Conveying control method applicable to small part transportation

A technology for conveying control and parts, applied in the field of conveying control of small parts transportation, can solve problems such as inability to be widely used, and efficient conveying, and achieve the effect of simplifying the control method, preventing position deviation, and stabilizing the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

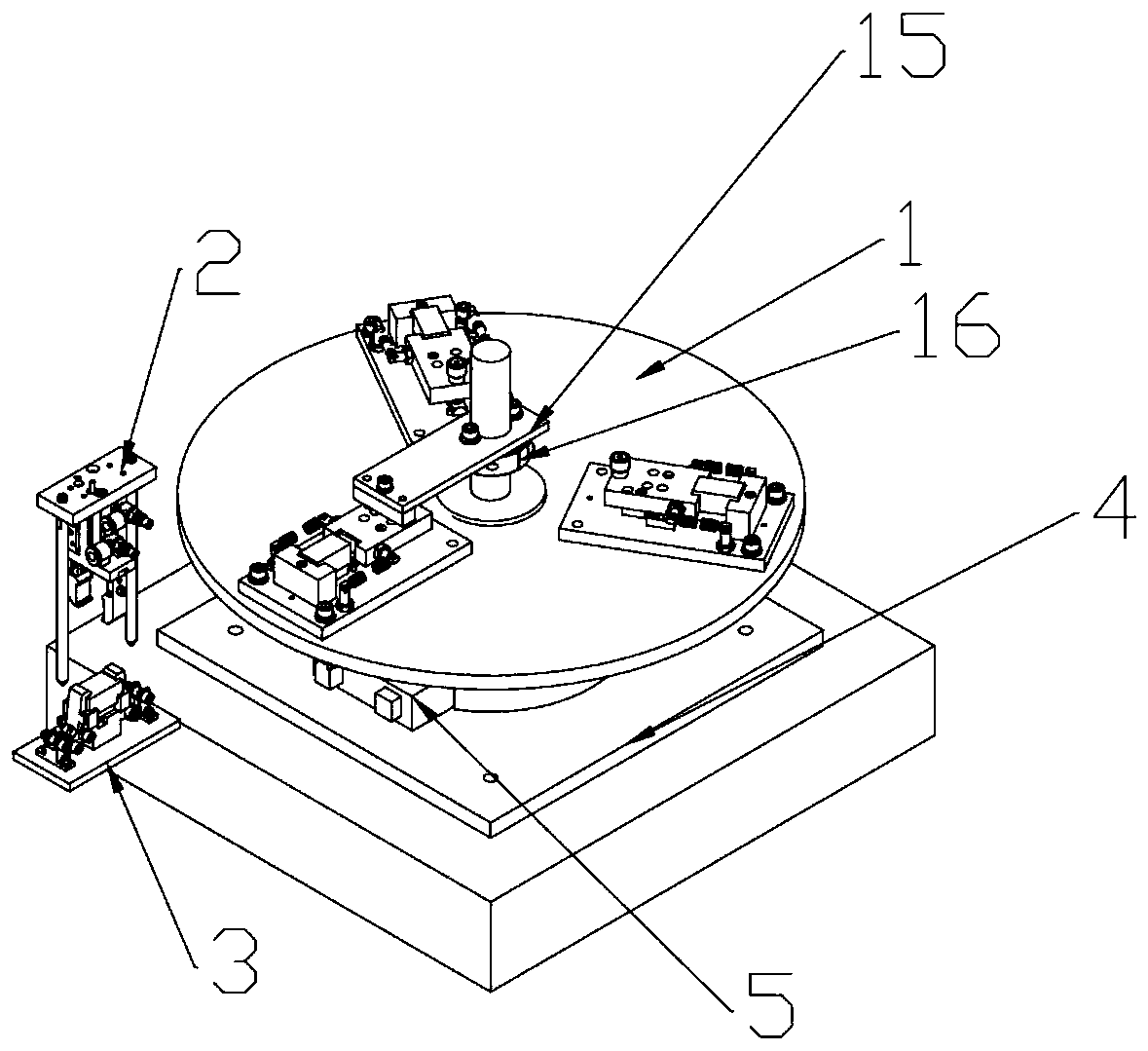

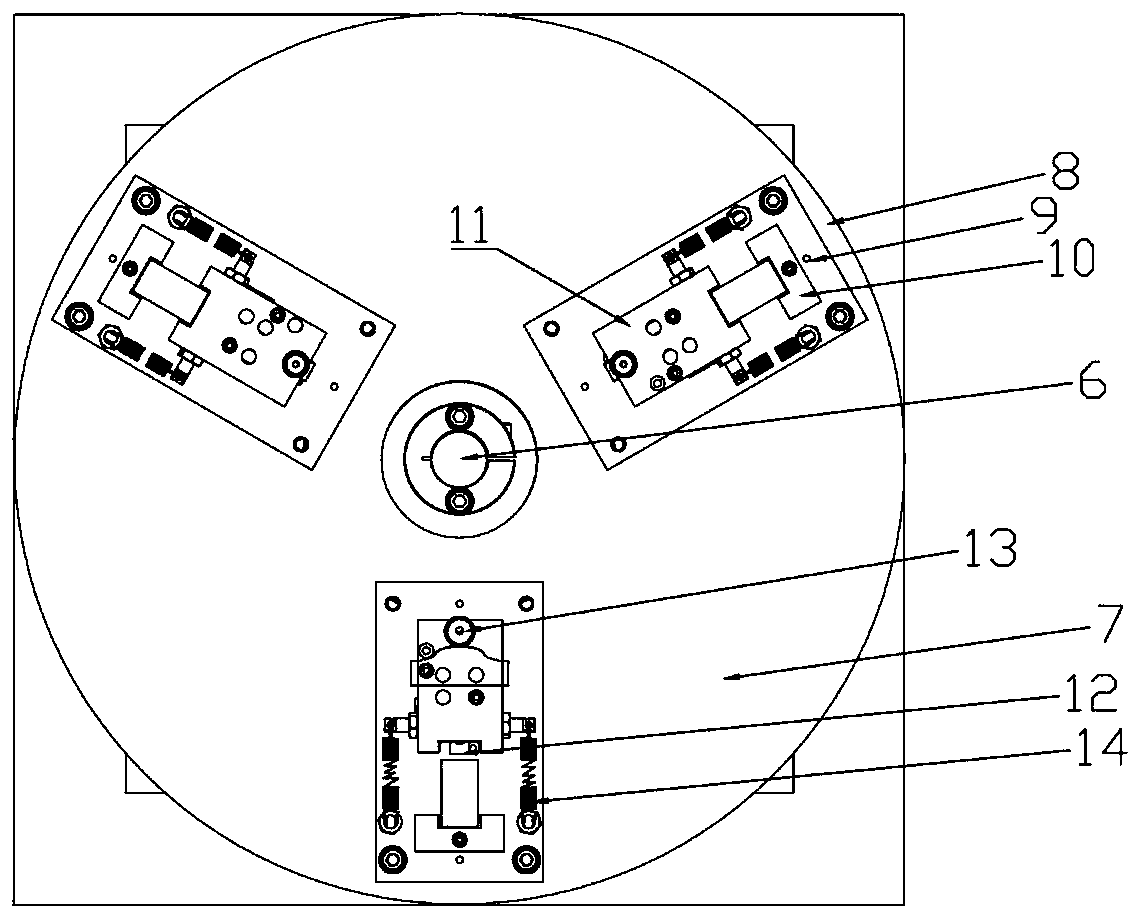

[0031] Firstly, the position of the intermittent rotating mechanism is calibrated. The motor drives the turntable to rotate intermittently. When it is fixed on the turntable and stops rotating intermittently, the cam bearing on the turntable is just located in the middle of the guide part of the cam plate, that is, the cam shape of the guide part The highest point in the middle.

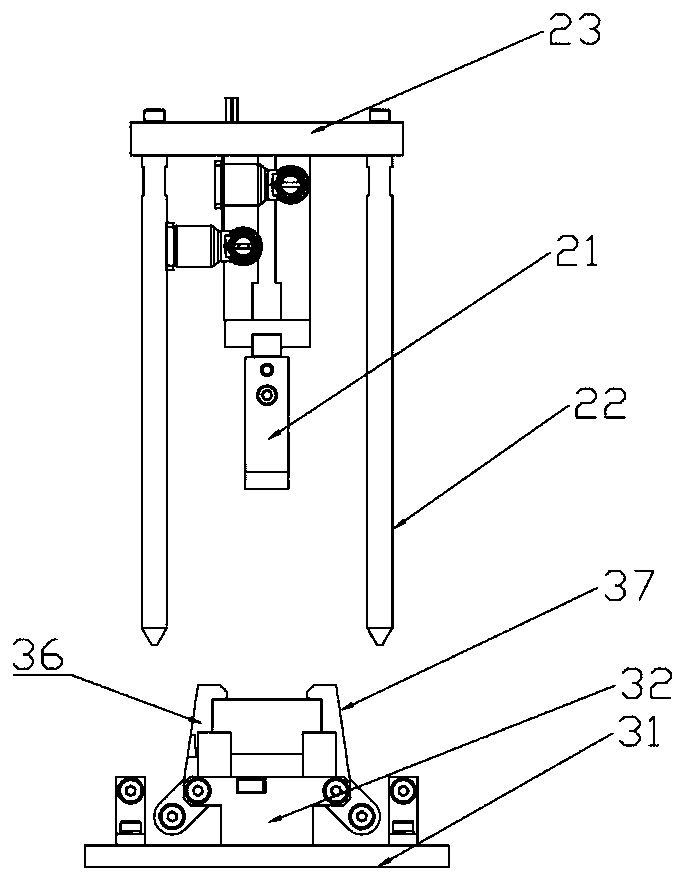

[0032] The workpiece feeding device is initialized, the workpiece is placed on the turntable 7 of the intermittent rotation mechanism 1, the transfer mechanism 2 is translated to the top of the intermittent rotation mechanism 1, and the extension rod of the transfer mechanism is at a high position, and the gripper is in an open state.

[0033] Drive the workpiece feeding device to work. When the induction device of the transfer mechanism 2 senses the stationary workpiece directly below it, the transfer mechanism will descend under the action of the lifting part. When the extension rod and the first cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com