Patents

Literature

41results about How to "Strong operational stability" patented technology

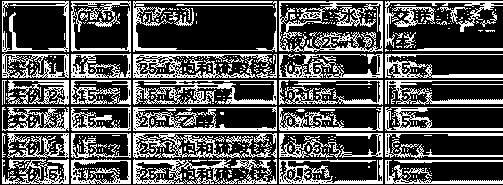

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

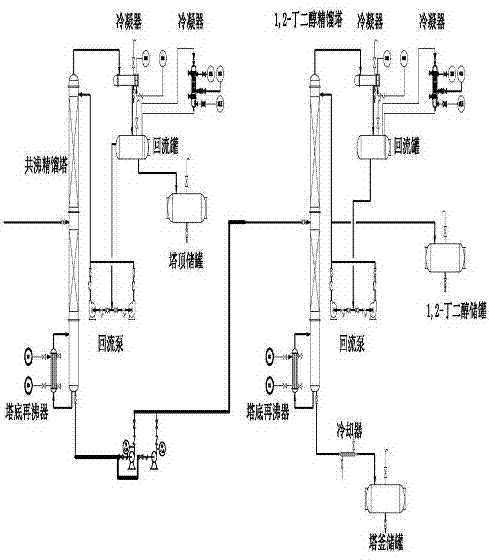

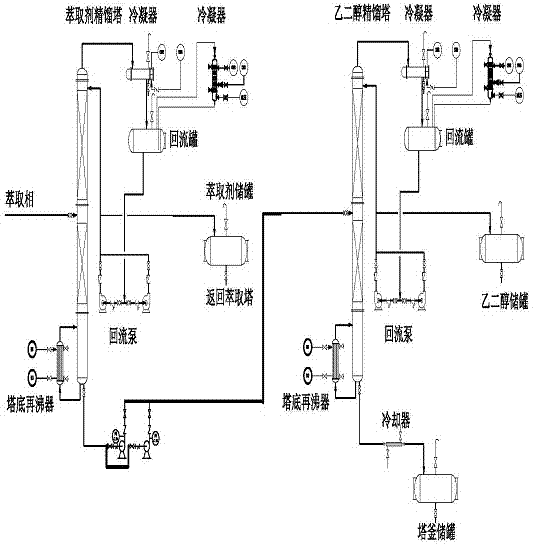

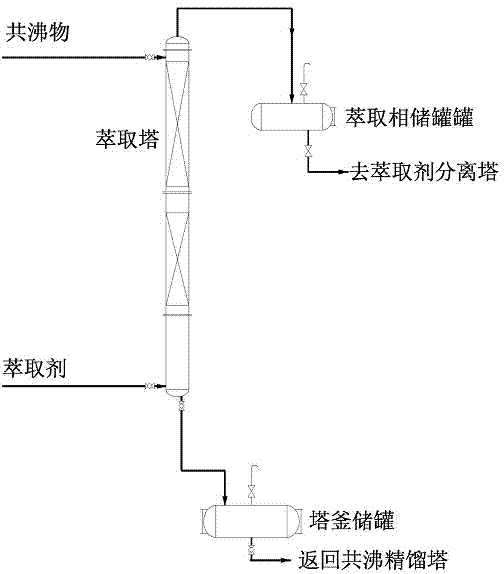

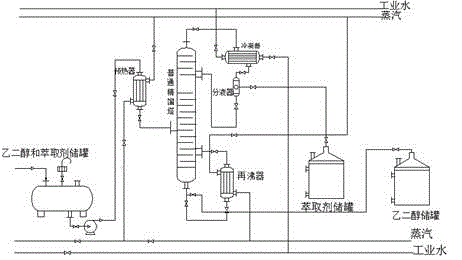

Novel method for separating mixture of ethylene glycol and 1, 2-butanediol by adopting azeotropic distillation and extraction coupling technologies

InactiveCN103772148AImprove versatilityImprove operational stabilityOrganic compound preparationHydroxy compound preparationHigh concentrationPolyol

The invention provides a novel method for separating a mixture of ethylene glycol and 1, 2-butanediol by adopting azeotropic distillation and extraction coupling technologies. The method adopts continuous azeotropic distillation and extraction coupling separation technologies to separate an azeotropic mixture of ethylene glycol and 1, 2-butanediol; an entrainer and an extraction agent are selected through ASPEN modeling and simulation, and rectification and extraction conditions are determined preliminarily; a polyatomic alcohol mixed solution and the entrainer enter a rectification tower, and azeotropic liquid of ethylene glycol and the entrainer is obtained at the tower top, and 1,2-butanediol with high concentration is obtained at a tower kettle; the extraction agent is not dissolved into the entrainer but can be mutually dissolved with ethylene glycol; the extraction agent is added into the azeotropic liquid at the tower top for extraction, and the entrainer can be recovered; a mixture of ethylene glycol and the extraction agent is rectified under normal pressure or reduced pressure, so as to obtain the ethylene glycol product, and the extraction agent is recovered for cyclic utilization.

Owner:JILIN INST OF CHEM TECH

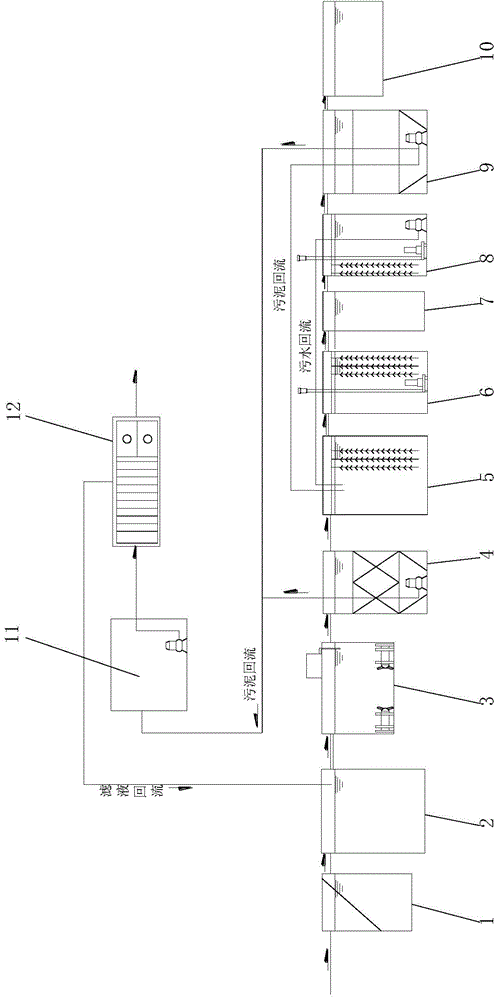

Sewage treatment method in garment production process

InactiveCN104016550ASimple processing methodEasy to manageMultistage water/sewage treatmentFlocculationSewage

The invention discloses a sewage treatment method in a garment production process. The sewage treatment method comprises the following steps: filtering, adjusting of water quality and water quantity, flocculation reaction, solid-liquid separation, hydrolytic acidification, first biodegradation, reducing of dissolved oxygen concentration, second biodegradation, solid-liquid separation and discharging. The sewage treatment method in the garment production process is simple and practical, convenient to manage, strong in operation stability, small in maintenance work, and good in sewage treatment effect, meets the standard requirements, and simultaneously can adapt to large change in sewage quality and quantity.

Owner:福建省佩吉服装股份有限公司

Clothing dyeing wastewater treatment process

InactiveCN104724853ASimple processing methodEasy to manageMultistage water/sewage treatmentWaste water treatment from textile industryTextile printerWater quality

The invention discloses a clothing dyeing wastewater treatment process. The process comprises the steps of filtering, decolourizing, performing flocculoreaction, and performing solid-liquid separation, wherein a decolourizing agent A and a decolourizing agent B are added while decolourizing; the decolourizing agent A is prepared from potassium permanganate and polymeric ferric sulfate at a ratio of 1:1, and the decolourizing agent B is prepared from tripolycyanamide, oxalaldehyde and ammonia chloride at a ratio of 10:2:3. The processing method provided by the invention has the characteristics of simple and practical, convenient management, strong operation stability, small maintenance workload, wastewater quality adaption and big moisture change. The processed discharged water quality reaches the Wastewater Pollutants Discharge Standard for Textile Printing Industry.

Owner:YIYANG FUHUI GARMENT CO LTD

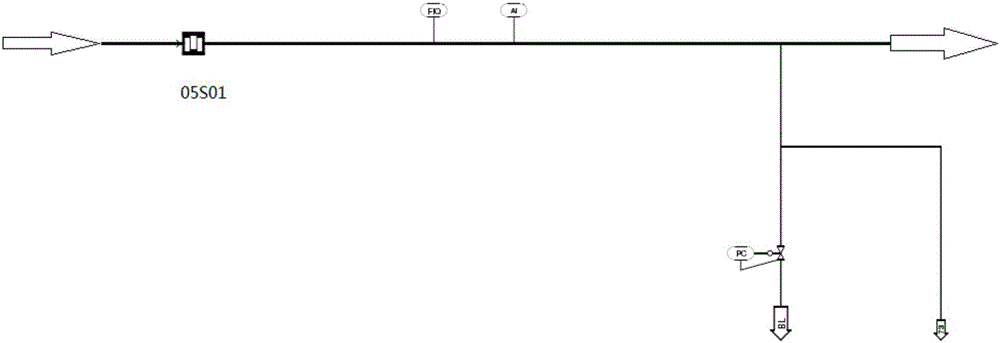

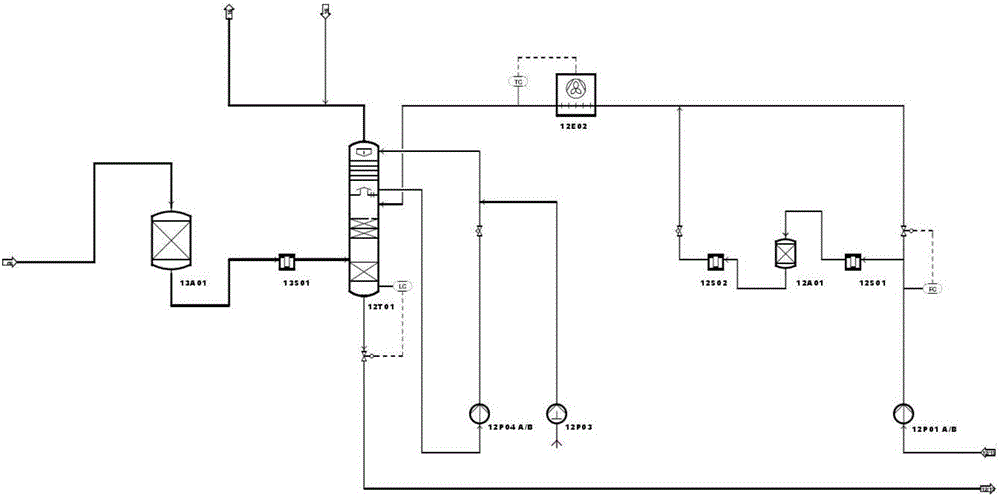

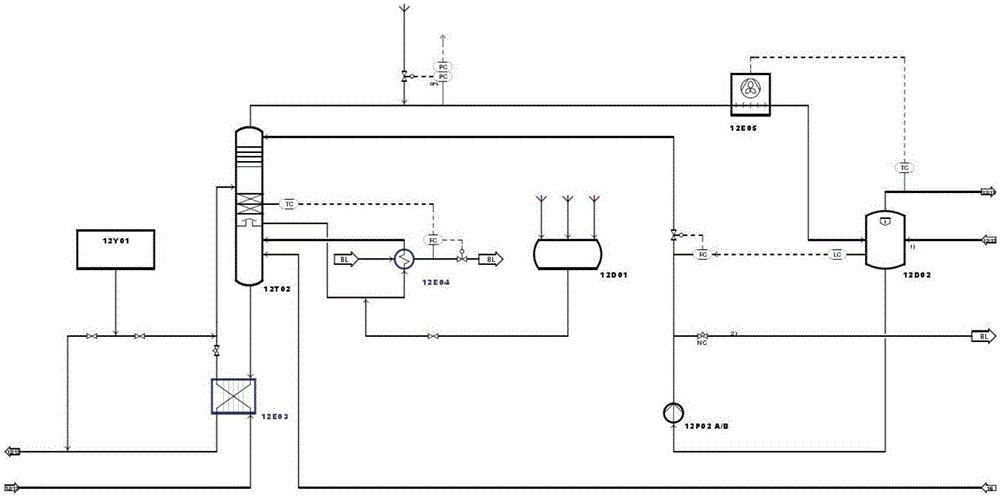

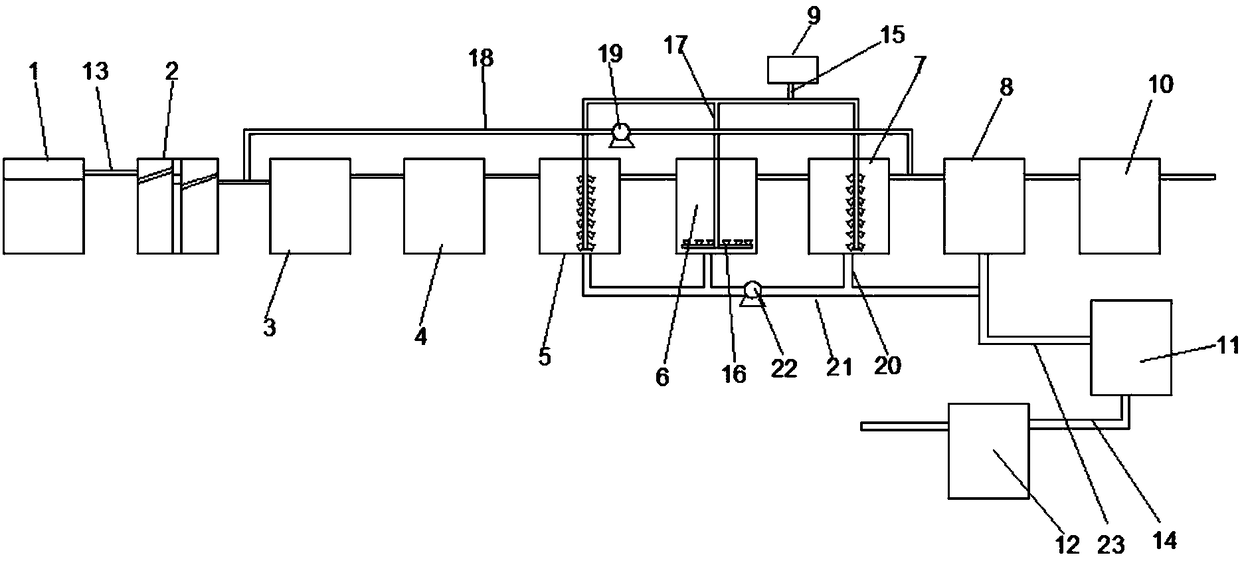

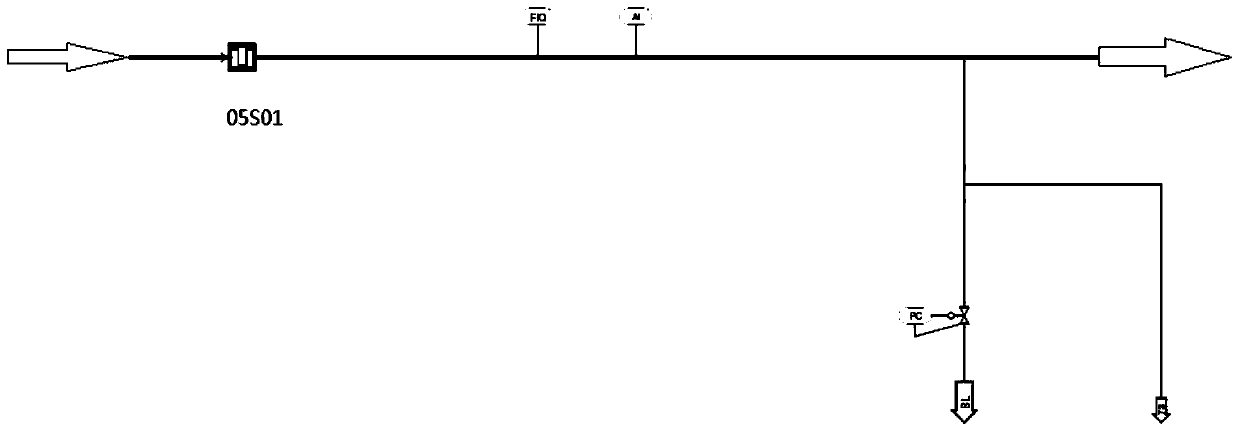

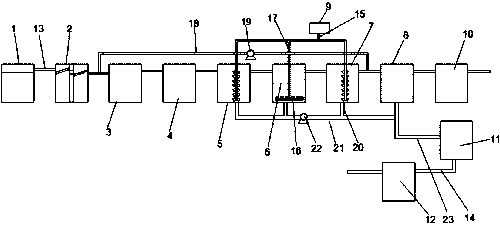

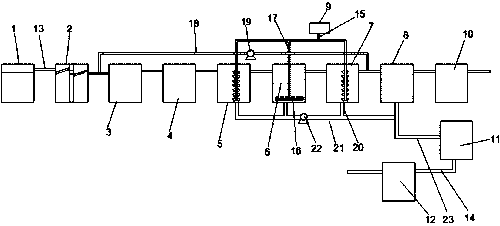

Coalbed methane liquefaction process

ActiveCN105865145AShorten the liquefaction processSimple processSolidificationLiquefactionRefrigerantPre cooling

The invention discloses a coalbed methane liquefaction process. A feeding unit, a mercury removing unit, a CO2 removing unit, a drying unit, a liquefaction unit, a refrigerant circulation unit, a refrigerant supplementing unit, a storage unit, a storage tank return gas compression unit, a hot oil unit and a torch unit are included. The feeding unit is sequentially connected with the mercury removing unit, the CO2 removing unit, the drying unit, the liquefaction unit and the storage unit; the liquefaction unit is pre-cooled, liquefied and supercooled through the refrigerant circulation unit; refrigerants are supplemented to the refrigerant circulation unit through the refrigerant supplementing unit; and the storage tank return gas compression unit is connected with the storage unit.

Owner:JINCHENG HUAGANG GAS CO LTD

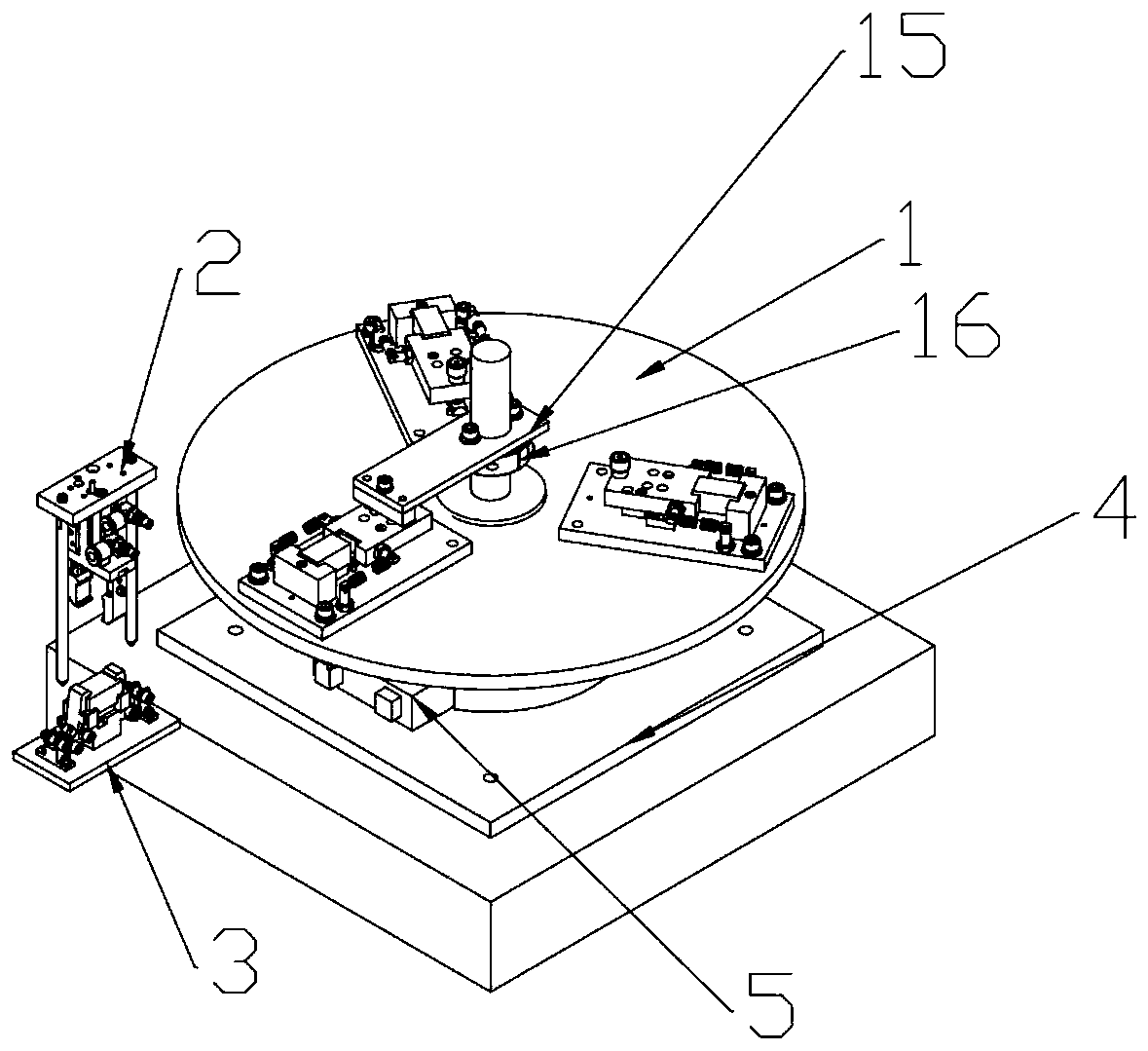

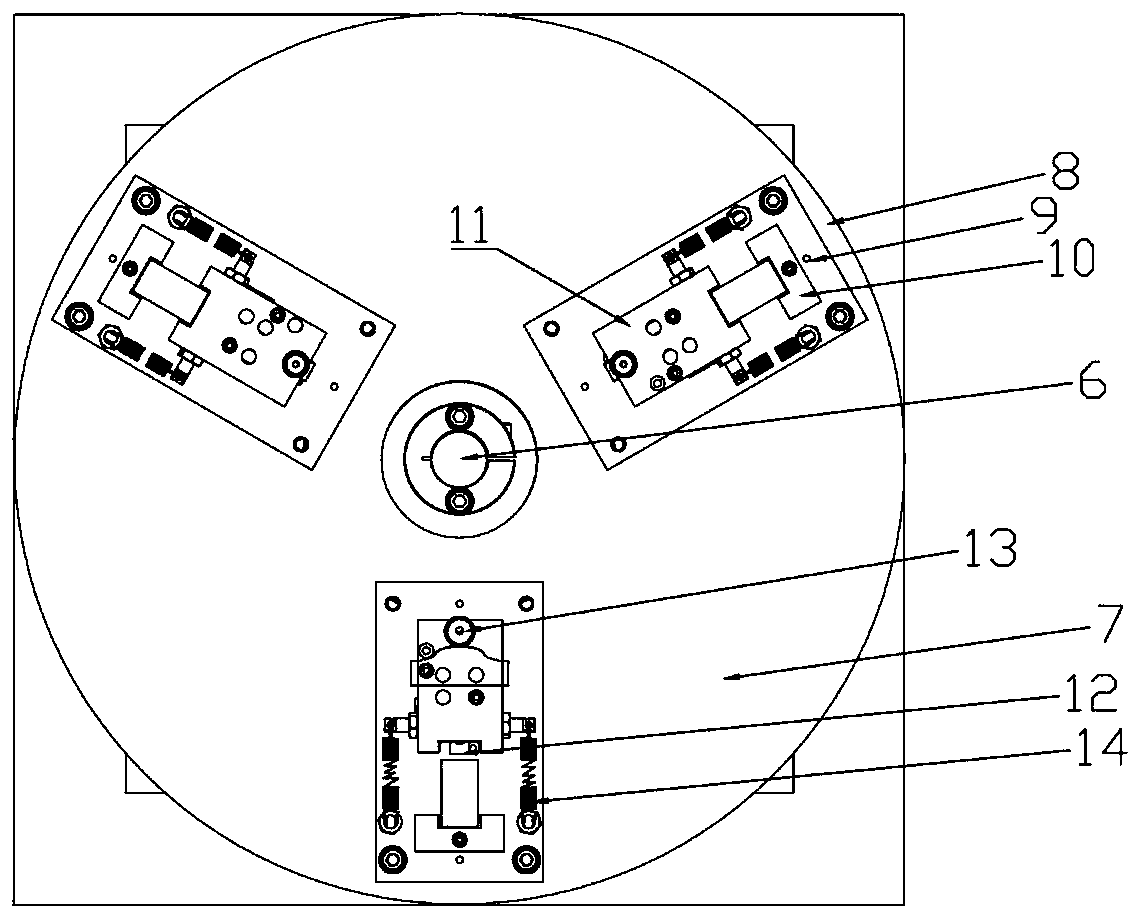

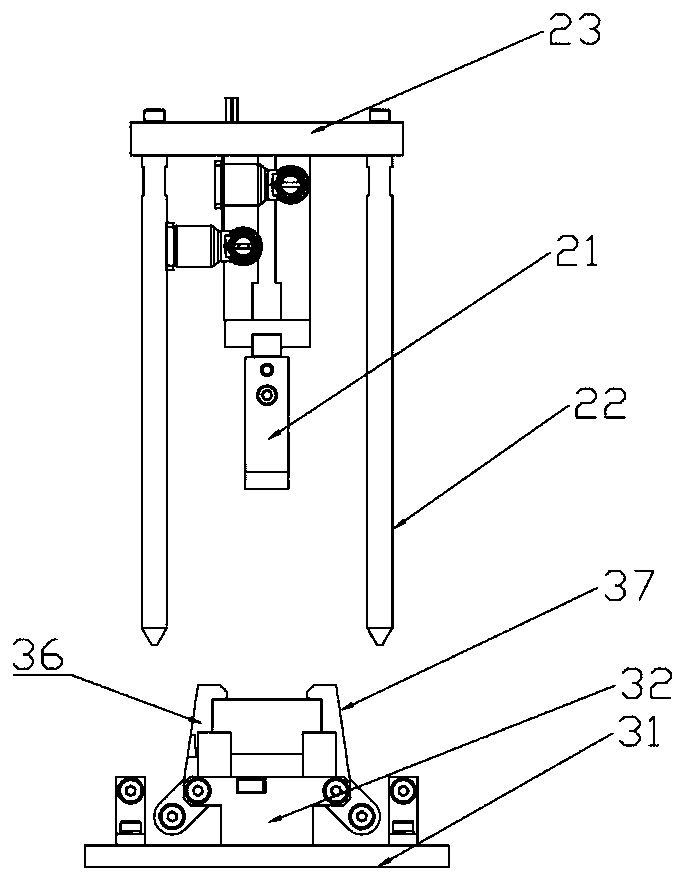

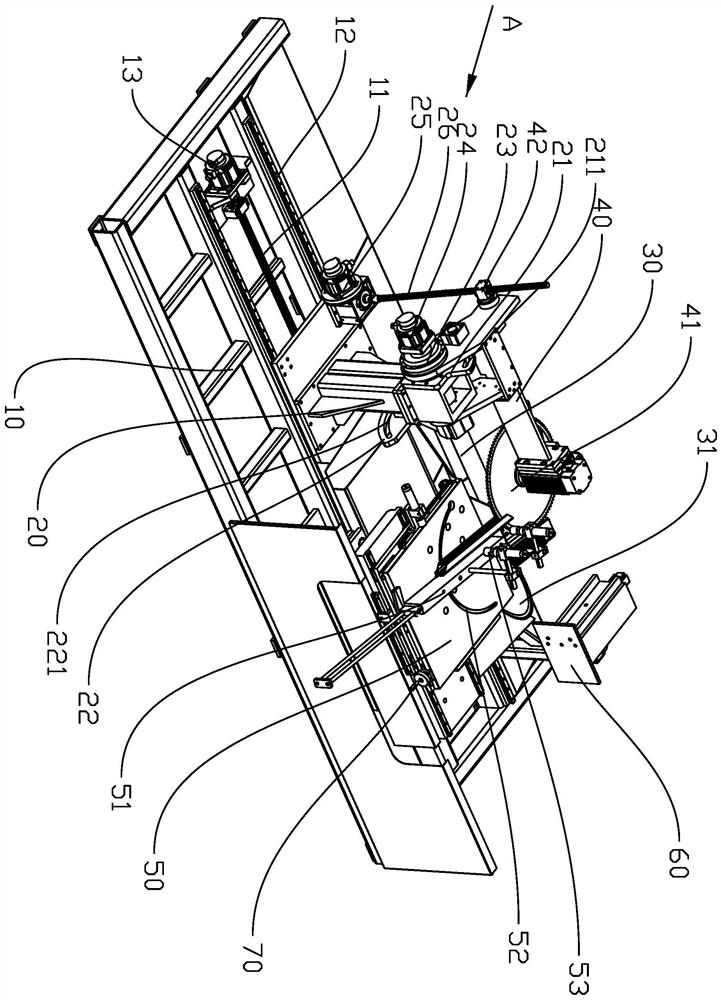

Conveying control method applicable to small part transportation

InactiveCN111038997ARealize automatic feedingEasy to controlConveyor partsMotor driveControl engineering

The invention discloses a conveying control method applicable to small part transportation. The method includes the following steps that position calibration is performed on an intermittent rotating mechanism, device initialization is performed, a motor drives a rotating disk to rotate intermittently, and when the intermittent rotating mechanism stops rotation, a workpiece clamping device on the intermittent rotating mechanism is in the open state; workpiece grasping work is performed, a workpiece feeding device is driven to work, when a sensing device of a transfer mechanism senses a static workpiece under the transfer mechanism, the transfer mechanism is lowered to the preset position, tongs of the transfer mechanism are closed, and the workpiece is clamped; the workpiece is transferred,and after the workpiece is grasped by the transfer mechanism, the transfer mechanism moves above the workpiece clamping position; the transfer mechanism is lowered to the preset position, and the transfer mechanism releases the workpiece while the workpiece is grasped in the workpiece clamping position; and the transfer mechanism moves above the station of the intermittent rotating mechanism after releasing the workpiece. With the control method, automatic feeding and control on the workpiece can be realized, the control program is simple, and the operation stability is high.

Owner:广州雅付信息科技有限公司

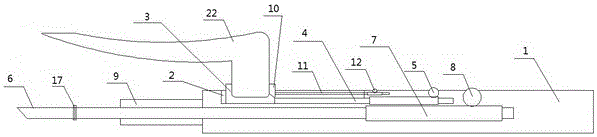

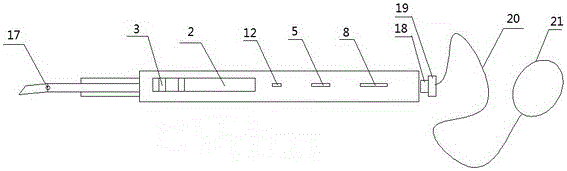

Scalpel for augmentation rhinoplasty

InactiveCN106037881AEasy to adjustStrong operational stabilitySurgeryAugmentation rhinoplastyProsthesis

The present invention belongs to the technical field of medical devices, and particularly relates to a scalpel for augmentation rhinoplasty. The scalpel comprises a handle, a sliding groove, a prosthesis clamping device, a clamping device worm, a clamping device worm wheel, a cutter head, a cutter head worm, a cutter head worm wheel and a cutter bar, wherein the handle is connected with the cutter bar; the cutter head worm penetrates through the cutter bar; the cutter head is connected with the cutter head worm; the cutter head worm wheel is meshed with the cutter head worm; the sliding groove is arranged on the handle; the prosthesis clamping device is arranged inside the sliding groove; the end, away from the cutter head, of the prosthesis clamping device is connected with the clamping device worm; and the clamping device worm is meshed with the clamping device worm wheel. The scalpel is specially used for augmentation rhinoplasty, can achieve the dual function of incision making and prosthesis implanting, and has the advantages of convenient adjustment of the position of the prosthesis, strong operation stability and reduced potential safety hazard.

Owner:大连达美医疗美容门诊有限公司

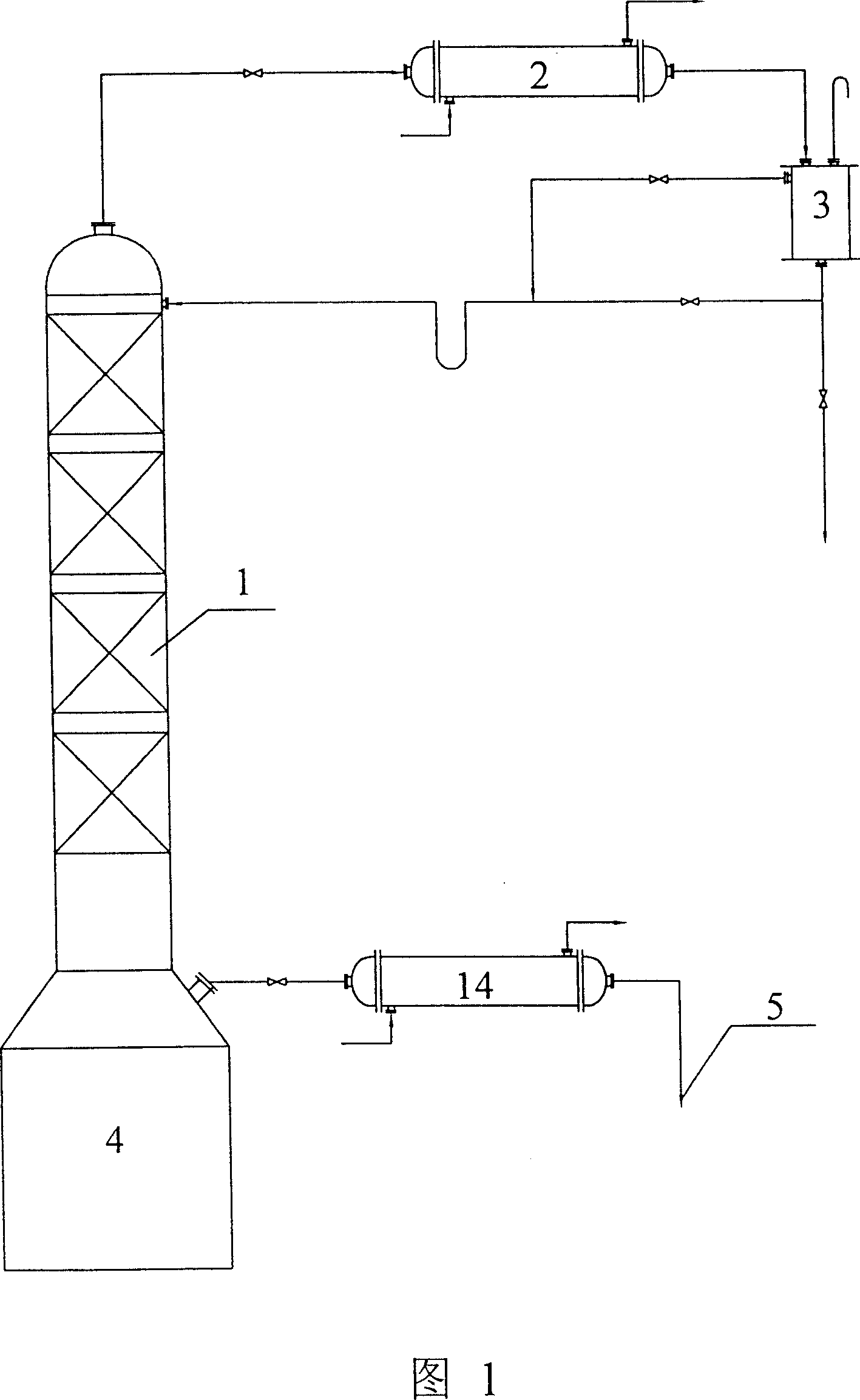

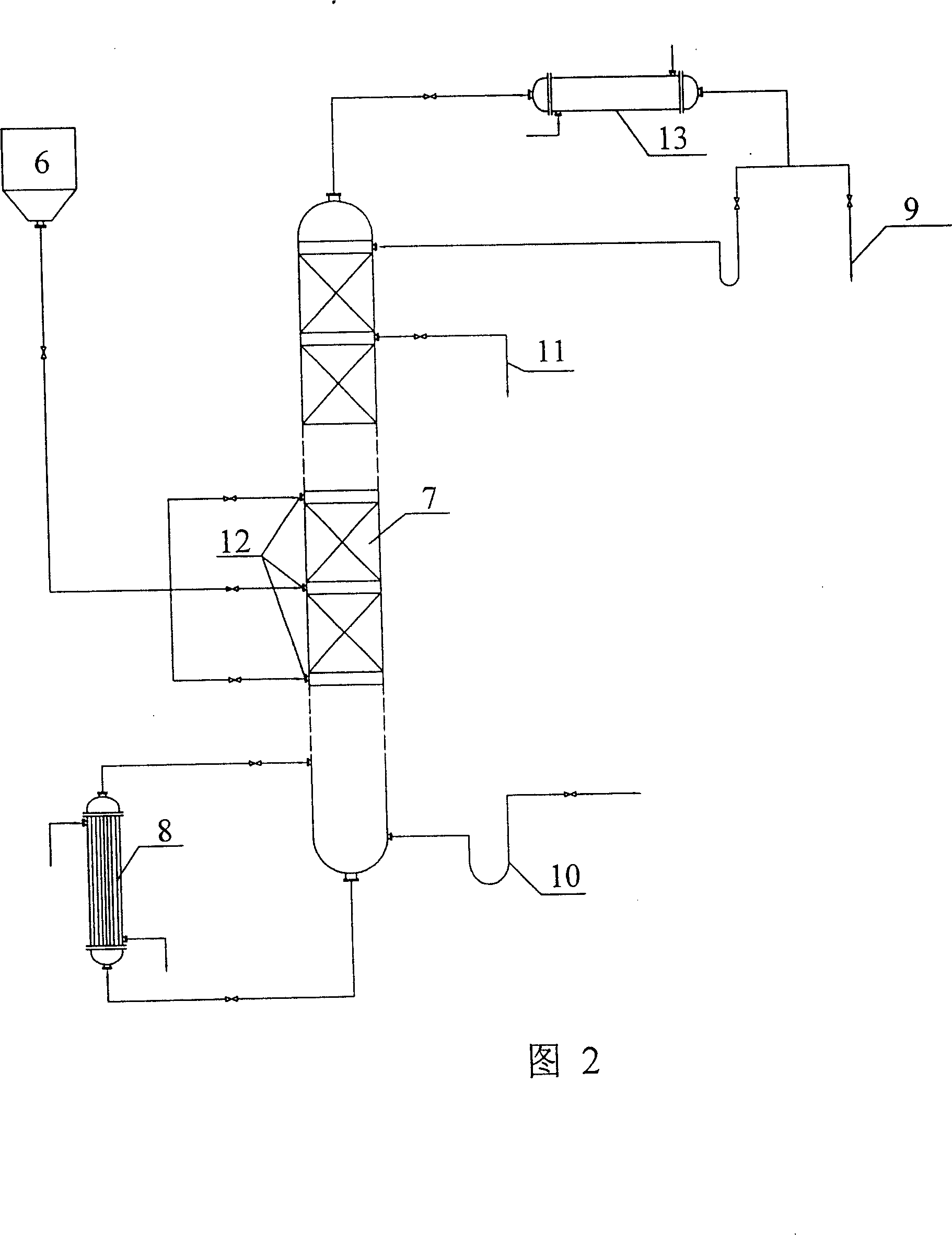

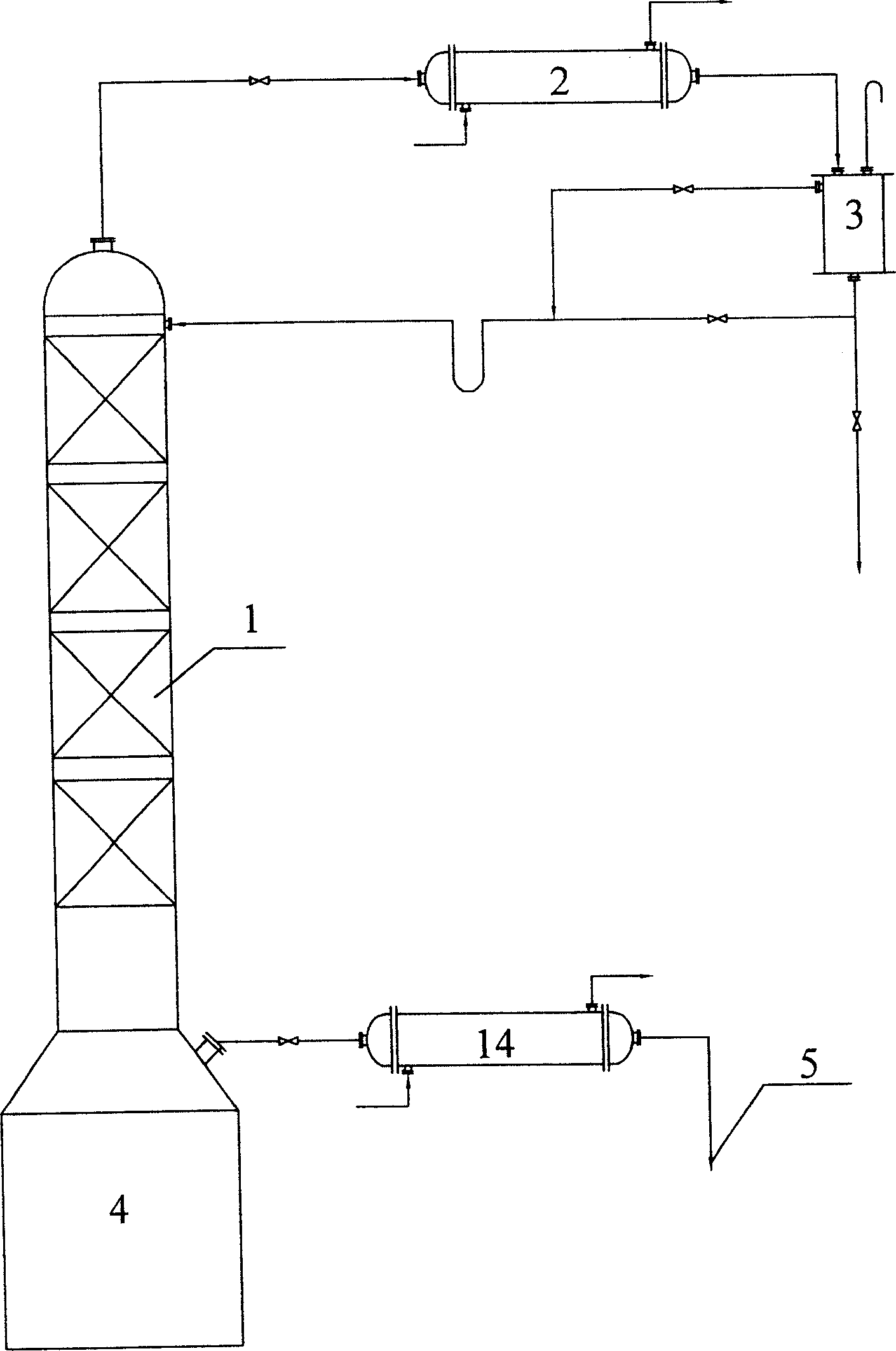

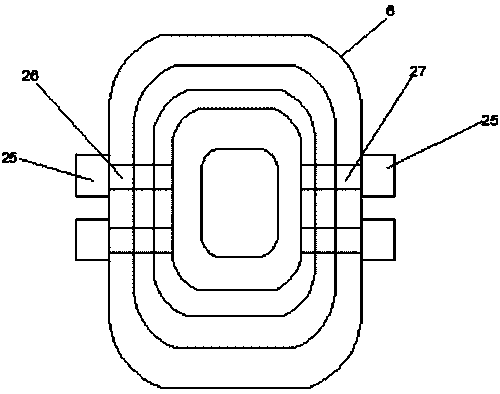

Device for separating 2-methyl butanol, 3-methyl butanol from iso amyl alcohol and its application method

InactiveCN100369875CSimple processProcess stabilityOrganic compound preparationHydroxy compound preparationIsoamyl alcoholAmyl alcohol

The present invention discloses apparatus for separating 2-methyl butanol and 3-methyl butanol from isoamyl alcohol product and its application method. The apparatus includes one continuous rectifying tower, which has re-boiler, automatic draining device, top discharge port with cooler, lateral line outlet, and parallel spiral stuffing of height over 10 m. The apparatus has simple structure, convenient operation, low cost, high yield and capacity of further amplification, and may be used in producing 2-methyl butanol and 3-methyl butanol or their mixture of purity over 99.5 % for use as edible perfume and essence.

Owner:上海天之冠可再生能源有限公司

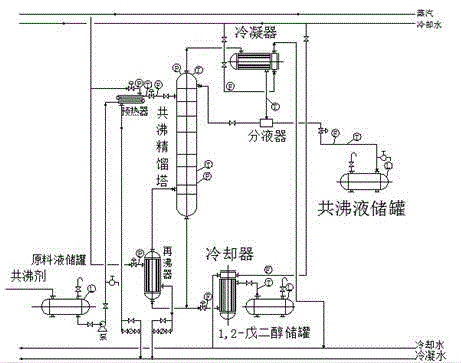

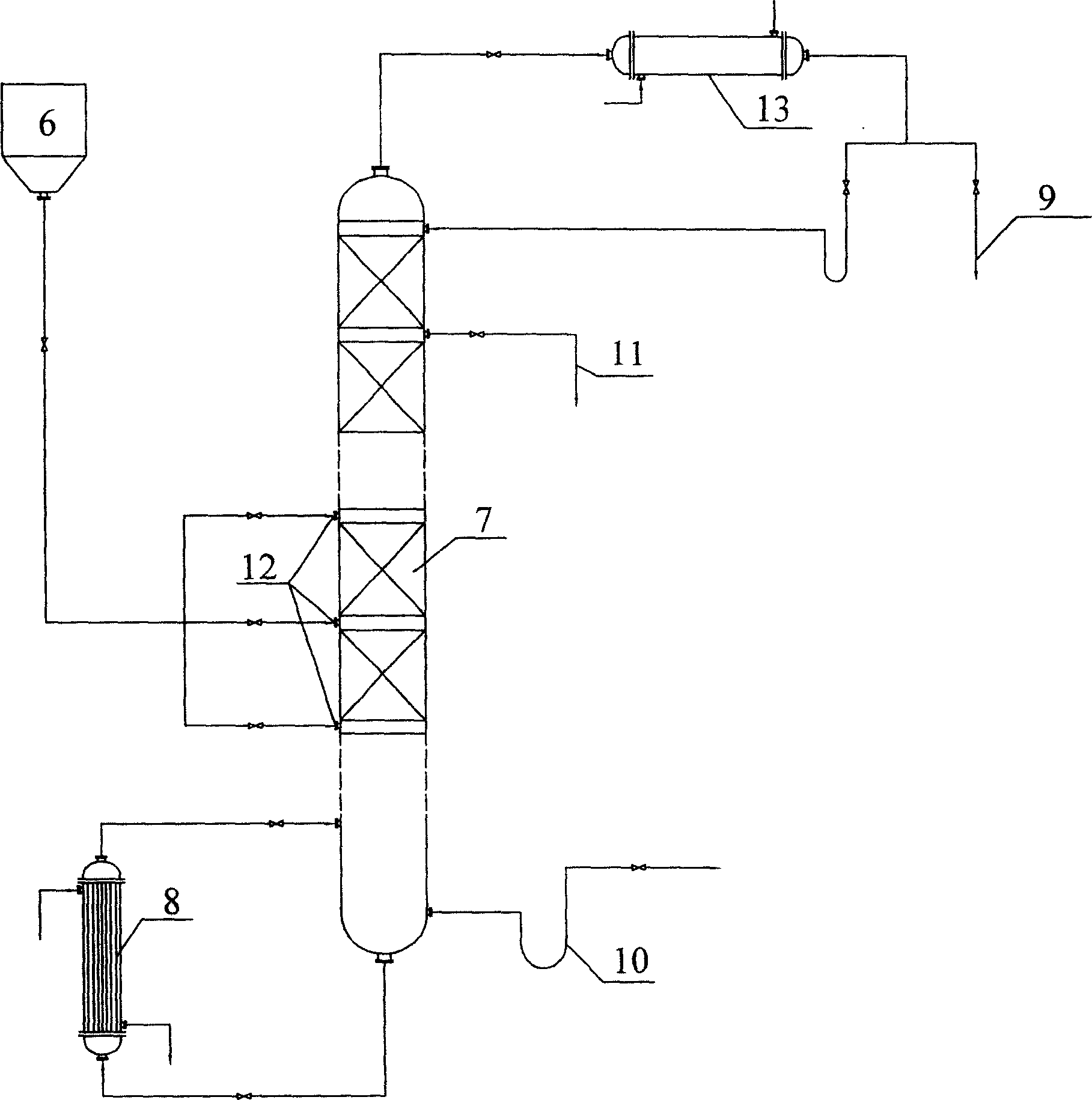

Novel method for separating ethylene glycol and 1,2-pentanediol

InactiveCN104370696APracticalStrong operational stabilityOrganic compound preparationHydroxy compound separation/purificationGlycol synthesisAzeotropic distillation

The invention discloses a novel method for separating ethylene glycol and 1,2-pentanediol. The separation process mainly comprises the unit operation steps of azeotropic distillation, extraction, filtration, rectification and the like. According to the method, a proper entrainer is selected, and the rectification operation condition is preliminarily determined; a mixture of ethylene glycol and 1,2-pentanediol is fed into a rectification tower together with the entrainer, an azeotrope liquid of ethylene glycol and the entrainer is obtained on the top of the tower, and a qualified 1,2-pentanediol product is obtained at the bottom of the tower; an extracting agent is insoluble in the entrainer, but is soluble with ethylene glycol, the extracting agent is added into the azeotrope liquid and cooling and filtering are carried out, so that the azeotrope liquid can be separated, the filter cake is the entrainer and can be recycled, and the filtrate is a mixture of ethylene glycol and the extracting agent; the qualified ethylene glycol product can be prepared from the filtrate by normal-pressure or reduced-pressure rectification, and the extracting agent can be reclaimed and recycled.

Owner:JILIN INST OF CHEM TECH

Device for separating 2-methyl butanol, 3-methyl butanol from iso amyl alcohol and its application method

InactiveCN1911882ASimple processProcess stabilityOrganic compound preparationHydroxy compound preparationIsoamyl alcoholAmyl alcohol

The present invention discloses apparatus for separating 2-methyl butanol and 3-methyl butanol from isoamyl alcohol product and its application method. The apparatus includes one continuous rectifying tower, which has re-boiler, automatic draining device, top discharge port with cooler, lateral line outlet, and parallel spiral stuffing of height over 10 m. The apparatus has simple structure, convenient operation, low cost, high yield and capacity of further amplification, and may be used in producing 2-methyl butanol and 3-methyl butanol or their mixture of purity over 99.5 % for use as edible perfume and essence.

Owner:上海天之冠可再生能源有限公司

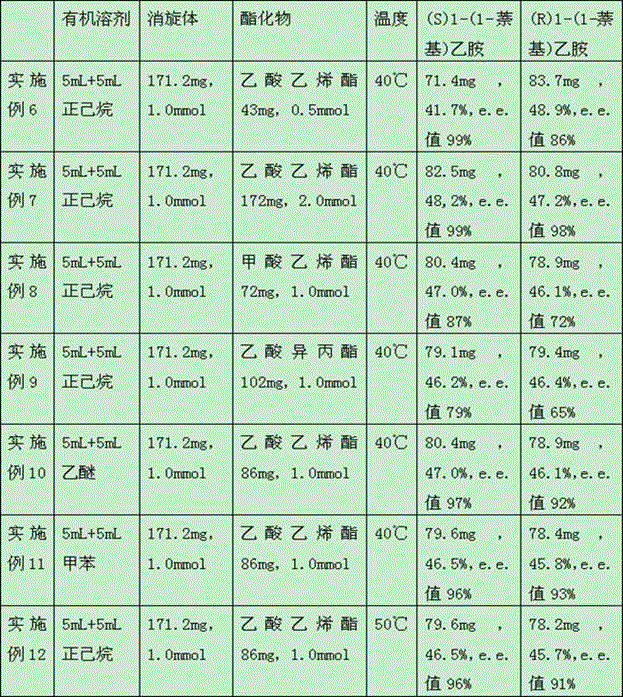

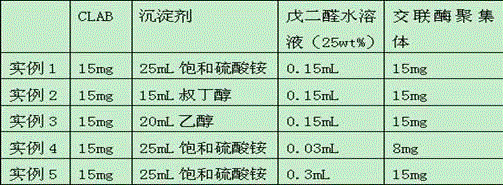

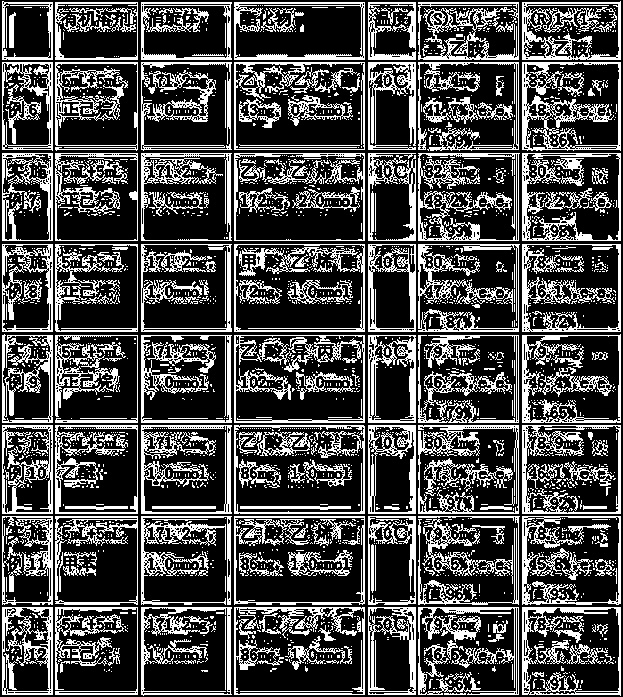

Method for preparing optical pure 1-(1-naphthyl)ethylamine through resolution with immobilized enzyme process

InactiveCN104630322AExtended reaction timeStrong operational stabilityFermentationCross-linked enzyme aggregateOrganosolv

The invention discloses a method for preparing optical pure 1-(1-naphthyl)ethylamine through resolution with immobilized enzyme process. The method comprises the following steps of selectively esterifying (R)-1-(1-naphthyl)ethylamine in 1-(1-naphthyl)ethylamine racemate, then separating (R)-1-(1-naphthyl)ethylamine esterified compound from (S)-1-(1-naphthyl)ethylamine to obtain (S)-1-(1-naphthyl)ethylamine, and finally hydrolyzing the (R)-1-(1-naphthyl)ethylamine compound to obtain the (R)-1-(1-naphthyl)ethylamine. The catalyst for selective esterification is crosslinked Candida antarctica lipase B aggregate which is prepared through the following steps of dissolving Candida antarctica lipase B in water to obtain enzyme solution, depositing zymoprotein from the enzyme solution with a precipitator, then adding a difunctional crosslinking agent for crosslinking, and drying. The crosslinked enzyme aggregate is high in repeated utilization rate, and has relatively strong operation stability in a pure organic solvent.

Owner:南京普瑞特生物科技有限公司

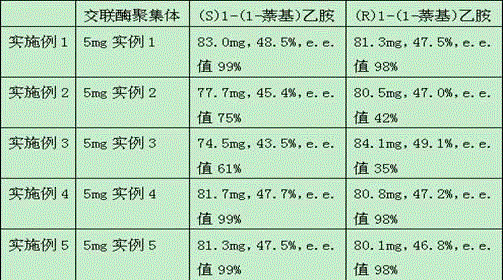

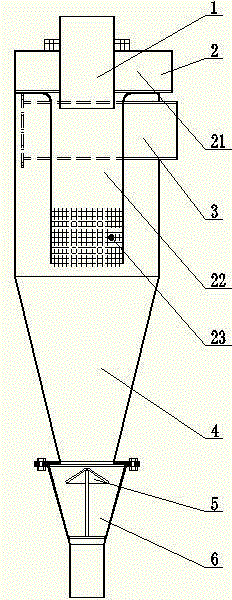

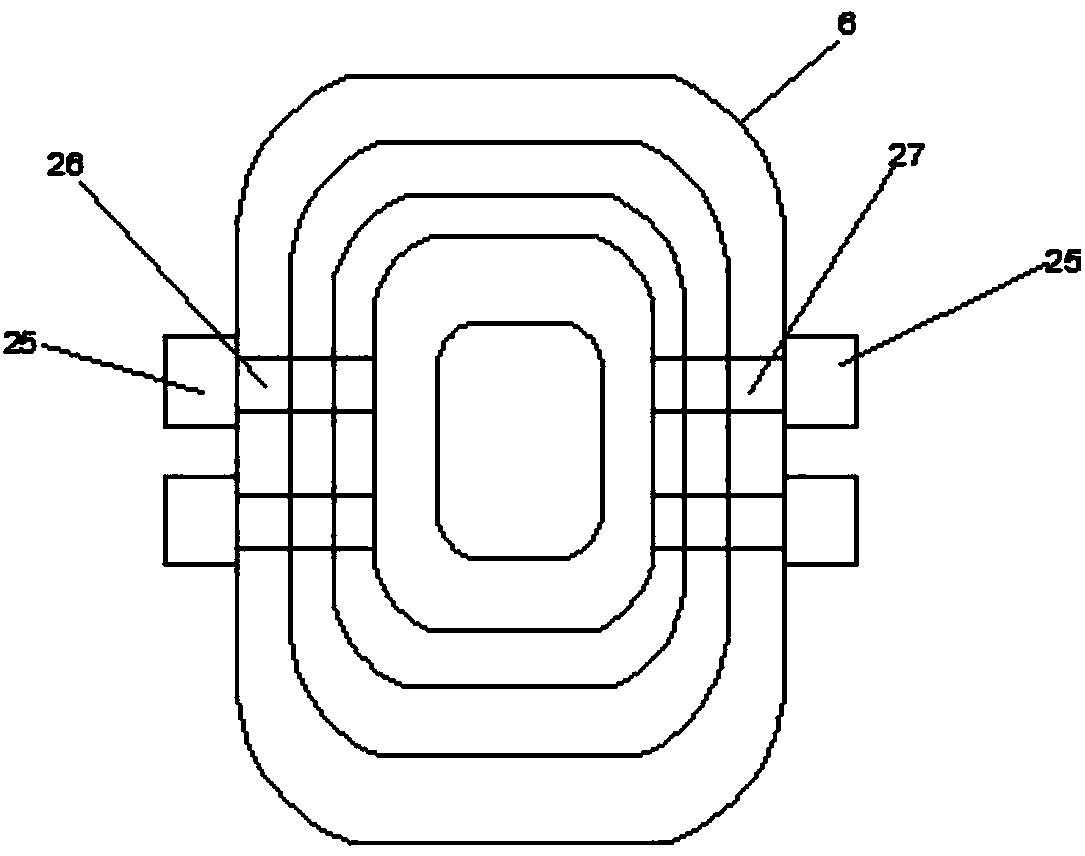

Integrated coaxial recycling serial connection type high-efficiency cyclone separator

The invention relates to an integrated coaxial recycling serial connection type high-efficiency cyclone separator which is small in size, short in air flow route, small in pressure drop, stable in air flow field, stable in property and high in separation efficiency. The integrated coaxial recycling serial connection type high-efficiency cyclone separator comprises a main shell, an air inlet tube, an exhaust tube and a discharge cabin. The integrated coaxial recycling serial connection type high-efficiency cyclone separator is structurally characterized in that a backflow device is further arranged on the top of the main shell; the backflow device comprises a backflow tube, a backflow volute and an inner cylinder which is connected with the lower end of the backflow volute; the inner cylinder is coaxially arranged with the main shell and the exhaust tube; the air inlet tube is arranged on the main shell below the backflow device; and the air inlet tube is connected with the main shell so as to form an air inlet volute.

Owner:魏昊元

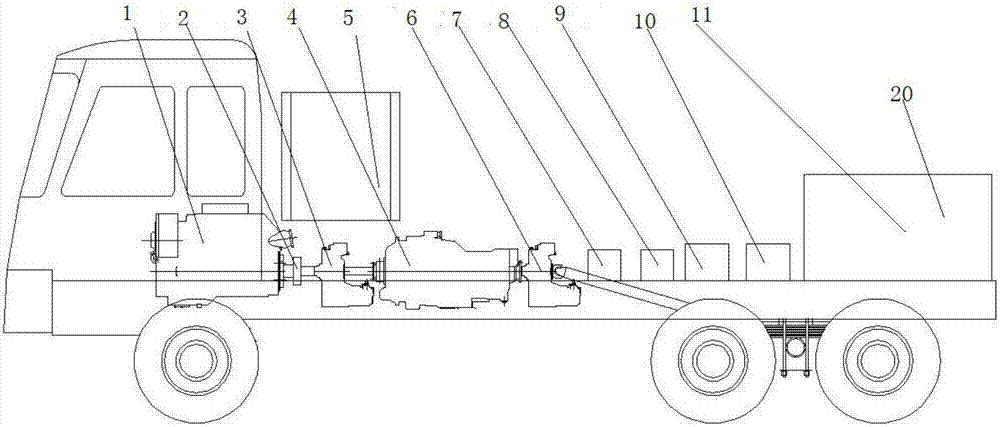

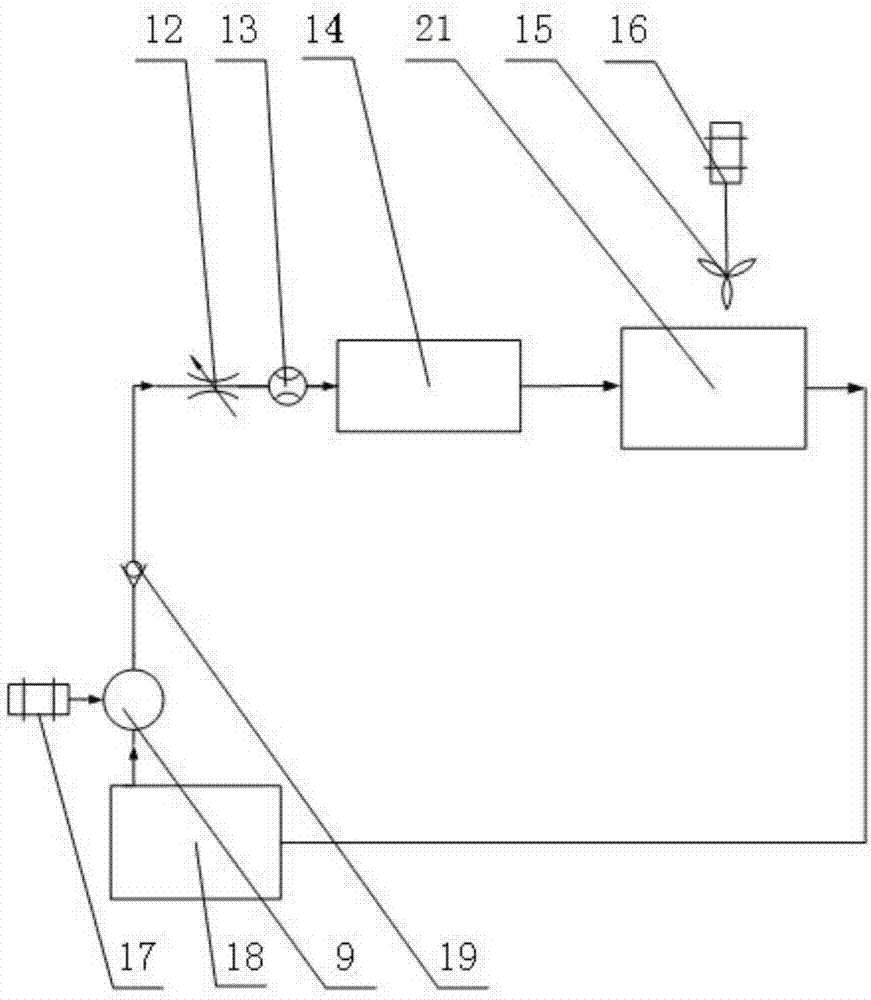

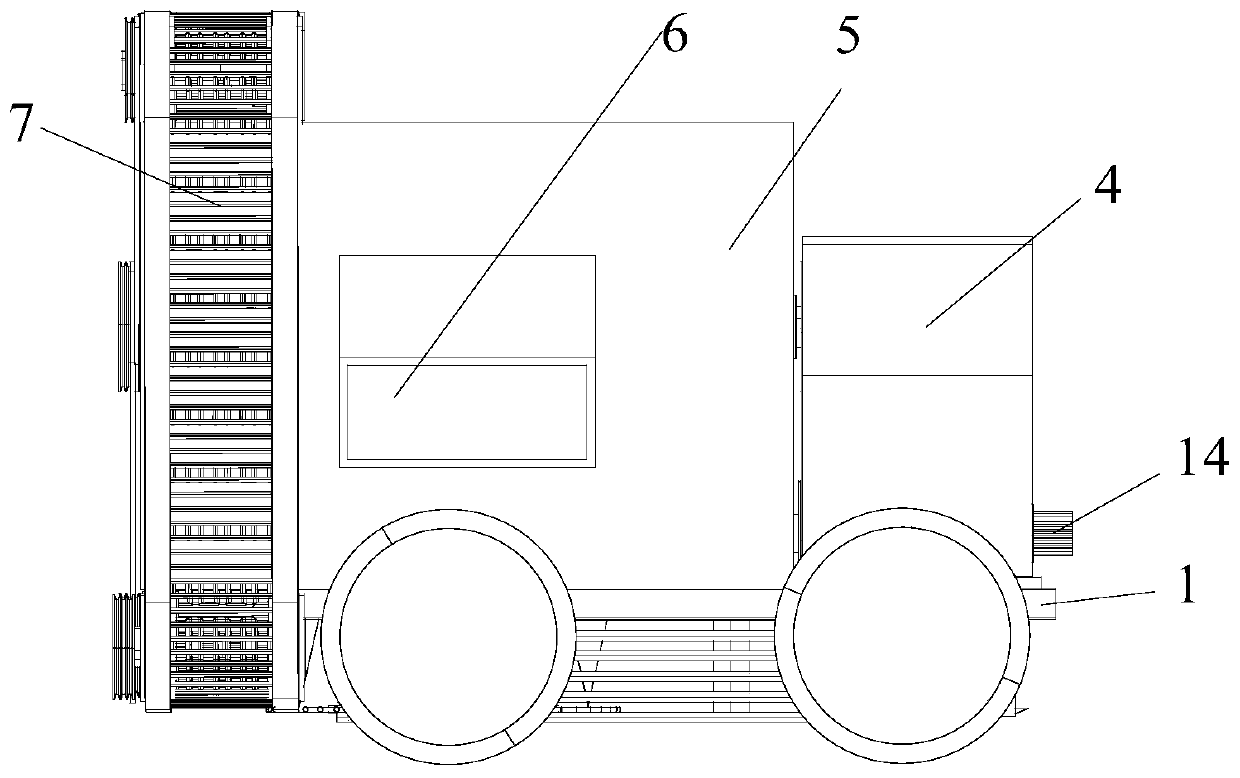

Hydrodynamic retarder type load simulation vehicle

InactiveCN107328583AImprove mobilityStrong operational stabilityVehicle testingOperational stabilityVehicle brake

The invention discloses a hydrodynamic retarder type load simulation vehicle. The hydrodynamic retarder type load simulation vehicle comprises a vehicle body; an engine, a total controller, a torque sensor, a first hydrodynamic retarder, a second hydrodynamic retarder, a transmission, and a retarder heat dissipation system. The torque sensor and the first hydrodynamic retarder are disposed between the engine and the transmission, and the second hydrodynamic retarder is disposed on the output end of the transmission. The retarder heat dissipation system is close to the first hydrodynamic retarder, and the controller is connected with the torque sensor, the first hydrodynamic retarder, the second hydrodynamic retarder, and the retarder heat dissipation system. The hydrodynamic retarder type load simulation vehicle is advantageous in that compared with a load trailer, the load simulation vehicle has stronger maneuverability and operation stability, and wear of a test vehicle brake system is reduced.

Owner:火箭军装备研究院第三研究所

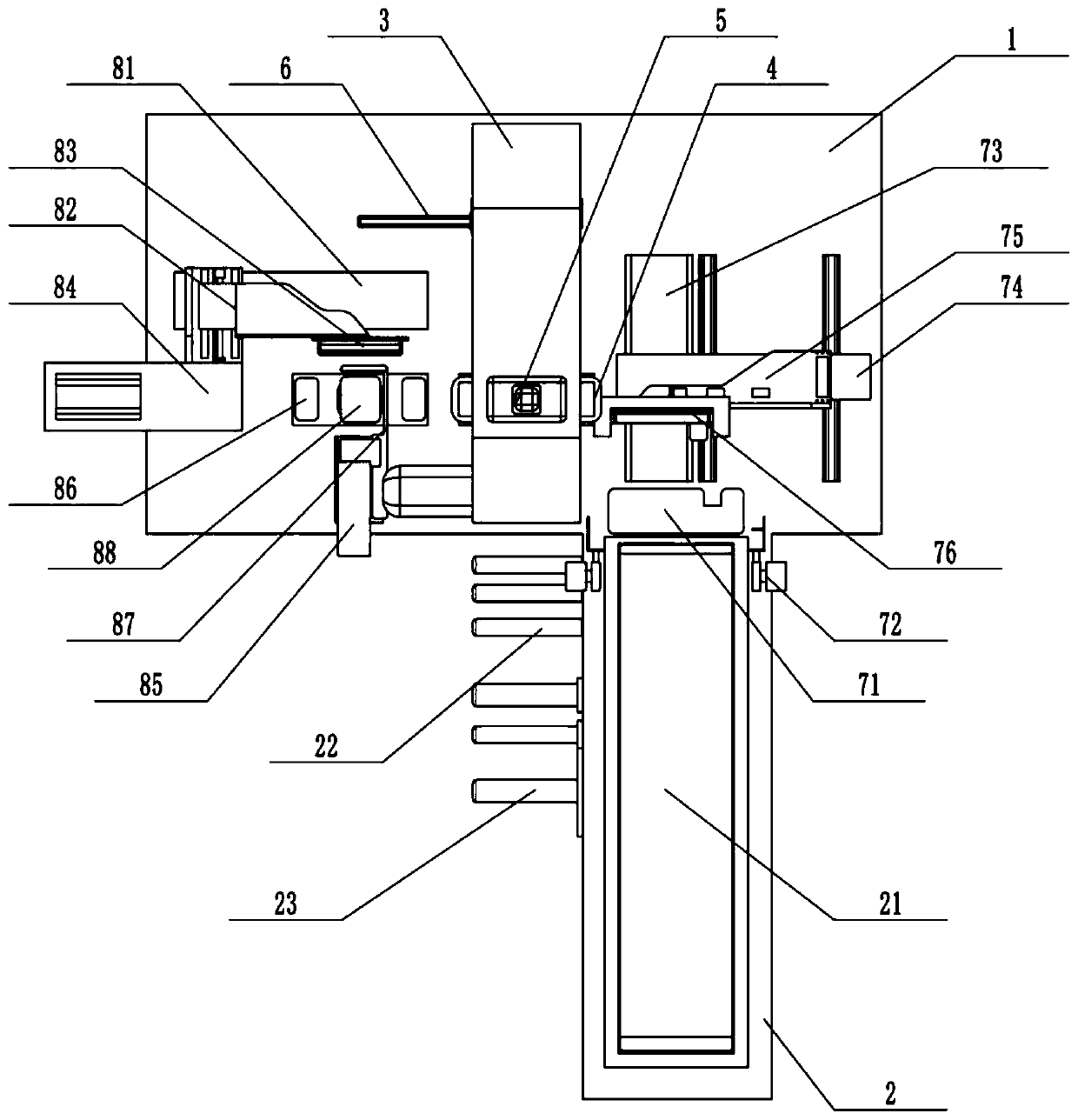

Automatic packaging device for cigarette case cardboard finished product

PendingCN111392121ARealize the purpose of automatic packagingEasy to operatePaper article packagingWrapping material feeding apparatusCardboardConveyor belt

The invention discloses an automatic packaging device for a cigarette case cardboard finished product. The automatic packaging device comprises a machine base, and the device further comprises a packaging mechanism arranged on a machine base, a neat feeding mechanism, a pasting and discharging mechanism, a conveyor belt, a tension adjusting mechanism and a placing roller arranged in the machine base, the machine base comprises a worktable and a transmission table, the packaging mechanism is placed in the upper middle of the worktable, the neat feeding mechanism and the pasting and dischargingmechanism are placed at the two sides of the packaging mechanism at the left and right sides. According to the invention, the automatic packaging device for the cigarette case cardboard finished product can pack cigarette case cardboard stacks placed in the packaging mechanism through the packaging mechanism, the purpose of automatic packaging is achieved, and the actual operation is convenient, the operation of personnel is reduced; and the cigarette case cardboard stacks are placed on the conveyor belt to complete the packaging and transport to the outside; at the same time, the overall operation stability of the equipment is strong, the structure is simple, the maintenance is convenient, the failure rate is low, and the working efficiency is greatly improved.

Owner:GUANGDONG NEW GRAND LONG PACKING CO LTD

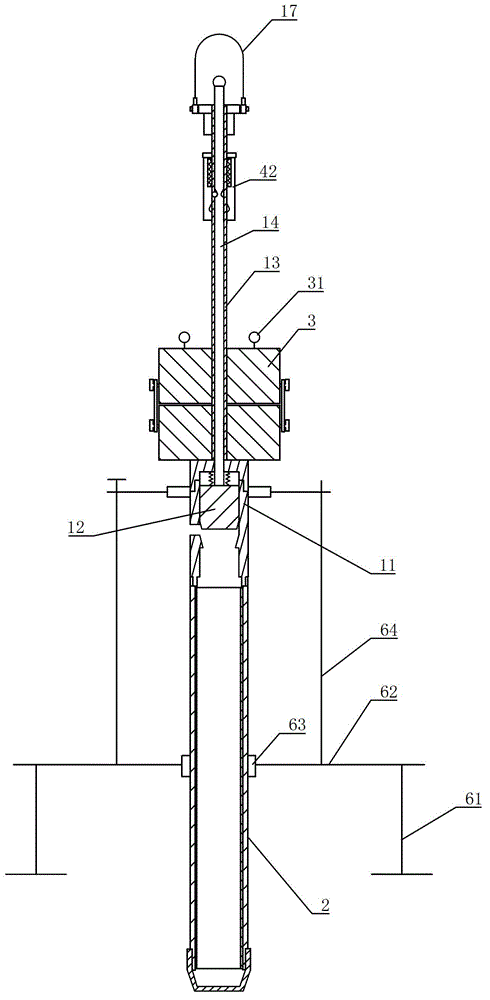

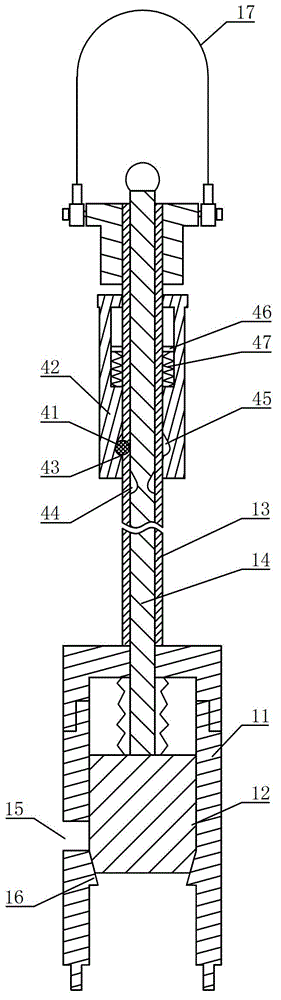

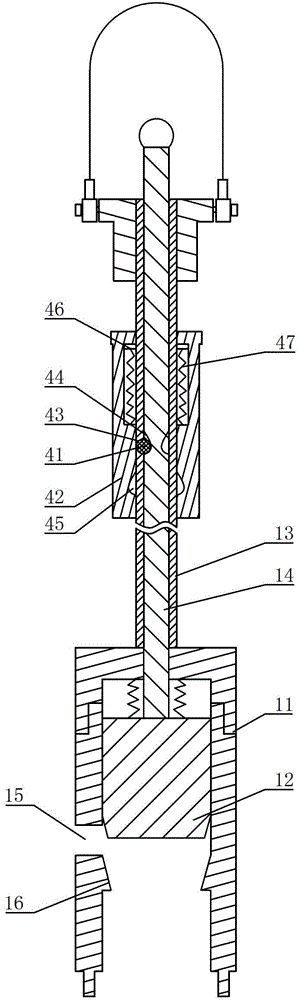

A kind of artificial tamping assisted gravity columnar sediment collector

InactiveCN103411791BIdeal entry depthPrevent slippingWithdrawing sample devicesSample waterOperational stability

The invention relates to a manual ramming assisted gravity type cylindrical sediment collector. The manual ramming assisted gravity type cylindrical sediment collector comprises a blocking mechanism, a counterweight ramming mechanism and a collecting mechanism, the blocking mechanism comprises a sealing plug sleeve, a sealing plug and a pull bar sleeve, the collecting mechanism comprises a collecting tube connected to the bottom of the sealing plug sleeve, the counterweight ramming mechanism comprises a counterweight block movably sleeved outside the pull bar sleeve and positioned between a blocking triggering device and the seal plug sleeve, and the counterweight block comprises a lower portion for ramming the sealing plug sleeve and an upper portion for triggering the blocking device to decrease the seal plug. In the invention, the lower portion of the counterweight block is used to assist the ramming of the sealing plug sleeve to make the collecting tube have an ideal penetration depth in the sediment, so the constant depth collection is realized; the upper portion of the counterweight block is used to trigger the blocking device, and the sealing plug is used to block a channel between a water outlet and the collecting tube, so the manual sealing of the collecting tube is realized, and the falling of the sediment in the rising process of the collecting tube is prevented; and the collector has the advantages of convenient operation, strong operation stability and high collection success rate. The collector can be used for sampling water sediments.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

A garment printing and dyeing sewage treatment process

InactiveCN104724853BSimple processing methodEasy to manageMultistage water/sewage treatmentWaste water treatment from textile industryTextile printerWater quality

The invention discloses a clothing dyeing wastewater treatment process. The process comprises the steps of filtering, decolourizing, performing flocculoreaction, and performing solid-liquid separation, wherein a decolourizing agent A and a decolourizing agent B are added while decolourizing; the decolourizing agent A is prepared from potassium permanganate and polymeric ferric sulfate at a ratio of 1:1, and the decolourizing agent B is prepared from tripolycyanamide, oxalaldehyde and ammonia chloride at a ratio of 10:2:3. The processing method provided by the invention has the characteristics of simple and practical, convenient management, strong operation stability, small maintenance workload, wastewater quality adaption and big moisture change. The processed discharged water quality reaches the Wastewater Pollutants Discharge Standard for Textile Printing Industry.

Owner:YIYANG FUHUI GARMENT CO LTD

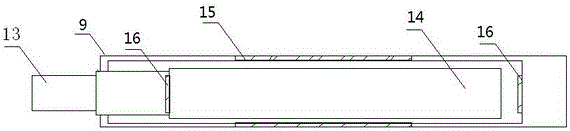

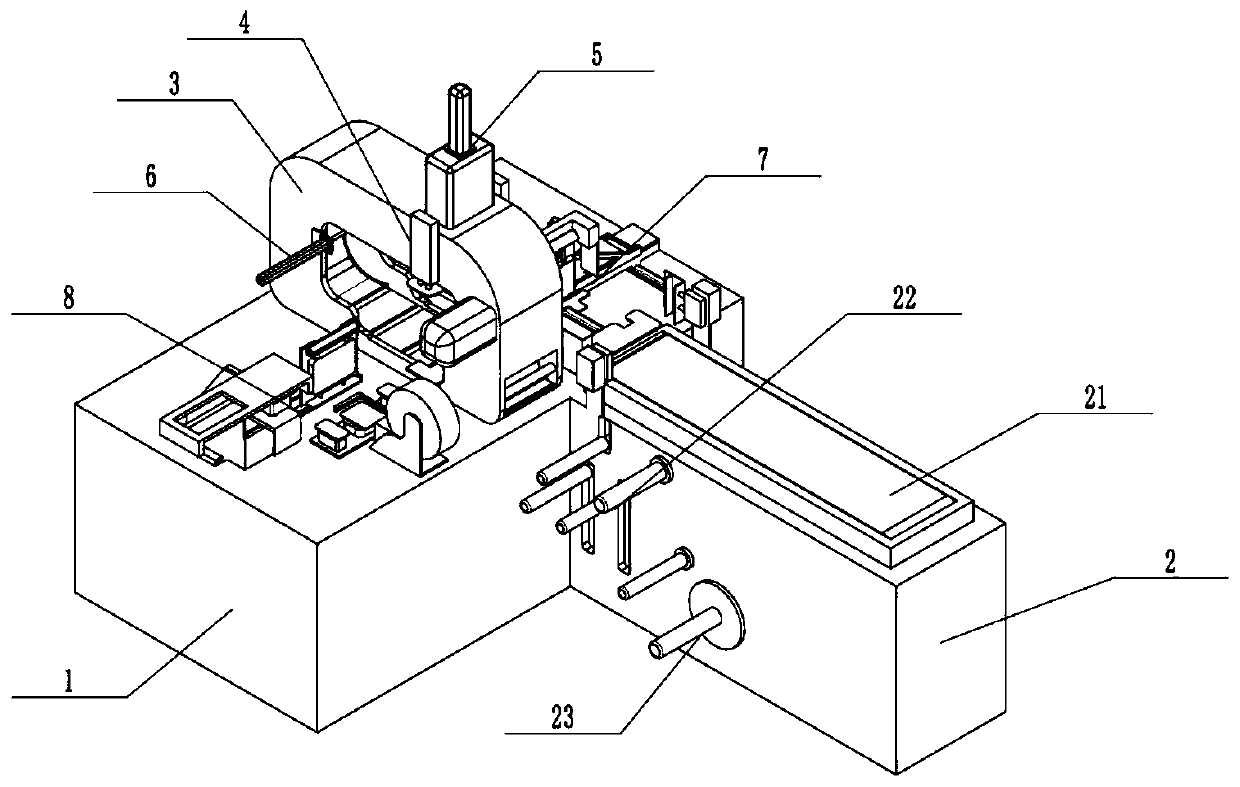

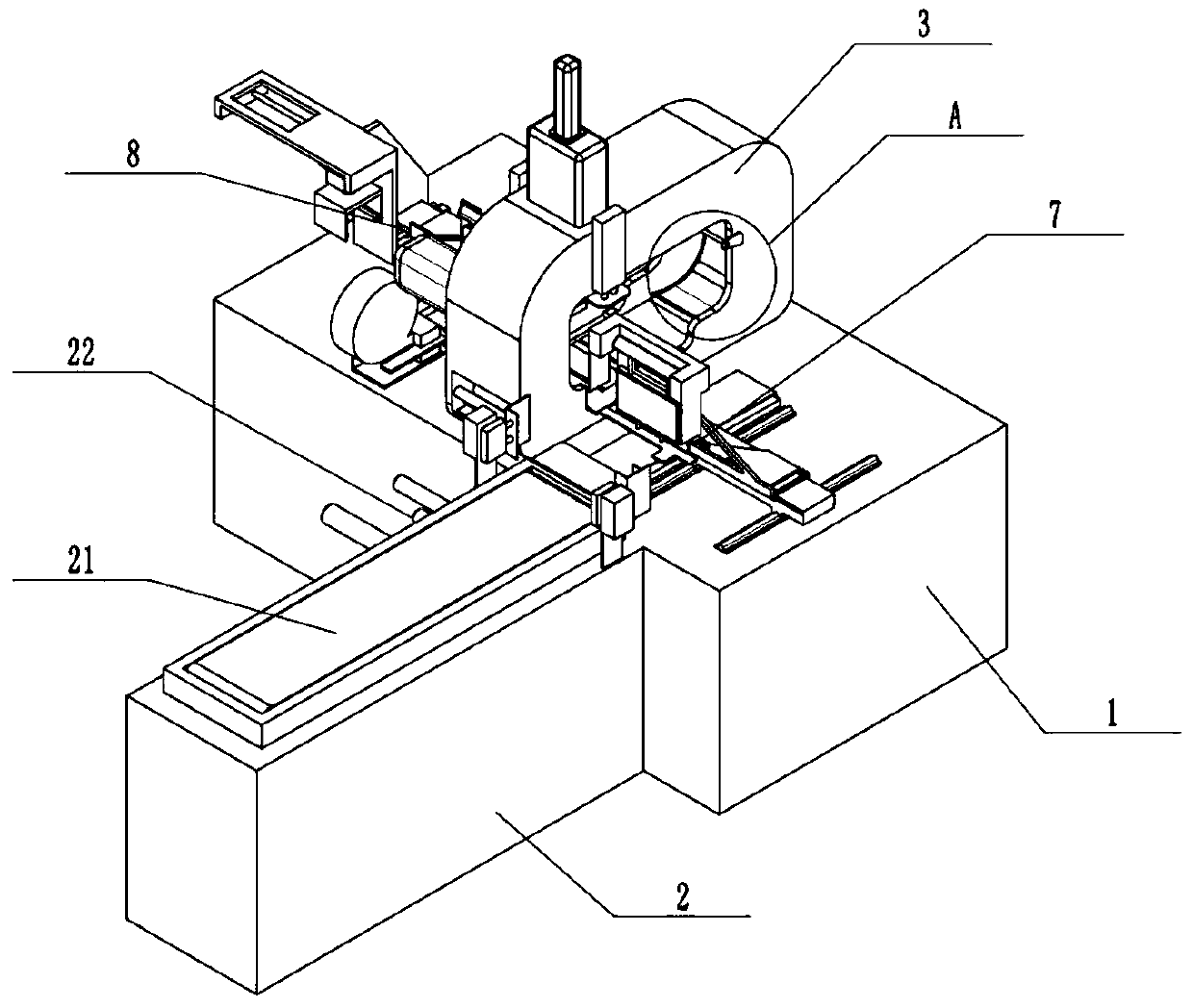

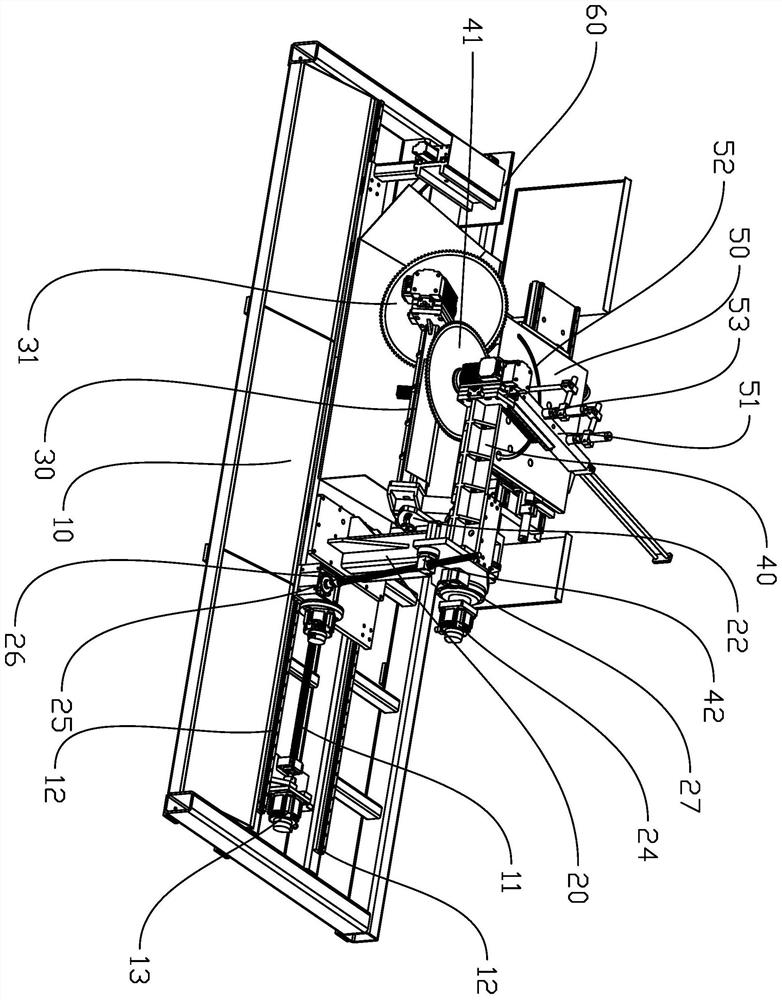

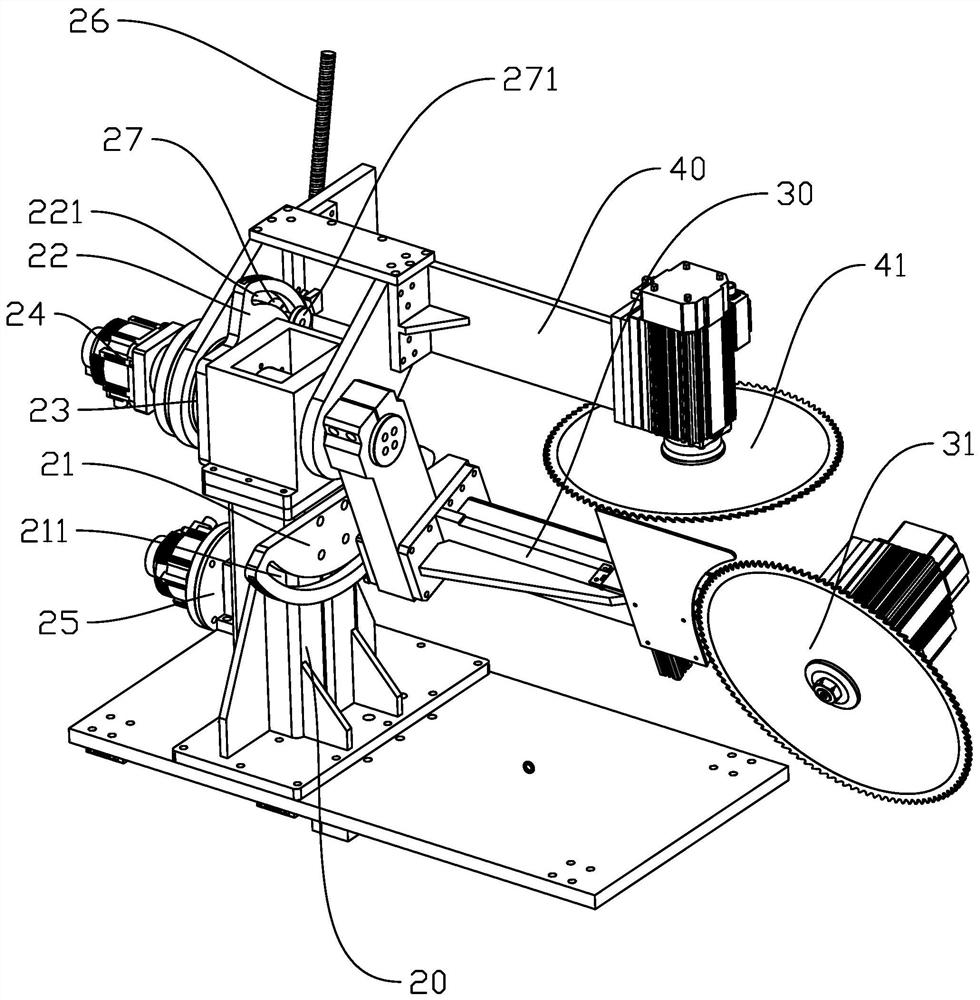

Sectional material cutting machine

The invention discloses a sectional material cutting machine. The sectional material cutting machine comprises a base, a tool apron, a first tool bar, a second tool bar, a workbench, a positioning plate and a feeding device. A first lead screw is arranged on the base, a driving threaded sleeve connected to the first lead screw in a threaded mode is arranged at the bottom of the tool apron, the base and the tool apron are tightly combined through a moving guide groove or a moving guide rail, the first lead screw is driven by a driver to rotate, and therefore the tool apron can stably move alongthe base, the moving range of the tool apron is smaller, and precision is higher. By means of the first tool bar and the second tool bar which are arranged on the tool apron, the angle between the first tool bar and the second tool bar is adjusted before use, so that the angle between a first saw blade and a second saw blade is adjusted, and then a sectional material to be cut is placed on a positioning table to be positioned according to the regulation; and the tool apron moves in the length direction of the base so that the first saw blade and the second saw blade can sequentially cut the sectional material in the transverse direction. Compared with the prior art, in the scheme, the structure is simple, the operation stability is higher, the error is smaller, and the sectional materialcutting effect is better.

Owner:中山市信元铝门窗机械制造有限公司

Method for preparing optically pure 1-(1-naphthyl)ethylamine by resolution of immobilized enzyme

InactiveCN104630322BExtended reaction timeStrong operational stabilityFermentationOrganic solventCross-linked enzyme aggregate

The invention discloses a method for splitting and preparing optically pure 1-(1-naphthyl)ethylamine by an immobilized enzyme method. Selective esterification of ‑1‑(1‑naphthyl)ethylamine followed by separation of (R)‑1‑(1‑naphthyl)ethylamine from (S)‑1‑(1‑naphthyl)ethylamine , to obtain (S)‑1‑(1‑naphthyl) ethylamine, and finally (R)‑1‑(1‑naphthyl) ethylamine ester hydrolysis to obtain (R)‑1‑(1‑naphthyl) Ethylamine. The catalyst used for selective esterification is the cross-linked Candida antarctica lipase B aggregate, which first dissolves Candida antarctica lipase B in water to obtain an enzyme solution, and then uses a precipitant to precipitate the enzyme protein from the enzyme solution Come out, then add a bifunctional cross-linking agent for cross-linking, and finally dry it. The cross-linked enzyme aggregate of the invention has high reutilization rate and strong operation stability in pure organic solvent.

Owner:南京普瑞特生物科技有限公司

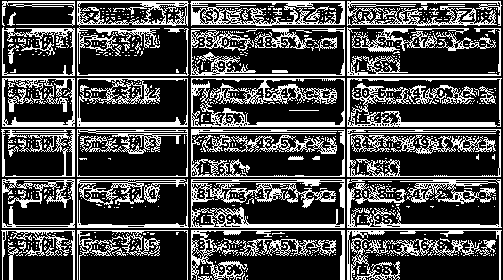

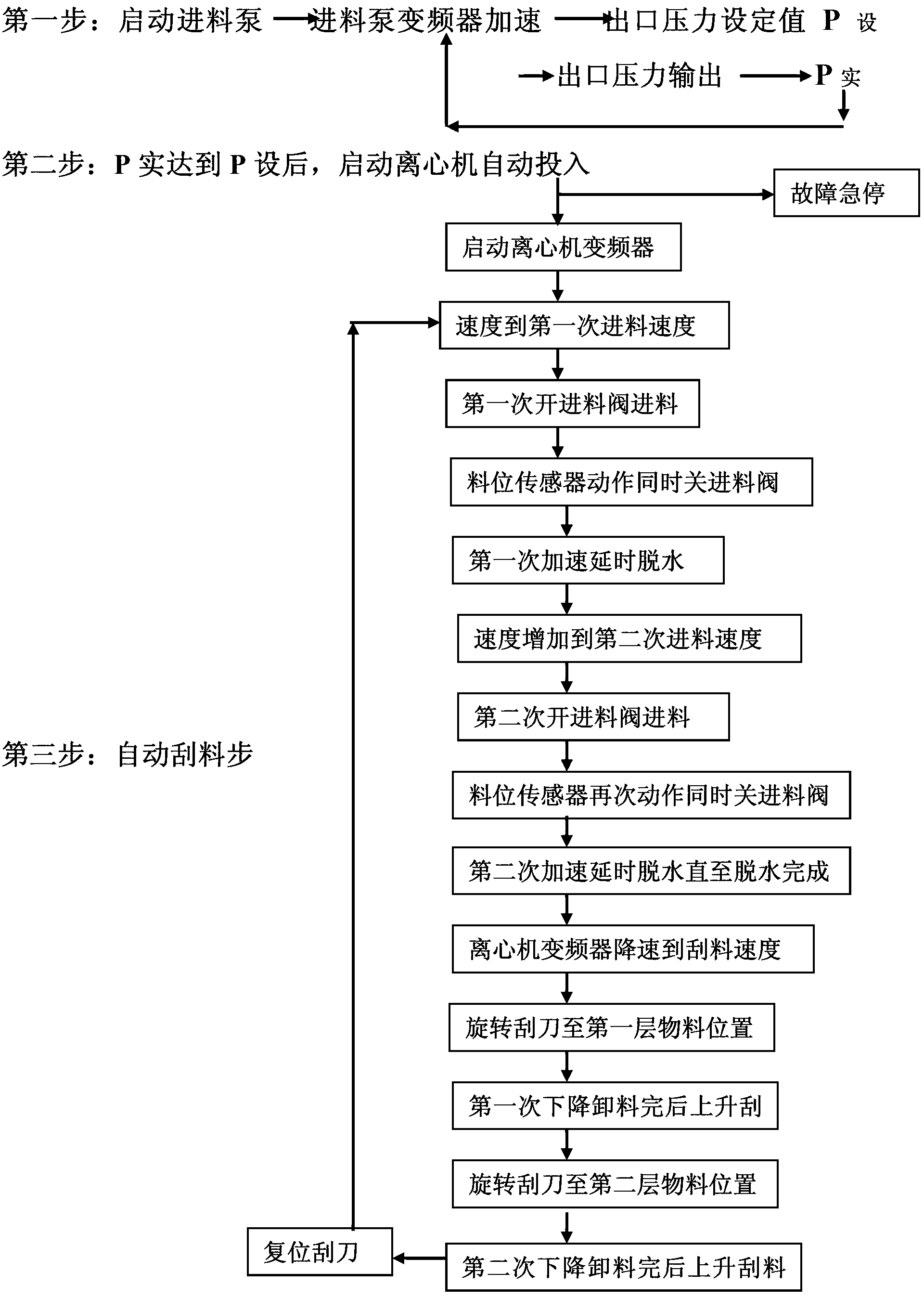

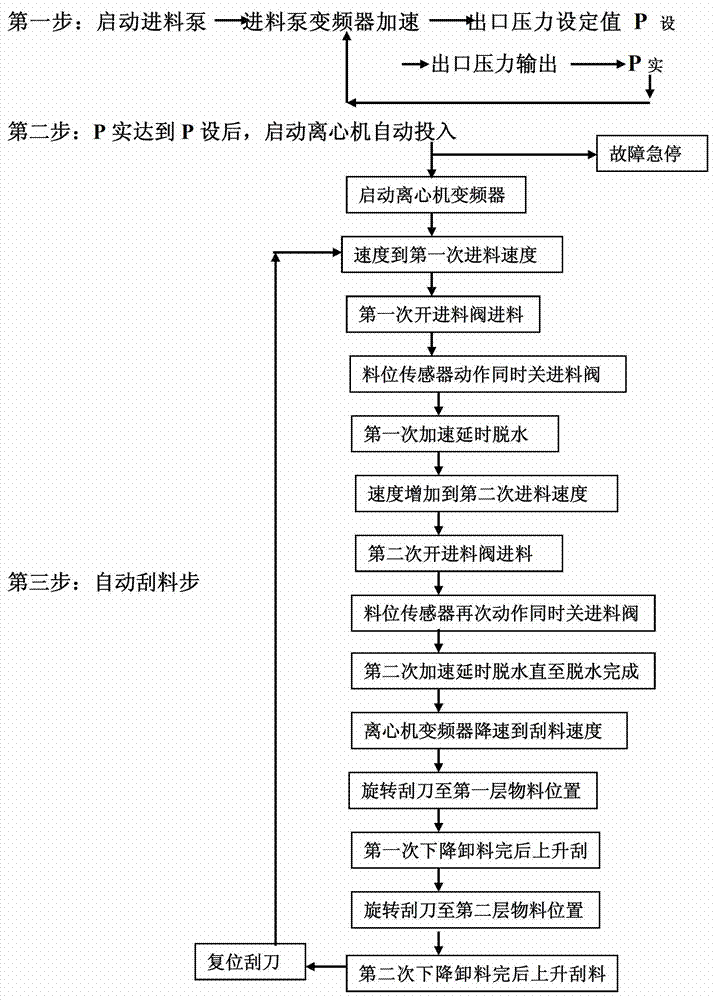

Process for conducting dehydration control on white clay calcium carbonate

InactiveCN103230840ARealize multi-stage dehydrationRealize centralized monitoringCalcium/strontium/barium carbonatesChemical industryEngineeringElectromagnetic valve

The invention relates to a dehydrating process, in particular to a process for conducting full-automatic dehydration control on white clay calcium carbonate. The process uses a distributed control system (DCS) to control a centrifugal machine to conduct full-automatic dehydration control on the white clay calcium carbonate and includes three steps of multi-time feeding, dehydration at different speeds and gradual material scraping. Devices required by feeding are controlled through DCS control configuration software respectively, a frequency conversion feeding pump motor and a pneumatic feeding adjusting valve in feeding are controlled, and a motor and valve control function block is programmed through control software. During dehydration, the DCS controls the frequency conversion dehydration motor directly to conduct speed adjusting. During material scraping, movement of a pneumatic cylinder is achieved through control of the DCS on an electromagnetic valve, so that a material scraper can scrape materials back and forth for a plurality of times. Whole-course monitoring and control are conducted through a step sequence mode in the whole process, an automation degree is high, centralized monitoring is achieved, labor production efficiency is high, operation stability and accuracy are high, product quality is high, and labor intensity is greatly reduced compared with a traditional control method.

Owner:BEIJING ALTERMODE ENVIRONMENTAL TECH

Resin-enzyme composite catalyst and preparation method thereof

InactiveCN102174499AGood anti-leakage performanceStrong resistance to leachingHydrolasesOn/in organic carrierIonic strengthPhosphate

The invention discloses a resin-enzyme composite catalyst and a preparation method thereof, belonging to the field of composite materials. The method comprises the following steps: dissolving a target enzyme in a phosphate buffer with pH value being neutral so as to obtain a solution A with concentration of 0.2mg / mL-10mg / mL; selecting a suitable large-hole type ion exchange resin as a carrier according to isoelectric points of an enzyme molecule; mixing and stirring the solution A and the resin carrier at room temperature; and taking out the resin, washing the surface of the resin by utilizing the phosphate buffer and drying the resin to obtain the resin-enzyme composite catalyst. The preparation method provided by the invention has the advantages of simplicity in operation, easiness in control and less loss of enzymatic activity; the fixed-load enzyme composite catalyst prepared by the method provided by the invention ensures that the stability of ordinary enzyme is greatly improved on the basis of maintaining the original catalytic activity of the enzyme molecules, can be applied to a water phase system and has the characteristic of good leaching-resisting property within a wide pH range and under high ionic strength.

Owner:NANJING UNIV

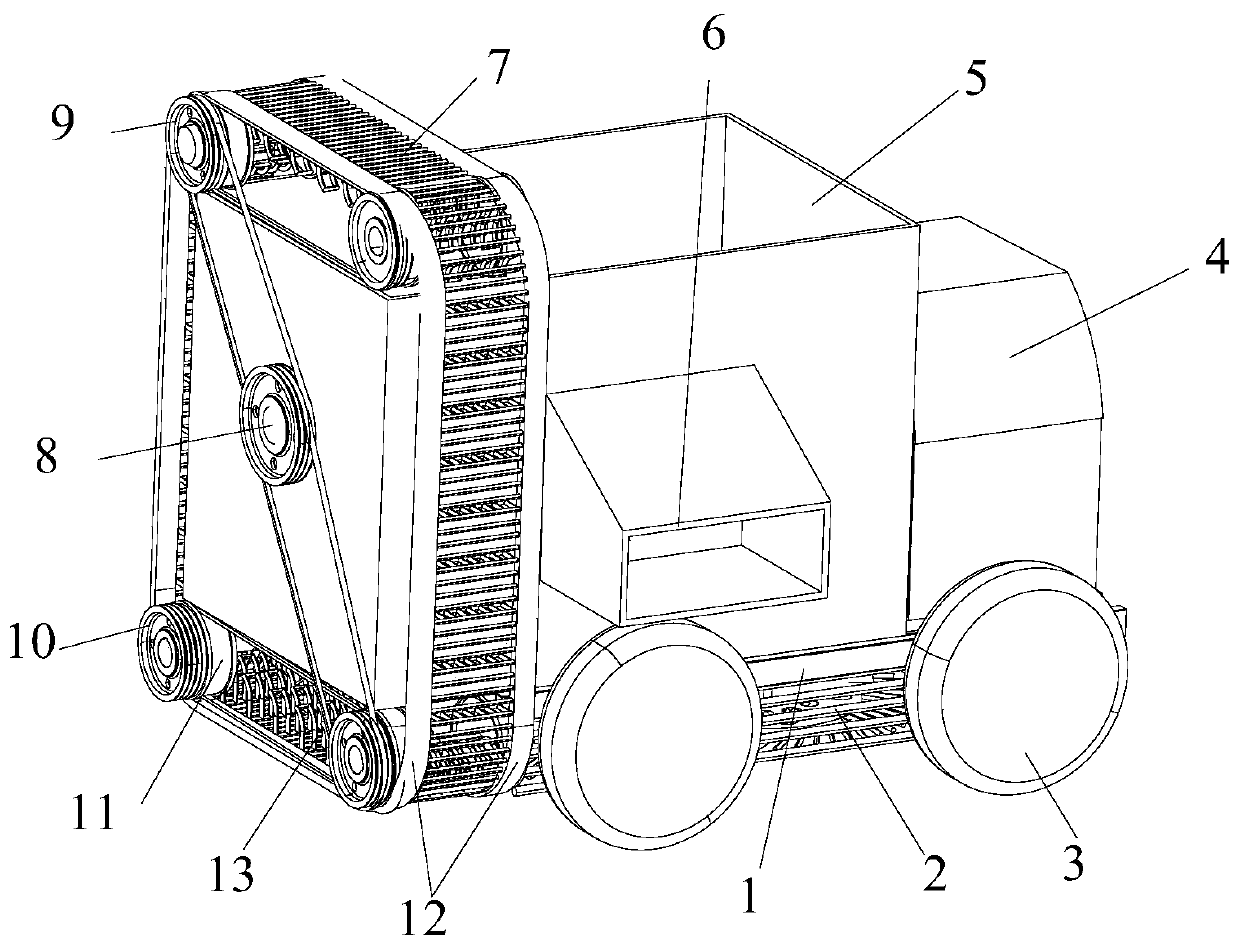

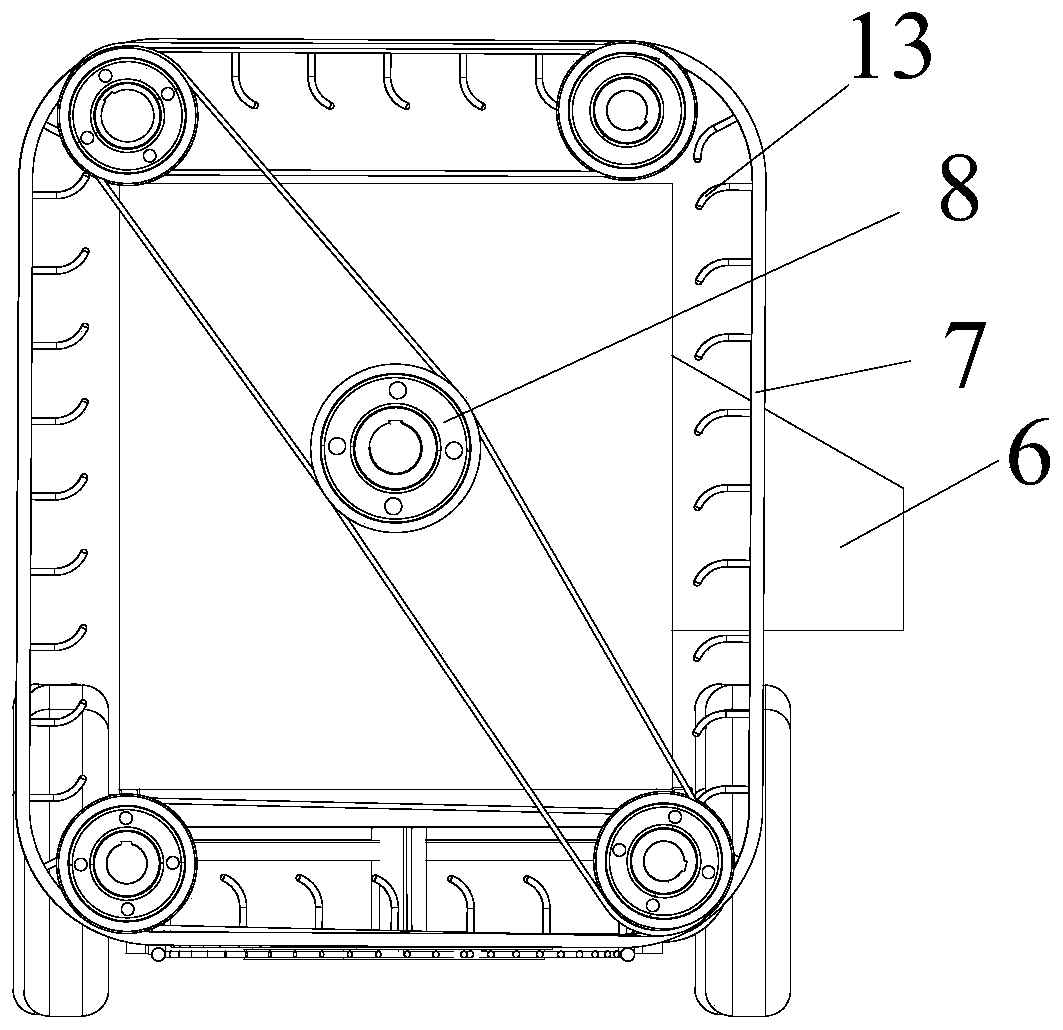

Sugar beet picking-up, loading and unloading machine

PendingCN110419314AGood digging qualityCarrying a small amount of soilLoadersLiftersSugarMechanical engineering

The invention discloses a sugar beet picking-up, loading and unloading machine which comprises a frame, a conveying and cleaning device and a lifting device. The frame is provided with traveling mechanisms and a carriage, the conveying and cleaning device is arranged on the lower portion of the carriage and comprises a picking-up frame, fences and at least two rotatable finger plates, the liftingdevice comprises a circular lifting chain, the circular lifting chain is arranged around the rear of the carriage and used for carrying sugar beets, so that the sugar beets are lifted along with rotation of the circular lifting chain and automatically fall off when being lifted to the top of the carriage, the conveying and cleaning device is used for picking up and cleaning sugar beets in a land then conveying the sugar beets to the lifting device, and the lifting device is used for lifting the sugar beets from the rotatable finger plates to the top of the carriage, so that the sugar beets fall into the carriage. According to the sugar beet picking-up, loading and unloading machine, by the aid of a conveying and cleaning mode combined a china-type lifting device with a disc conveying and cleaning device, soil removing, conveying, lifting and collecting of the sugar beets can be completed once, digging quality of the rotatable finger plates and the picking-up frame is good, soil carrying amount is less, the sugar beets are effectively improved, and weeds cannot be easily wound and hung.

Owner:JIESHOU XINYANG ELECTROMECHANICAL

Sewage treatment device and method for garment production process

PendingCN108101318AImprove biodegradabilityImprove removal efficiencyTreatment using aerobic processesSpecific water treatment objectivesSewageFilter press

The invention discloses a sewage treatment device for the garment production process. The sewage treatment device includes a grit chamber, a grid basin, a regulation tank, a hydrolysis acidification tank, a first aerobic tank, an oxidation ditch, a second aerobic tank, a sedimentation tank, a fan, a disinfection tank, a sludge tank and a filter press, wherein the sand basin, the grid basin, the regulation tank, the hydrolysis acidification tank, the first aerobic tank, the oxidation ditch, the second aerobic tank, the sedimentation tank, the fan and the disinfection tank are connected by a conveying pipeline in order, the sludge tank is connected to a sludge inlet of the filter press through a sludge pipeline, the air outlet of the fan is connected to a ventilation pipeline, and the firstaerobic tank, the oxidation ditch and the second aerobic tank are all internally equipped with aeration pipes introduced to the bottoms thereof. The sewage treatment device and method provided by theinvention can effectively improve the removal efficiency of sewage pollutants, runs stably, has good impact resistant load and high degradation efficiency, saves the treatment cost, also is simple andpractical, and is convenient for management.

Owner:HUNAN UNIV OF ARTS & SCI

Candida Antarctica lipase B gene and applications thereof in yeast display

ActiveCN101565713BIncrease vitalityImprove catalytic performanceFungiBiofuelsEscherichia coliEnzyme Gene

The invention relates to candida Antarctica lipase B gene and applications thereof in yeast display. Coded protein of improved candida Antarctica B and wild type candida Antarctica lipase protein havethe same function on the amino acid level; the heat resistance capacity of the enzyme is 50-80 DEG C, and the half-lift is 3-24 hours; a nucleotide sequence is hybridized with SEQ.ID.NO2 from 1st to978th of nucleotide under the moderate precise condition; and a preservation number of colon bacillus DH5Alpha / Puc57-CALB (Escherichia coliDH5Alpha / pUC57-CALB) which carries the plasmids is CCTCC M 209081. The candida Antarctica lipase B gene is transferred into pichia pastoris host bacteria so as to realize the high-efficient display expression of the candida Antarctica lipase B in pichia pastoris; and the provided pichia pastoris bacteria can effectively display candida Antarctica lipase B, can be widely applied to the synthesis of ethyl caproate, has different melting points and does not contain triglyceride of various fatty acids, a plurality of structured lipids, and the like.

Owner:SOUTH CHINA UNIV OF TECH

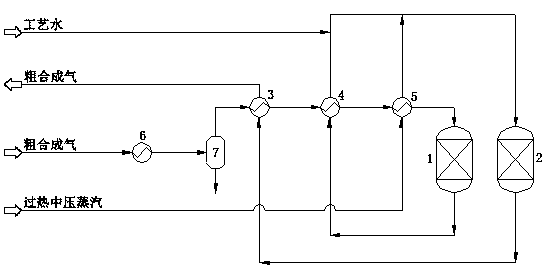

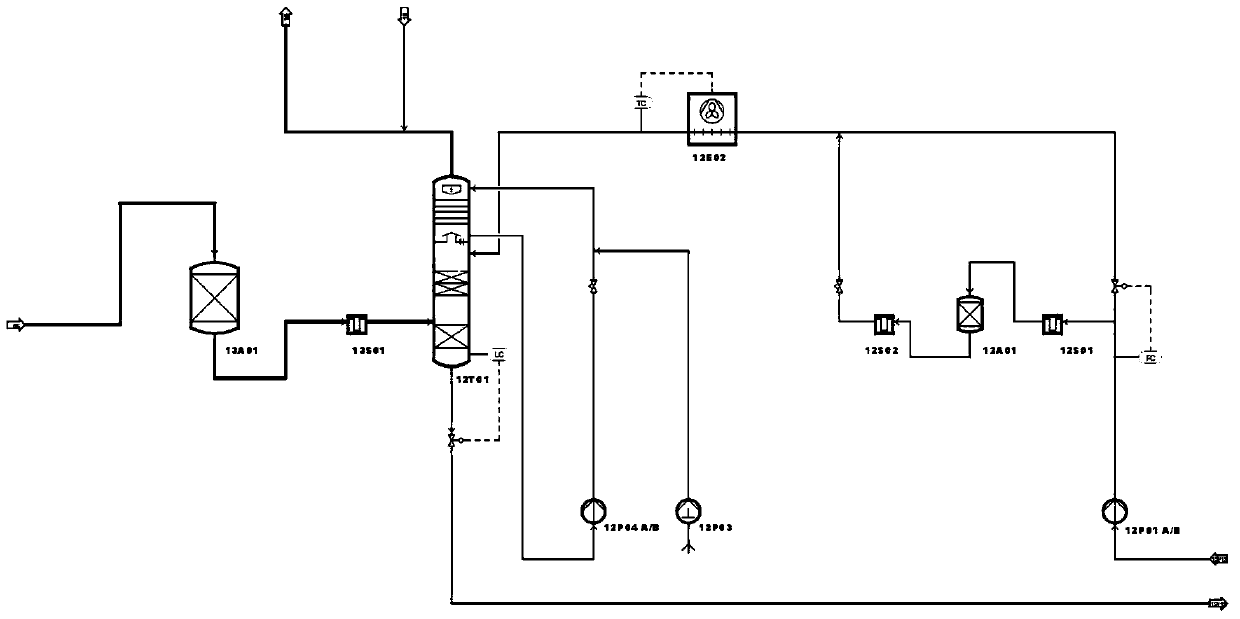

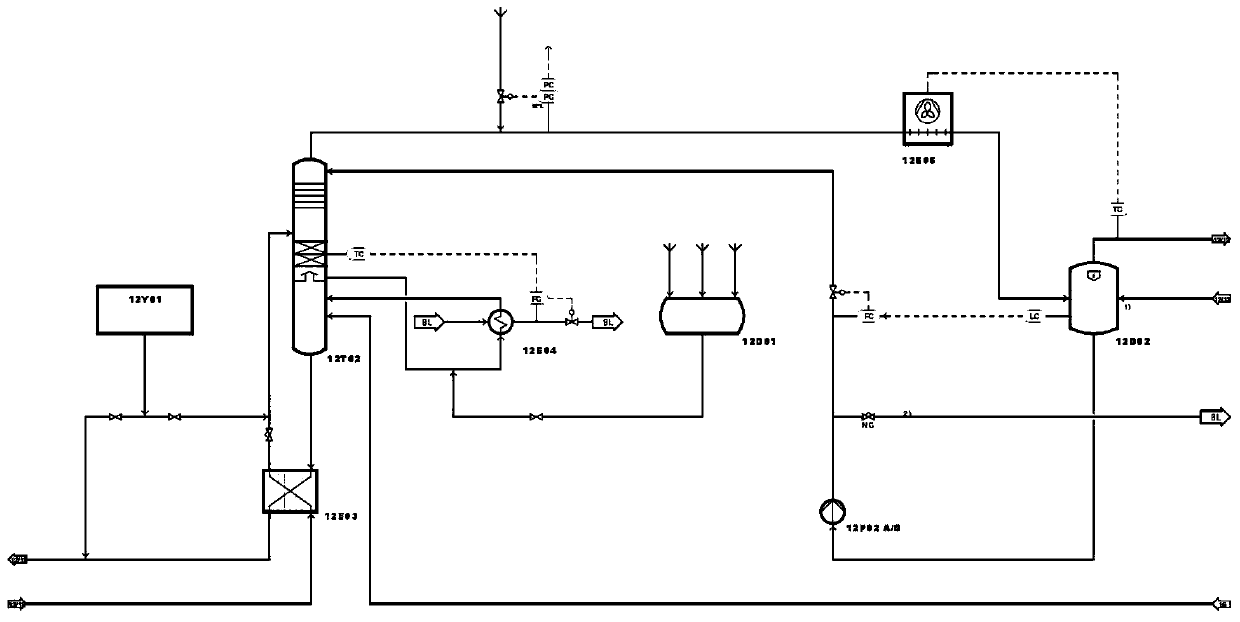

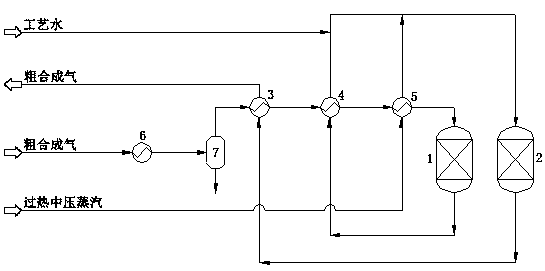

A device and process for converting multi-component complex organic sulfur in crude synthesis gas into hydrogen sulfide

ActiveCN109181784BSimplify plant-wide processesIncrease the depth of conversion equilibrium reactionGas treatmentDispersed particle separationHydrogenation reactionPhysical chemistry

The invention discloses a device and a method used for converting multi-component complex organic sulfur in crude synthetic gas into hydrogen sulfide. The device comprises a high temperature hydrogenation reactor, a low temperature hydrolysis reactor, a steam content adjusting assembly, and a heating assembly; the steam content adjusting assembly is used for controlling steam content of crude synthetic gas introduced into the device; the heating assembly is used for heating crude synthetic gas introduced into the high temperature hydrogenation reactor; the crude synthetic gas is introduced into the high temperature hydrogenation reactor and the low temperature hydrolysis reactor successively for conversion treatment. According to the method, the crude synthetic gas is subjected to direct organic sulfur conversion, hydrogen sulfide removing pre-treatment is not needed, the whole process is simplified; high temperature hydrogenation and low temperature hydrolysis combined organic sulfuris adopted, high temperature is beneficial for treatment of composite organic sulfides such as thiophene, thioether, and mercaptan, low temperature is beneficial for increasing of organic sulfur conversion balance reaction depth, so that the whole organic sulfur conversion rate is increased.

Owner:CHINA CHENGDA ENG

A coal bed gas liquefaction process

ActiveCN105865145BShorten the liquefaction processSimple processSolidificationLiquefactionRefrigerantPre cooling

The invention discloses a coalbed methane liquefaction process. A feeding unit, a mercury removing unit, a CO2 removing unit, a drying unit, a liquefaction unit, a refrigerant circulation unit, a refrigerant supplementing unit, a storage unit, a storage tank return gas compression unit, a hot oil unit and a torch unit are included. The feeding unit is sequentially connected with the mercury removing unit, the CO2 removing unit, the drying unit, the liquefaction unit and the storage unit; the liquefaction unit is pre-cooled, liquefied and supercooled through the refrigerant circulation unit; refrigerants are supplemented to the refrigerant circulation unit through the refrigerant supplementing unit; and the storage tank return gas compression unit is connected with the storage unit.

Owner:JINCHENG HUAGANG GAS CO LTD

Sewage treatment device and sewage treatment method in garment production process

InactiveCN111115945AImprove removal efficiencyGuaranteed uptimeWater treatment parameter controlSludge treatmentSewageFilter press

Owner:江苏达摩信息咨询有限公司

Device and method used for converting multi-component complex organic sulfur in crude synthetic gas into hydrogen sulfide

ActiveCN109181784ASimplify plant-wide processesIncrease the depth of conversion equilibrium reactionGas treatmentDispersed particle separationPre treatmentHydrolysis

The invention discloses a device and a method used for converting multi-component complex organic sulfur in crude synthetic gas into hydrogen sulfide. The device comprises a high temperature hydrogenation reactor, a low temperature hydrolysis reactor, a steam content adjusting assembly, and a heating assembly; the steam content adjusting assembly is used for controlling steam content of crude synthetic gas introduced into the device; the heating assembly is used for heating crude synthetic gas introduced into the high temperature hydrogenation reactor; the crude synthetic gas is introduced into the high temperature hydrogenation reactor and the low temperature hydrolysis reactor successively for conversion treatment. According to the method, the crude synthetic gas is subjected to direct organic sulfur conversion, hydrogen sulfide removing pre-treatment is not needed, the whole process is simplified; high temperature hydrogenation and low temperature hydrolysis combined organic sulfuris adopted, high temperature is beneficial for treatment of composite organic sulfides such as thiophene, thioether, and mercaptan, low temperature is beneficial for increasing of organic sulfur conversion balance reaction depth, so that the whole organic sulfur conversion rate is increased.

Owner:CHINA CHENGDA ENG

Hollow polysaccharide microsphere immobilized enzyme and preparation method thereof

InactiveCN101643727BIncrease enzyme activityImprove stabilityOn/in organic carrierOn/in biological cellYeastMicrosphere

The invention discloses a hollow polysaccharide microsphere immobilized enzyme and a preparation method thereof. The hollow polysaccharide microsphere immobilized enzyme comprises enzyme and a carrier, wherein the carrier is hollow polysaccharide microsphere; and the preparation method of the hollow polysaccharide microsphere comprises the steps of carbonizing yeast in liquid at a constant temperature and obtaining the hollow polysaccharide microsphere, wherein the constant temperature is any temperature from 150 to 240 DEG C. The invention also discloses a preparation method for the hollow polysaccharide microsphere immobilized enzyme. The hollow polysaccharide microsphere immobilized enzyme prepared by the method has a wide raw material source for preparing the carrier, and is simple and easy in technology of carrier preparation, surface modification and enzyme immobilization; in addition, the carrier is characterized by high specific surface area, large inner space, rich surface functional groups, good biocompatibility and the like.

Owner:CHINA AGRI UNIV

Process for conducting dehydration control on white clay calcium carbonate

InactiveCN103230840BRealize multi-stage dehydrationRealize centralized monitoringCalcium/strontium/barium carbonatesChemical industryElectromagnetic valveCalcium carbonate

The invention relates to a dehydrating process, in particular to a process for conducting full-automatic dehydration control on white clay calcium carbonate. The process uses a distributed control system (DCS) to control a centrifugal machine to conduct full-automatic dehydration control on the white clay calcium carbonate and includes three steps of multi-time feeding, dehydration at different speeds and gradual material scraping. Devices required by feeding are controlled through DCS control configuration software respectively, a frequency conversion feeding pump motor and a pneumatic feeding adjusting valve in feeding are controlled, and a motor and valve control function block is programmed through control software. During dehydration, the DCS controls the frequency conversion dehydration motor directly to conduct speed adjusting. During material scraping, movement of a pneumatic cylinder is achieved through control of the DCS on an electromagnetic valve, so that a material scraper can scrape materials back and forth for a plurality of times. Whole-course monitoring and control are conducted through a step sequence mode in the whole process, an automation degree is high, centralized monitoring is achieved, labor production efficiency is high, operation stability and accuracy are high, product quality is high, and labor intensity is greatly reduced compared with a traditional control method.

Owner:BEIJING ALTERMODE ENVIRONMENTAL TECH

Improved Rhizomucor miehei lipase gene and use thereof in yeast display

InactiveCN101481695BIncrease vitalityImprove catalytic performanceMicroorganism based processesGenetic engineeringEscherichia coliEnzyme Gene

The invention relates to an improved rhizomucor miehei lipase gene and an application to yeast display. The sequence of the improved rhizomucor miehei lipase gene is SEQ.ID.No2, with respect to a recombinant vector pMD18-T-RML containing the gene, RML means lipase gene; and the collection number of a bacterial strain Escherichia coli TOP10 / pMD18-T-RML carrying the plasmid is CCTCC M 208136. In the invention, the gene is transferred into pichia stipitis host strain, so that the rhizomucor miehei lipase is displayed and expressed in the pichia stipitis. The provided pichia stipitis can effectively display the rhizomucor miehei lipase. The lipase can be widely applicable for producing fatty acid methyl ester, ethyl caproate, triglycerides which have different melting points but does not contain various types of fatty acid and a few 'reconstructed esters'.

Owner:DONGGUAN HUAQI BIOLOGICAL SCI & TECH +1

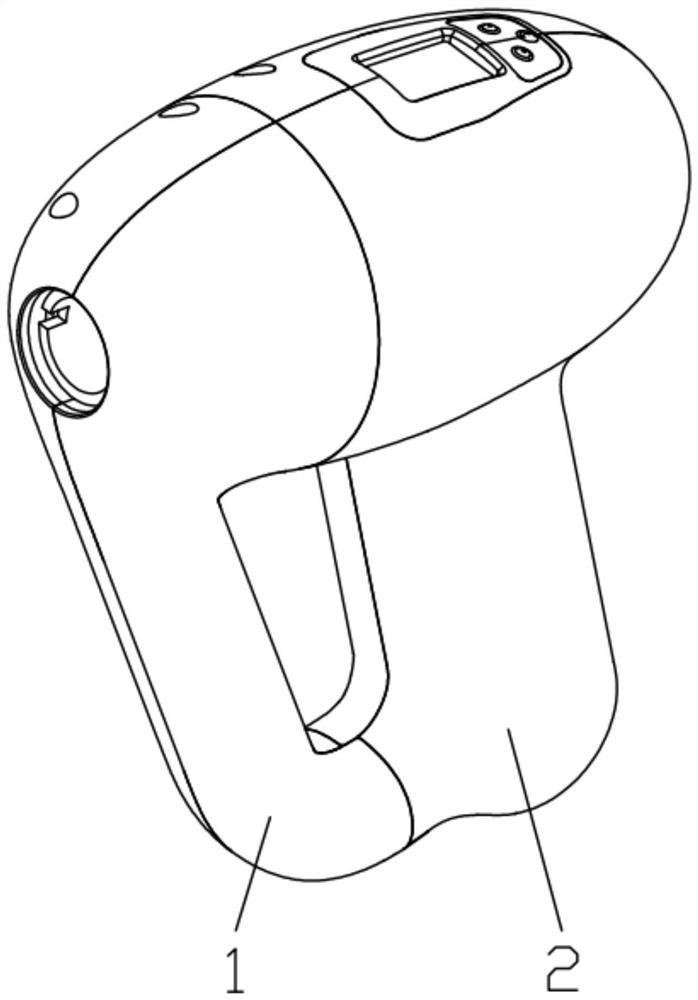

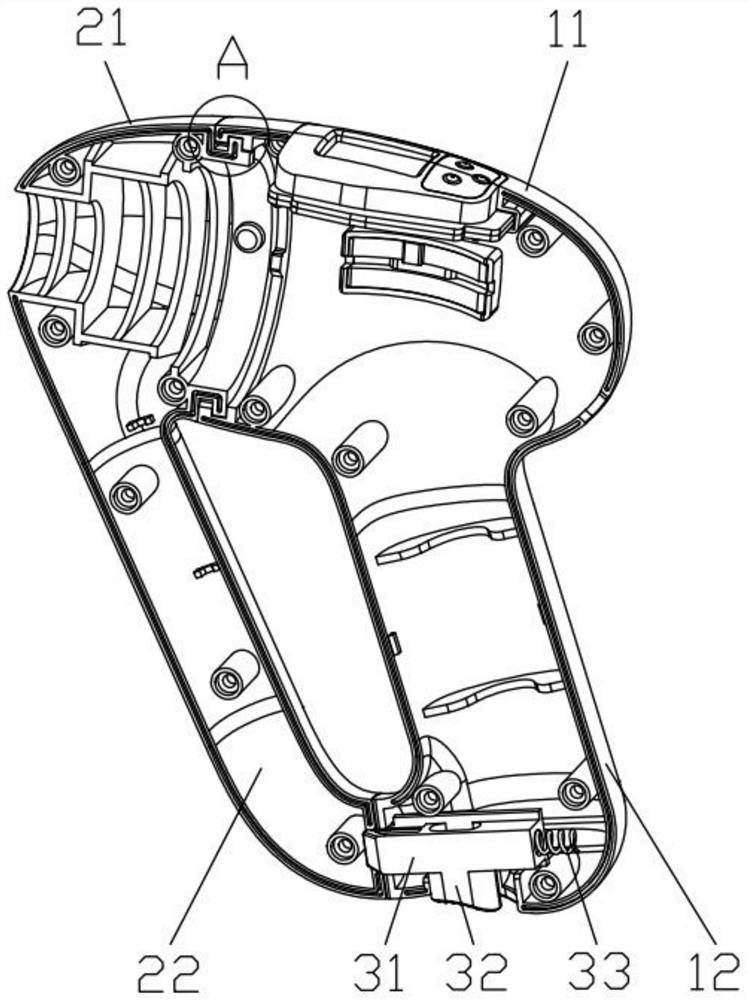

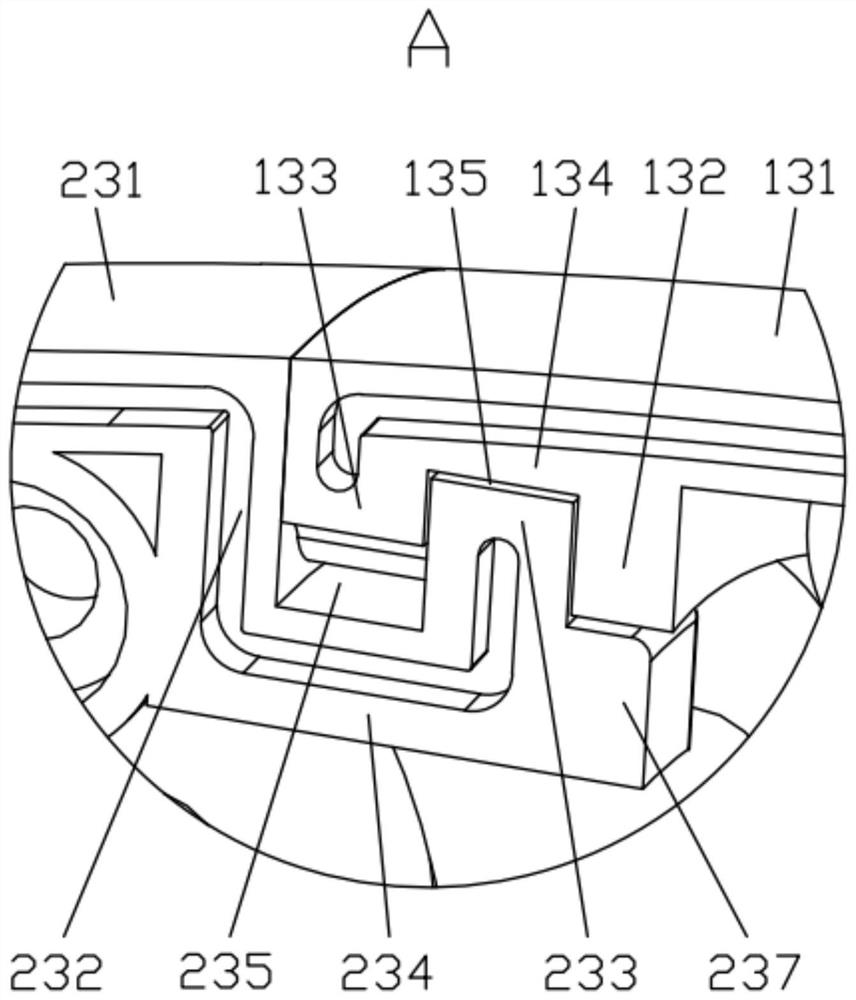

Massager shell, massager bracket and massager

ActiveCN110612003BGood massagePrevent rotationClosed casingsCasings/cabinets/drawers detailsStructural engineeringMechanical engineering

Owner:SUZHOU WIN TECH TOOLS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com