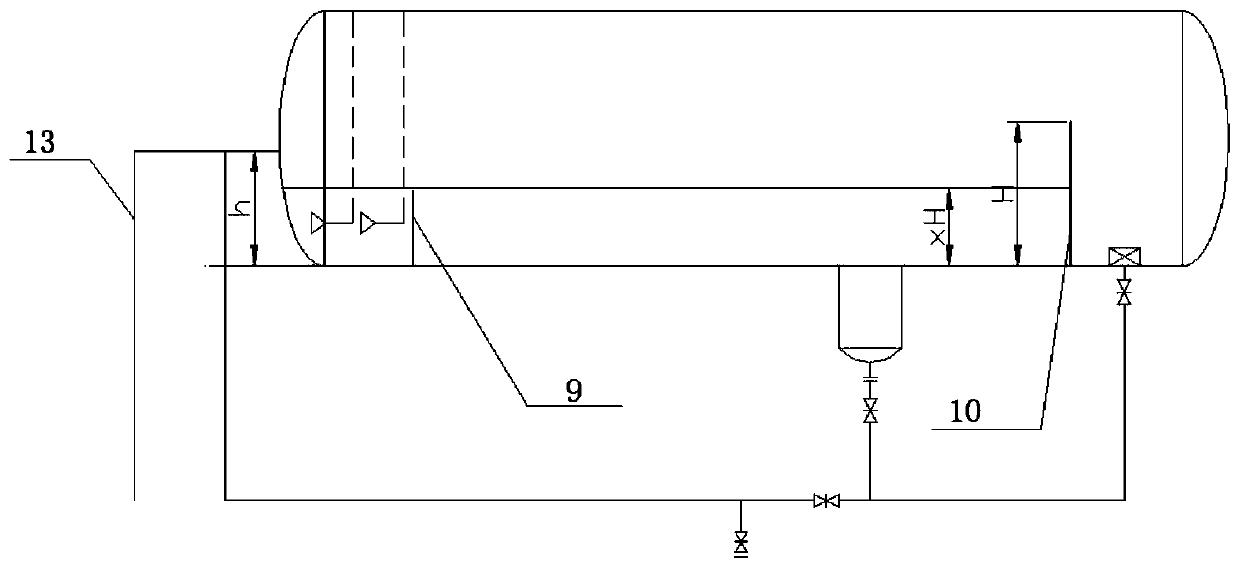

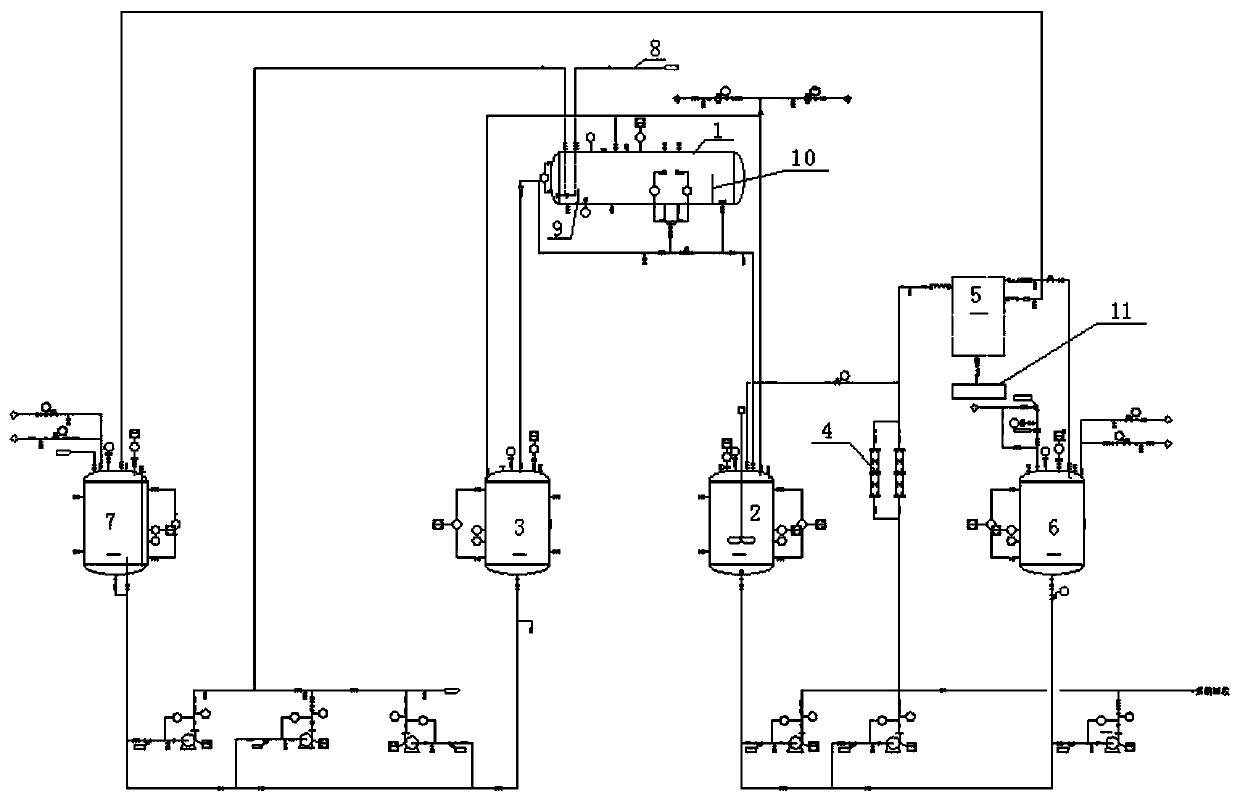

[0036] Deep separation of light components with variable working conditions

[0037] refer to figure 1 , figure 2 , Figure 5 , a liquid-liquid two-phase separation system with partial emulsification of unsteady feed, the system includes a pre-separation tank 1, a light component collection tank 2, a heavy component collection tank 3, an extrusion demulsification device 4, a centrifuge 5 and a recovery tank 6, the pre-separation tank 1 is a horizontal tank structure, the light component collection tank 2 and the heavy component collection tank 3 are vertical tank structures, and the centrifuge is a three-phase centrifuge. The three-phase centrifuge 5 is communicated with the circulation tank 7, and the circulation tank 7 is communicated with the pre-separation tank 1; the pre-separation tank 1 is communicated with the separation liquid inlet pipe 8, and the separation liquid inlet pipe 8, The circulation tank 7 extends into the bottom of the pre-separation tank through the...

Embodiment 2

[0047] Implementation of regrouping and deep separation with changing working conditions

[0048] refer to figure 1 , image 3 , Figure 5 Referring to Example 1 for other structures of a partially emulsified liquid-liquid two-phase separation system with unsteady feed, the pre-separation tank 1 is connected to the light component collection tank 2 and the heavy component collection tank 3 respectively, so The light component collecting tank 2 is not provided with a stirring device, and the heavy component collecting tank 3 is provided with a stirring device; The three-phase centrifuge 5 is connected, and the three-phase centrifuge 5 is connected with the recovery tank 6; the light component collection tank 2 is connected with the circulation tank 7; the light and heavy component collection tank 3 and the recovery tank 6 are respectively connected with The system recovery device is connected; the three-phase centrifuge 5 is connected to the centrifuge slag tank 11 . The to...

Embodiment 3

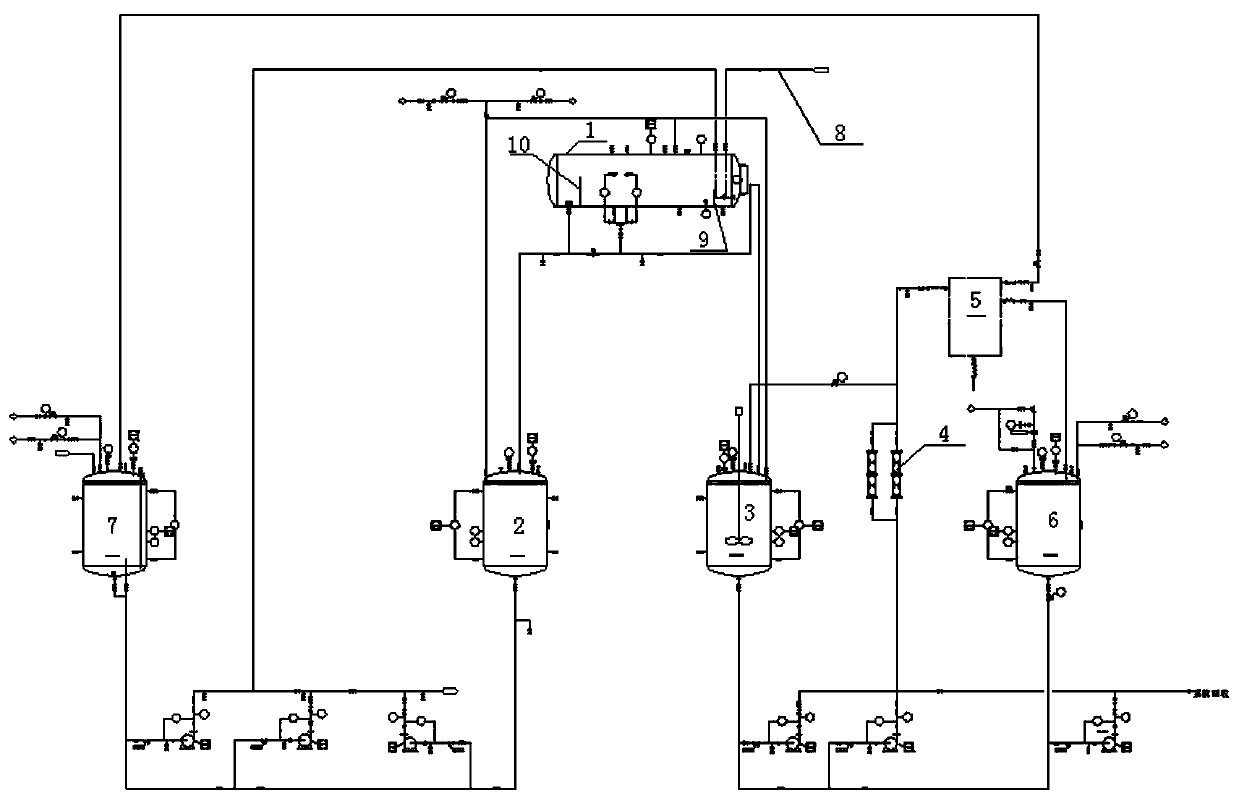

[0054] Implementation of deep separation of light and heavy components under changing working conditions

[0055] refer to figure 1 , Figure 4 , Figure 5 , a kind of non-steady-state feed partial emulsified liquid-liquid two-phase separation system with reference to embodiment 1, the collection tank includes a light component collection tank 2 and a heavy component collection tank 3, the light component collection tank The tank 2 and the heavy component collection tank 3 are all equipped with agitators; the pre-separation tank 1 communicates with the light component collection tank 2 and the heavy component collection tank 3 respectively, and the light component collection tank 2 is connected to the first extrusion The demulsification device 4-1 is connected, the first demulsification device 4-1 is connected with the first centrifuge 5-1, and the first centrifuge 5-1 is connected with the first recovery tank 6-1 The heavy component collection tank 3 is communicated with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com